| [1] |

CHANG R, ZANG J B, WANG Y H, et al. Study of Ti-coated diamond grits prepared by spark plasma coating [J]. Diamond and Related Materials,2017,77:72-78. doi: 10.1016/j.diamond.2017.06.004

|

| [2] |

沙小花. 镀膜金刚石微粉烧结聚晶金刚石制备及其热损伤机制 [D]. 北京: 中国地质大学(北京), 2020.SHA Xiaohua. Preparation and thermal damage mechanism of sintered polycrystalline diamond with coated diamond powder [D]. Beijing: China University of Geosciences, 2020.

|

| [3] |

翟豪. 化学气相沉积硼掺杂金刚石薄膜的研究 [D]. 长沙: 中南大学, 2013.ZHAI Hao. Study on boron-doped diamond films deposited by chemical vapor deposition [D]. Changsha: Central South University, 2013.

|

| [4] |

黄世玲. 金刚石化学镀镍工艺研究及电化学分析 [D]. 郑州: 郑州大学, 2014.HUANG Shiling. Study on electroless nickel plating on diamond and electrochemical analysis [D]. Zhengzhou: Zhengzhou University, 2014.

|

| [5] |

张杨, 崔仲鸣, 冯常财, 等. 采用旋转电极的金刚石表面镀镍方法及工艺 [J]. 金刚石与磨料磨具工程,2021,41(6):44-50. doi: 10.13394/j.cnki.jgszz.2021.6.0008ZHANG Yang, CUI Zhongming, FENG Changcai, et al. Nickel plating method and process on diamond surface with rotating electrode [J]. Diamond & Abrasives Engineering,2021,41(6):44-50. doi: 10.13394/j.cnki.jgszz.2021.6.0008

|

| [6] |

WEI C L, XU X, WEI B Z, et al. Titanium coating on the surface of diamond particles by a novel rapid low-temperature salt bath plating method [J]. Chemical Physics Letters,2020,761:138091. doi: 10.1016/j.cplett.2020.138091

|

| [7] |

常锐. 放电等离子体镀覆颗粒状金刚石和碳化硅的研究 [D]. 秦皇岛: 燕山大学, 2017.CHANG Rui. Study on granular diamond and silicon carbide plated by discharge plasma [D]. Qinhuangdao: Yanshan University, 2017.

|

| [8] |

窦志强, 肖长江, 栗正新. 金刚石微粉表面镀覆技术研究进展 [J]. 电镀与精饰,2017,39(10):23-27. doi: 10.3969/j.issn.1001-3849.2017.10.005DOU Zhiqiang, XIAO Changjiang, LI Zhengxin. Research progress of plating technology on ultrafine diamond surface [J]. Plating & Finishing,2017,39(10):23-27. doi: 10.3969/j.issn.1001-3849.2017.10.005

|

| [9] |

吕建伟, 赵强, 安会芬, 等. 金刚石表面熔盐法镀钛的研究 [J]. 电镀与涂饰,2006,25(7):17-20. doi: 10.3969/j.issn.1004-227X.2006.07.006LÜ Jianwei, ZHAO Qiang, AN Huifen, et al. Research on Ti-plated diamond surface by molten salt process [J]. Electroplating & Finishing,2006,25(7):17-20. doi: 10.3969/j.issn.1004-227X.2006.07.006

|

| [10] |

吴建华, 张海龙, 张洋, 等. 镀Ti金刚石/Al复合材料的热性能 [J]. 功能材料,2012,43(17):2295-2298, 2303. doi: 10.3969/j.issn.1001-9731.2012.17.006WU Jianhua, ZHANG Hailong, ZHANG Yang, et al. Thermal properties of Ti coated diamond/Al composites [J]. Journal of Functional Materials,2012,43(17):2295-2298, 2303. doi: 10.3969/j.issn.1001-9731.2012.17.006

|

| [11] |

梁宝岩, 王明智, 王长通. 金刚石表面镀覆纳米Ti涂层 [J]. 中原工学院学报,2019,30(3):1-5. doi: 10.3969/j.issn.1671-6906.2019.03.001LIANG Baoyan, WANG Mingzhi, WANG Changtong. Nanometer Ti coating on diamond [J]. Journal of Zhongyuan University of Technology,2019,30(3):1-5. doi: 10.3969/j.issn.1671-6906.2019.03.001

|

| [12] |

项东, 李木森, 刘科高, 等. 金刚石表面盐浴镀Ti层研究 [J]. 热加工工艺,2009,38(4):74-77. doi: 10.3969/j.issn.1001-3814.2009.04.023XIANG Dong, LI Musen, LIU Kegao, et al. Study on salt-bath plating Ti layers on diamond surface [J]. Hot Working Technology,2009,38(4):74-77. doi: 10.3969/j.issn.1001-3814.2009.04.023

|

| [13] |

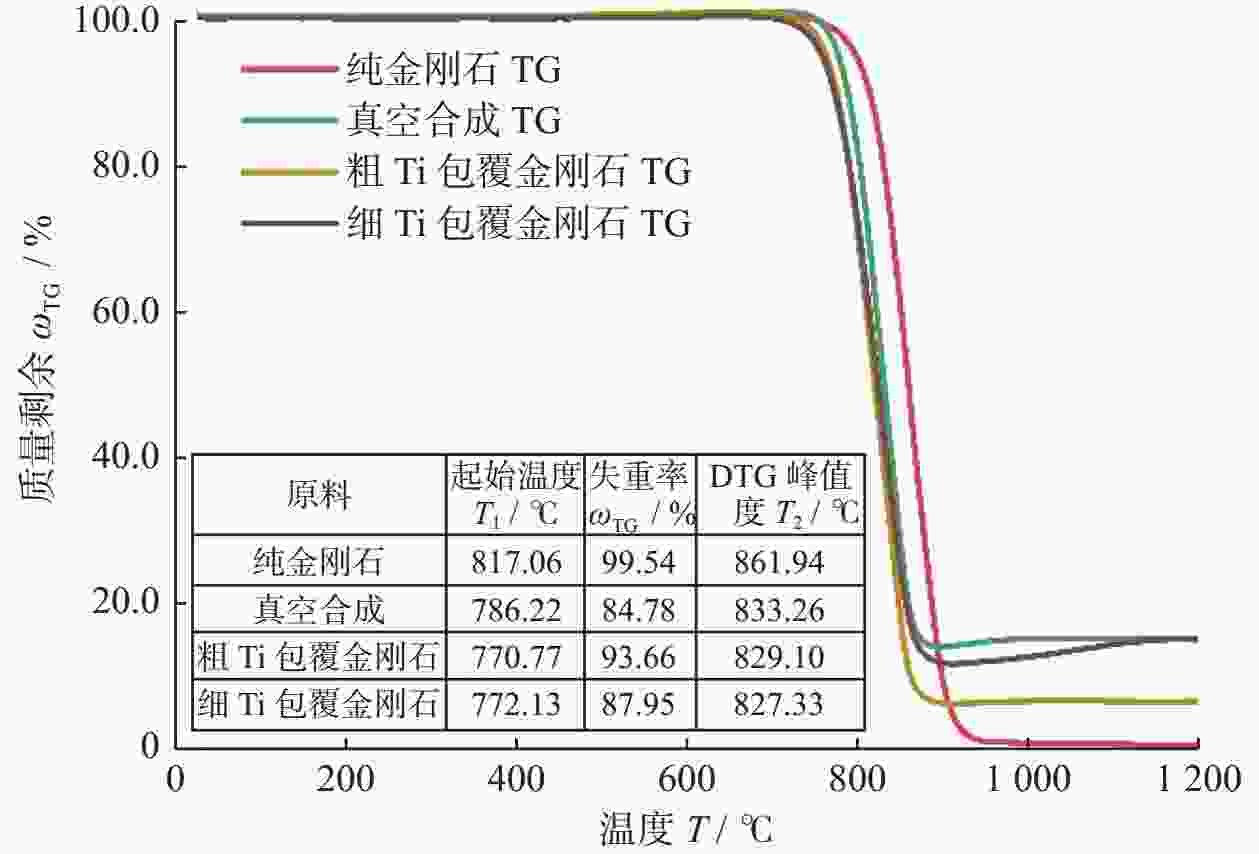

武玺旺, 皇甫战彪, 刘雪坤, 等. 熔盐法合成Ti和TiC镀覆层对金刚石热稳定性的影响 [J]. 金刚石与磨料磨具工程,2023,43(2):196-201. doi: 10.13394/j.cnki.jgszz.2022.0054WU Xiwang, HUANGFU Zhanbiao, LIU Xuekun, et al. Effect of Ti and TiC coating on the thermal stability of diamond [J]. Diamond & Abrasives Engineering,2023,43(2):196-201. doi: 10.13394/j.cnki.jgszz.2022.0054

|

| [14] |

GU Q C, HAN Z H, XU L, et al. Preparation of Ti-coated diamond/WC-Co-based cemented carbide composites by microwave-evaporation titanium-plating of diamond particles and microwave hot-press sintering [J]. Ceramics International,2023,49(6):10139-10150. doi: 10.1016/j.ceramint.2022.11.197

|

| [15] |

徐大印, 赵浩. 直流磁控溅射镀镍的金刚石粉体的拉曼光谱 [J]. 烟台大学学报(自然科学与工程版),2022,35(2):248-252. doi: 10.13951/j.cnki.371213/n.210116XU Dayin, ZHAO Hao. Raman spectra of nickel-plated diamond powder by DC magnetron sputtering [J]. Journal of Yantai University (Natural Science and Engineering Edition),2022,35(2):248-252. doi: 10.13951/j.cnki.371213/n.210116

|

| [16] |

王艳辉. 金刚石磨料表面镀钛层的制备、结构、性能及应用 [D]. 秦皇岛: 燕山大学, 2003.WANG Yanhui. Preparation, structure, properties and application of titanium coating on diamond abrasive surface [D]. Qinhuangdao: Yanshan University, 2003.

|

| [17] |

MENG Y F, YAN C S, LAI J, et al. Enhanced optical properties of chemical vapor deposited single crystal diamond by low-pressure/high-temperature annealing [J]. Proceedings of the National Academy of Sciences of the United States of America,2008,105(46):17620-17625. doi: 10.1073/pnas.0808230105

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS