Trajectory optimization and experiment of robotic belt grinding blisk

-

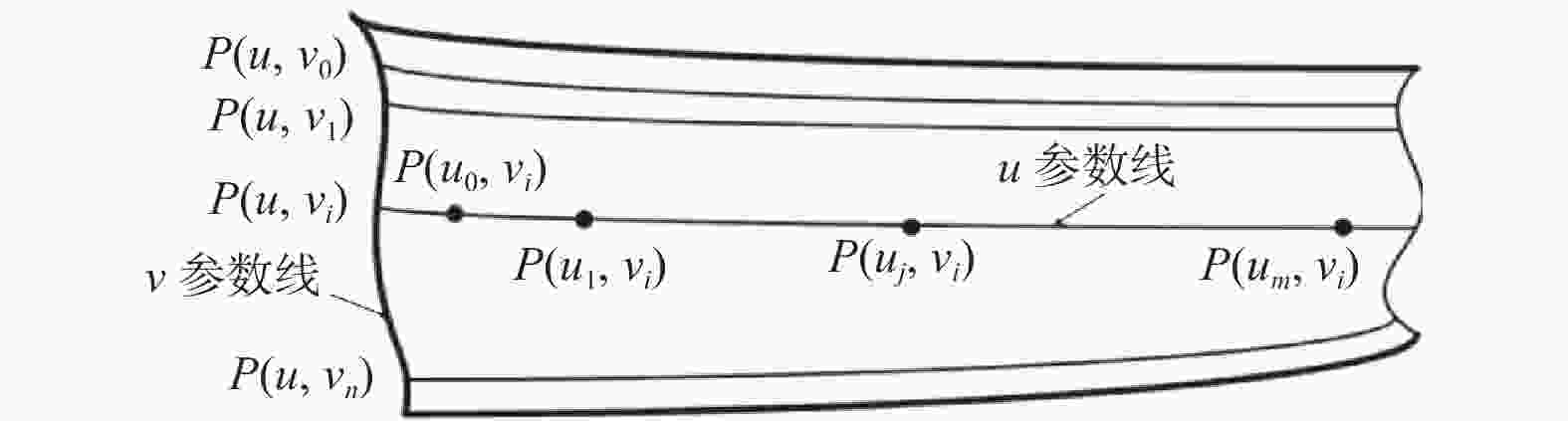

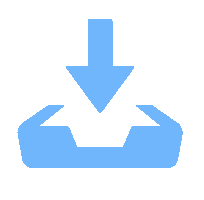

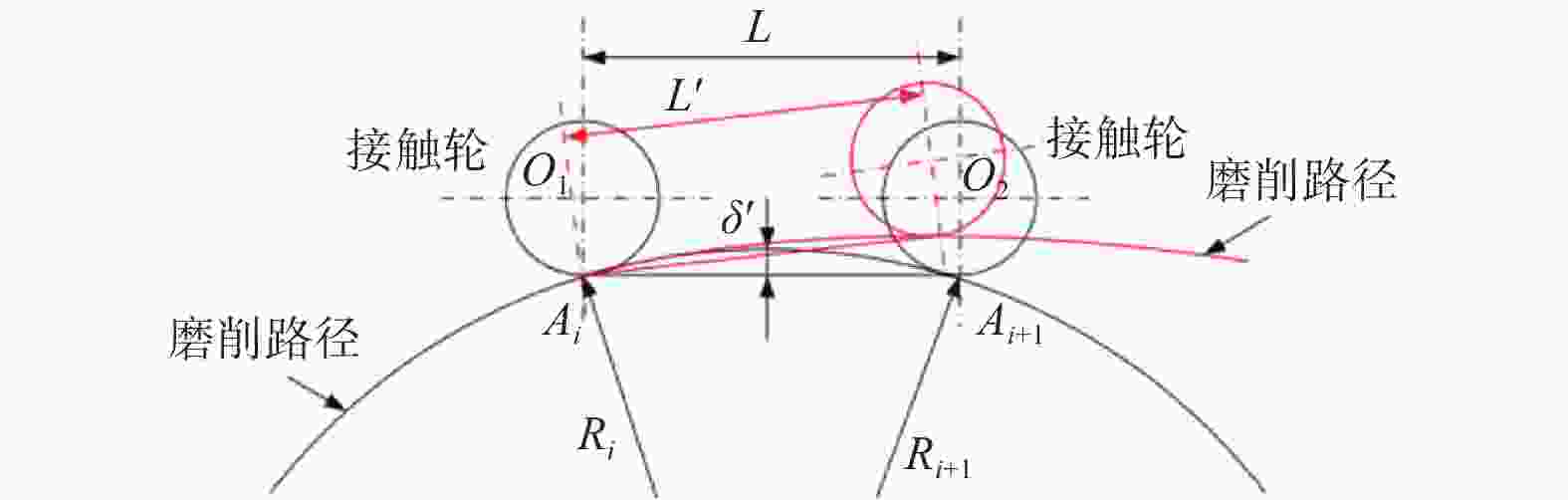

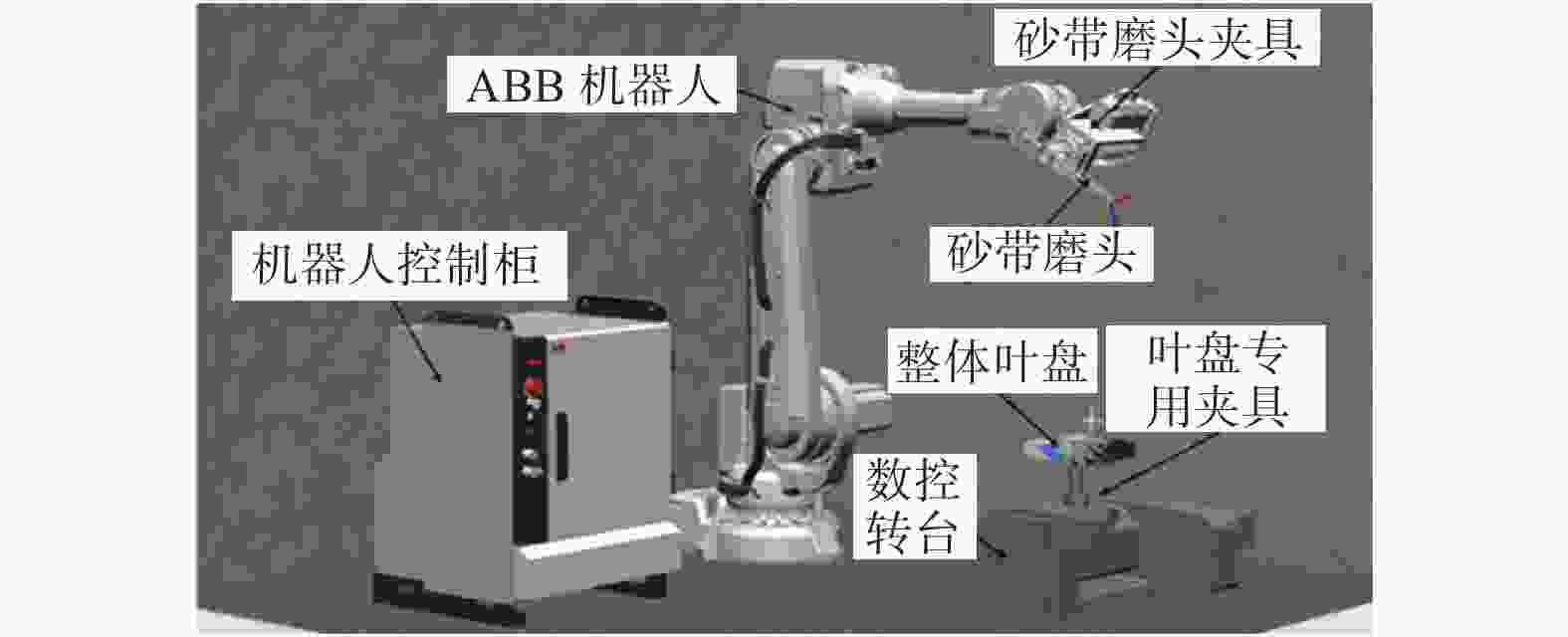

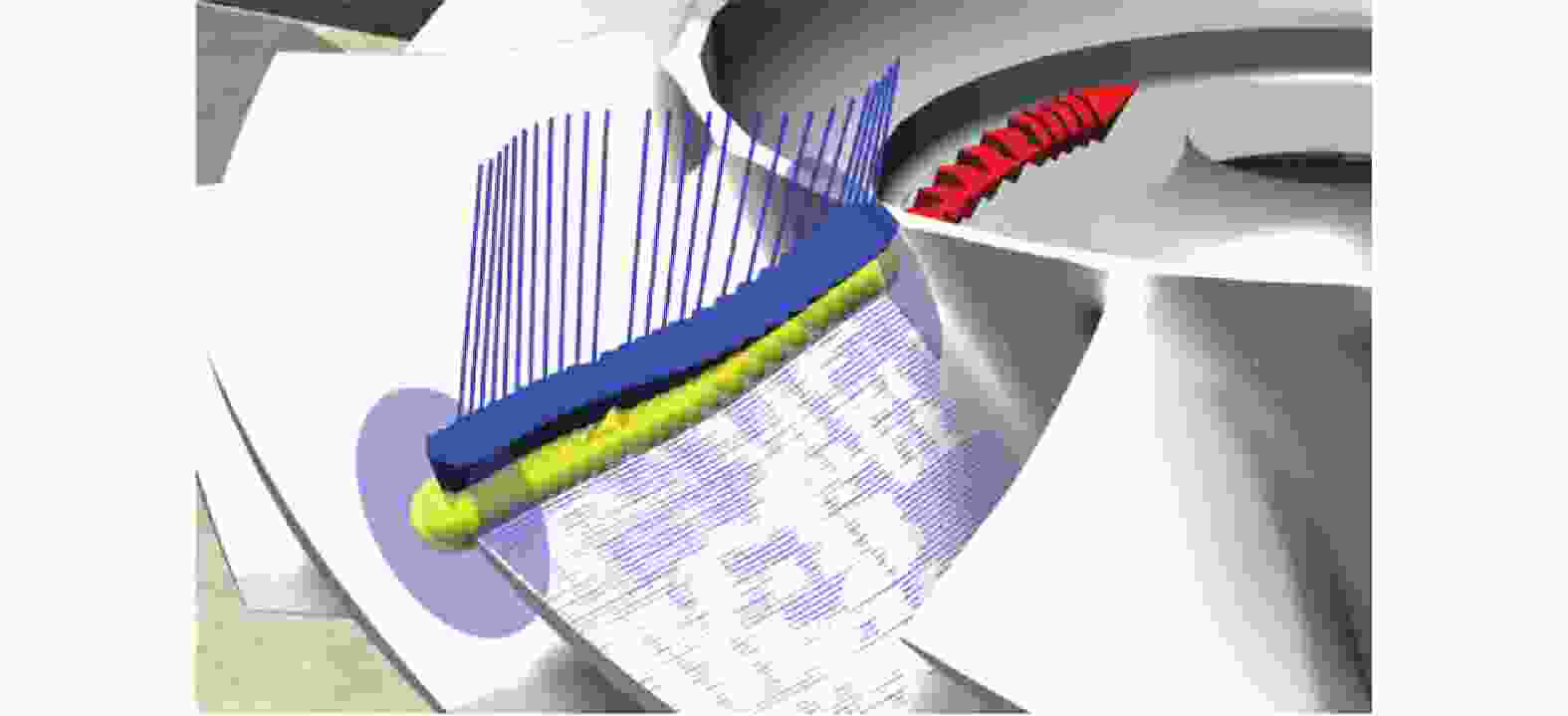

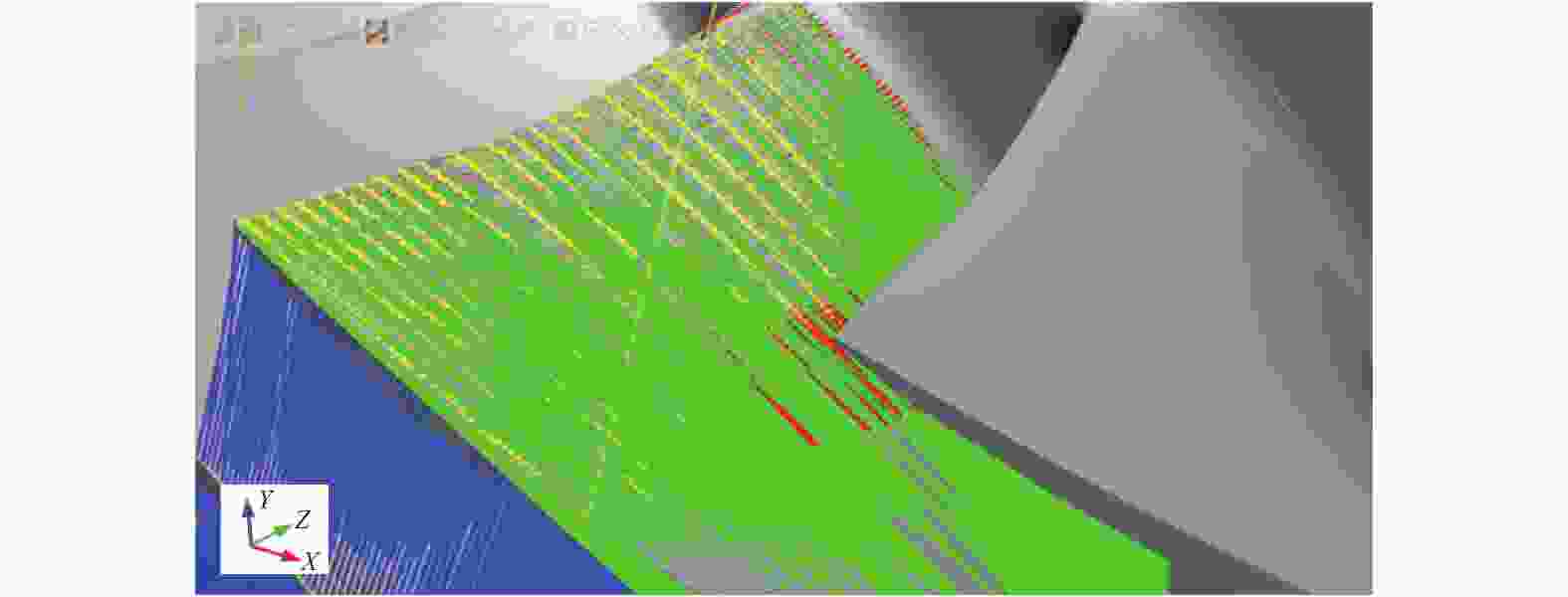

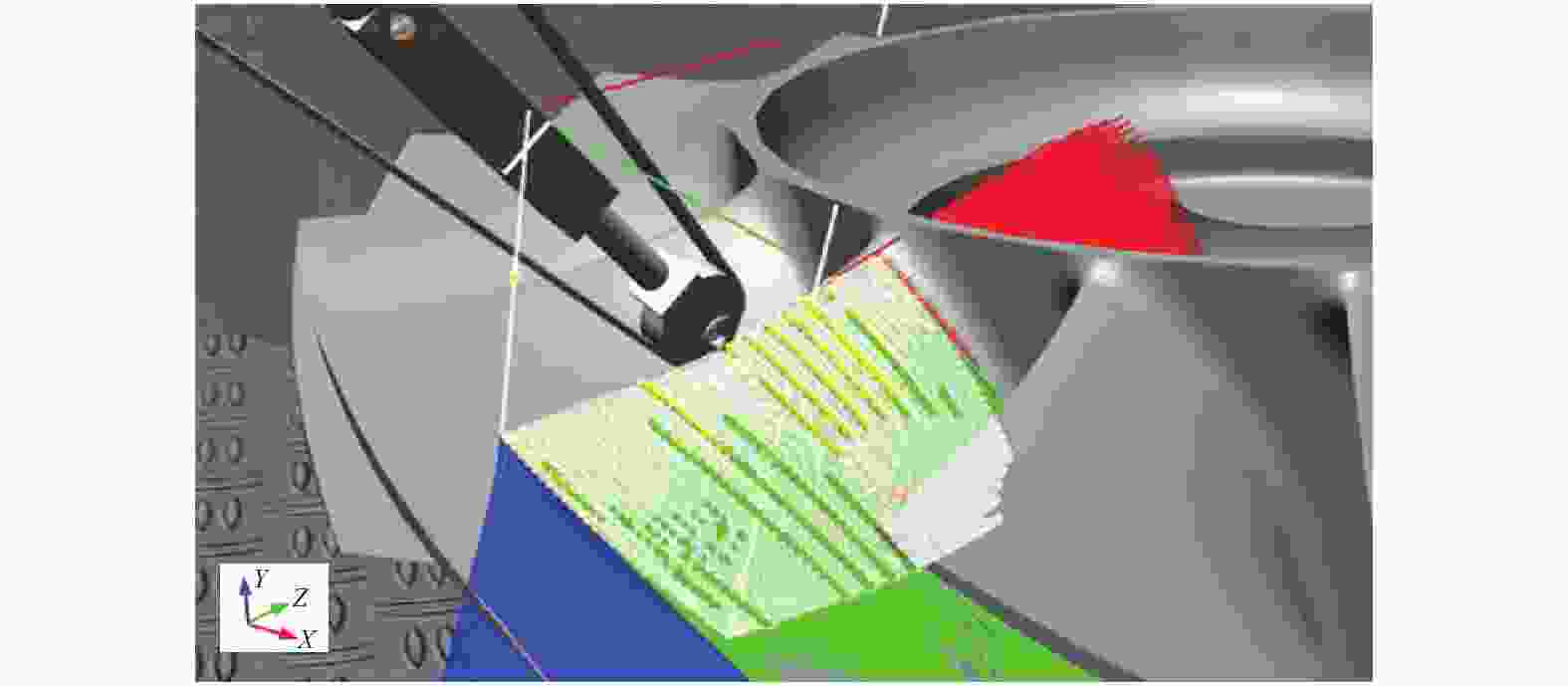

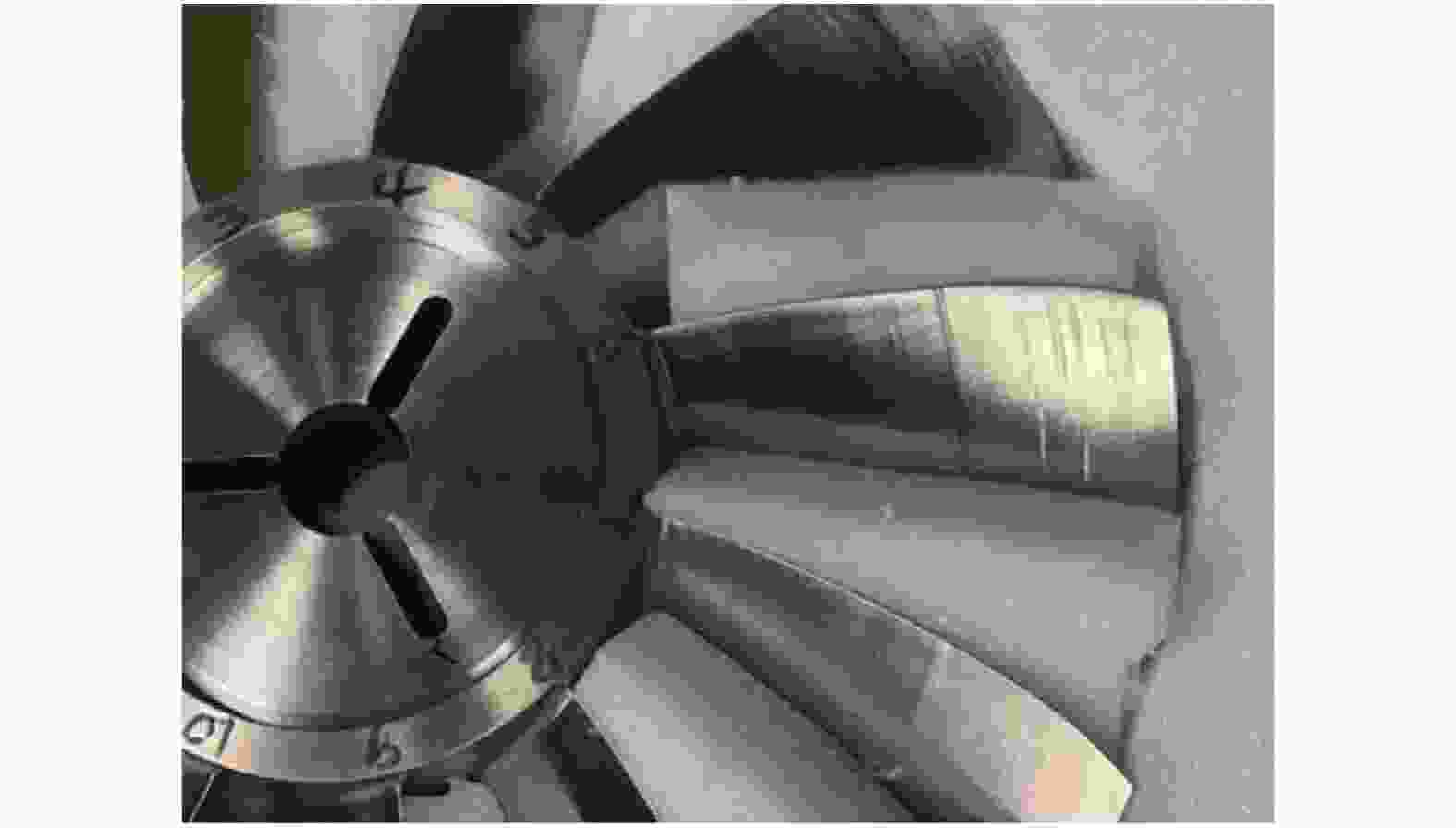

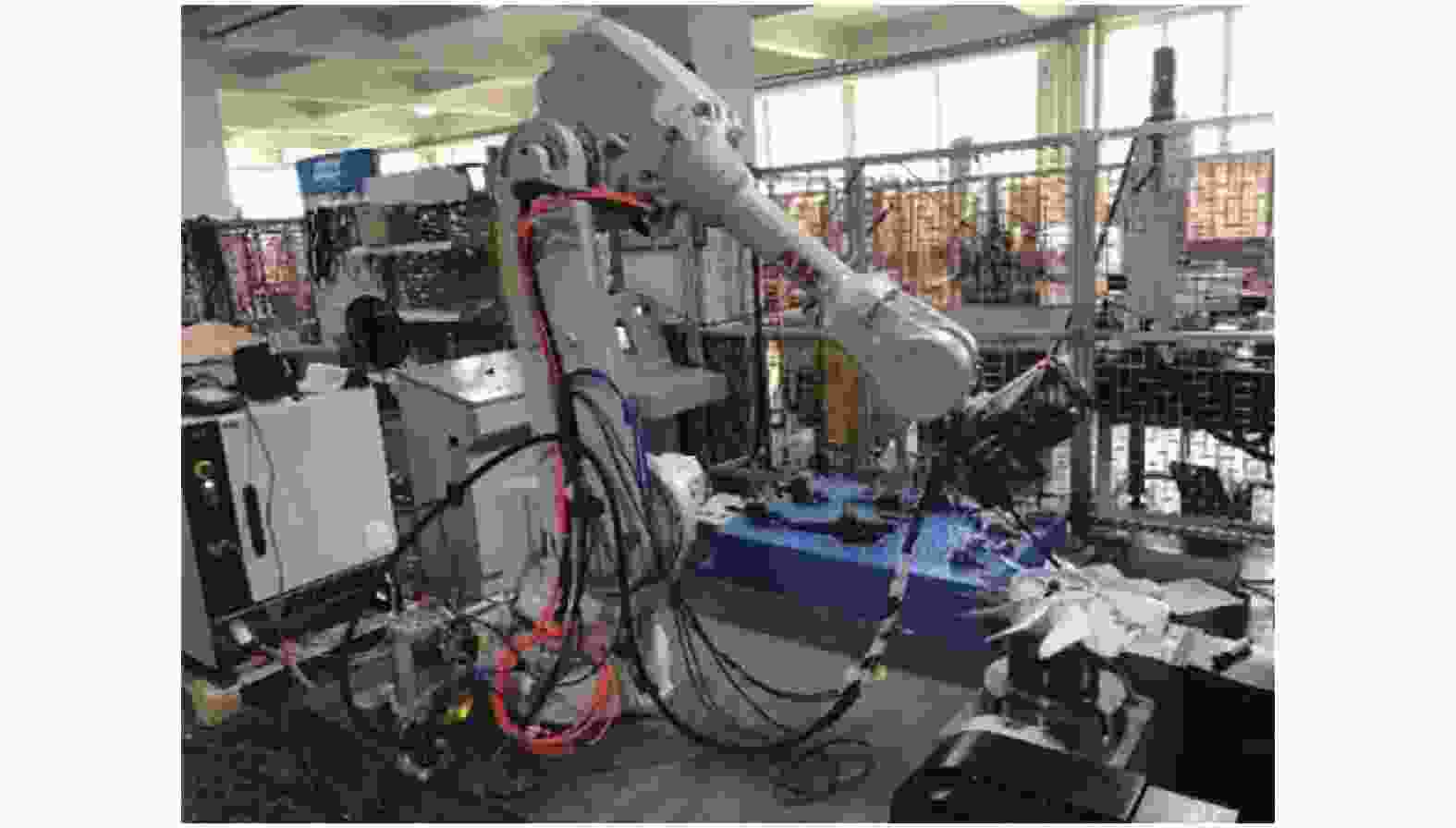

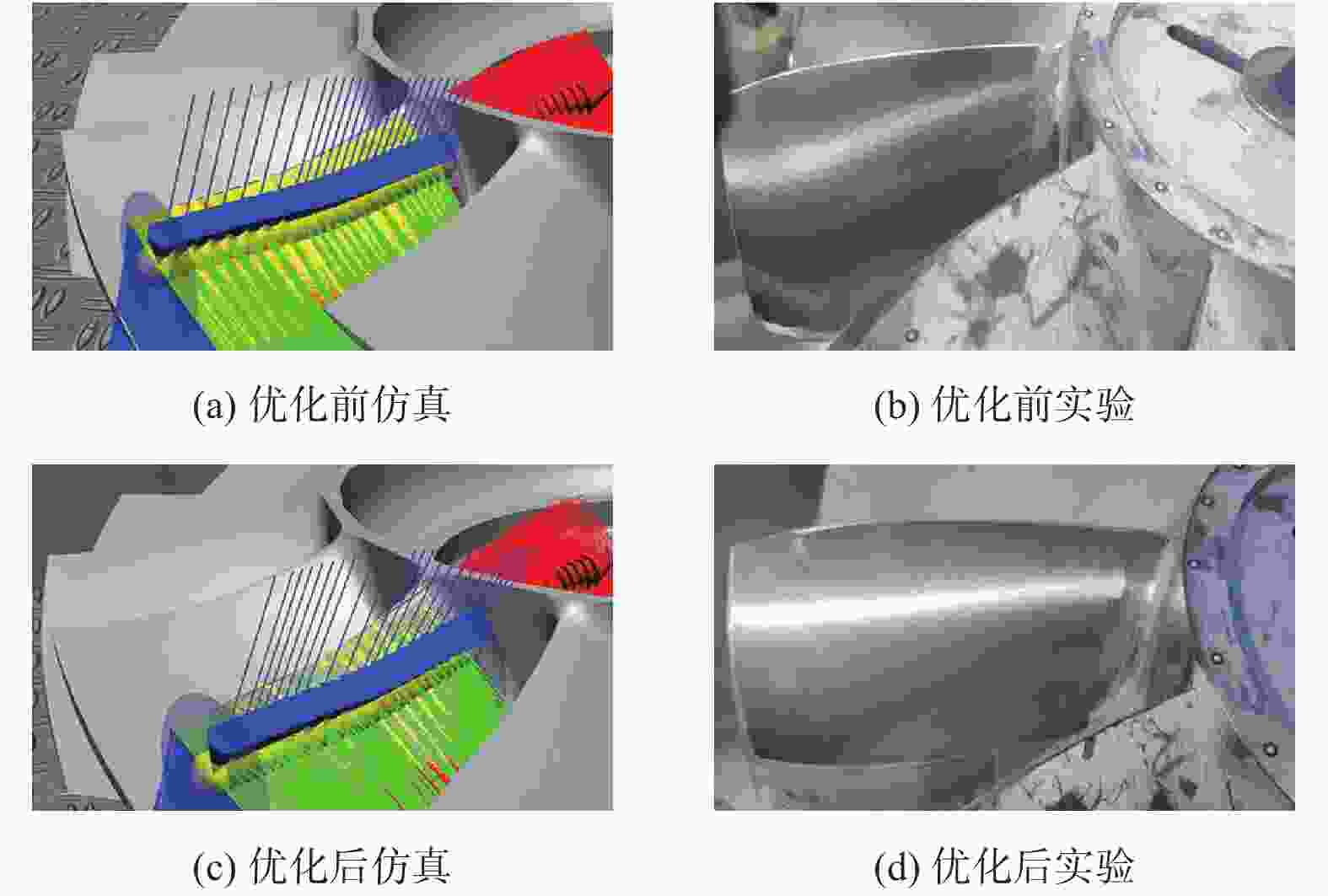

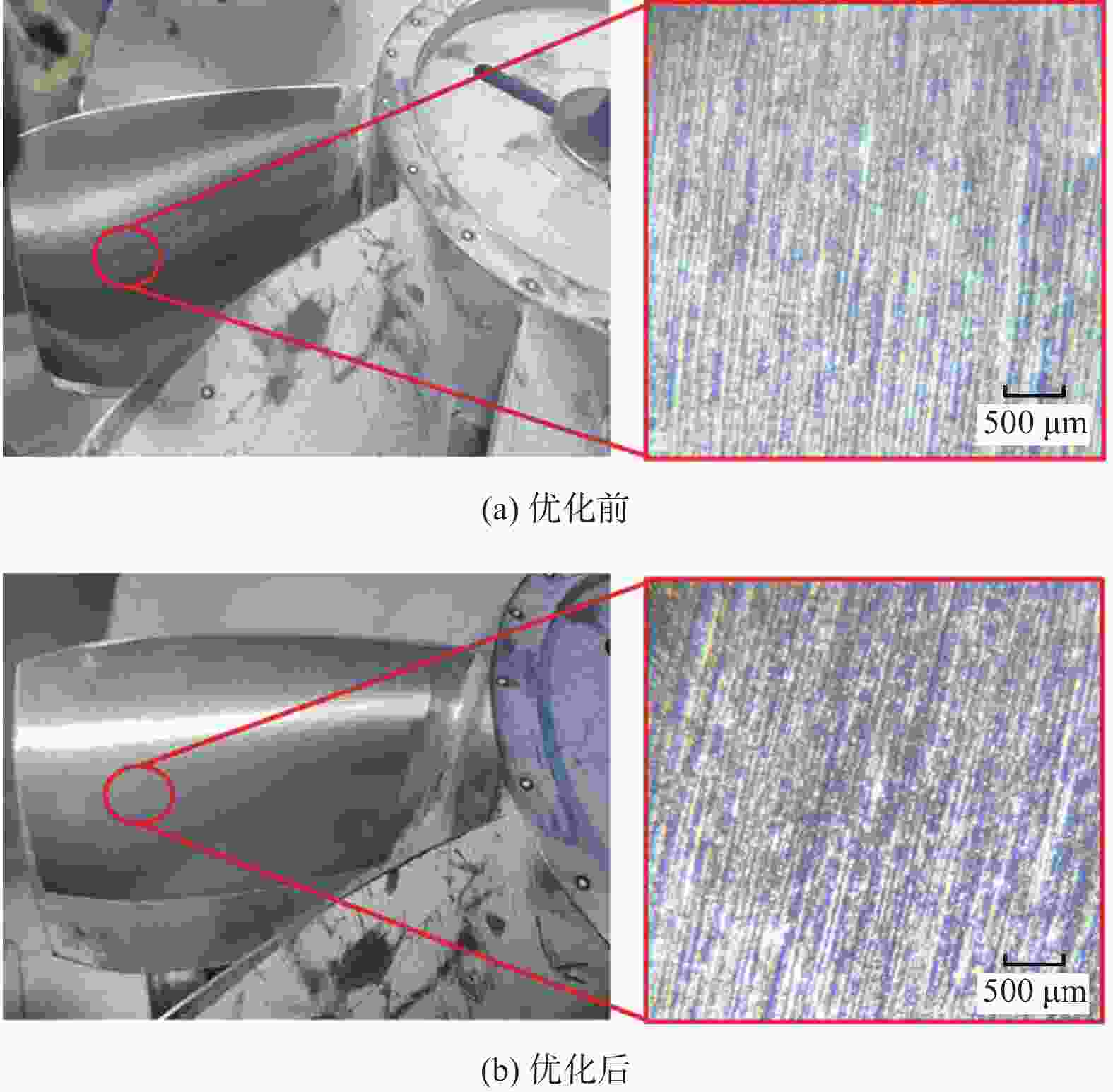

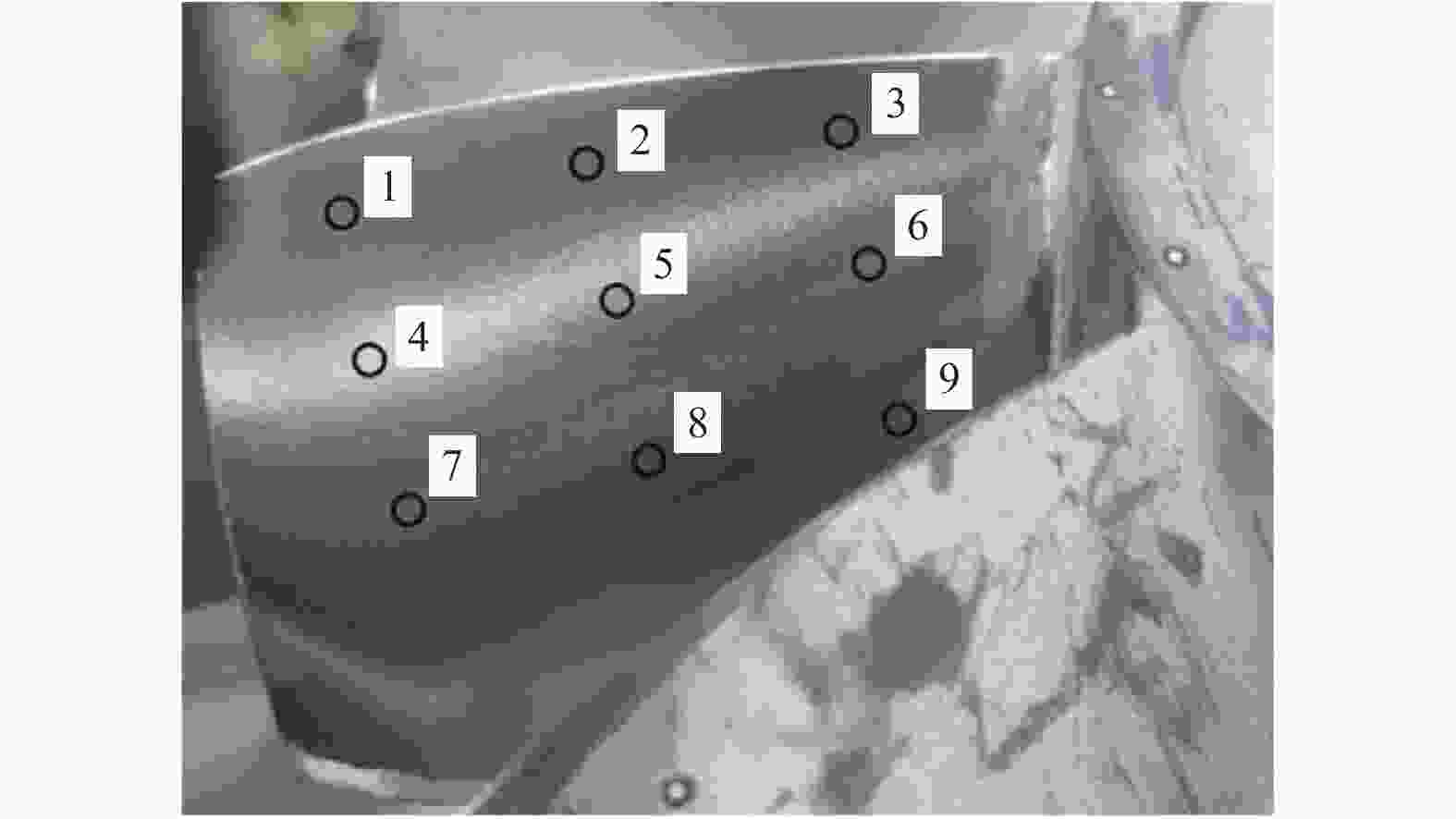

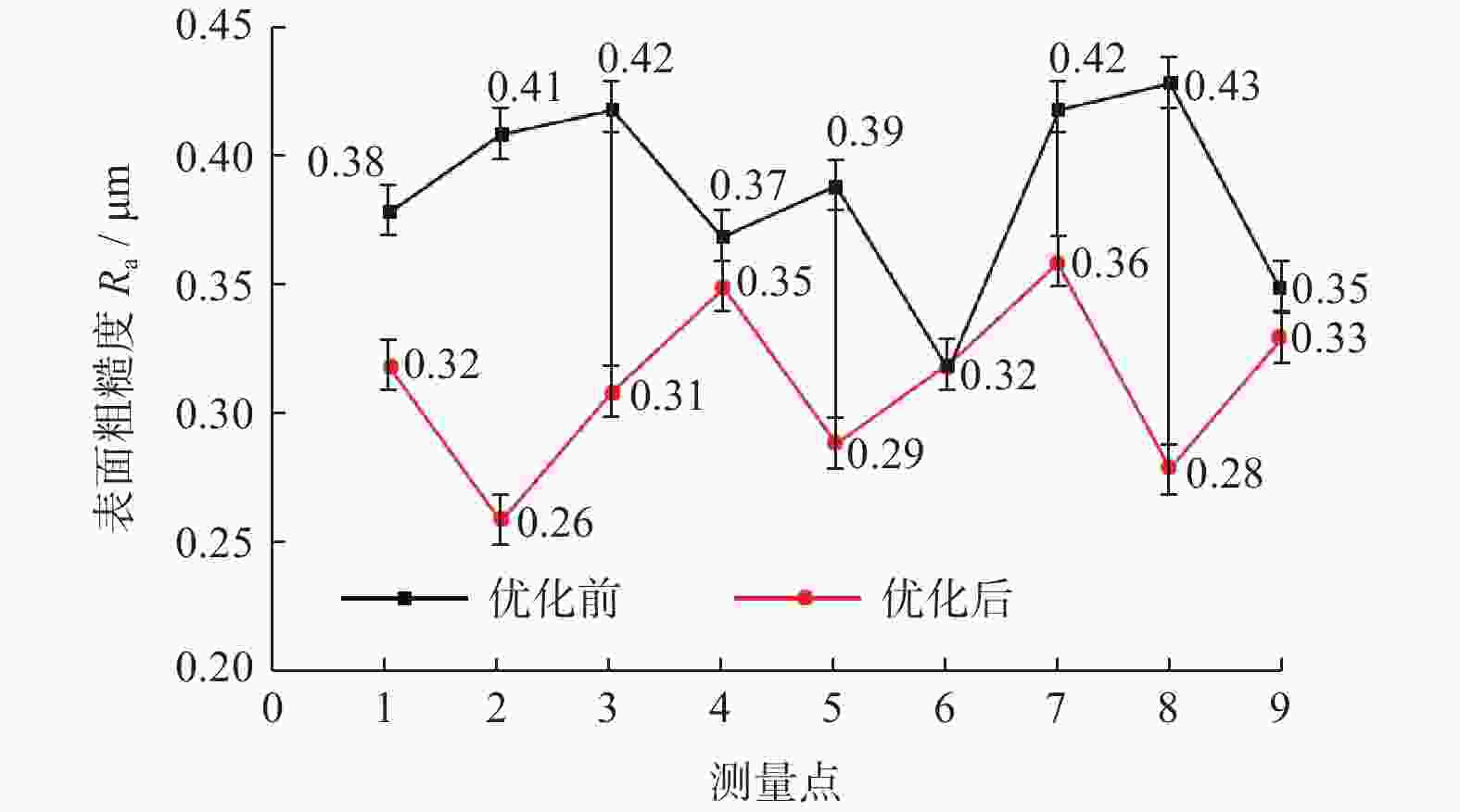

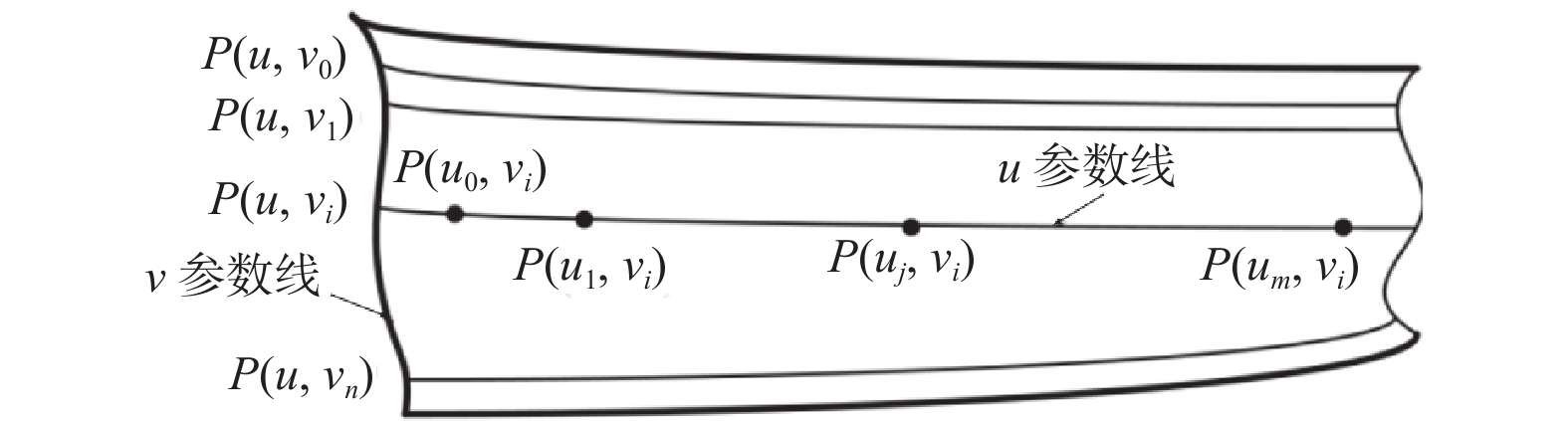

摘要: 整体叶盘具有结构复杂、材料难加工的特点,其加工精度和表面质量对航空发动机整体性能有至关重要的影响。当前,机器人砂带磨削技术已应用于整体叶盘类复杂曲面的磨削加工。然而,在磨削轨迹规划时多采用目标点均布的方式,这就要求目标点必须足够多,从而导致加工效率过低。基于改进的等弦高误差法对整体叶盘机器人砂带磨削的磨削轨迹进行优化分析,并开展相关仿真与实验验证。结果表明:改进的等弦高误差法可根据曲率变化优化磨削轨迹,减少目标加工点数量,从而提高加工效率。经实验验证,与轨迹优化前相比,优化后整体叶盘的加工效率提高了42.9%;优化后的表面粗糙度Ra可达0.26 μm,且叶片一致性较好,尤其是在曲率变化较大的位置。Abstract: The blisk has the characteristics of complex structure and difficult material processing. Its machining accuracy and surface quality have a crucial impact on the overall performance of the aero-engine. At present, the robotic belt grinding has been applied to grinding the complex surface of the blisk. However, since the target points are usually distributed evenly in the grinding trajectory plan, it requires a large amount of points, which leads to low processing efficiency. In this paper, the trajectory is optimized based on the improved equal chord height error method, and relevant simulation and experimental verification are carried out. The results show that the improved equal chord height error method can optimize the grinding trajectory according to the curvature change, reduce the number of target machining points and improve the machining efficiency. Experiments indicate that the machining efficiency of the blisk, compared with that before trajectory optimization, is increased by 42.9%. The surface roughness Ra after optimization can reach 0.26 μm, and the blade consistency is good, especially in the positions where the curvature changes greatly.

-

Key words:

- robot /

- belt grinding /

- blisk /

- trajectory optimization

-

表 1 机器人砂带磨削加工工艺参数设置

Table 1. Parameter setting of robotic belt grinding process

砂带类型 砂带粒度代号 线速度vw / (m·s−1) 进给速度vt / (mm·s−1) 金刚石 P200 10 20 -

[1] 黄云, 肖贵坚, 邹莱. 航空发动机叶片机器人精密砂带磨削研究现状及发展趋势 [J]. 航空学报,2019,40(3):53-72.HUANG Yun, XIAO Guijian, ZOU Lai. Current situation and development trend of robot precise belt grinding for aero-engine blade [J]. Acta Aeronautica et Astronautica Sinica,2019,40(3):53-72. [2] 陈霖. 航空发动机整体叶盘机器人磨抛工艺与参数优化 [D]. 武汉: 华中科技大学, 2020.CHEN Lin. Robotic blisk grinding process and parameter optimization for aero engine [D]. Wuhan: Huazhong University of Science and Technology, 2020. [3] 刘秀梅, 肖贵坚, 刘智武, 等. 航空发动机整体叶盘数控砂带磨削变形行为及其试验研究 [J]. 金刚石与磨料磨具工程,2020,40(3):25-32. doi: 10.13394/j.cnki.jgszz.2020.3.0004LIU Xiumei, XIAO Guijian, LIU Zhiwu, et al. Research on deformation behavior of NC belt grinding of aero-engine blisk and its test [J]. Diamond & Abrasives Engineering,2020,40(3):25-32. doi: 10.13394/j.cnki.jgszz.2020.3.0004 [4] SONG Y X, YANG H J, LV H B. Intelligent control for a robot belt grinding system [J]. IEEE Transactions on Control Systems Technology,2013,21(3):716-724. doi: 10.1109/TCST.2012.2191587 [5] 黄云, 侯明明, 刘阳, 等. 航空发动机钛合金叶片机器人浮动砂带磨削技术及其试验研究 [J]. 航空制造技术,2020,63(5):14-19. doi: 10.16080/j.issn1671-833x.2020.05.014HUANG Yun, HOU Mingming, LIU Yang, et al. Robotic floating belt grinding technology and experimental study on aero-engine titanium alloy blade [J]. Aeronautical Manufacturing Technology,2020,63(5):14-19. doi: 10.16080/j.issn1671-833x.2020.05.014 [6] XIE H L, LI J R, LIAO Z Y, et al. A robotic belt grinding approach based on easy-to-grind region partitioning [J]. Journal of Manufacturing Processes,2020,56(8):830-844. doi: 10.1016/j.jmapro.2020.03.051 [7] LV Y J, PENG Z, QU C, et al. An adaptive trajectory planning algorithm for robotic belt grinding of blade leading and trailing edges based on material removal profile model [J]. Robotics and Computer-Integrated Manufacturing,2020,66:101987. doi: 10.1016/j.rcim.2020.101987 [8] 龙樟, 李显涛, 帅涛, 等. 工业机器人轨迹规划研究现状综述 [J]. 机械科学与技术,2021,40(6):853-862. doi: 10.13433/j.cnki.1003-8728.20200132LONG Zhang, LI Xiantao, SHUAI Tao, et al. Review of research state of trajectory planning for industrial robots [J]. Mechanical Science and Technology for Aerospace Engineering,2021,40(6):853-862. doi: 10.13433/j.cnki.1003-8728.20200132 [9] MA K W, HAN L, SUN X X, et al. A path planning method of robotic belt grinding for workpieces with complex surfaces [J]. IEEE/ASME Transactions on Mechatronics,2020,25(2):728-738. doi: 10.1109/TMECH.2020.2974925 [10] 梁子龙, 丁毓峰. 一种自由曲面抛光机器人轨迹规划方法 [J]. 机械科学与技术,2018,37(10):1489-1495. doi: 10.13433/j.cnki.1003-8728.20180071LIANG Zilong, DING Yufeng. A trajectory planning method for free-form surface polishing robot [J]. Mechanical Science and Technology for Aerospace Engineering,2018,37(10):1489-1495. doi: 10.13433/j.cnki.1003-8728.20180071 [11] WANG Y M, YANG J X, LI D W, et al. Tool path generation with global interference avoidance for the robotic polishing of blisks [J]. The International Journal of Advanced Manufacturing Technology, 2021, 117(3/4): 1223-1232. [12] CUI L L, WANG H S, CHEN W D. Trajectory planning of a spatial flexible manipulator for vibration suppression [J]. Robotics and Autonomous Systems,2020,123:1-11. doi: 10.1016/j.robot.2019.103316 [13] 张铁, 张斌. 机器人砂带磨削路径优化插补算法 [J]. 中国机械工程,2018,29(8):983-990.ZHANG Tie, ZHANG Bin. Optimized interpolation algorithm for robotic belt grinding processes [J]. China Mechanical Engineering,2018,29(8):983-990. [14] WANG T, XIN Z J, MIAO H B, et al. Optimal trajectory planning of grinding robot based on improved whale optimization algorithm [J]. Mathematical Problems in Engineering,2020(4):1-8. doi: 10.1155/2020/3424313 [15] 徐立国, 孙瑞东, 党敬民. 可变阶数NURBS曲面的相机标定模型 [J]. 农业机械学报,2020,51(8):420-426. doi: 10.6041/j.issn.1000-1298.2020.08.048XU Liguo, SUN Ruidong, DANG Jingmin. Variable order NURBS surface model for camera calibration [J]. Transactions of the Chinese Society for Agricultural Machinery,2020,51(8):420-426. doi: 10.6041/j.issn.1000-1298.2020.08.048 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS