Model construction and experimental research on end grinding force of SiCp/Al composites

-

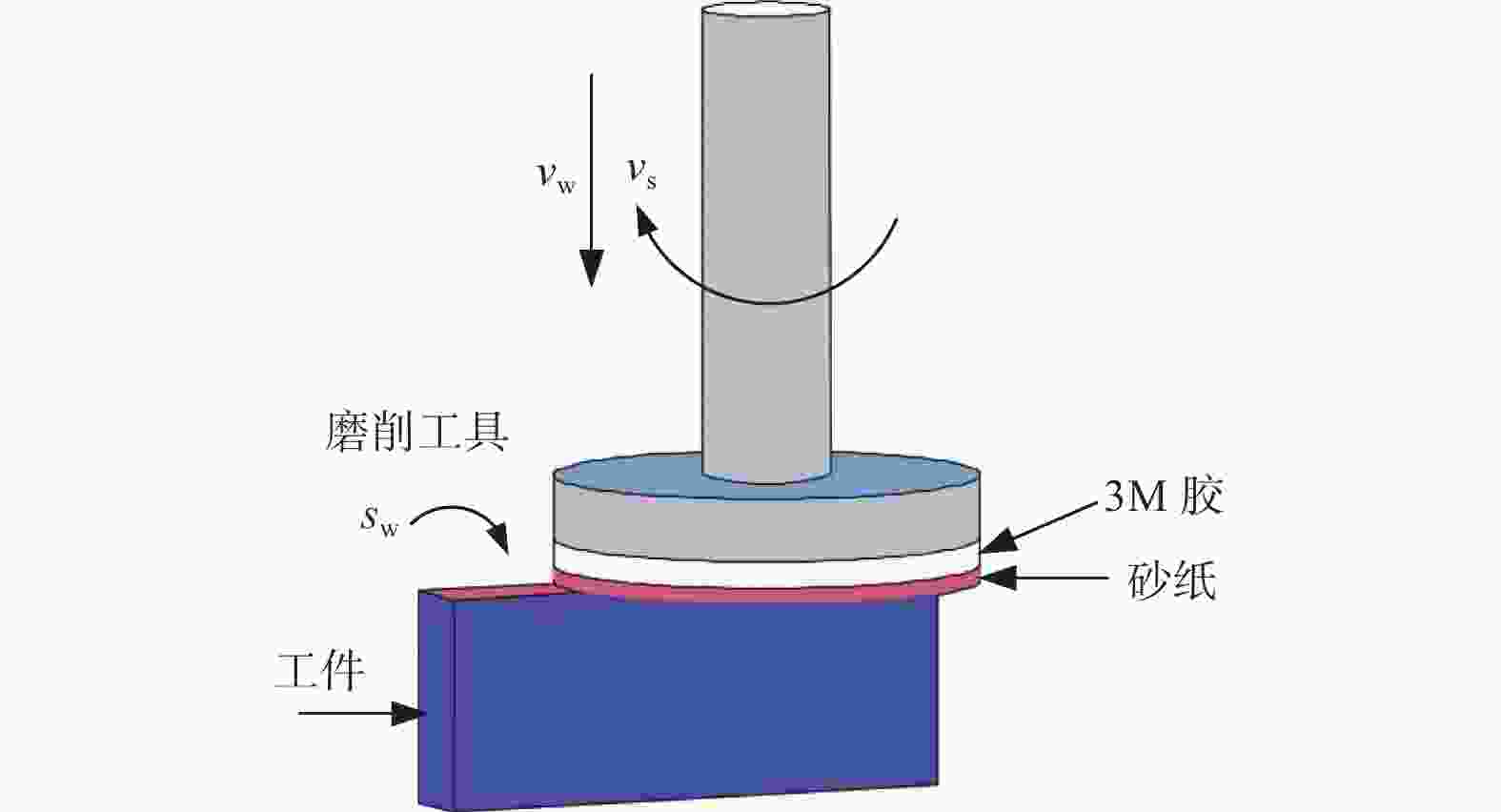

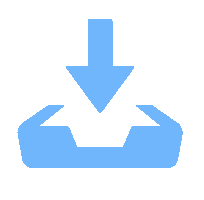

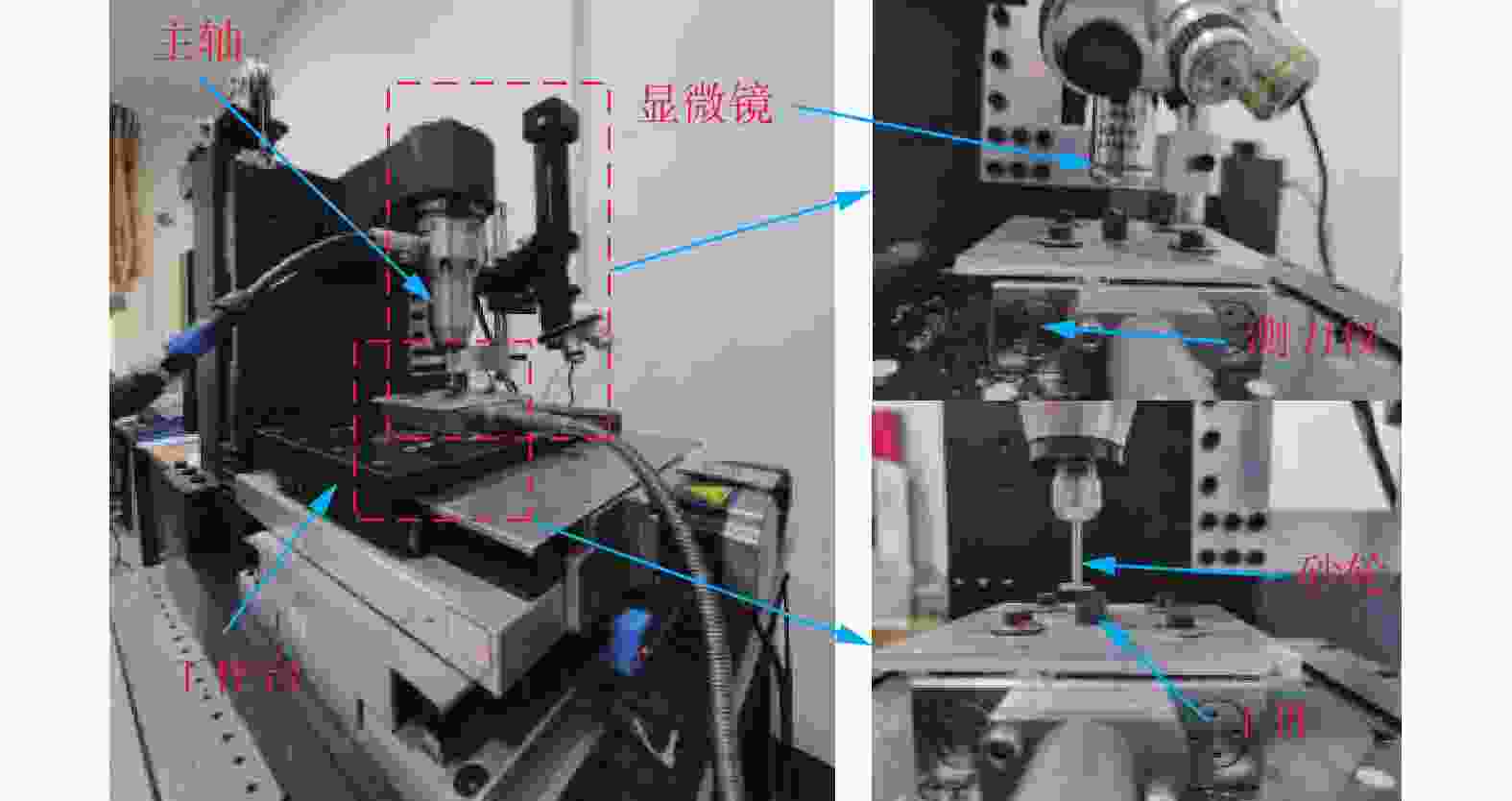

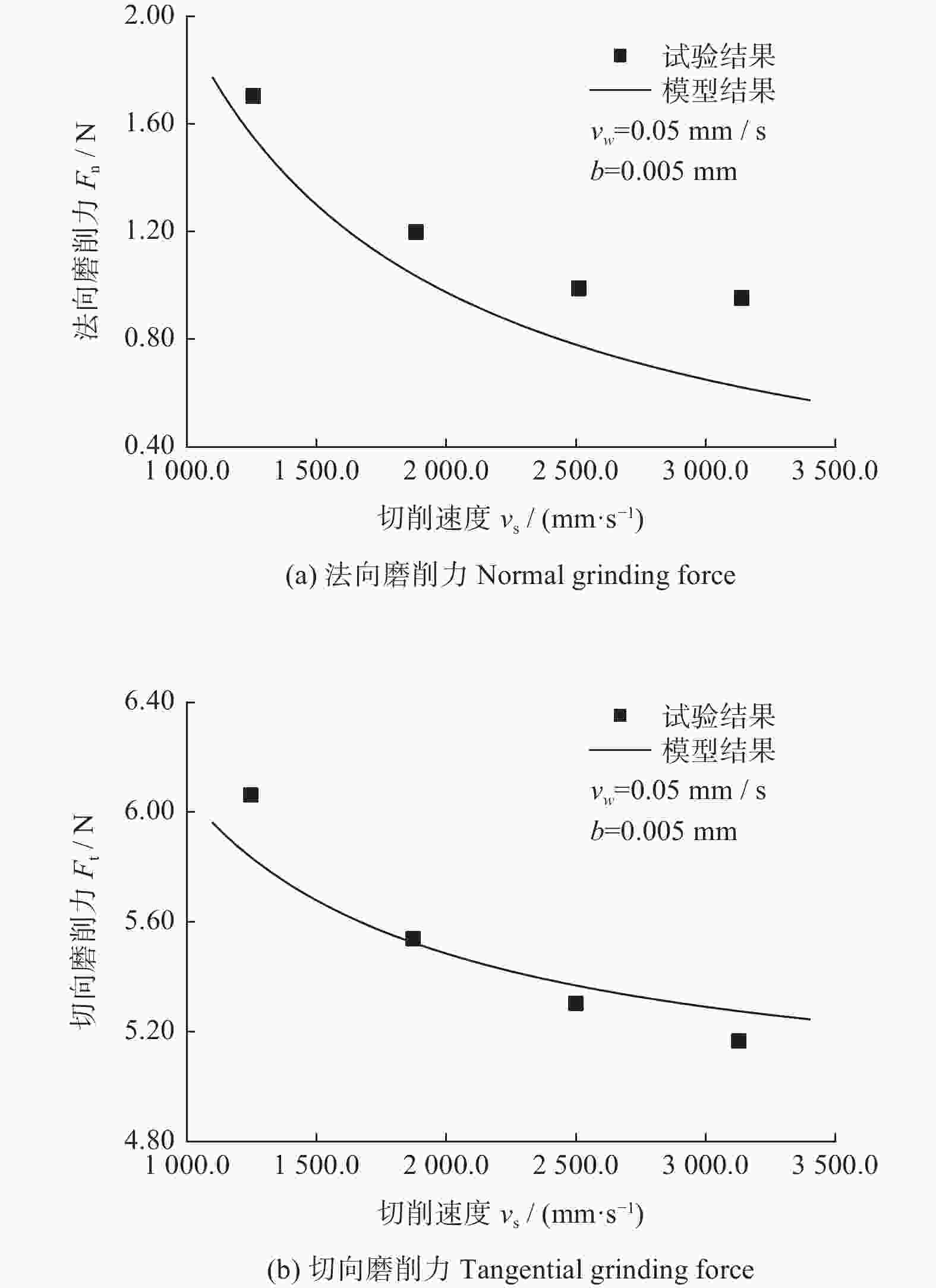

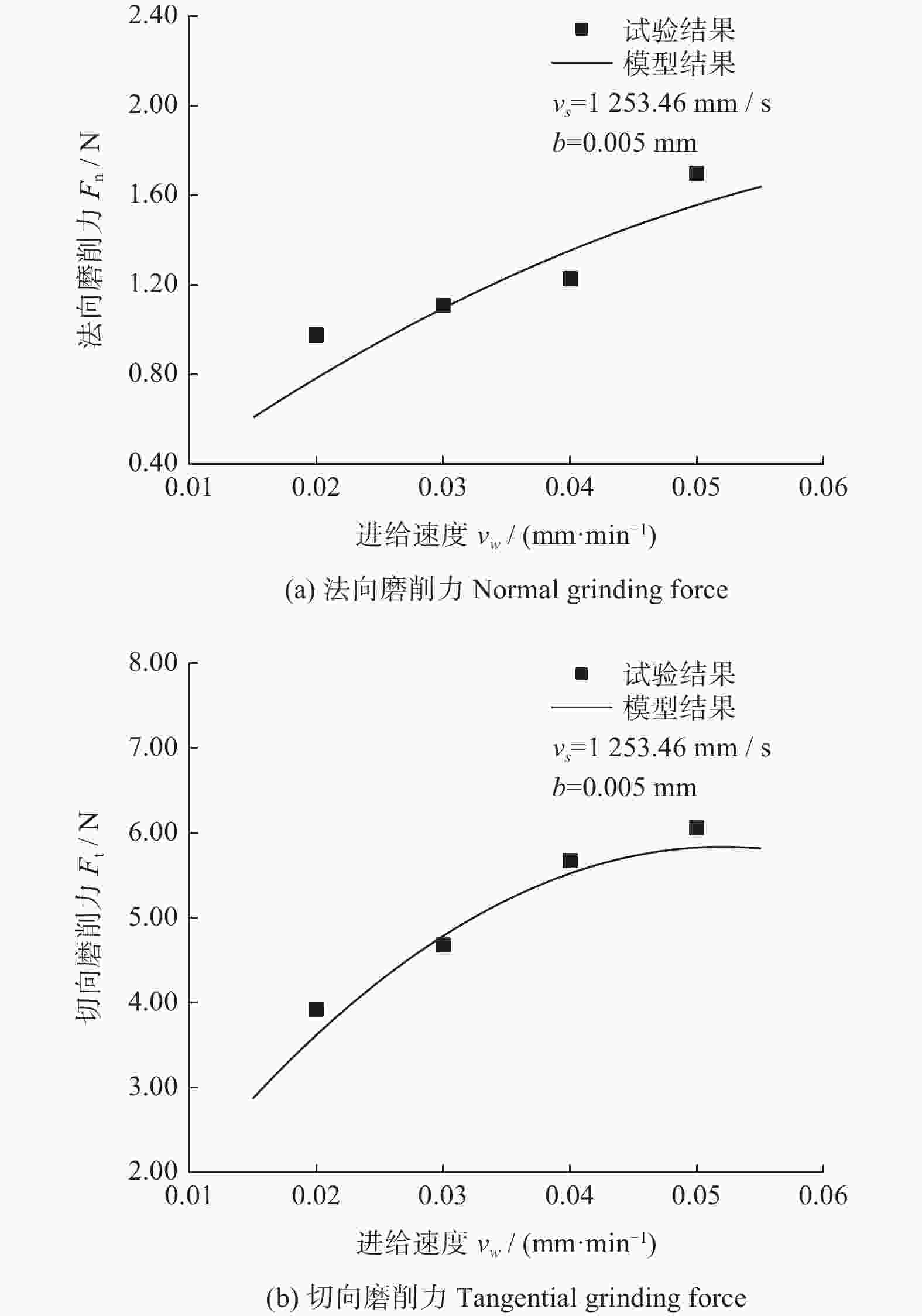

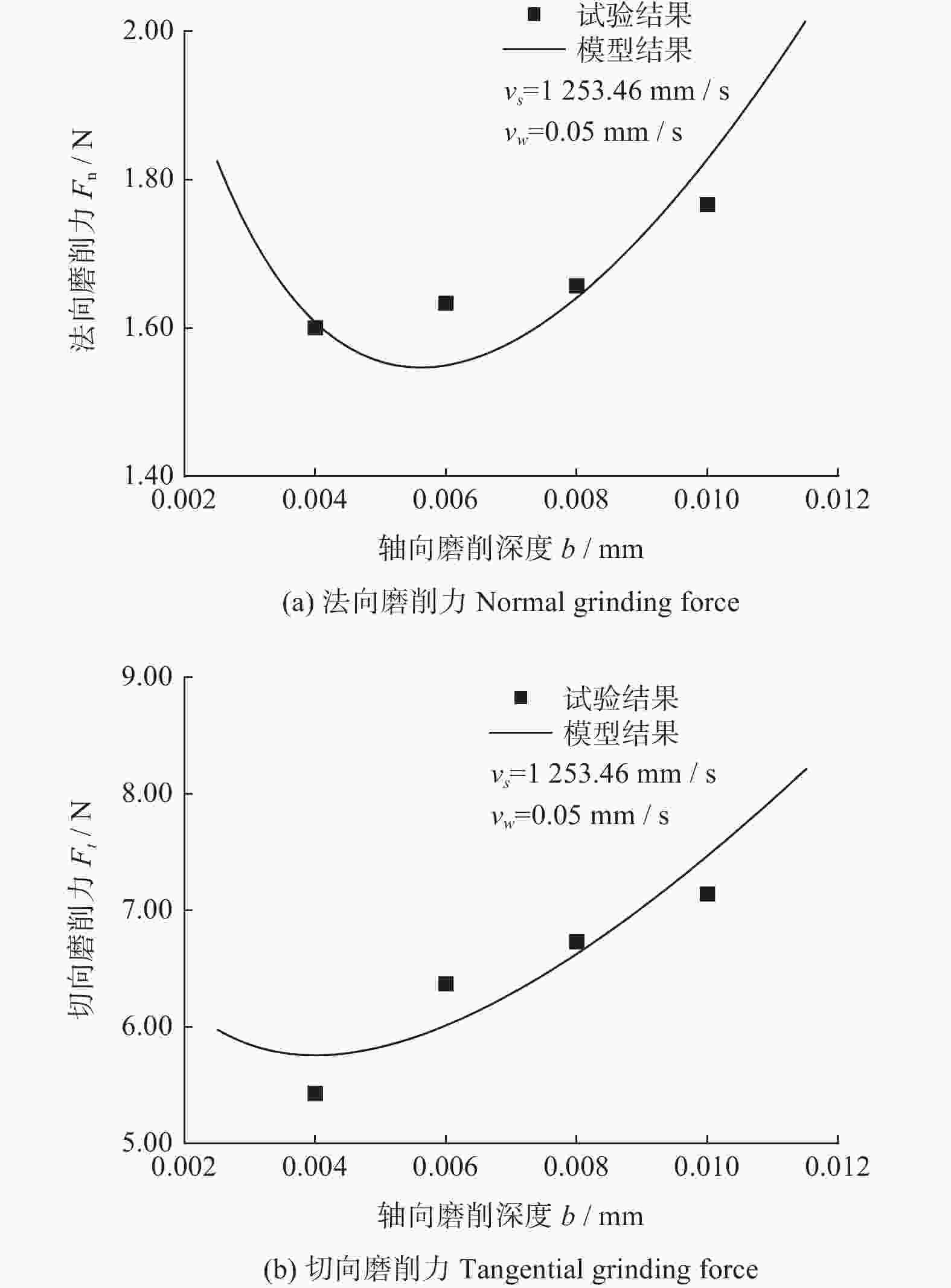

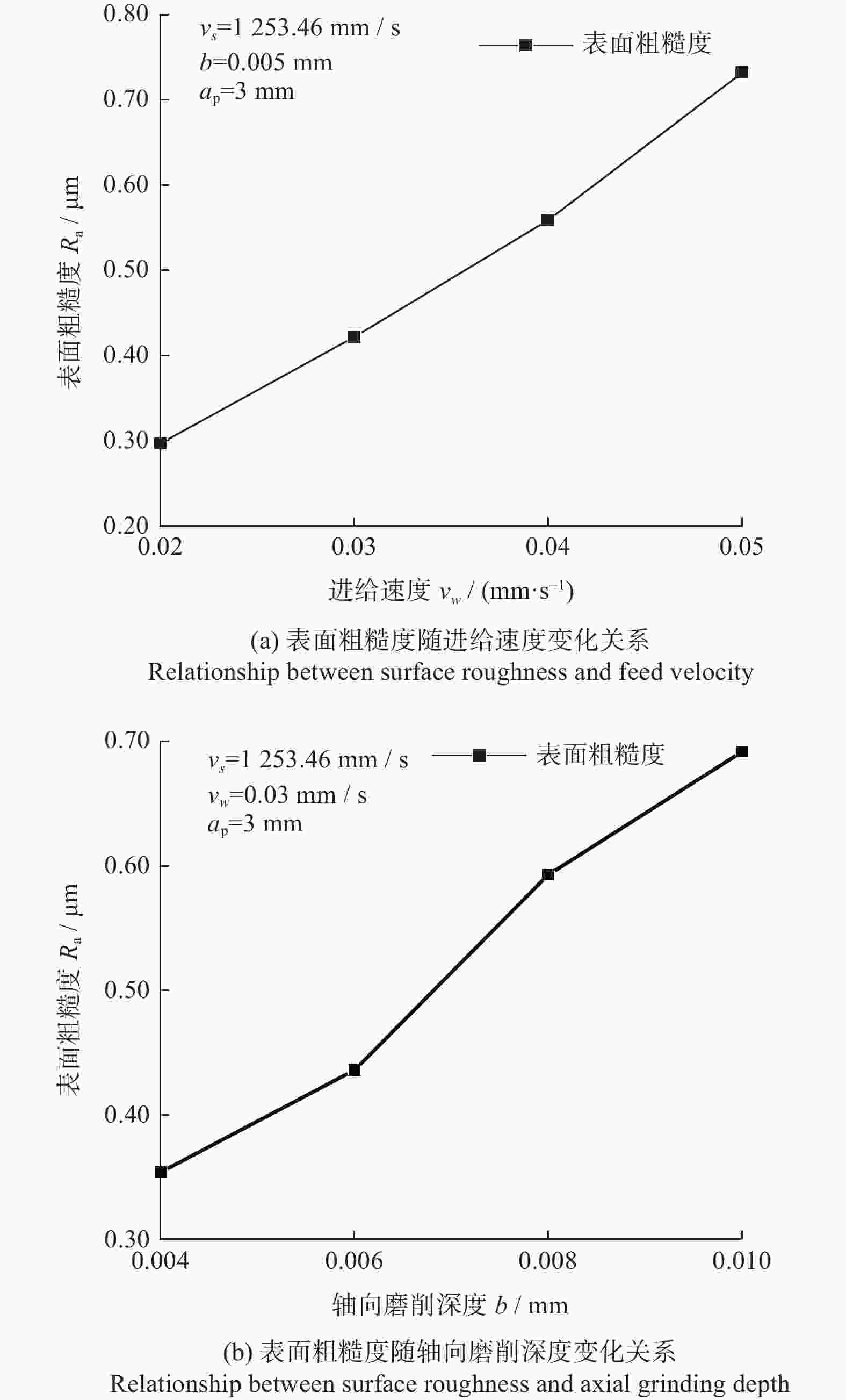

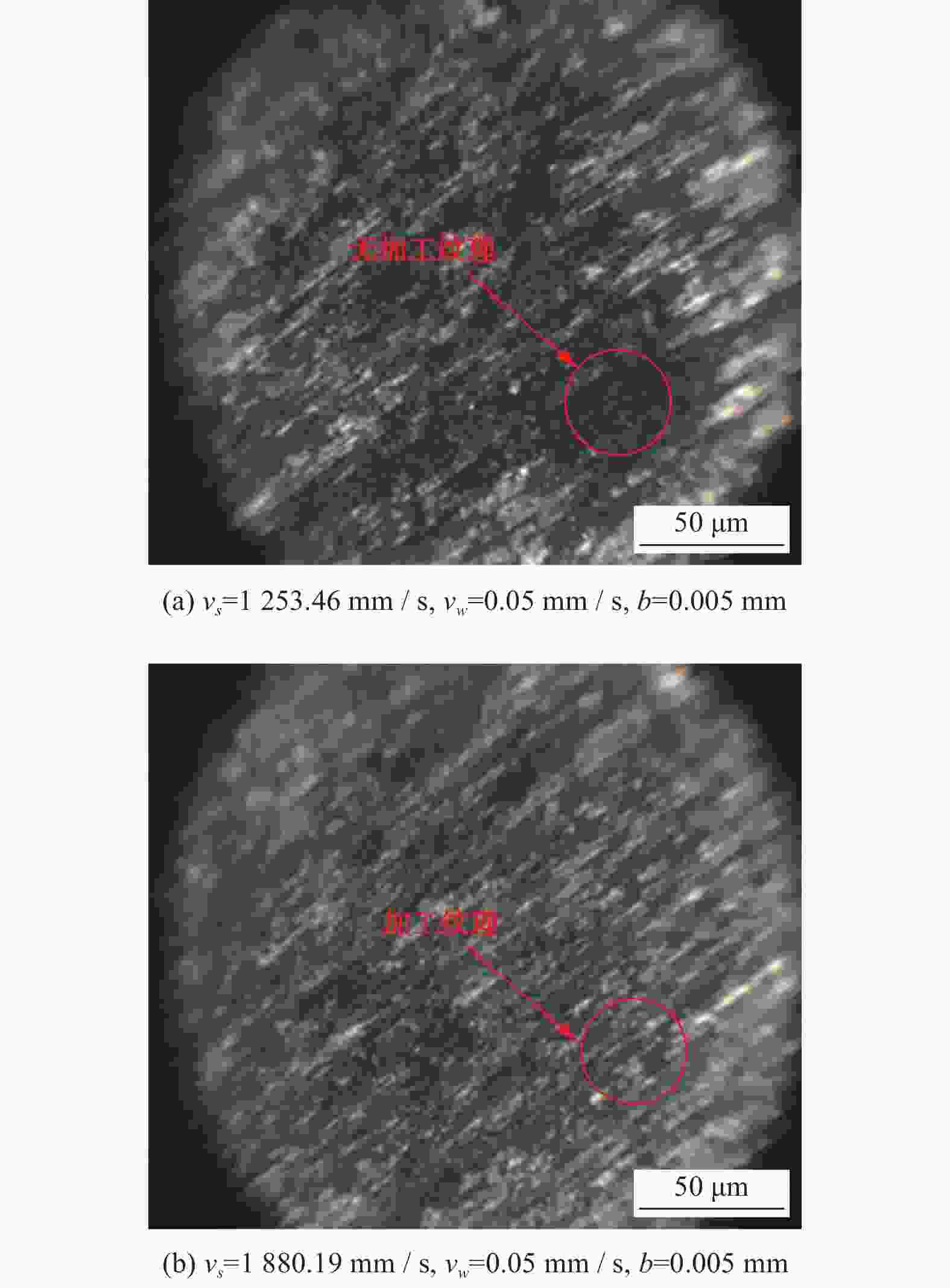

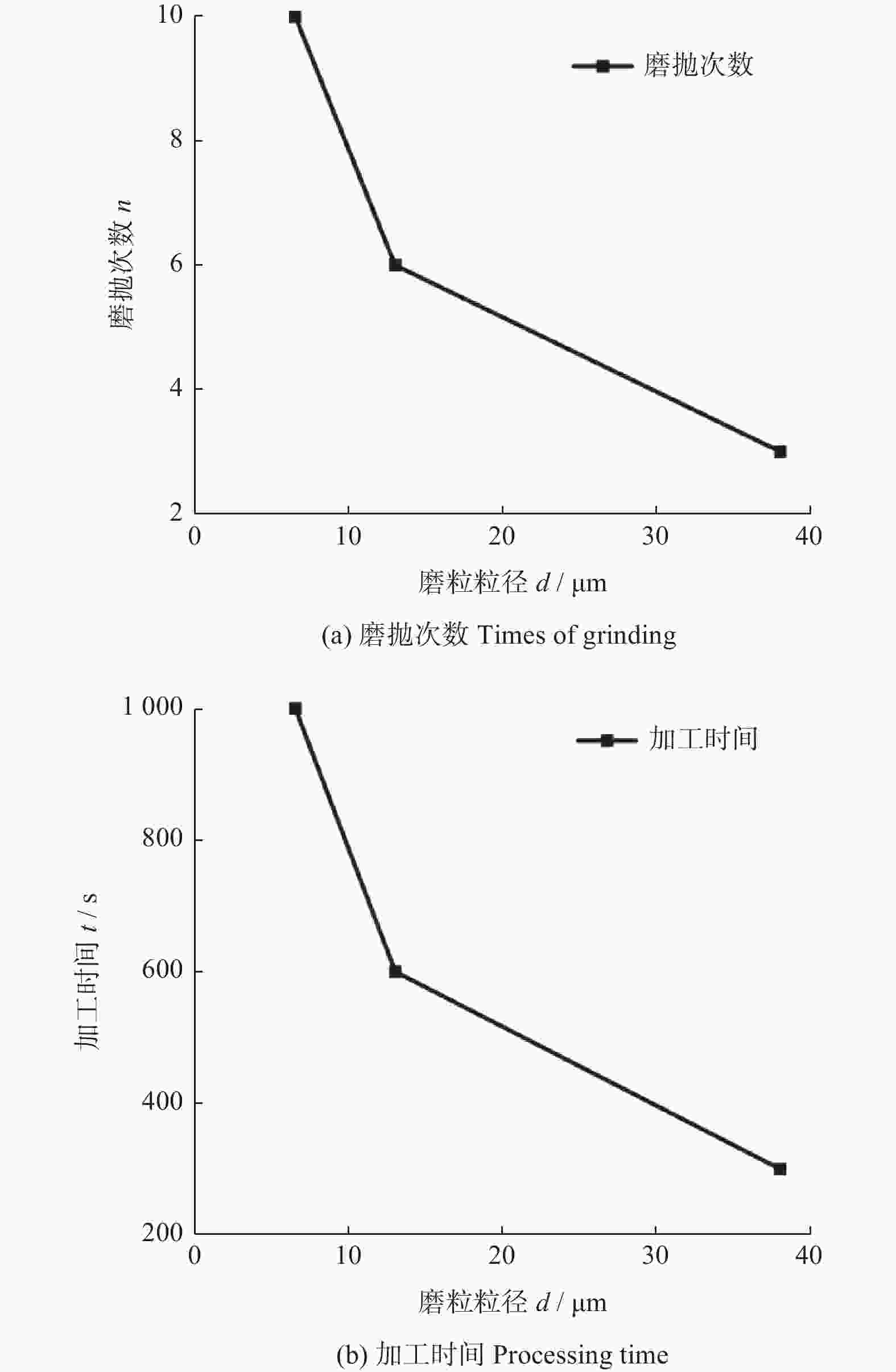

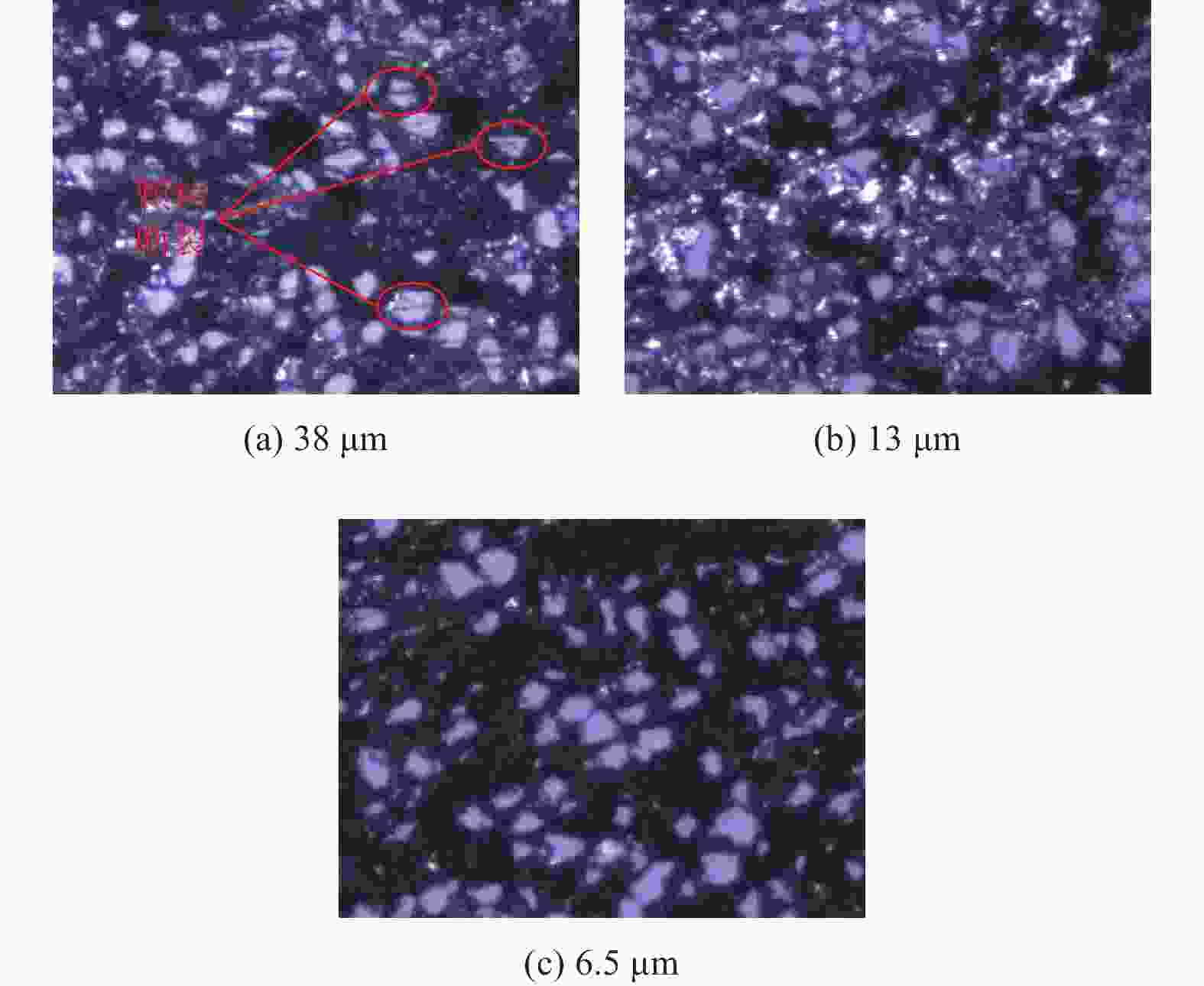

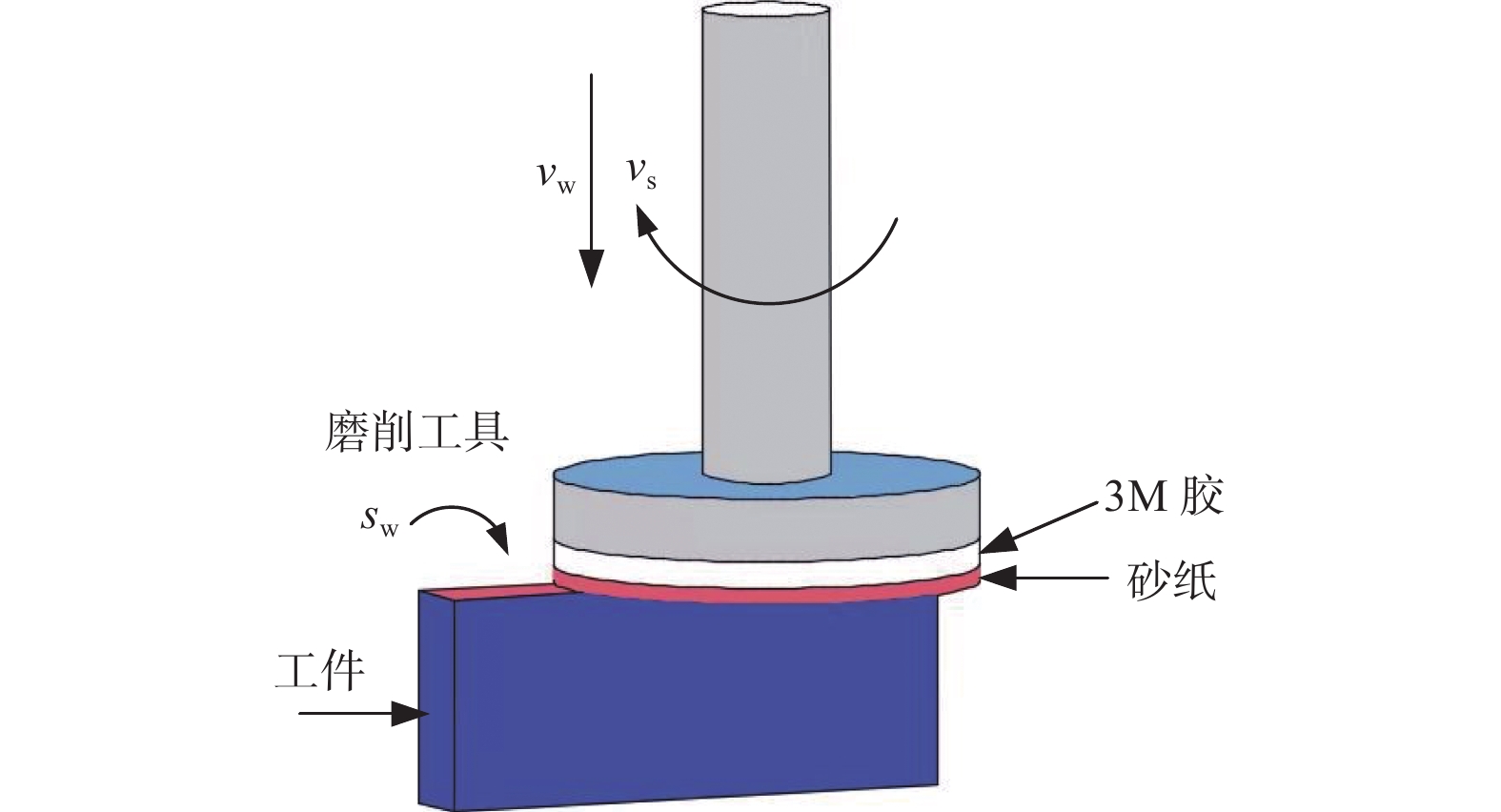

摘要: 针对SiCp/Al逐层磨削两相三维重构需要精密高效端磨的问题,基于单颗磨粒磨削SiCp/Al的磨削力,在考虑切屑变形力、摩擦力、SiC颗粒断裂破碎力的基础上,建立SiCp/Al的端磨磨削力解析模型,结合试验研究切削速度、工件进给速度和轴向磨削深度等参数对加工表面粗糙度的影响规律,并探讨SiCp/Al金相表面快速磨削的加工工艺。结果表明:构建的端磨磨削力解析模型与试验的法向磨削力Fn的总体平均误差为12.98%,切向磨削力Ft的总体平均误差为3.49%;表面粗糙度随切削速度增大而减小,随进给速度和轴向磨削深度的增大而增大;用磨料颗粒基本尺寸为13.0 μm的磨具,经过6次磨抛获得良好金相表面,所需磨削加工时间为600 s,可实现SiCp/Al金相表面的快速磨削。Abstract: Aiming at the problem that precision and efficient end grinding is required for the two-phase 3D reconstruction of SiCp/Al grinding layer by layer, an analytical model of end grinding force of SiCp/Al is established based on the grinding force of SiCp/Al grinding with a single abrasive particle, considering the chip deformation force, friction force and the breaking force of SiC particles. The effects of cutting speed, workpiece feed speed and axial grinding depth on the surface roughness were studied by experiments. The machining technology of SiCp/Al metallographic surface rapid grinding was also discussed. The results show that the overall average error between the analytical model of end grinding force and the experimental normal grinding force Fn is 12.98%, and that the overall average error of tangential grinding force Ft is 3.49%. The surface roughness decreases with the increase of cutting speed and increases with the increase of feed speed and axial grinding depth. The grinding time for obtaining a good metallographic surface is 600 s after 6 grinding times with a grinding tool of 13.0 μm grain size. The rapid grinding of SiCp/Al metallographic surface can be realized.

-

Key words:

- precision grinding /

- grinding force model /

- SiCp/Al /

- metallographic surface

-

表 1 系数确定用试验参数

Table 1. Test parameters for coefficient determination

编号 切削速度

vs / (mm·s−1)进给速度

vw / (mm·s−1)径向磨削深度

ap / mm轴向磨削深度

b / mm1 1 253.46 0.03 3 0.005 2 1 253.46 0.05 3 0.008 3 3 313.65 0.05 3 0.008 4 3 313.65 0.03 3 0.008 表 2 dav与vw对应表

Table 2. dav and vw corresponding table

vw / (mm·s−1) 0.02 0.03 0.04 0.05 dav / mm 5.994 5.991 5.988 5.985 表 3 各试验系数参数值

Table 3. Parameter values of each test coefficient

系数 数值 K1 2.735 291 788 × 107 K2 6.516 577 4 × 107 K3 4.055 336 × 106 K4 32.68 K5 5.888 781 × 106 K6' 1.118 88 × 107 K7' 3.164 09 × 107 表 4 试验参数

Table 4. Test parameters

编号 切削速度

vs / (mm·s−1)进给速度

vw / (mm·s−1)轴向磨削深度

b / mm径向磨削深度

ap / mm1 1 253.46 0.05 0.005 3 2 1 880.19 0.05 0.005 3 3 2 506.92 0.05 0.005 3 4 3 313.65 0.05 0.005 3 5 1 253.46 0.02 0.005 3 6 1 253.46 0.03 0.005 3 7 1.253.46 0.04 0.005 3 8 1 253.46 0.05 0.005 3 9 1 253.46 0.05 0.004 3 10 1.253.46 0.05 0.006 3 11 1 253.46 0.05 0.008 3 12 1 253.46 0.05 0.00 3 -

[1] DILLIO A, PAOLETTI A, ADDONA D D. Characterization and modelling of the grinding process of metal matrix composite [J]. CIRP Annals,2009,58(1):291-294. doi: 10.1016/j.cirp.2009.03.023 [2] 都金光. SiC颗粒增强铝基复合材料铣磨加工及其关键技术研究 [D]. 哈尔滨: 哈尔滨工业大学, 2014DU Jinguang. Research on milling and grinding of SiC particle reinforced aluminum matrix composites and its key technologies [D]. Harbin: Harbin Institute of Technology, 2014. [3] 李德溥, 李志奎. 颗粒增强铝基复合材料磨削加工表面质量与磨削力研究 [J]. 现代制造工程,2009(9):93-95. doi: 10.3969/j.issn.1671-3133.2009.09.025LI Depu, LI Zhikui. Study on surface quality and grinding force of particle reinforced aluminum matrix composites grinding [J]. Modern Manufacturing Engineering,2009(9):93-95. doi: 10.3969/j.issn.1671-3133.2009.09.025 [4] 李德溥. SiC颗粒增强铝基复合材料磨削中砂轮磨损与加工质量研究 [J]. 金刚石与磨料磨具工程,2009(3):77-80. doi: 10.3969/j.issn.1006-852X.2009.03.018LI Depu. Research on grinding wheel wear and machining quality in grinding of SiC particle reinforced aluminum matrix composites [J]. Diamond & Abrasives Engineering,2009(3):77-80. doi: 10.3969/j.issn.1006-852X.2009.03.018 [5] 刘江省, 李德溥, 姚英学. 电镀金刚石砂轮端面磨削Al2024/SiCp试验研究 [J]. 现代制造工程,2008(9):92-95. doi: 10.3969/j.issn.1671-3133.2008.09.028LIU Jiangsheng, LI Depu, YAO Yingxue. Experimental research on Al2024/SiCp face grinding with electroplated diamond grinding wheel [J]. Modern Manufacturing Engineering,2008(9):92-95. doi: 10.3969/j.issn.1671-3133.2008.09.028 [6] 马尔金. 磨削技术理论与应用 [M]. 沈阳: 东北大学出版社, 2002.MALKIN. Theory and application of grinding technology [M]. Shenyang: Northeastern University Press, 2002. [7] 任敬心, 华定安. 磨削原理 [M]. 北京: 电子工业出版社, 2011.REN Jingxin, HUA Dingan. Grinding principle [M]. Beijing: Electronic Industry Press, 2011. [8] DURGUMAHANTI U, SINGH V, RAO P V. A new model for grinding force prediction and analysis [J]. International Journal of Machine Tools and Manufacture,2010,50(3):231-240. doi: 10.1016/j.ijmachtools.2009.12.004 [9] SIKDER S, KISHAWY H A. Analytical model for force prediction when machining metal matrix composite [J]. International Journal of Mechanical Sciences,2012,59:95-103. doi: 10.1016/j.ijmecsci.2012.03.010 [10] 张红哲, 张旭, 朱晓春, 等. 基于单颗磨粒划切试验的SiCp/Al复合材料表面去除机理研究 [J]. 浙江大学学报 (工学版),2022,56(2):388-397. doi: 10.3785/j.issn.1008-973X.2022.02.020ZHANG Hongzhe, ZHANG Xu, ZHU Xiaochun, et al. Surface removal mechanism of SiCp/Al composites based on single abrasive particle cutting test [J]. Journal of Zhejiang University (Engineering Science),2022,56(2):388-397. doi: 10.3785/j.issn.1008-973X.2022.02.020 [11] 王逸轩, 李勋, 柏帆. SiCp/Al复合材料内螺纹螺旋磨削加工方法研究 [J]. 航空制造技术,2018,61(Z1):88-92. doi: 10.16080/j.issn1671-833x.2018.01/02.088WANG Yixuan, LI Xun, BAI Fan. Research on SiCp/Al composite internal thread spiral grinding method [J]. Aviation Manufacturing Technology,2018,61(Z1):88-92. doi: 10.16080/j.issn1671-833x.2018.01/02.088 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS