Simulation and experimental analysis of composite chamfering of superhard cutting tools based on edge grinding technology

-

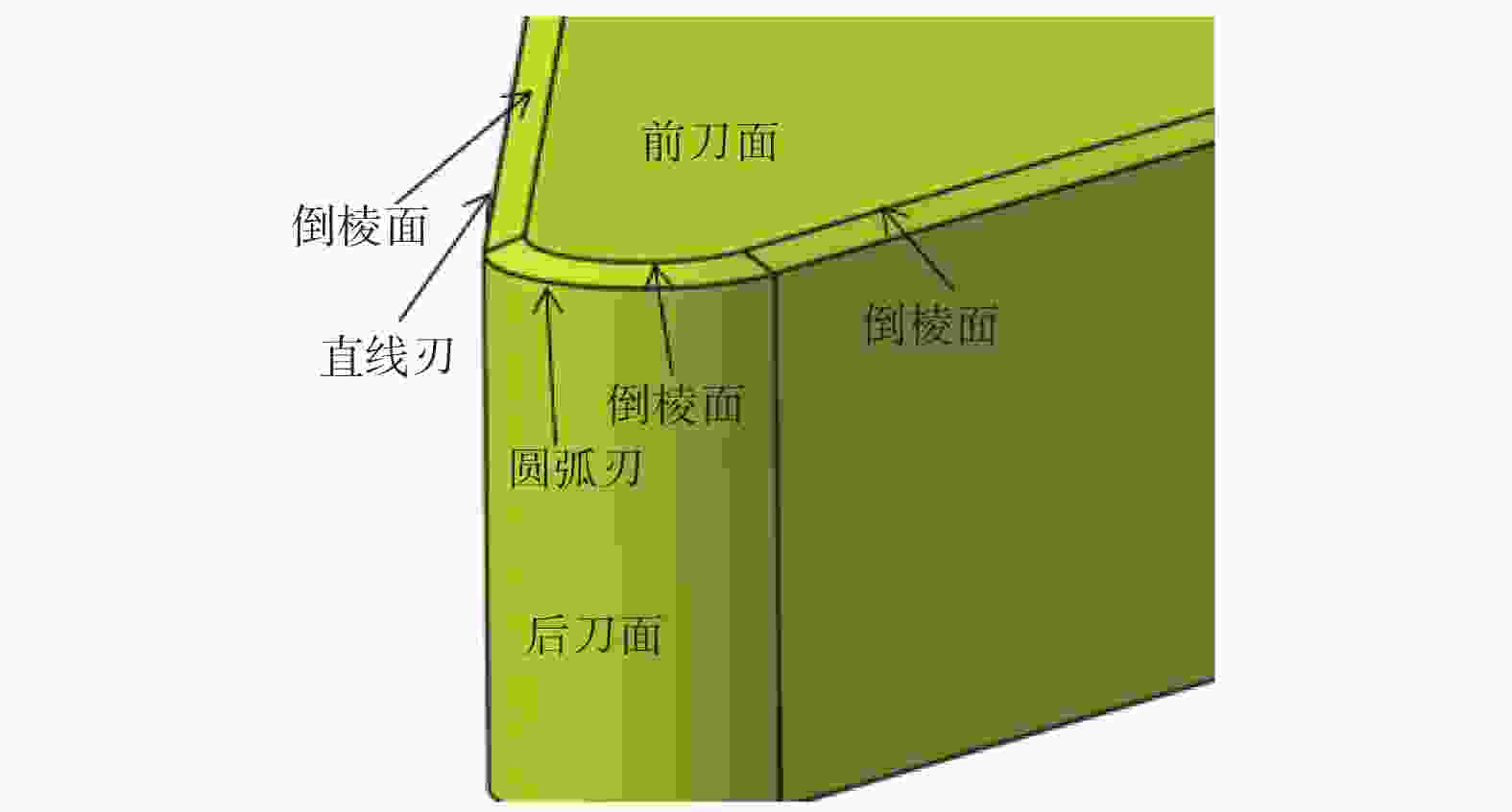

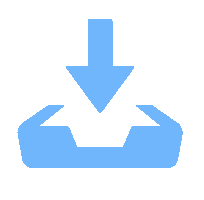

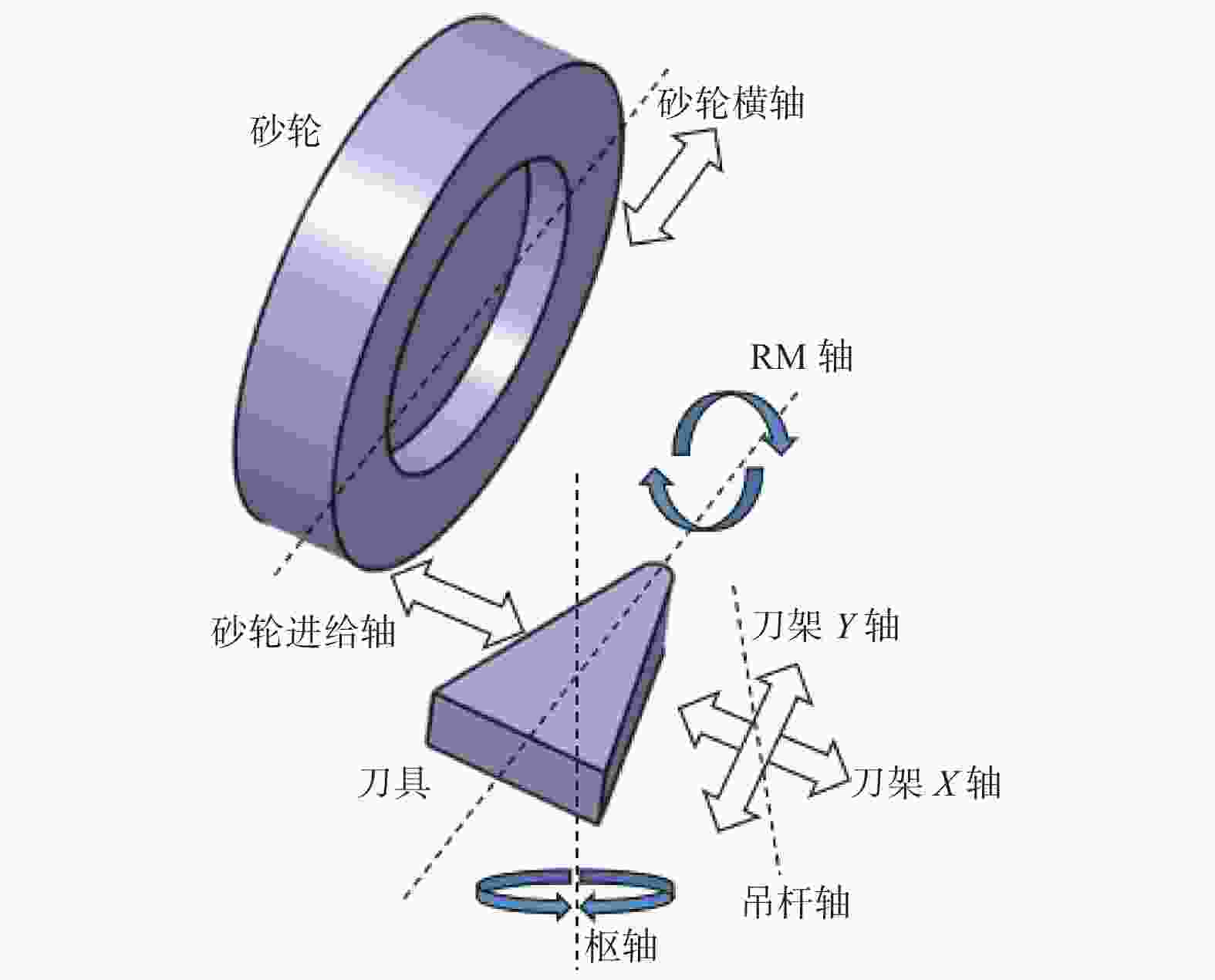

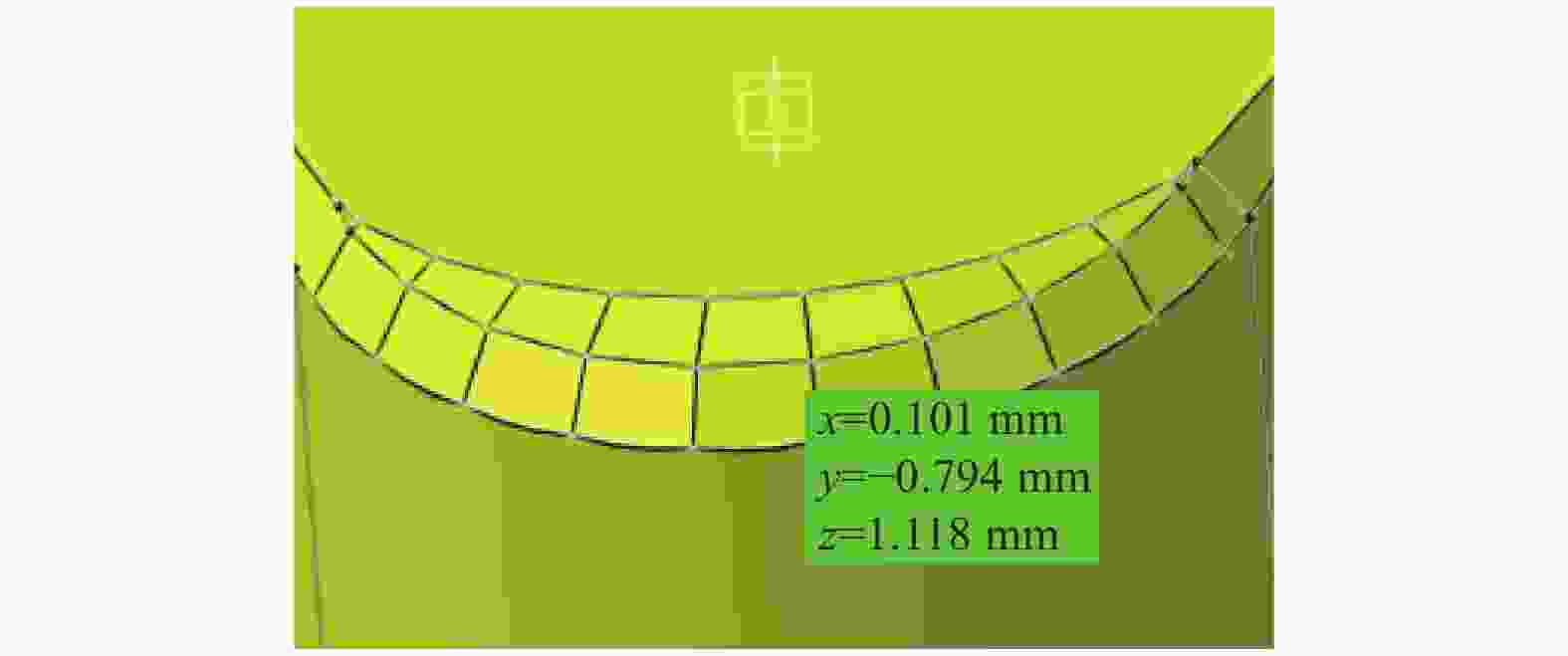

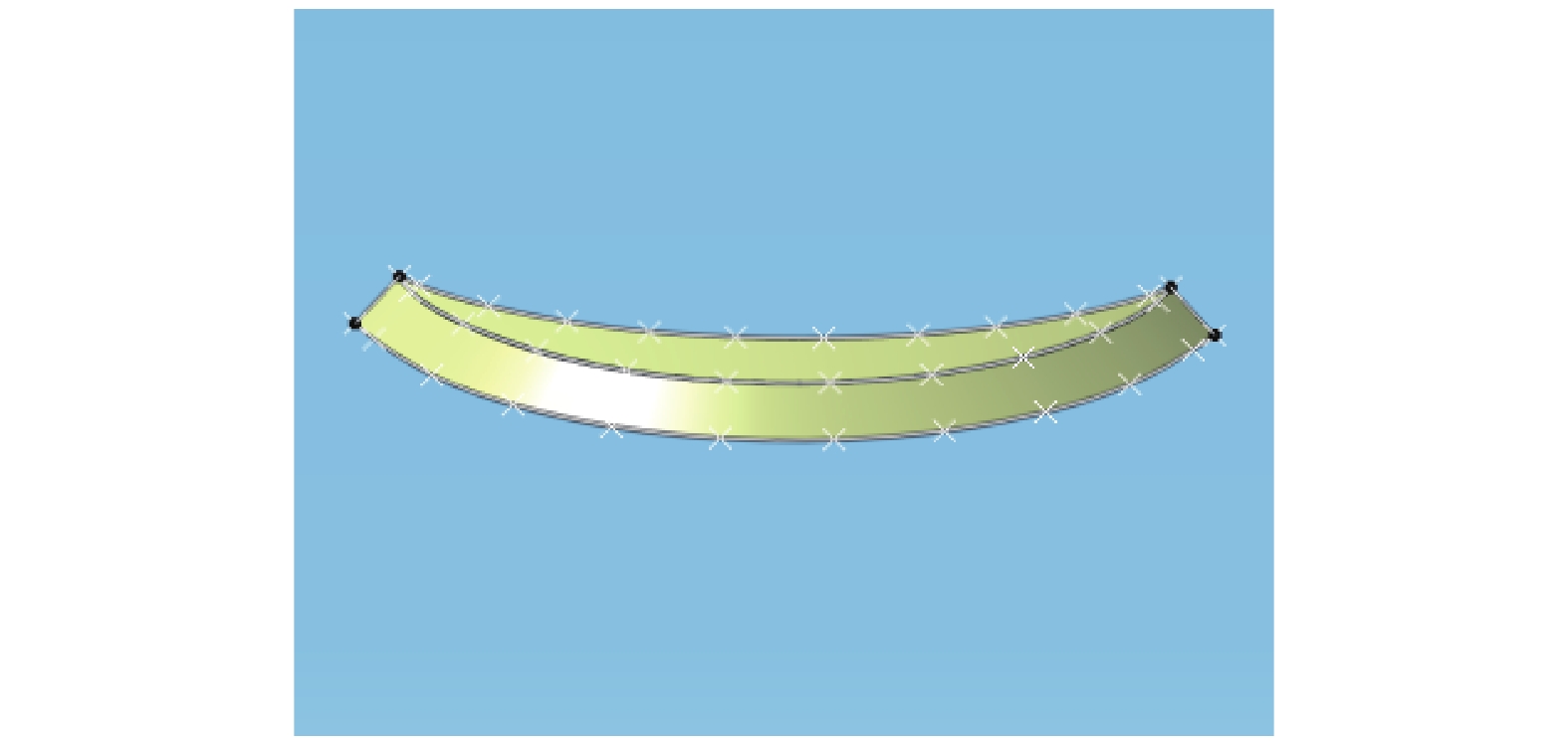

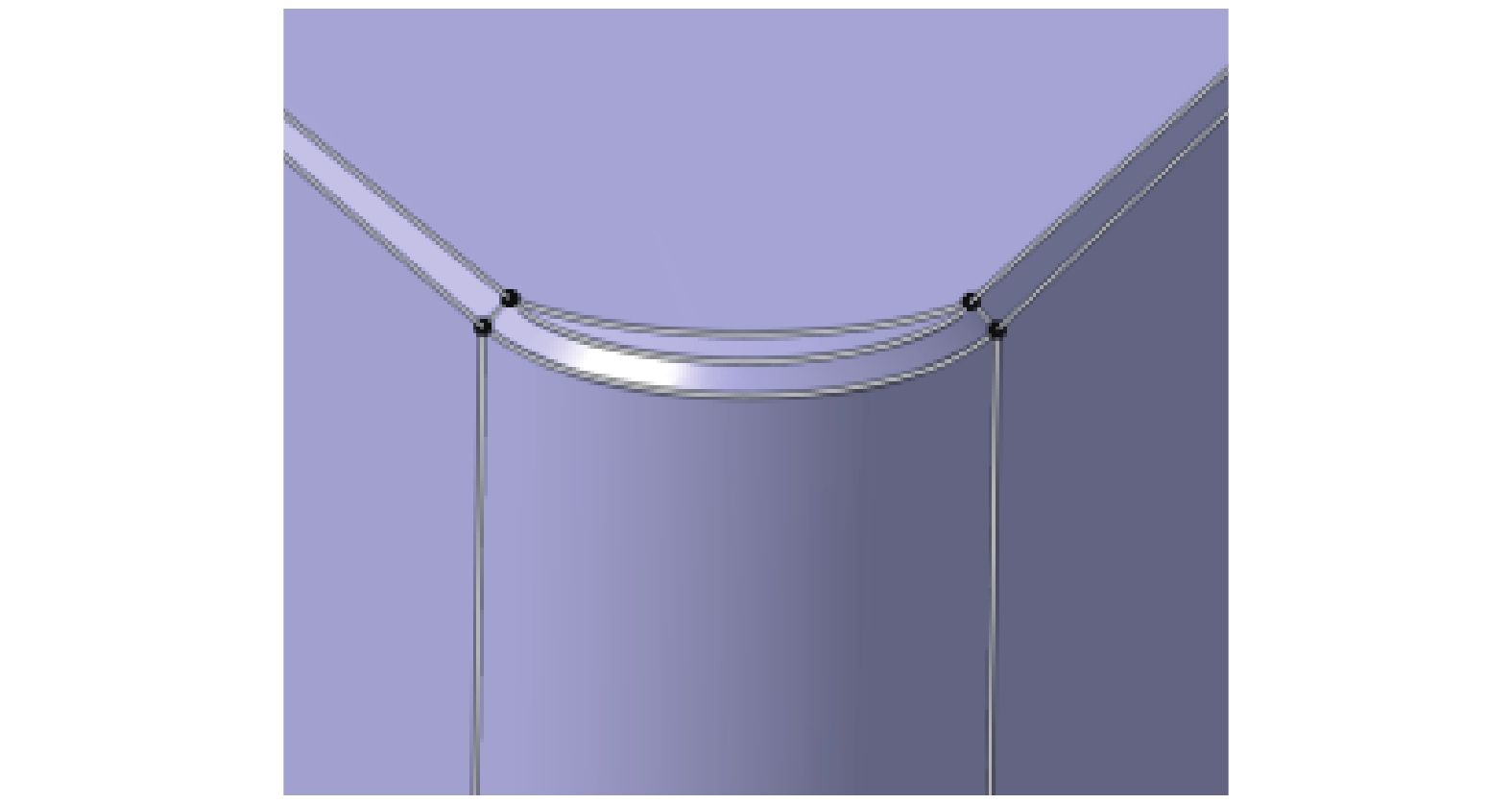

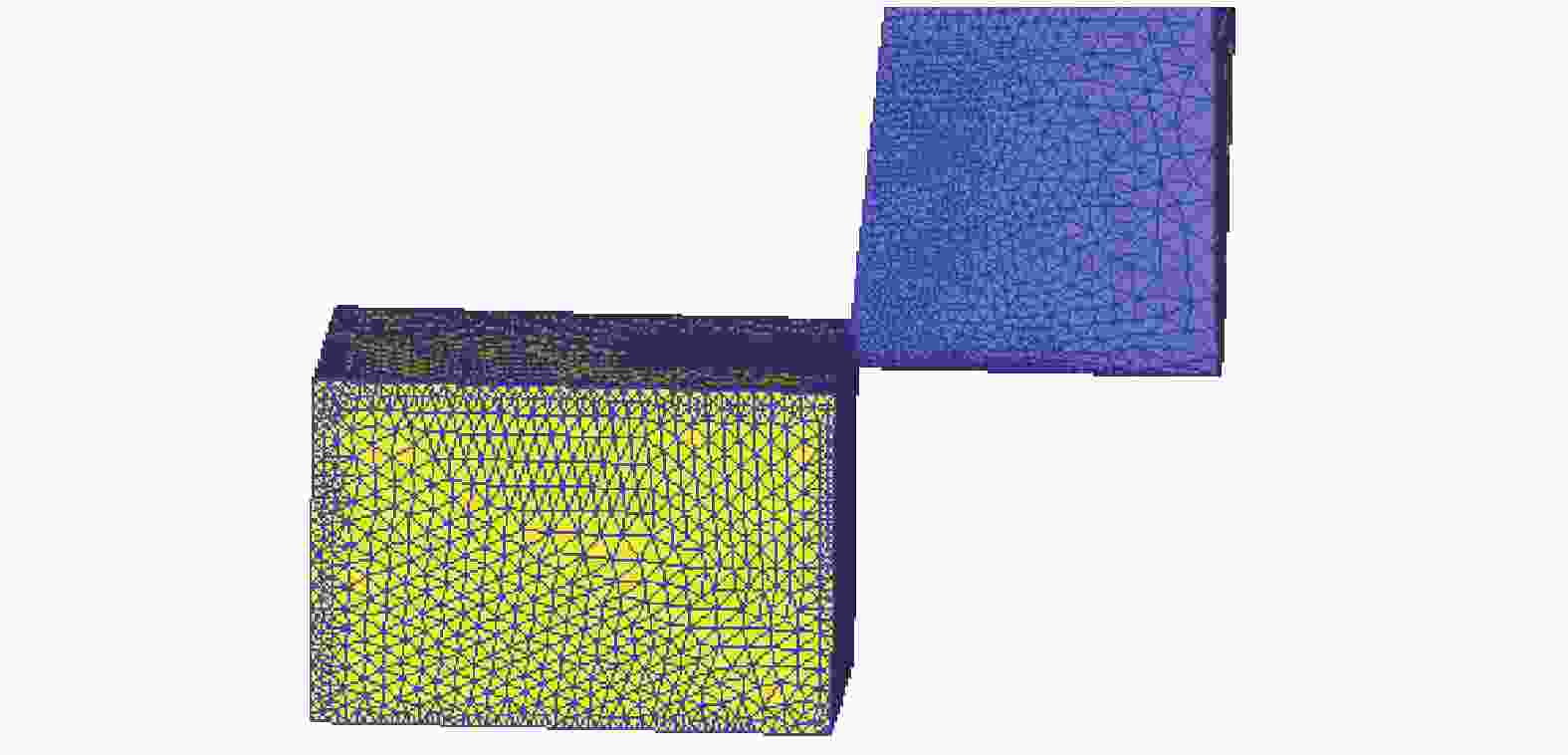

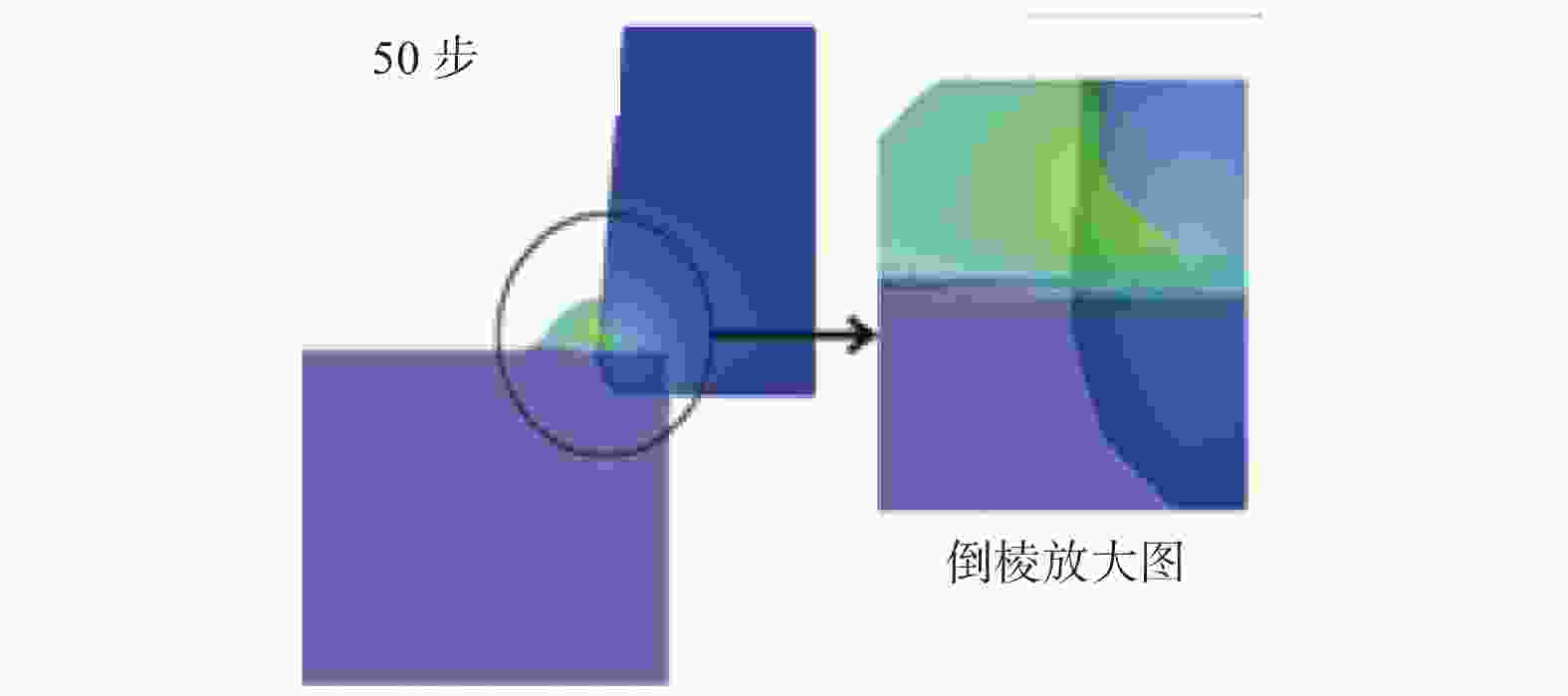

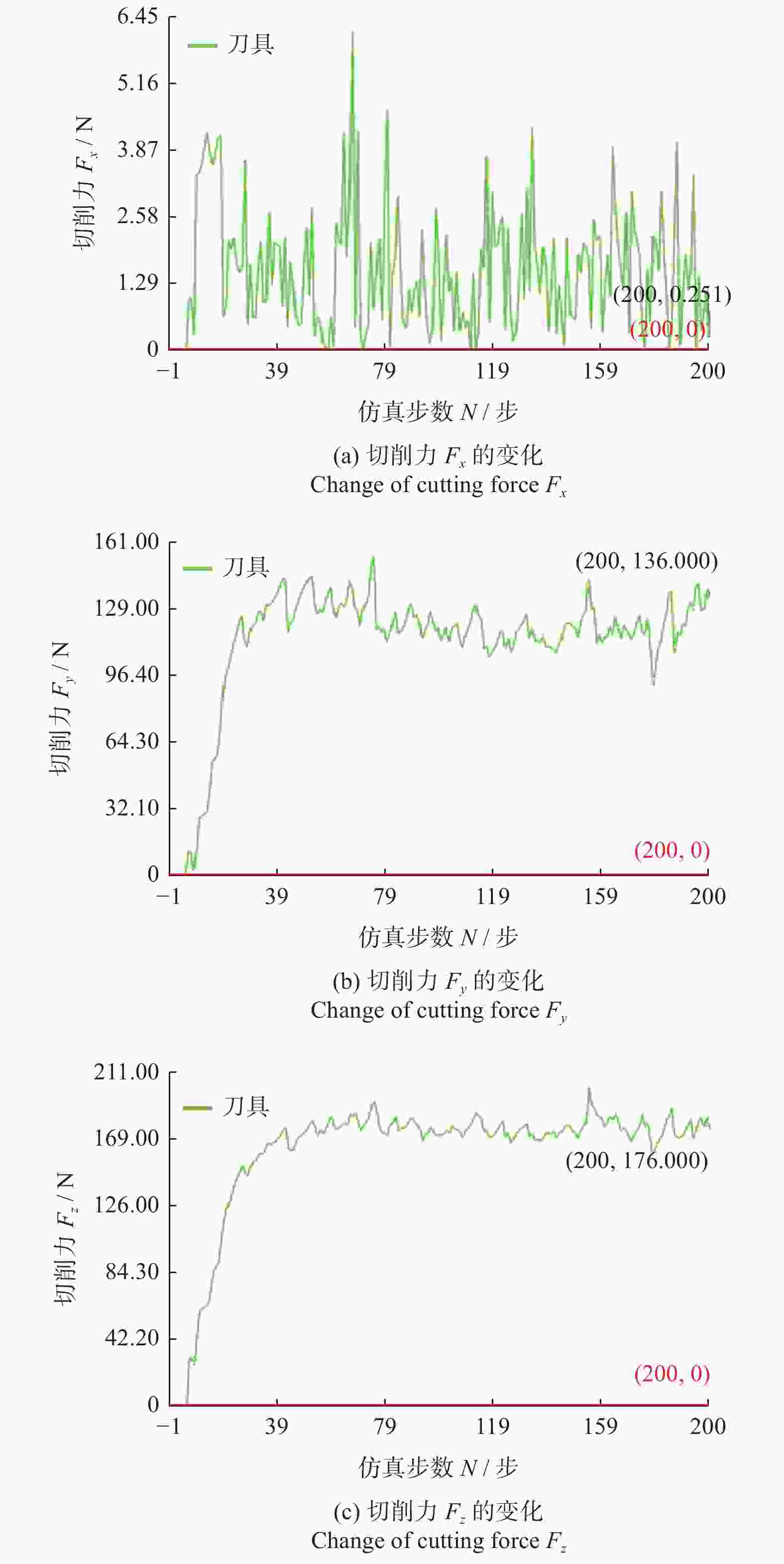

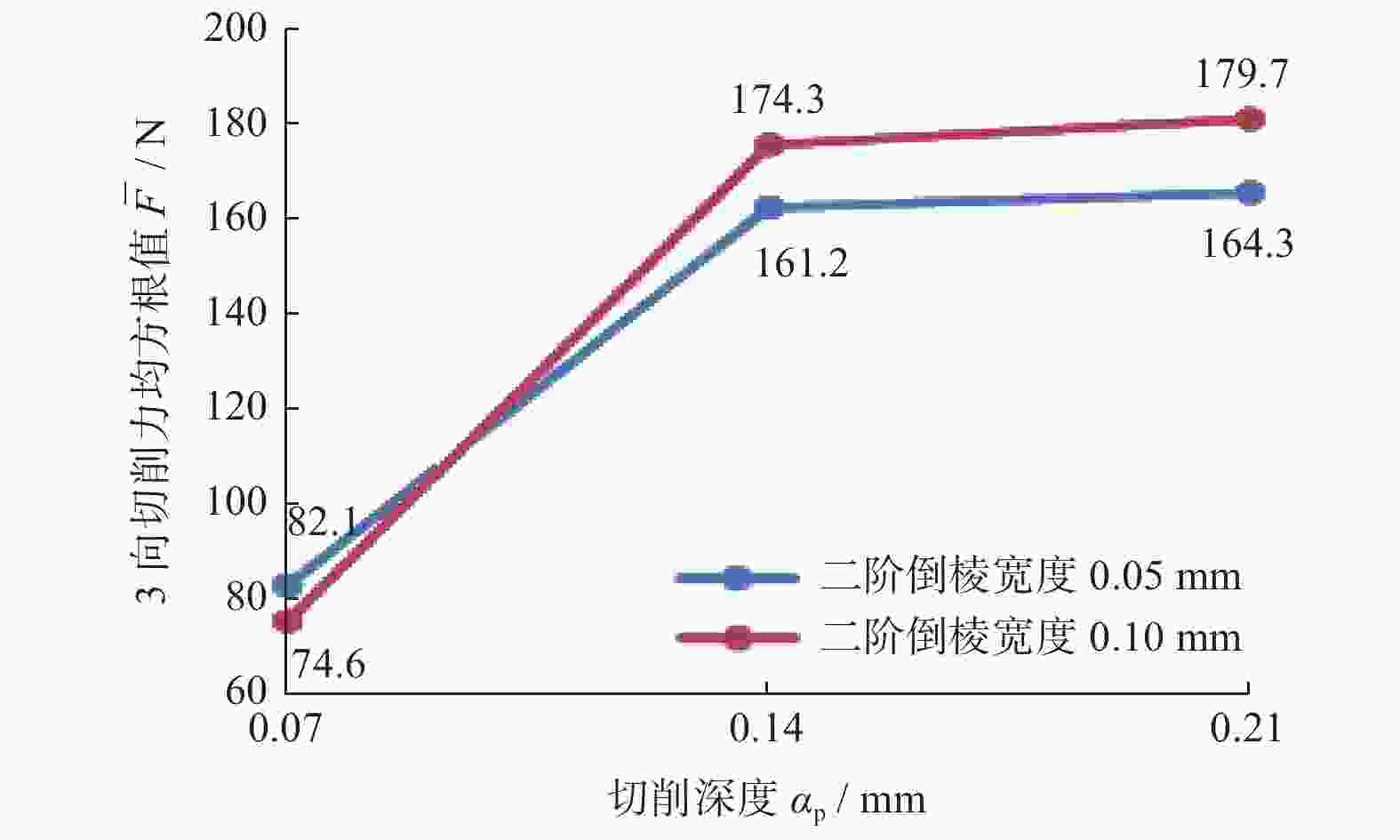

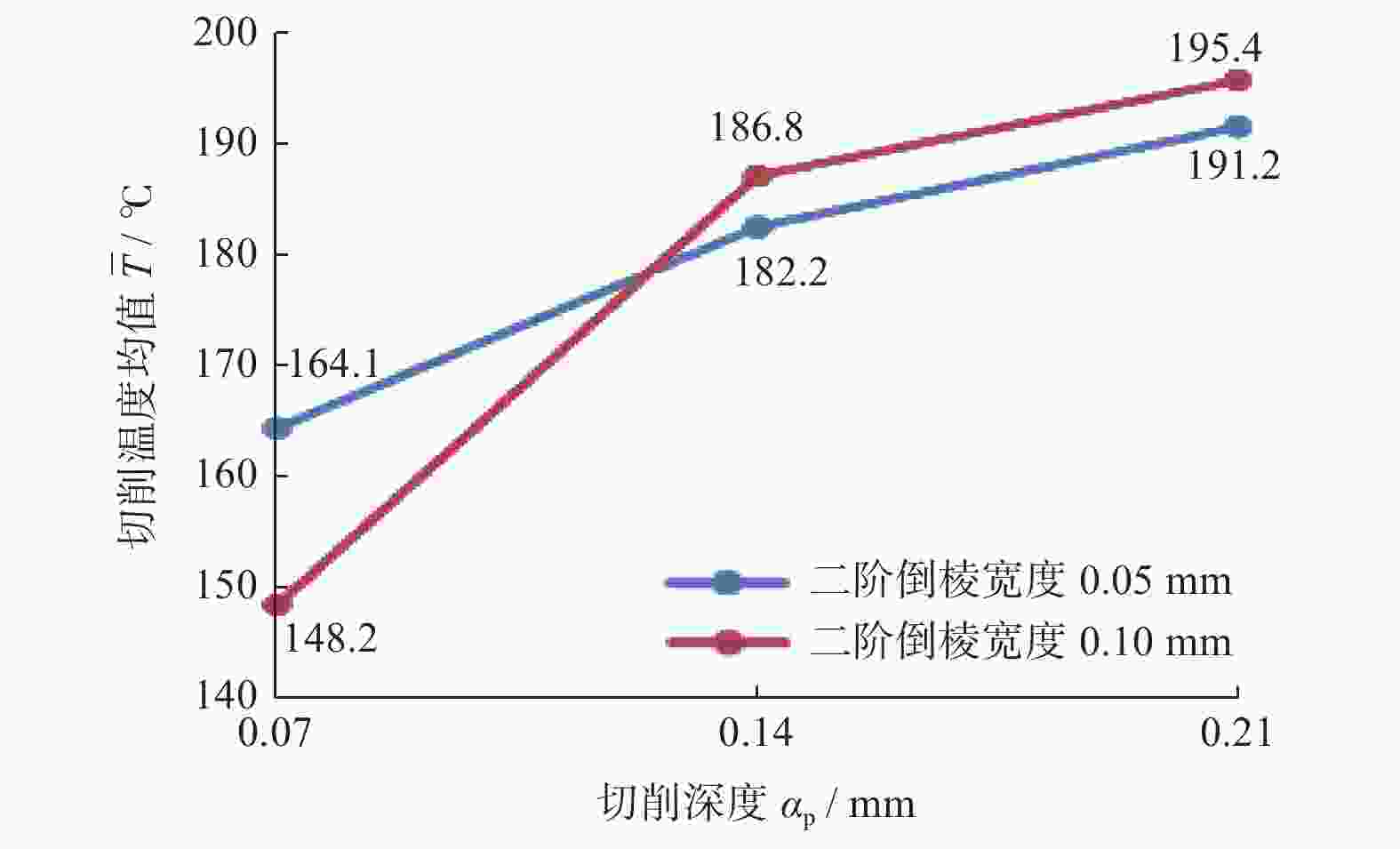

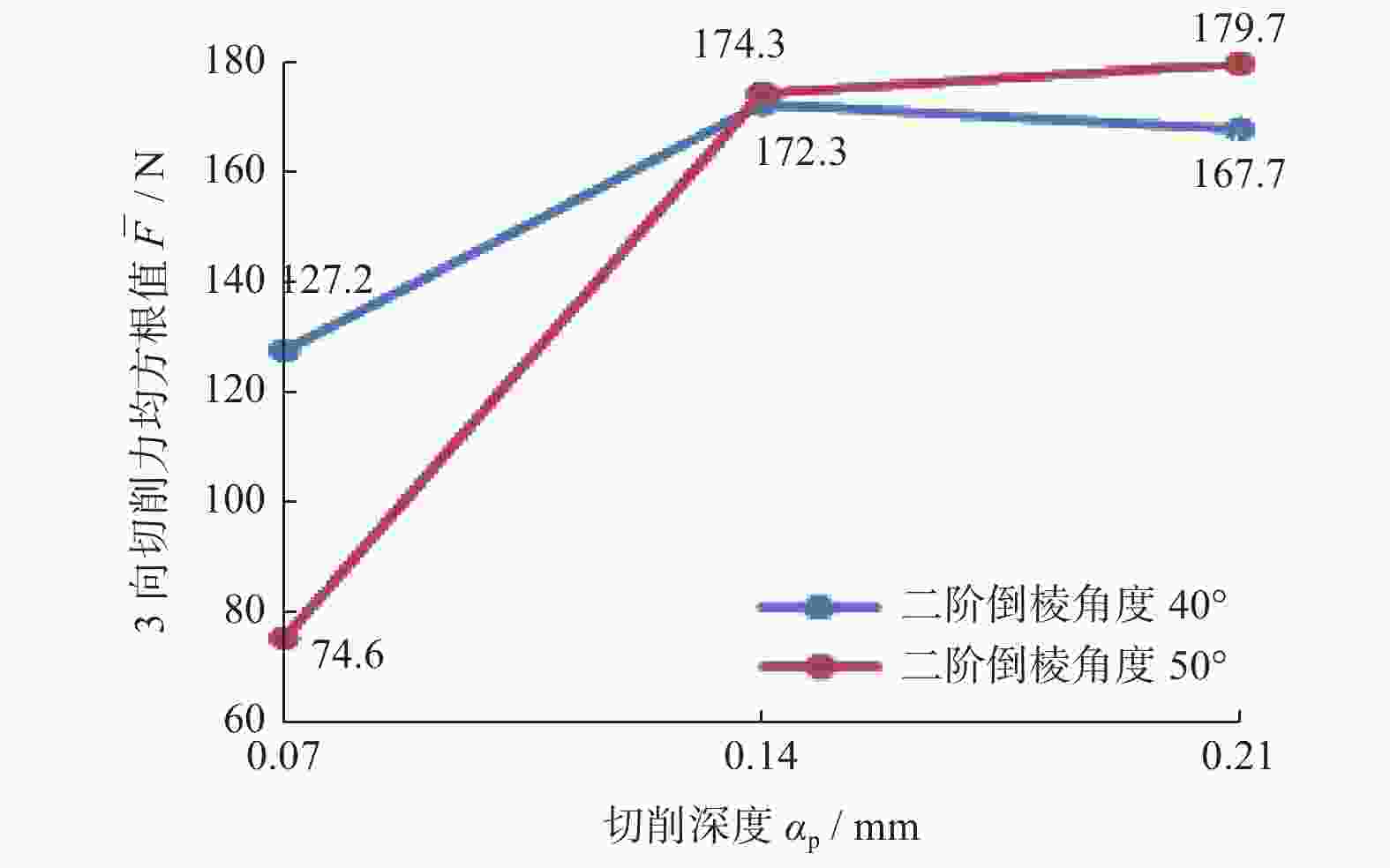

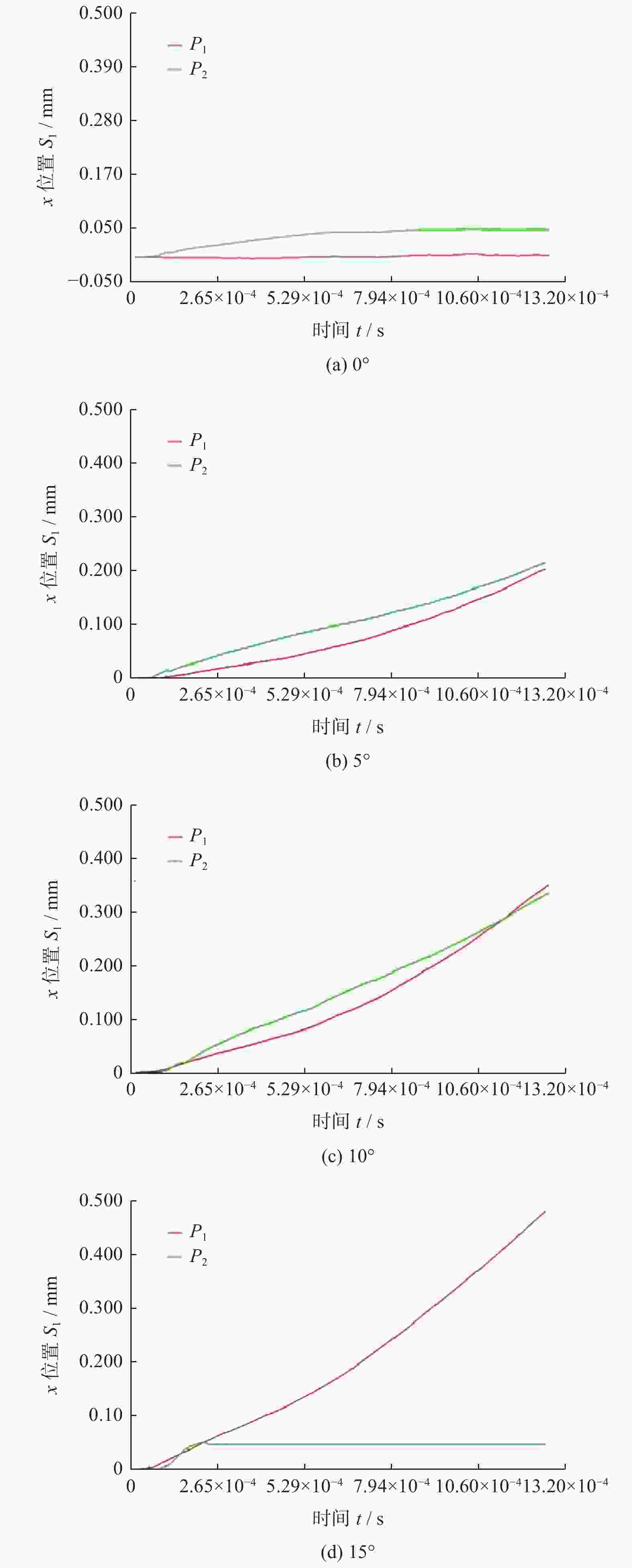

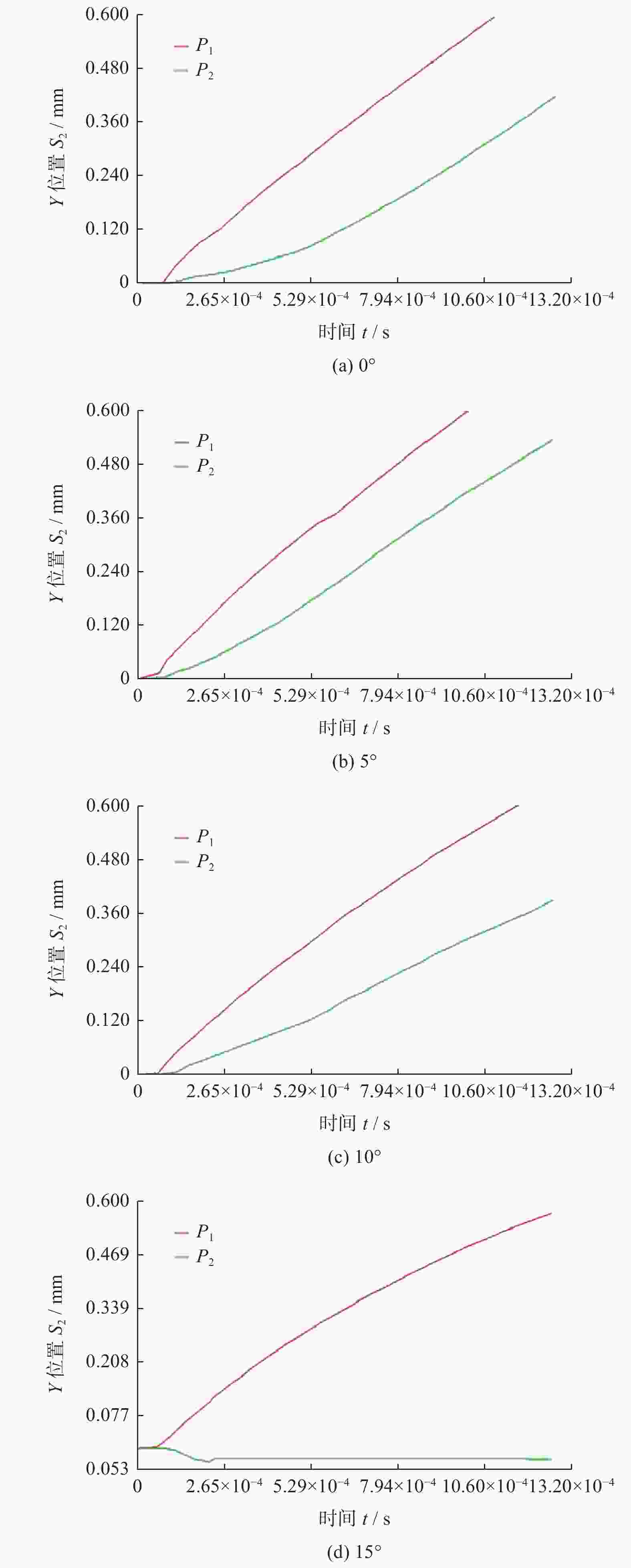

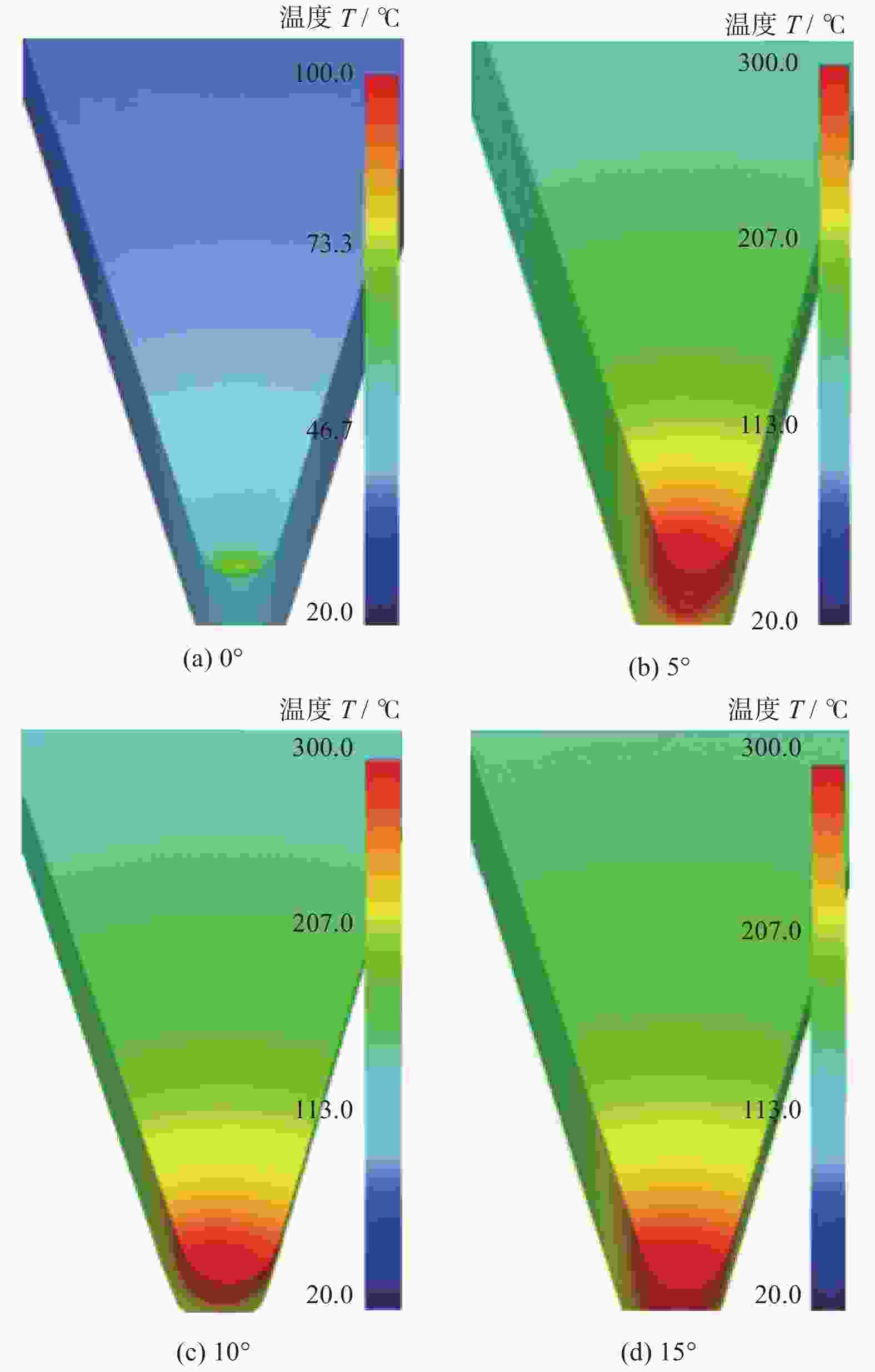

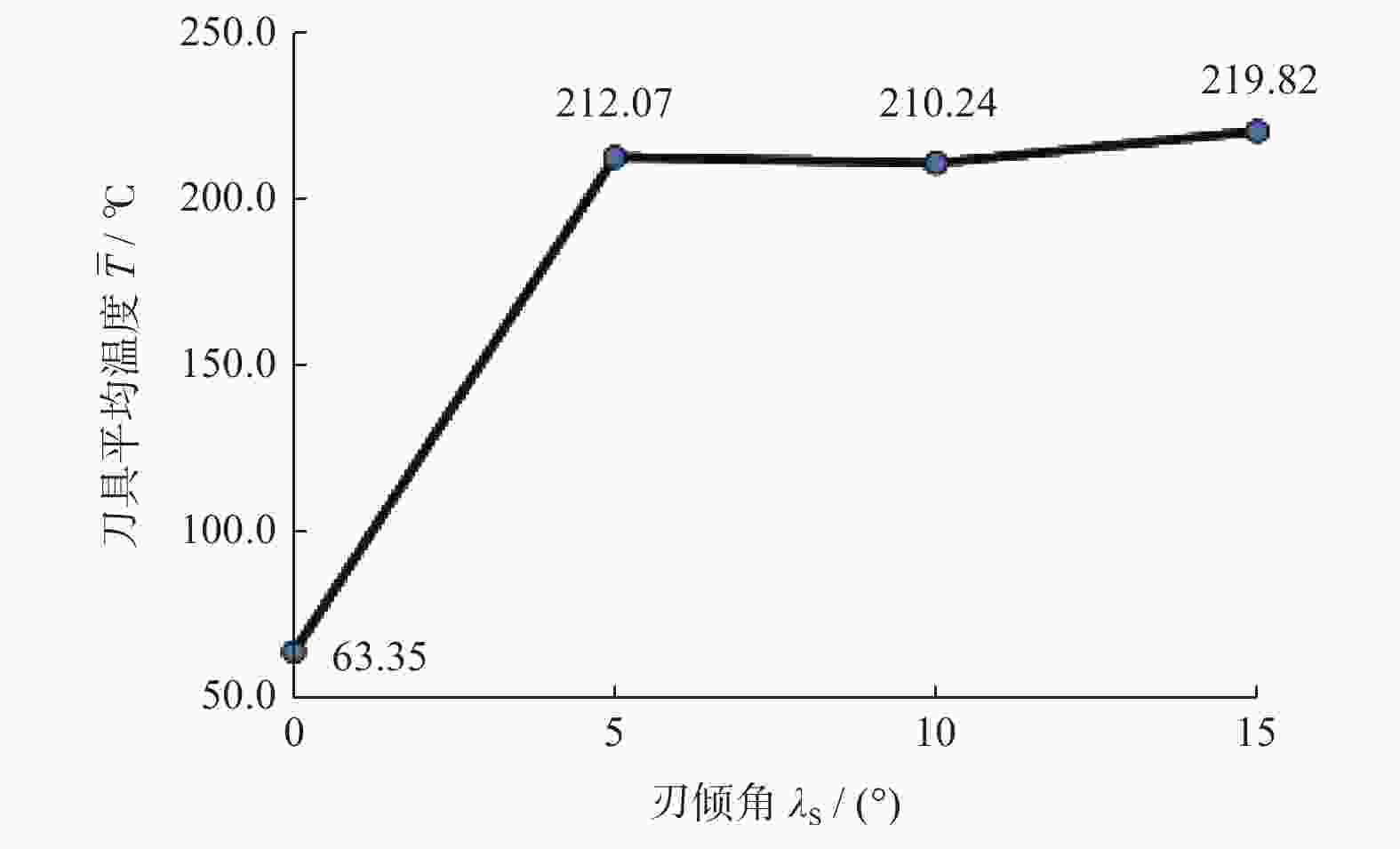

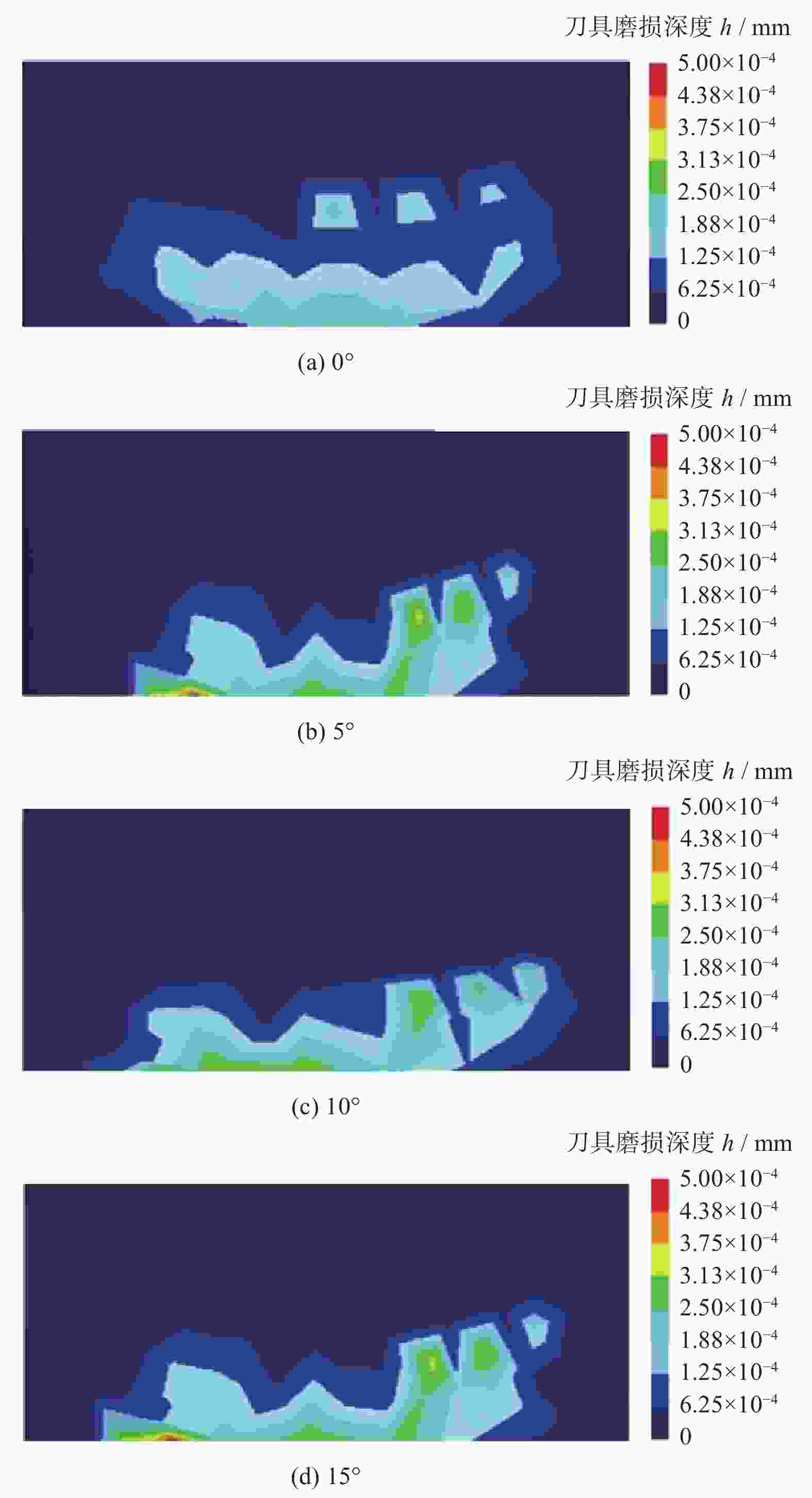

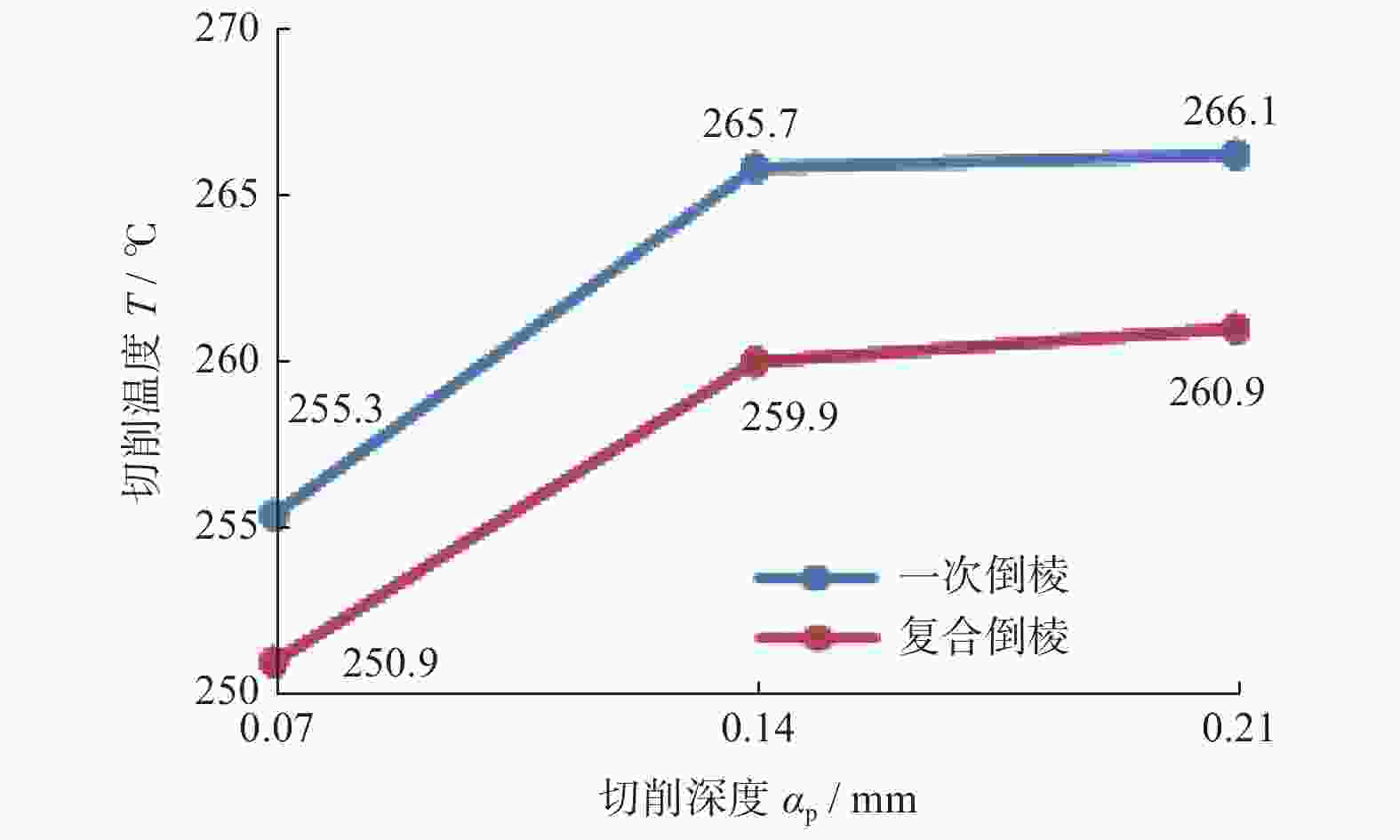

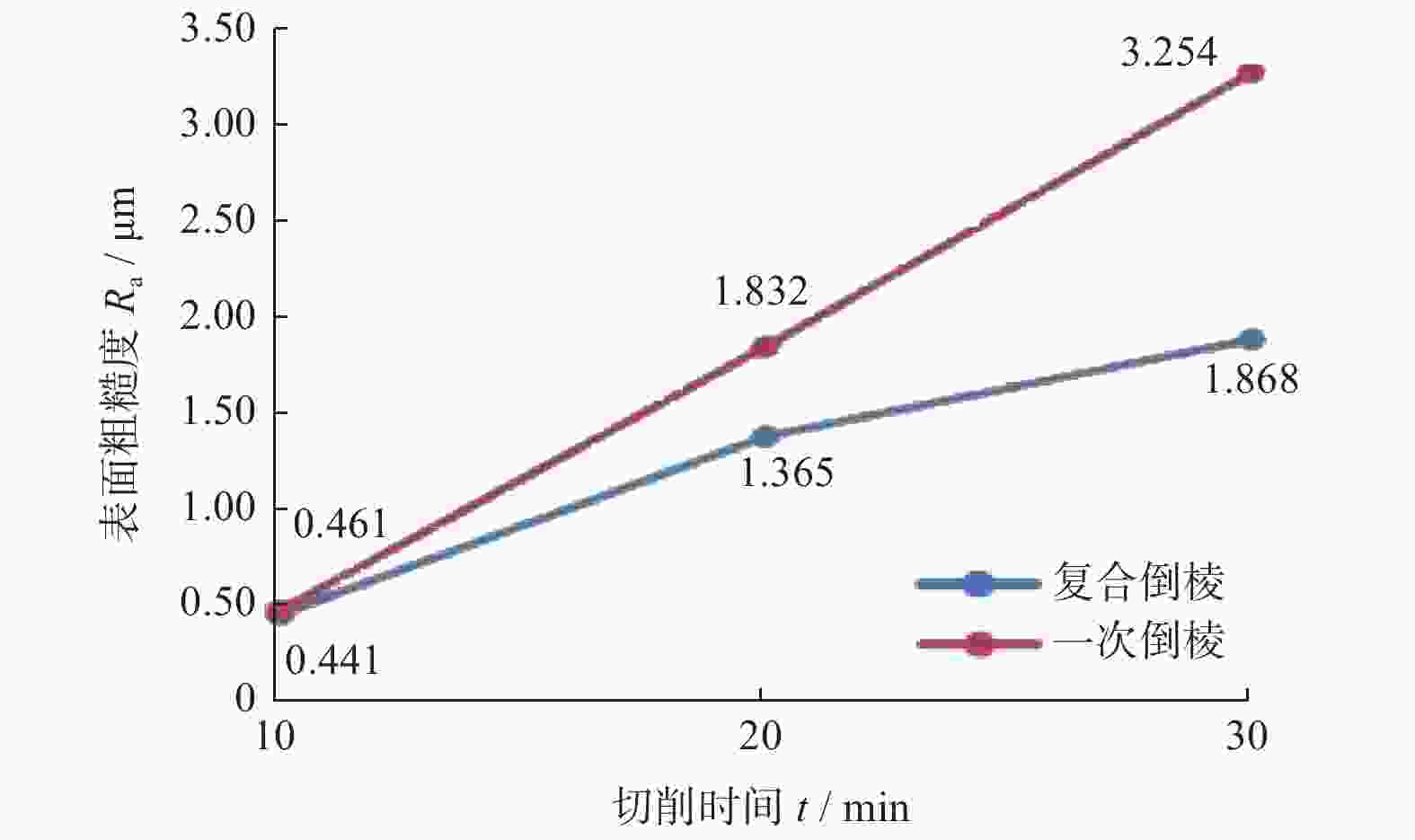

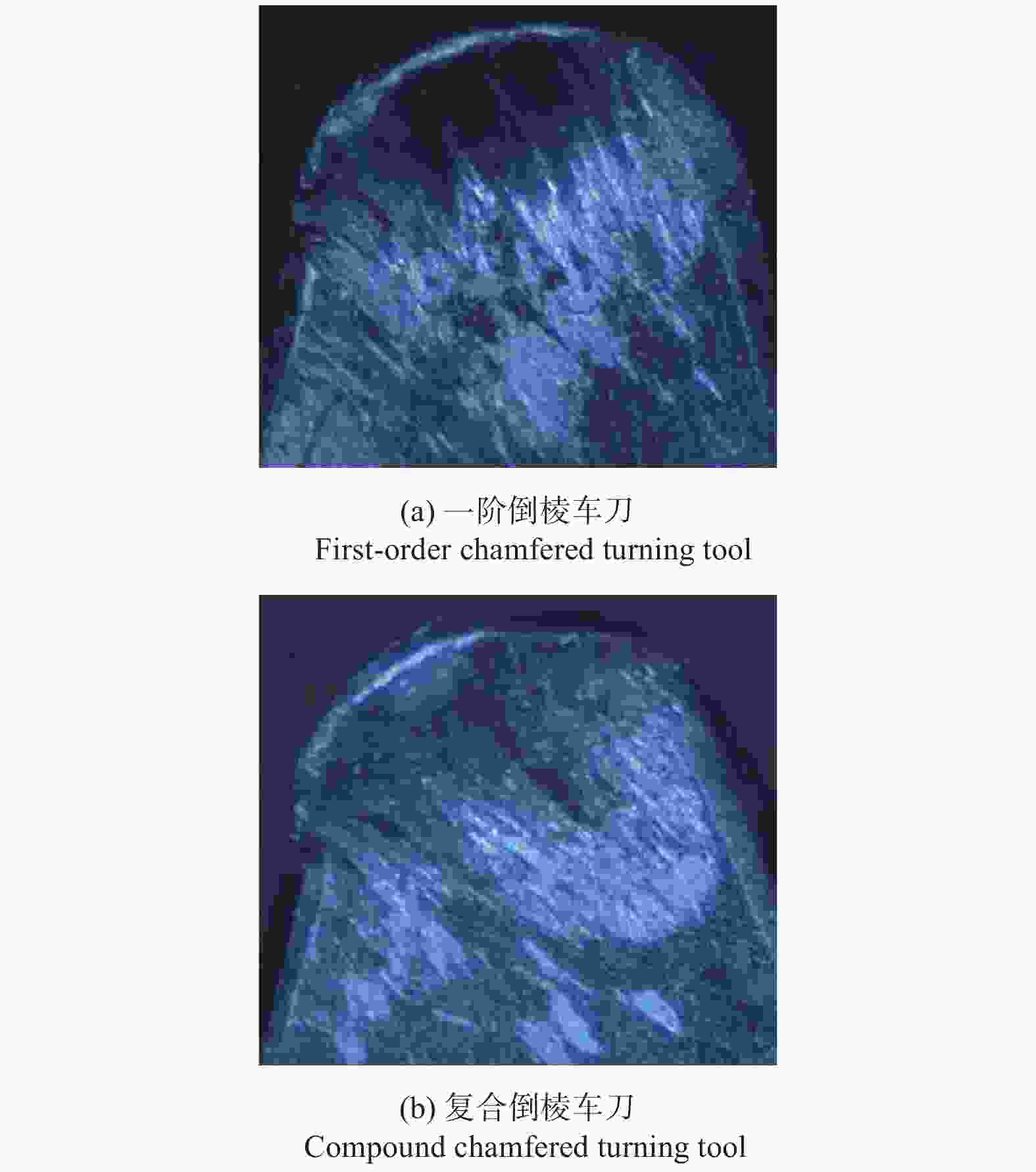

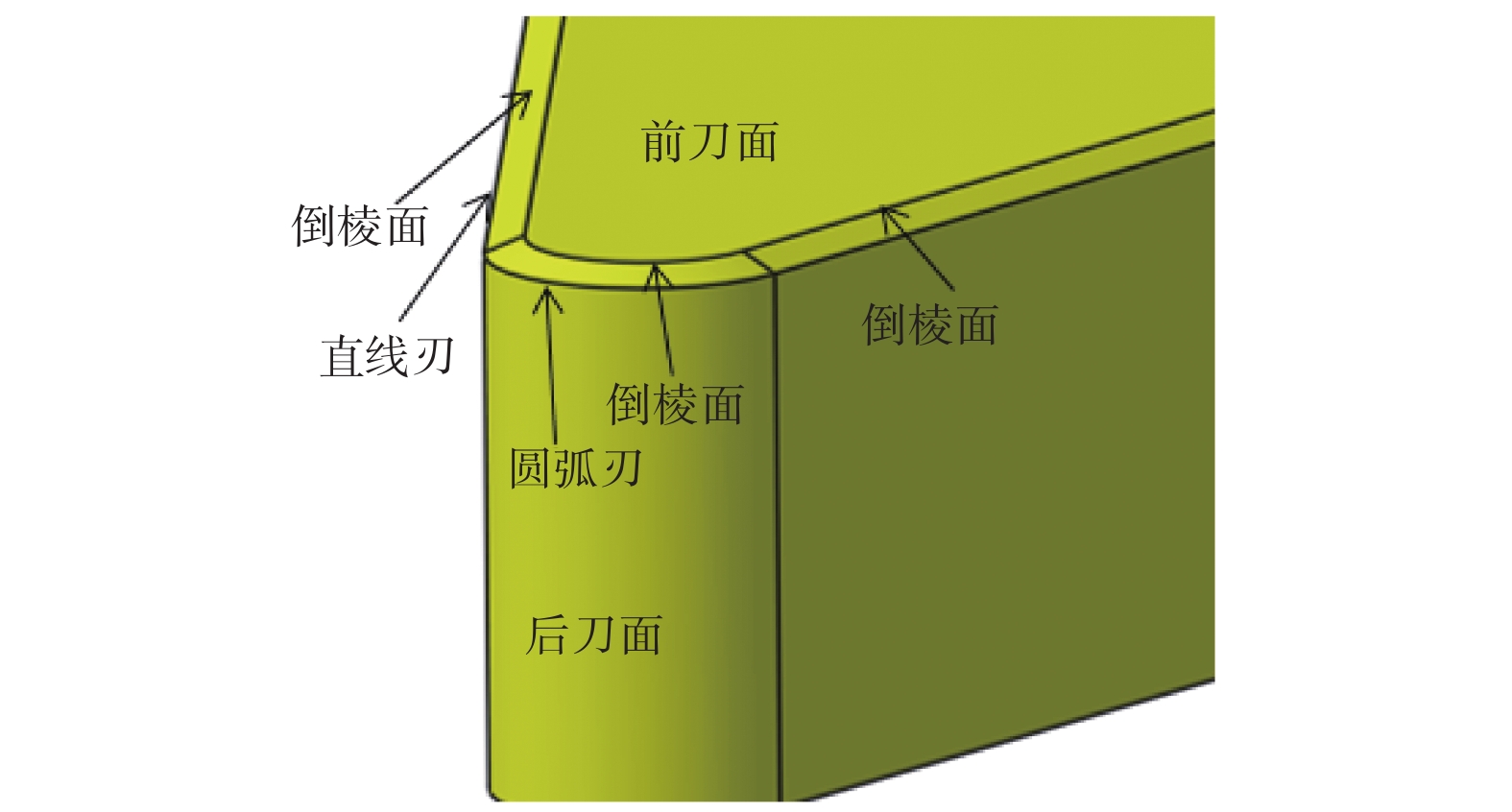

摘要: 为了改善圆弧刃倒棱聚晶金刚石(poly crystalline diamond,PCD)车刀加工有色金属的光亮程度,特在圆弧刃倒棱车刀基础上进行二次倒棱处理,使其形成复合倒棱结构。在CATIA软件中根据COBORN RG9磨床实际刃磨PCD倒棱刀具的工艺,建立圆柱形后刀面复合倒棱车刀三维模型,使用Deform V11.0软件进行PCD复合倒棱车刀的三维切削仿真分析,并根据仿真分析结果进行PCD复合倒棱车刀与PCD一阶倒棱车刀的切削实验对比。结果表明:复合倒棱结构只在较大的切削深度时才有提升工件光亮度的作用;在相同切削深度下,PCD复合倒棱车刀的切削温度小于PCD一阶倒棱车刀的;在切削深度为0.14 mm时,随着切削时间增加,PCD复合倒棱车刀加工零件的表面粗糙度要小于PCD一阶倒棱车刀的。结合PCD刀具的最终磨损状态发现,PCD复合倒棱车刀对切削后工件的捋平效果更佳,工件的光亮度更高,其抗磨损性能更好。Abstract: Objectives: Circular edge chamfering PCD turning tools often feature a chamfered surface at the cutting edge to enhance tool durability. However, the arc at the tool tip causes a large amount of chip accumulation in front of the tool, making chip discharge difficult. This leads to increased cutting temperatures, accelerated tool wear, and reduced surface brightness of the workpiece. To improve the brightness of circular edge chamfering PCD turning tools when processing non-ferrous metals and enhance the tool's durability, a composite chamfering structure is created by performing secondary chamfering on the basis of the circular edge chamfering tool. Methods: Using CATIA software and based on the actual grinding process of the PCD chamfering tool by the COBORN RG9 grinder, the grinding wheel is positioned at different points along the tool's moving path using the trajectory discrete envelope method. The unmachined tool is enveloped, and the overlap between the grinding wheel and the tool is removed, resulting in a three-dimensional approximate model of the composite chamfering tool. By extracting point coordinates, performing curve fitting, surface fitting, surface joining, and other methods, a three-dimensional model of the composite chamfering tool with a cylindrical back surface is established. Deform V11.0 software is then used to simulate the 3D cutting of the PCD composite chamfering tool, calculating the root-mean-square value of the cutting force and the mean cutting temperature under different cutting depths and second-order chamfering widths, as well as under different cutting depths and second-order chamfering angles. The analysis focuses on selecting the second-order chamfering width for different cutting depths when the first-order chamfering width is fixed, and choosing the second-order chamfering angle for different cutting depths when the second-order chamfering width is fixed. Based on this analysis, the effects of different inclination angles on the machining performance of the composite chamfering tool—such as chip flow changes, tool temperature variations, and tool wear—are analyzed. Finally, cutting experiments comparing the PCD composite chamfering tool and the PCD first-order chamfering tool are conducted to analyze changes in cutting temperature under different cutting depths, surface roughness of the workpiece over different processing times, and the final wear states of the two tools. Results: The simulation analysis results show that: (1) When the first-order chamfering width is constant and the cutting depth is smaller than the first-order chamfering width, the second-order chamfering width should be greater than the cutting depth. (2) If the cutting depth is large (even close to the first-order chamfering width), the second-order chamfering width should be smaller than the cutting depth. (3) When the cutting depth is small and does not exceed the second-order chamfering area, a larger second-order chamfering angle should be selected. (4) When the cutting depth is large, a smaller second-order chamfering angle should be selected. When cutting at an oblique angle, as the inclination angle of the tool gradually increases, interference with chip removal generally increases. The wear and tool temperature of the composite chamfered turning tool generally increase, but when the inclination angle is 10°, wear and temperature of the tool are lower, and chip removal interference is minimized. (5) When cutting at an oblique angle, as the inclination angle of the tool gradually increases, chip removal interference generally shows an increasing trend. However, at a 10° inclination angle, tool wear and temperature are lower, and chip removal interference is reduced. Specific experimental results of PCD tools show that, at the same cutting depth, the cutting temperature of the PCD composite chamfering tool is lower than that of the PCD first-order chamfering tool. Furthermore, when the cutting depth is 0.14 mm and the workpiece is turned for 30 minutes, as processing time increases, the surface roughness of the workpiece processed by the PCD composite chamfering tool remians lower than that of the PCD first-order chamfering tool. Conclusions: The composite chamfering of the PCD tool improves the brightness of the workpiece when the cutting depth is greater. The final wear state of the tool indicates that the PCD composite chamfering tool has a better smoothing effect during cutting than the PCD first-order chamfering tool, resulting in higher workpiece brightness and better wear resistance.

-

Key words:

- PCD turning tool /

- cutting depth /

- surface roughnesse /

- tool wear

-

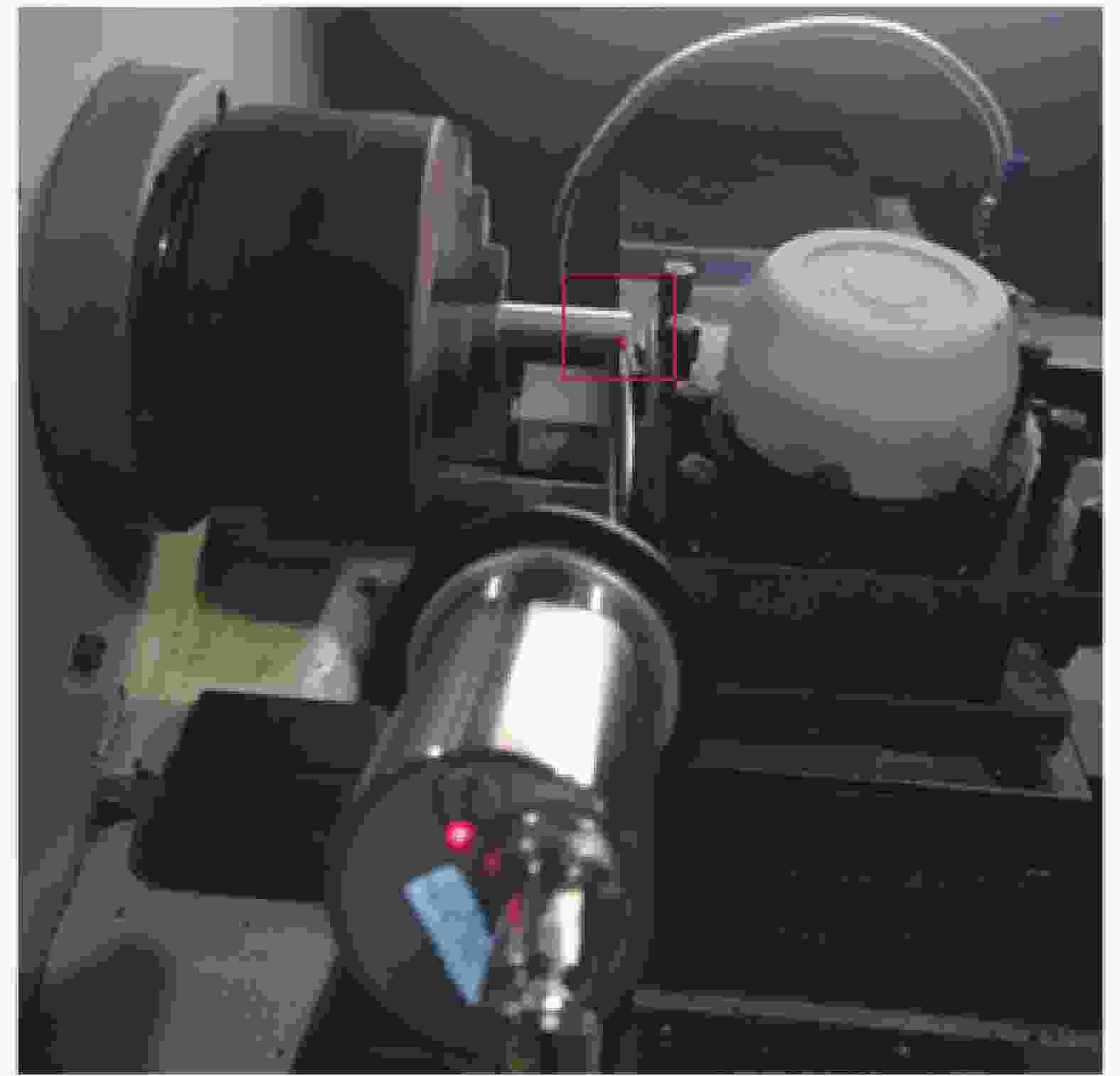

表 1 实验车床具体参数

Table 1. Specific parameters of experimental lathe

参数 规格或取值 机床最大回转直径 D / mm 320 最大工件长度 L / mm 750 主轴转速范围 n / (r·min−1) 200~ 3000 主轴电机功率 P / kW 5.5 刀方尺寸 20 mm×20 mm -

[1] 王森, 董海, 谷雨, 等. 聚晶金刚石刀具研磨质量及去除机理研究 [J]. 金刚石与磨料磨具工程,2022,42(4):467-472. doi: 10.13394/j.cnki.jgszz.2021.3002WANG Sen, DONG Hai, GU Yu, et al. Research on grinding quality and removal mechanism of polycrystalline diamond tools [J]. Diamond & Abrasives Engineering,2022,42(4):467-472. doi: 10.13394/j.cnki.jgszz.2021.3002 [2] LI G S, XIAN C, XIN H M. Study on cutting chip in milling GH4169 with indexable disc cutter [J]. Materials,2021,14(11):3135. doi: 10.3390/ma14113135 [3] KLOCKE F, KRTAZ H. Advanced tool edge geometry for high precision hard turning [J]. CIRP Annals,2005,54(1):47-50. doi: 10.1016/S0007-8506(07)60046-8 [4] 陈涛, 王道源, 李素燕, 等. 渐变倒棱PCBN刀具设计制造及磨削精度检测 [J]. 机械工程学报,2018,54(11):214-221. doi: 10.3901/JME.2018.011.214CHEN Tao, WANG Daoyuan, LI Suyan, et al. Design manufacture and grinding accuracy detection of PCBN tools with variable chamfer edge [J]. Journal of Mechanical Engineering,2018,54(11):214-221. doi: 10.3901/JME.2018.011.214 [5] 郭健. 双斜壁分屑结构余弦强化刃PCBN刀具切削性能研究 [D]. 哈尔滨: 哈尔滨理工大学, 2019.GUO Jian. Study on hard cutting performance of the cosine enhanced PCBN tool with the structure of double inclined walls [D]. Harbin: Harbin University of Science and Technology, 2019. [6] 刘思宇. 超硬车刀渐变负倒棱设计及刃磨工艺研究 [D]. 长春: 长春理工大学, 2020.LIU Siyu. Research on design of negative chamfer of superhard turning tool and grinding process [D]. Changchun: Changchun University of Science and Technology, 2020. [7] 魏子洋, 石广丰, 史国权, 等. 车刀双倒棱结构切削效应的仿真分析 [J]. 制造技术与机床,2022(3):40-43. doi: 10.19287/j.cnki.1005-2402.2022.03.006WEI Ziyang, SHI Guangfeng, SHI Guoquan, et al. Simulation analysis of cutting effect of double chamfer structure of turning tools [J]. Manufacturing Technology and Machine Tools,2022(3):40-43. doi: 10.19287/j.cnki.1005-2402.2022.03.006 [8] 计伟, 刘献礼, 李录彬, 等. 球头铣刀倒棱刃磨削砂轮轨迹建模 [J]. 哈尔滨理工大学学报,2015,20(5):34-38. doi: 10.15938/j.jhust.2015.05.007JI Wei, LIU Xianli, LI Lubin, et al. Modeling of centre trace and axis vector of grinding wheel for manufacturing of ball end mill with chamfered cutting edge [J]. Journal of Harbin University of Science and Technology,2015,20(5):34-38. doi: 10.15938/j.jhust.2015.05.007 [9] 王道源. 近余弦强化刃 PCBN 刀具设计制造技术研究 [D]. 哈尔滨: 哈尔滨理工大学, 2018.WANG Daoyuan. Research on the design and manufacture of PCBN tool with cosine enhanced edge [D]. Harbin: Harbin University of Science and Technology, 2018. [10] 高崇金, 皮云云. 倒棱切削刃对6061铝合金大应变挤出切削仿真影响研究 [J]. 工具技术,2022,56(7):92-98. doi: 10.3969/j.issn.1000-7008.2022.07.018GAO C J, PI Y Y. Research on influence of chamfering cutting edge on simulation of 6061 aluminum alloy large strain extrusion machining process [J]. Tool Engineering,2022,56(7):92-98. doi: 10.3969/j.issn.1000-7008.2022.07.018 [11] 曹永泉, 张弘弢, 董海, 等. PCBN刀具切削淬硬钢GCr15的磨损实验研究 [J]. 中国机械工程,2006(21):2305-2308. doi: 10.3321/j.issn:1004-132X.2006.21.025CAO Yongquan, ZHANG Hongtao, DONG Hai, et al. Experimental study on wear of PCBN tool cutting hardened steel GCr15 [J]. China Mechanical Engineering,2006(21):2305-2308. doi: 10.3321/j.issn:1004-132X.2006.21.025 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS