The selection and simplification of physical models for simulation of abrasive flow machining uniformity

-

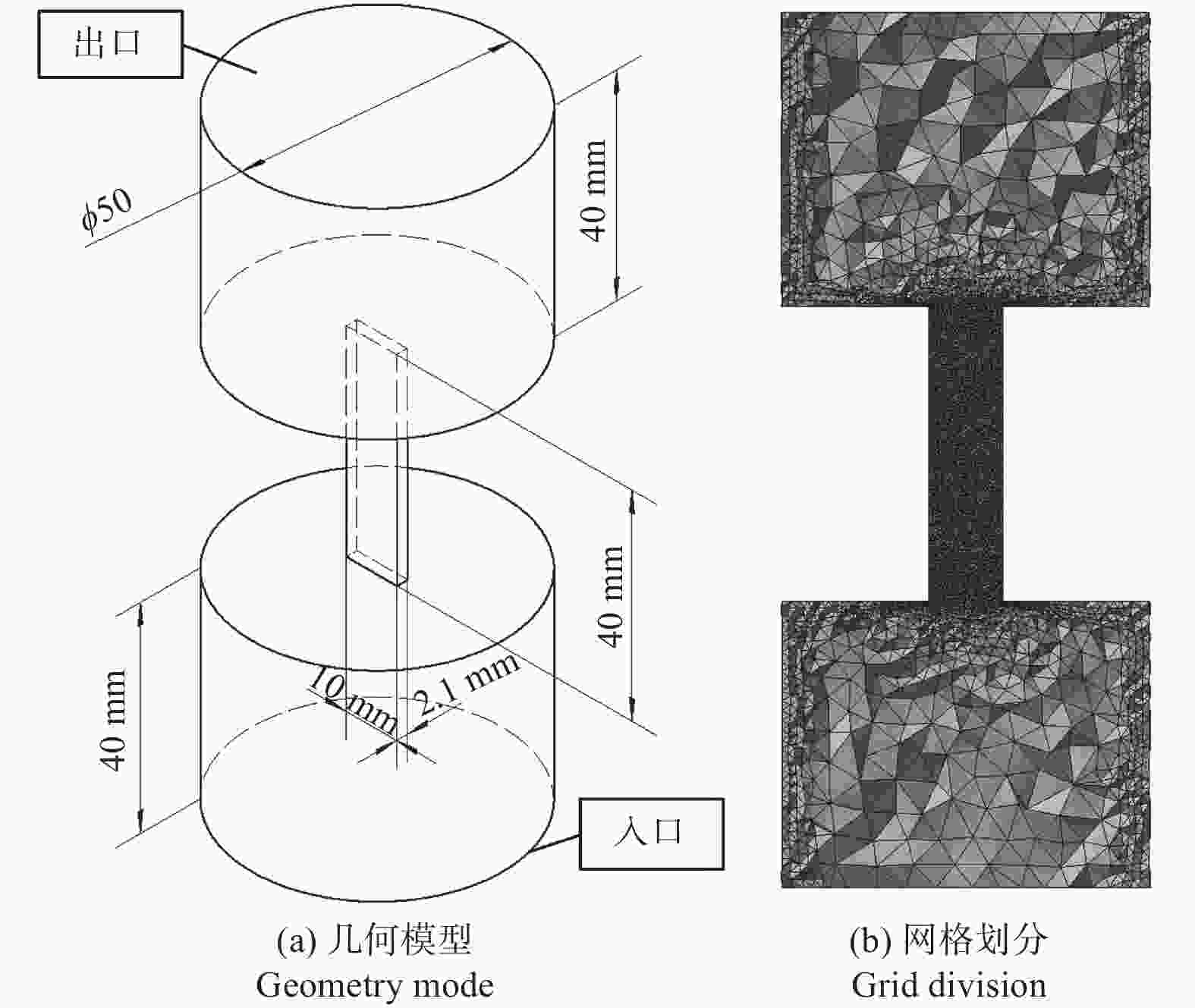

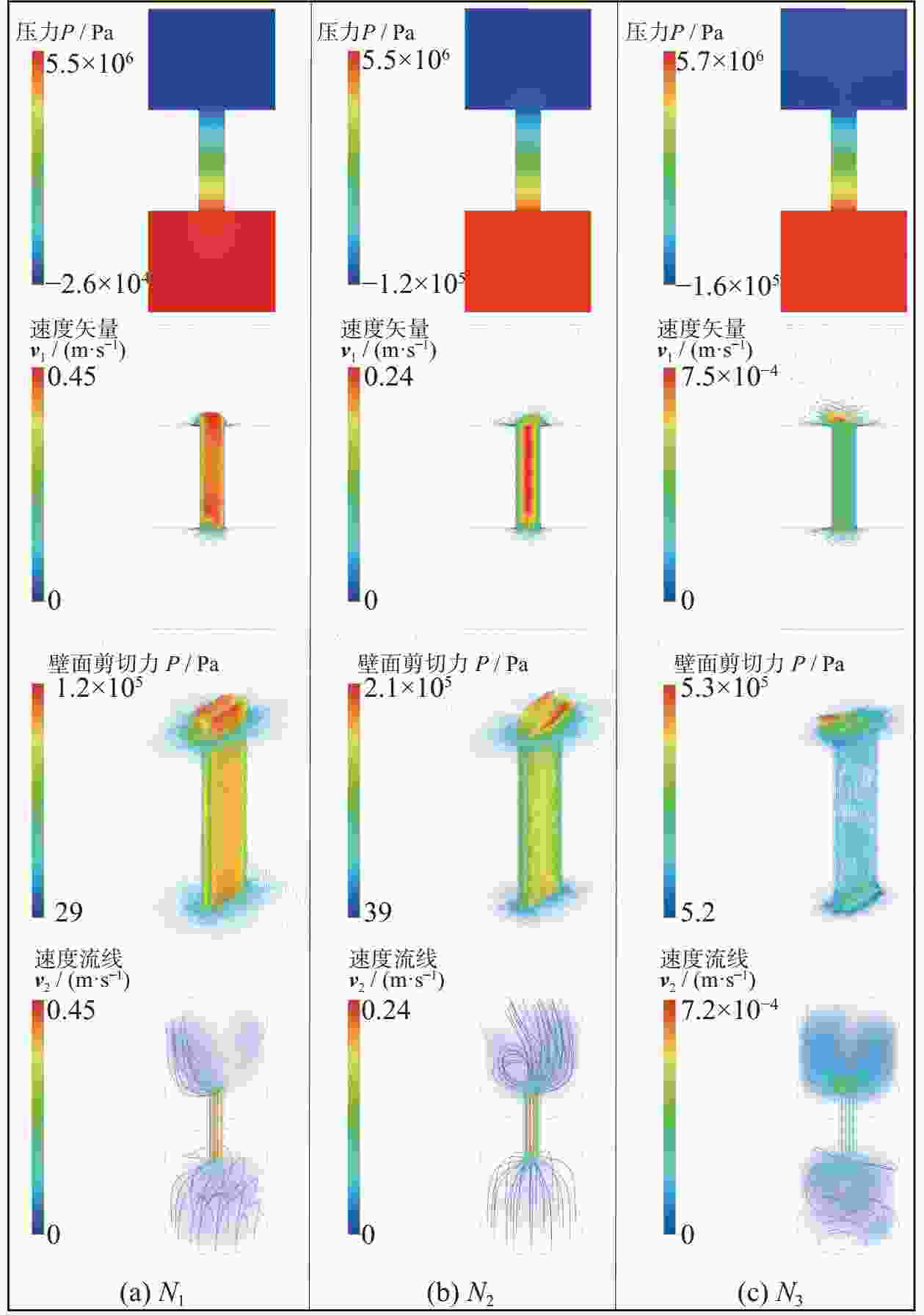

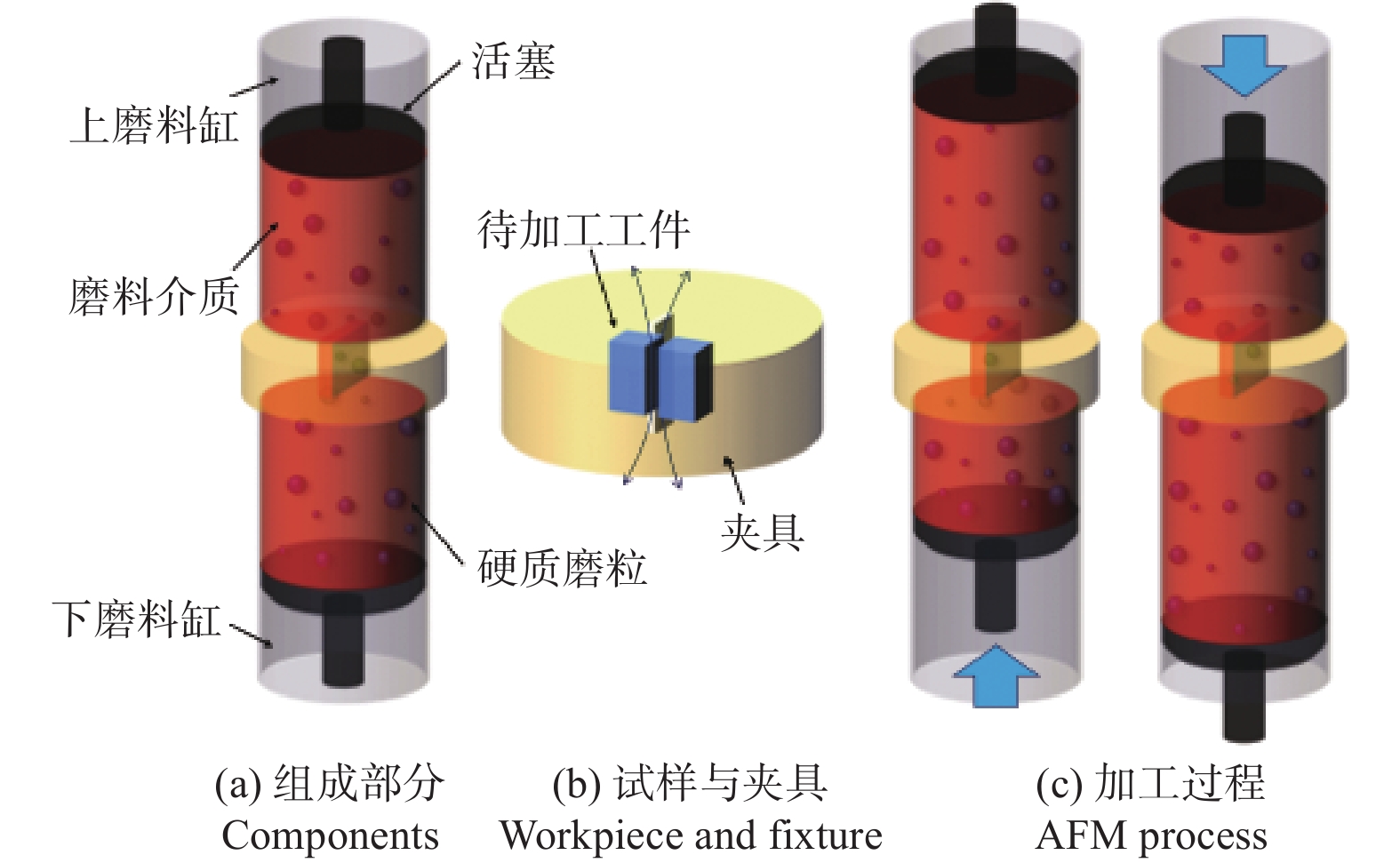

摘要: 新能源汽车齿轮磨齿加工后的精密抛光对于改善其噪声、振动和声振粗糙度性能至关重要,磨料流加工是最适用于复杂齿面高效抛光的关键技术之一,而夹具设计是实现工艺目标(减小波纹度及粗糙度,同时尽量不破坏齿面精度)的关键。结合仿真方法设计磨料流加工夹具优势突出,但物理模型的选择与仿真结果的准确性和计算成本之间存在着矛盾。采用不同黏度介质、黏度模型和流动模型进行仿真试验,分析体现加工均匀性的流体压力分布、速度矢量、壁面剪切力和流线分布云图,探究狭缝模型中磨料流稳态仿真结果,发现不同物理模型的仿真结果具有相似的分布趋势,能够实现加工区域流线的一致,证明了用简化的物理模型替代复杂的物理模型进行夹具优化仿真的可行性,而复杂模型有望用于深入分析磨料流体流动行为及材料去除机理。基于简化模型,采用最简单的牛顿流体──水作为介质,以加工区域流线分布均匀化作为优化目标,进行齿轮轴磨料流夹具设计优化,成功实现了去除齿轮鬼阶的目标。Abstract: Objectives: With the rapid development of electric vehicles (EVs), the maximum rotational speed of EV motors has reached up to 20 000 r/min. Precision polishing of gear surfaces after grinding has become a promising method for improving the noise, vibration, and harshness (NVH) performance of EVs. Abrasive Flow Machining (AFM) is one of the key technologies for efficiently polishing complex gear tooth surfaces. Fixture design plays a critical role in achieving process objectives, reducing surface ripple and roughness, and minimizing damage to the tooth surface accuracy. This article addresses the trade-off between selecting physical models and balancing the accuracy and computational cost of simulation results. It analyzes the impact of different simulation models on the results, providing guidance for AFM fixture design and offering practical experience for fixture optimization in AFM gear processing. Methods: Simulations are conducted using media with different viscosities, viscosity models, and flow models, within the simplest and most typical slit model. Fluid pressure distribution, velocity vectors, wall shear, and streamline distribution cloud mapsare analyzed to reflect machining uniformity. Based on the conclusions drawn from slit model simulations, the simplest Newtonian fluid—water—is selected as the medium for AFM gear shaft processing simulations. The focus is on the uniformity of streamline distribution in the machining area to optimize fixture design. Results: The analysis of slit model simulation results reveals that different physical models have varying impacts on the outcomes: (1) The selection of viscosity models decisively affects the pressure distribution of low-viscosity media. The type of viscosity and turbulence models has little impact on pressure distribution, but it significantly affects the velocity vector, wall shear, and streamline distribution within the abrasive cylinder. (2) For low-viscosity media: implementing a non-Newtonian fluid model has a significant impact on the pressure distribution. Different flow models show marked differences only in wall shear force distributions. Various viscosity models yield different cloud map distributions, but they produce numerically similar values. (3) For high-viscosity media: simulations with non-Newtonian and Newtonian fluid models show consistent results. However, different flow models greatly influence the results, while various viscosity models lead to changes in all simulation results, except for pressure distribution and streamlines within the slit. Despite these variations, the streamline distribution in the processing area remains largely unchanged. Based on the consistency of streamline distribution, fixture design optimization for the AFM gear shaft is carried out, successfully achieving the goal of eliminating gear "ghost frequencies". Conclusions: Despite variations in the physical models, the simulation results exhibit similar trends in distribution, enabling consistent streamline distribution in the processing area. For low-viscosity media, a non-Newtonian fluid viscosity model with laminar flow simulation can be used, and the selection of viscosity models can be simplified based on the rheological characteristics of the actual abrasive flow medium. For high-viscosity media, setting appropriate viscosity values and using laminar flow simulation with a Newtonian fluid model yields consistent pressure and streamline distribution in the processing area, similar to adding viscosity and turbulence models. The slit model simulation results and AFM gear shaft processing tests both demonstrate that streamline information derived from simple physical models can significantly assist in AFM fixture design. In cases where the physical properties of the abrasive flow medium are uncertain—especially in complex flow paths prone to divergence—using the simplest Newtonian fluid, such as water, with laminar flow simulation can provide a reasonable streamline distribution in the processing area. This approach aids in the analysis of processing uniformity, significantly reduces simulation difficulty and costs, and accelerates the fixture design cycle, ultimately enhancing optimization efficiency.

-

表 1 因素水平表

Table 1. Factor level table

试验因素 各因素试验条件(水平) 黏度介质 V V1=水 V2=低黏 V3=高黏 黏度模型 N N1=Power-Law N2=Carreau N3=Cross 流动模型 T 层流模型 T0=Laminar 湍流模型 T1=Spalart-Allmaras T2=Standard k-ε T3=SST k-omega T4=Reynolds Stress T5=LES 表 2 流体介质参数

Table 2. Fluid medium parameters

流体介质 密度 ρ / (kg·m−3) 黏度 η / (Pa·s) 雷诺数 Re 湍流强度 I / % 牛顿流体参数 水 998.2 0.001 286 673.597 3.326 低黏 2 865.5 1.33 232.201 5 8.098 高黏 1308.16 412.11 0.001 165 7 37.220 非牛顿流体

黏度模型参数K / (Pa·sn) n η0 / (Pa·s) η∞ / (Pa·s) λ / s 最小黏度 / (kg·m−1s−1) 最大黏度 / (kg·m−1s−1) Power-Law 低黏 33.29 0.488 高黏 7295.23 0.358 0 196 438.41 Carreau 低黏 0.36 347.3 0 60 高黏 0.41 196438.41 0 138.04 Cross 低黏 0.221 514.63 50.91 高黏 1.813 236934.77 70.85 -

[1] GEORGE M A, KAMAT D V, KURIAN C P. Electronically tunable ACO based fuzzy FOPID controller for effective speed control of electric vehicle [J]. IEEE Access,2021,9:73392-73412. doi: 10.1109/ACCESS.2021.3080086 [2] WU Z G, LI W L, TANG H Y, et al. Research on the calculation of rotor's convective heat transfer coefficient of high-speed drive motor for EVs based on multiple scenarios [J]. Journal of Electrical Engineering & Technology,2023,18(6):4245-4256. doi: 10.1007/s42835-023-01485-0 [3] HAZRA S, REDDY J K. An aspect of noise, vibration, and harshness issues in electric vehicles [J]. SAE International Journal of Vehicle Dynamics, Stability, and NVH,2021,6(1):23-33. doi: 10.4271/10-06-01-0002 [4] 幸人 中野, 直 富田, 真琴 瀬木, 等. パルプモウルド製ヘルムホルツ共鳴器によるEV低速走行時の耳位置騒音低減 [J]. 日本機械学会論文集,2022,88(911):21-00395. doi: 10.1299/transjsme.21-00395NAKANO S, TOMITA S, SEGI M, et al. Reduction of ear-position sound pressure at low speed in electric vehicles by pulp mold [J]. Transactions of the JSME (in Japanese),2022,88(911):21-00395. doi: 10.1299/transjsme.21-00395 [5] 占雨兰. 电驱动NVH特点以及研究现状 [J]. 时代汽车,2021,12:109-110, 121. doi: 10.3969/j.issn.1672-9668.2021.12.048ZHAN Yulan. Characteristics and research status of electric drive NVH [J]. Auto Time,2021,12:109-110, 121. doi: 10.3969/j.issn.1672-9668.2021.12.048 [6] SWART D J, BEKKER A. The relationship between consumer satisfaction and psychoacoustics of electric vehicle signature sound [J]. Applied Acoustics,2019,145:167-175. doi: 10.1016/j.apacoust.2018.09.019 [7] PADAVALA P, INAVOLU N, THAVEEDU J R, et al. Challenges in noise refinement of a pure electric passenger vehicle [J]. SAE International Journal of Vehicle Dynamics, Stability, and NVH,2021,5(1):45-64. doi: 10.4271/10-05-01-0004 [8] KAHNENBLEY T, GRAVEL G. Gear standards for reliable measurement of noise-causing tooth flank ripples [J]. Forschung im Ingenieurwesen,2019,83(3):537-543. doi: 10.1007/s10010-019-00366-1 [9] SINGH S, KUMAR H, KUMAR S, et al. A systematic review on recent advancements in abrasive flow machining (AFM) [J]. Materials Today-Proceedings,2022,56:3108-3116. doi: 10.1016/j.matpr.2021.12.273 [10] ZHANG B C, CHEN S F, KHIABANI N, et al. Research on the underlying mechanism behind abrasive flow machining on micro-slit structures and simulation of viscoelastic media [J]. Advances in Manufacturing,2022,10(3):382-396. doi: 10.1007/s40436-022-00395-0 [11] SAMBHARIA J, MALI H S. Recent developments in abrasive flow finishing process: A review of current research and future prospects [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,2019,233(2):388-399. doi: 10.1177/0954405417731466 [12] DIXIT N, SHARMA V, KUMAR P. Research trends in abrasive flow machining: A systematic review [J]. Journal of Manufacturing Processes,2021,64:1434-1461. doi: 10.1016/j.jmapro.2021.03.009 [13] ZOU T G, YAN Q D, WANG L X, et al. Research on quality control of precision machining straight internal gear by abrasive flow based on large eddy simulation [J]. The International Journal of Advanced Manufacturing Technology,2022,119(7/8):5315-5334. doi: 10.1007/s00170-021-08453-w [14] ZHAO W H, LIU J H, WANG L X, et al. Numerical simulation and experimental research on abrasive flow machining of helical internal gear [J]. International Journal of Abrasive Technology (IJAT),2024,12(2). doi: 10.1504/IJAT.2024.10065531 [15] FU Y Z, GAO H, YAN Q S, et al. Rheological characterisation of abrasive media and finishing behaviours in abrasive flow machining [J]. The International Journal of Advanced Manufacturing Technology,2020,107(7):3569-3580. doi: 10.1007/s00170-020-05288-9 [16] ZHANG B C, CHEN S F, WANG X C. Machining uniformity and property change of abrasive media for micro-porous structures [J]. Journal of Materials Processing Technology,2022,307:117675. doi: 10.1016/j.jmatprotec.2022.117675 [17] PAL P, JAIN K K. Computational simulation of abrasive flow machining for two dimensional models [J]. Materials Today: Proceedings,2018,5(5):12969-12983. doi: 10.1016/j.matpr.2018.02.282 [18] ZHANG B C, QIAO Y, KHIABANI N, et al. Study on rheological behaviors of media and material removal mechanism for abrasive flow machining (AFM) micro structures and corresponding simulations [J]. Journal of Manufacturing Processes,2022,73:248-259. doi: 10.1016/j.jmapro.2021.11.006 [19] KUMAR M, KUMAR V, KUMAR A, et al. CFD analysis of MR fluid applied for finishing of gear in MRAFF process [J]. Materials Today: Proceedings,2021,45:4677-4683. doi: 10.1016/j.matpr.2021.01.116 [20] CHENG K C, WANG A C, CHEN K Y, et al. Study of the polishing characteristics by abrasive flow machining with a rotating device [J]. Processes,2022,10(7):1362. doi: 10.3390/pr10071362 [21] LI J Y, WANG L X, ZHANG H F, et al. Mechanism research and discussion of the quality of precision machining of a fifth-order variable-diameter pipe using abrasive flow [J]. Strojniški Vestnik – Journal of Mechanical Engineering,2020,66(6):358-374. doi: 10.5545/sv-jme.2020.6554 [22] SAMOILENKO M, LANIK G, BRAILOVSKI V. Towards the determination of machining allowances and surface roughness of 3D-printed parts subjected to abrasive flow machining [J]. Journal of Manufacturing and Materials Processing,2021,5(4):111. doi: 10.3390/jmmp5040111 [23] 高航, 付有志, 王宣平, 等. 螺旋面磨料流光整加工仿真与试验 [J]. 浙江大学学报(工学版),2016,50(5):920-926. doi: 10.3785/j.issn.1008973X.2016.05.015GAO Hang, FU Youzhi, WANG Xuanping, et al. Simulations and experiments on finishing process of screw surface by using abrasive flow machining [J]. Journal of Zhejiang University (Engineering Science),2016,50(5):920-926. doi: 10.3785/j.issn.1008973X.2016.05.015 [24] 郑志鑫, 董志国, 李孟楠, 等. 涡轮叶片内冷通道的磨料流光整加工特性 [J]. 金刚石与磨料磨具工程,2023,43(1):110-117. doi: 10.13394/j.cnki.jgszz.2022.0093ZHENG Zhixin, DONG Zhiguo, LI Mengnan, et al. Abrasive flow finishing characteristics of internal cooling channel of turbine blade [J]. Diamond & Abrasives Engineering,2023,43(1):110-117. doi: 10.13394/j.cnki.jgszz.2022.0093 [25] 李孟楠, 董志国, 郑志鑫, 等. 喷油嘴喷孔流道磨料流光整特性仿真与试验 [J]. 金刚石与磨料磨具工程,2023,43(2):265-271. doi: 10.13394/j.cnki.jgszz.2022.0142LI Mengnan, DONG Zhiguo, ZHENG Zhixin, et al. Simulation and experiment of abrasive flow finishing characteristics of nozzle jetting hole runner [J]. Diamond & Abrasives Engineering,2023,43(2):265-271. doi: 10.13394/j.cnki.jgszz.2022.0142 [26] 宋桂珍. 磨料流加工技术的理论分析和实验研究[D]. 太原: 太原理工大学, 2010.SONG Guizhen. Theoretical analysis and experimental research on abrasive flow machining [D]. Taiyuan: Taiyuan University of Technology, 2010. [27] 付有志. 粘性挤压磨料流加工边缘效应及抑制策略 [D]. 大连:大连理工大学, 2018.FU Youzhi. Edge effect and suppresion strategies in extrusion abrasive flow machining with viscous abrasive media [D]. Dalian: Dalian University of Technology, 2018. [28] GRAVEL G, SEEWIG J. Ripple analysis of gearing measurement [J]. Verzahnungsmesstechnik: Praktisch Anwendungen Und Neue Losungen,2008,2053:49-59. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS