Experiments on relative angles of grinding two sides of involute pole groups

-

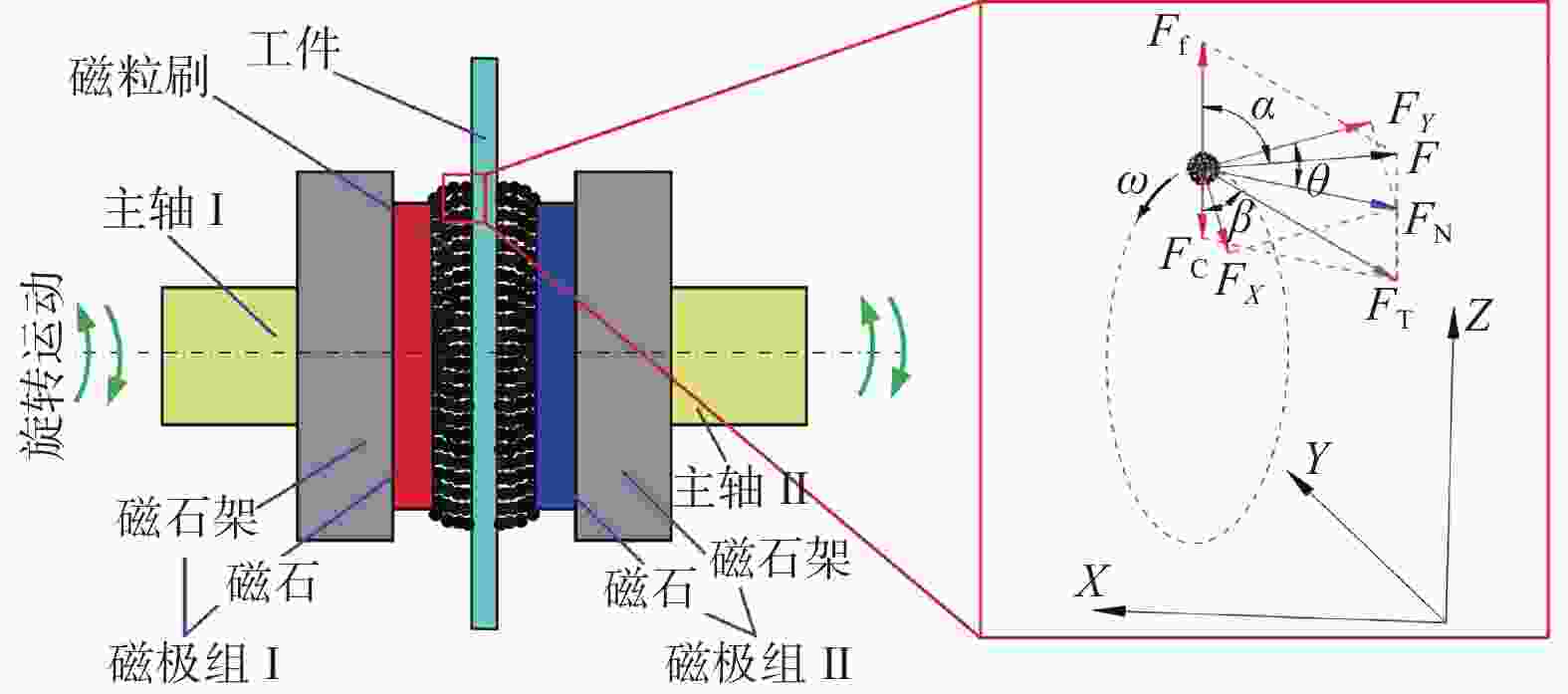

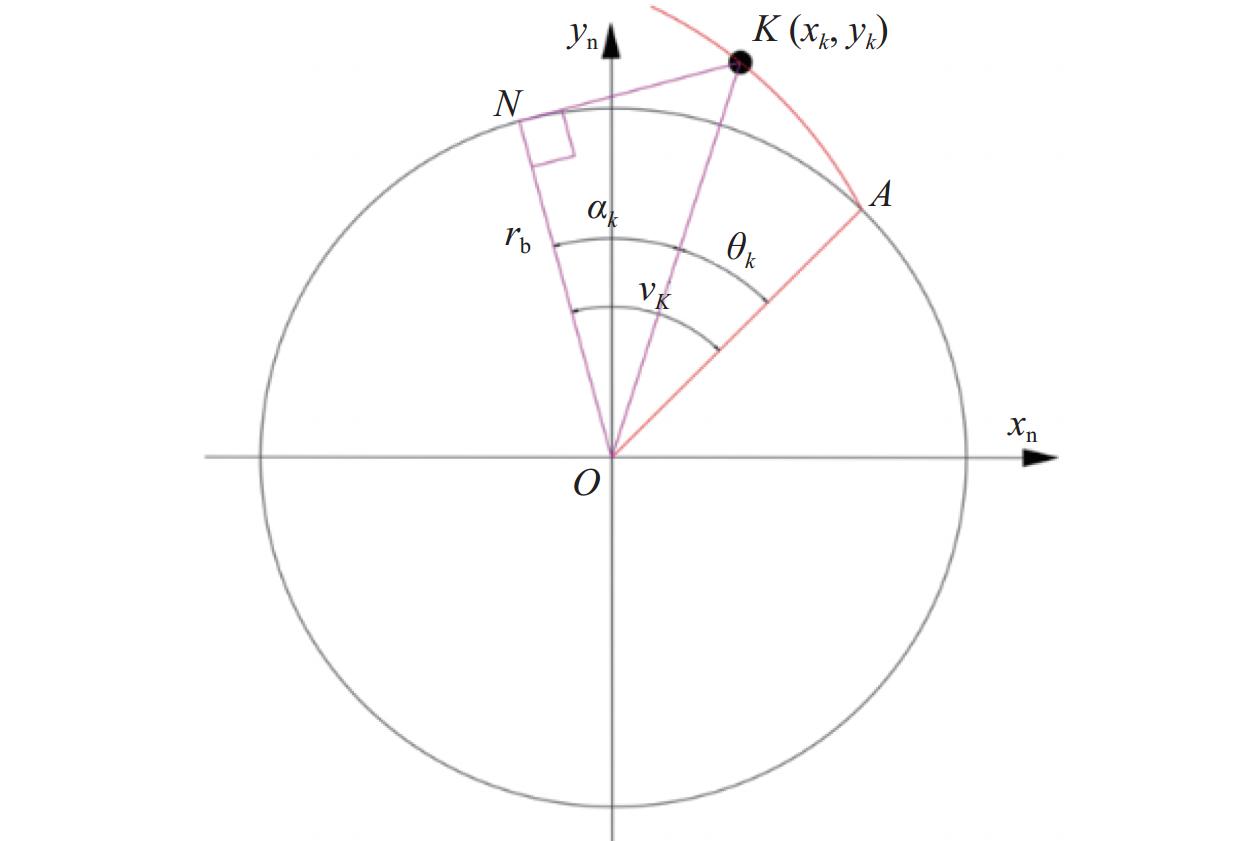

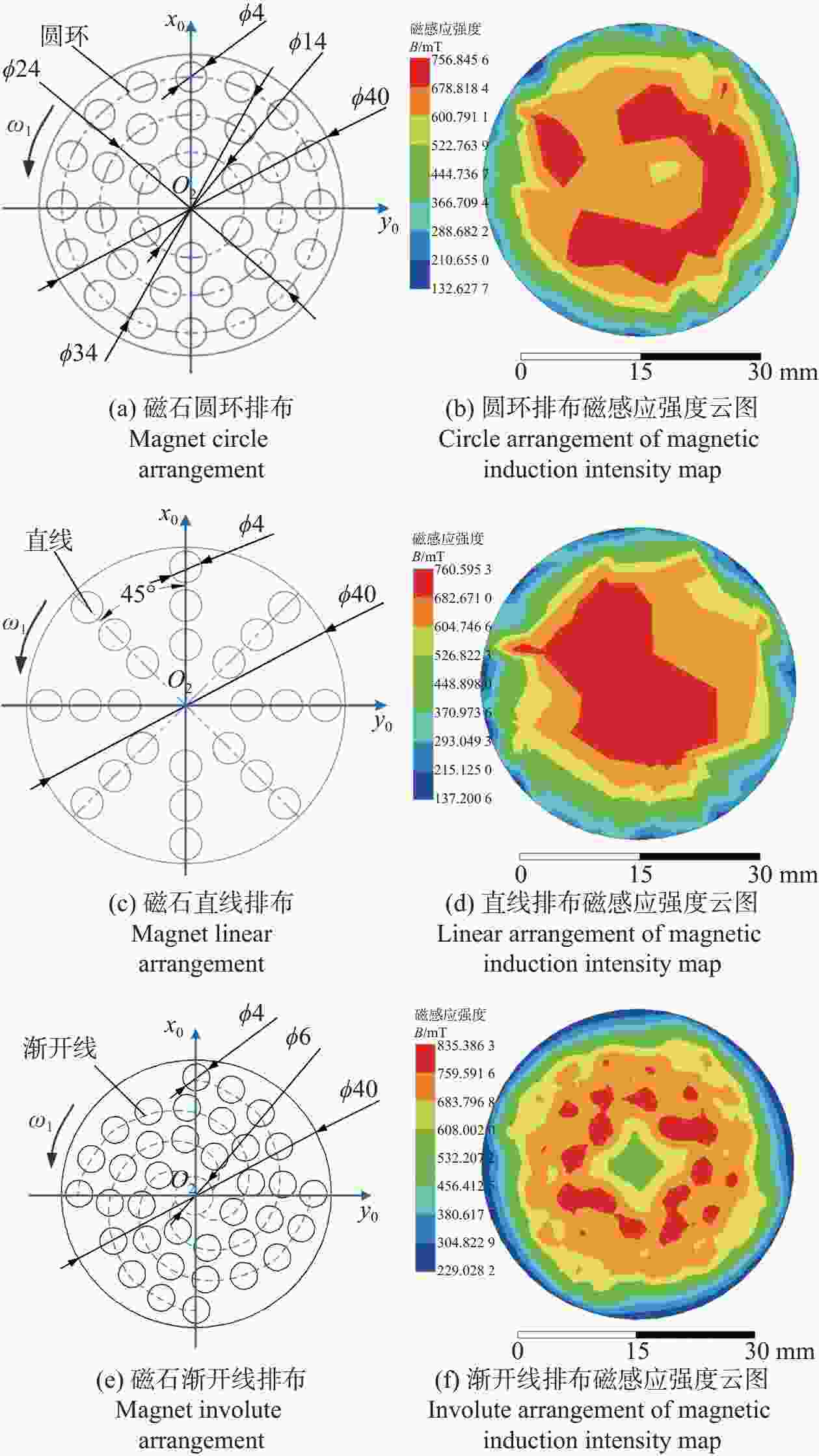

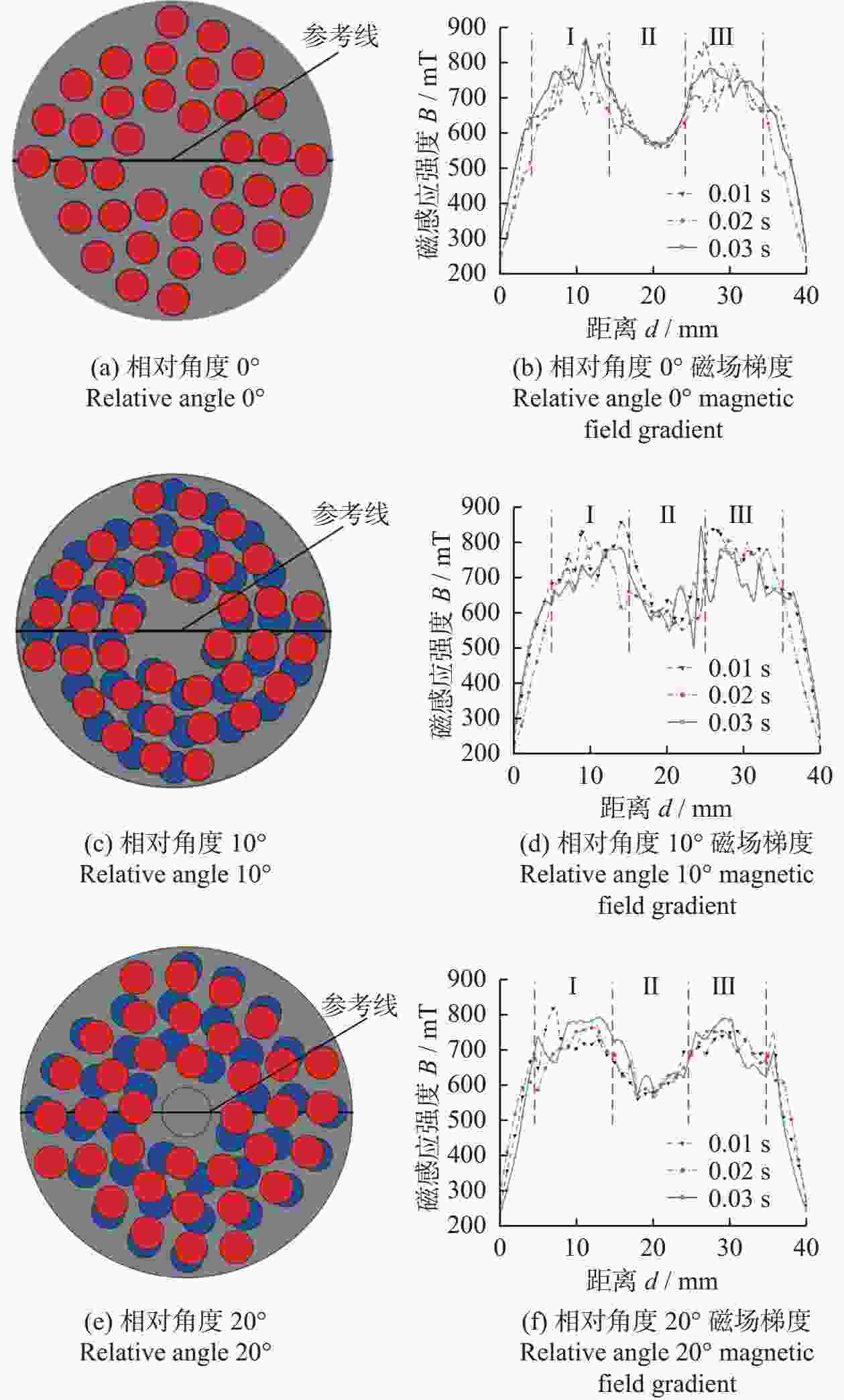

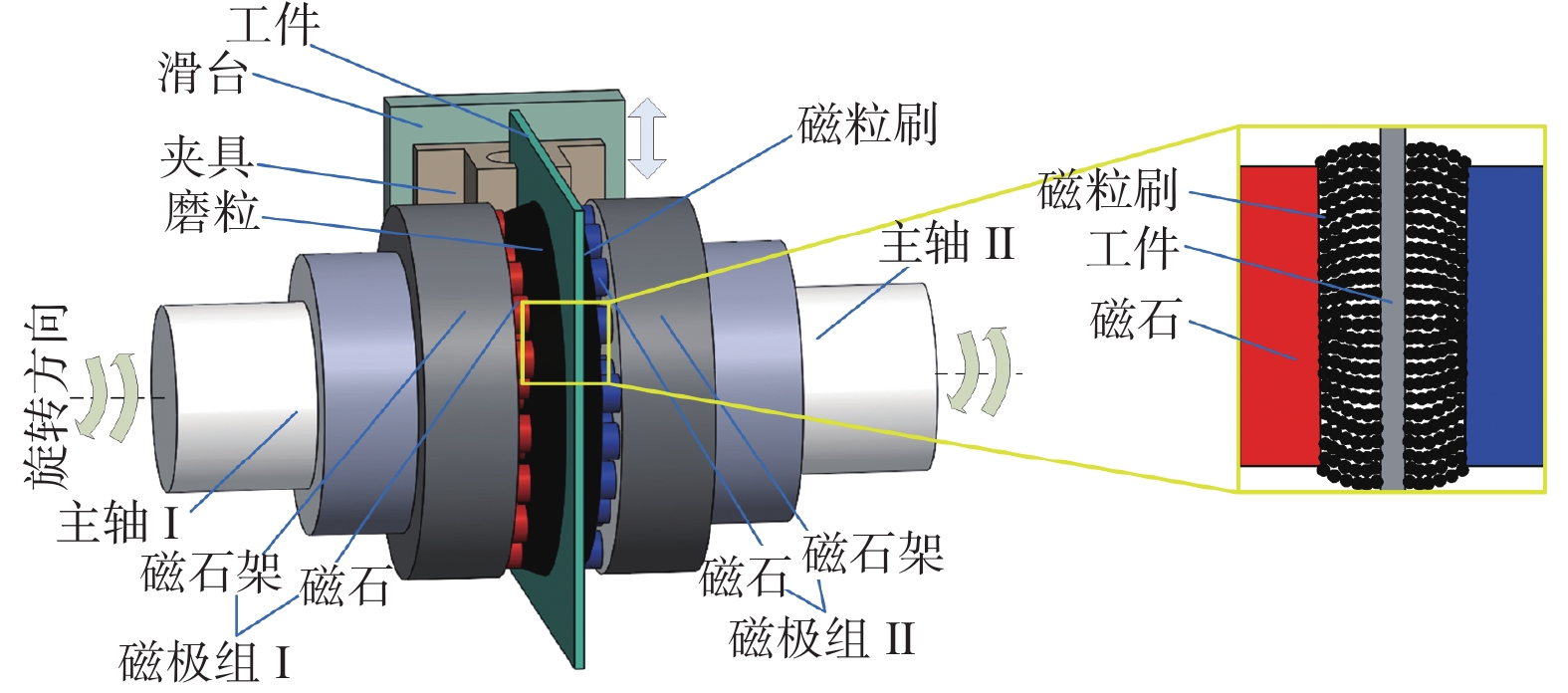

摘要: 为解决钛合金TC4表面的凸起、划痕和微裂纹等缺陷问题,提出一种对立磁极组产生相对角度的双面磁粒研磨方式,从而提高其研磨效率。在双面旋转研磨试验的基础上,对磁性磨粒进行受力分析,通过渐开线排布磁石的设计,对比该磁极下磁感应强度的变化,进而分析对立磁极组产生相对角度的磁场梯度对表面质量的影响规律,最后进行表面粗糙度变化检测,以及对研磨前后的工件表面微观形貌检测。结果表明:采用渐开线排布磁石,覆盖面积相对较大并且磁场分布均匀;相对角度$ {10}{\text{°}} $双面研磨时,磁场梯度变化较大,有利于磁性磨粒的及时翻滚。工件正面的表面粗糙度Ra由初始的0.458 μm降至0.116 μm,表面高度差由原始的43.3 μm降至7.8 μm;工件反面的表面粗糙度Ra由初始的0.434 μm降至0.111 μm,表面高度差由原始的44.2 μm降至8.4 μm。通过渐开线排布磁石产生相对角度的研磨加工,工件表面的凸起、划痕、沟壑和微裂纹等缺陷得到明显改善,工件双面同时研磨,提高了研磨效率。Abstract: Objectives : Titanium alloys are increasingly widely used in the aerospace field, and their research and development significantly influence the advancement of military aircraft, civil aviation, engines, and other high-tech equipment. However, titanium alloy are challenging to machine due to theri small deformation coefficient, low thermal conductivity, and the high temperatures generated during traditional cutting methods, which leads to tool wear. As a result, parts often have low precision, and surface quality is generally poor. This study proposes a double-sided magnetic abrasive finishing (MAF) method using opposing magnetic pole sets with adjustable relative angles to address surface defects—such as bumps, scratches, and microcracks—on the surface of titanium alloy TC4 and to improve its grinding efficiency. Methods: This study compares three types of lined magnets and introduces an involute-lined magnet design. Based on this design, opposing magnetic pole sets are used to generate an initial relative angle between them. The effects of different relative angles on double-sided MAF are tested to determine whether this method can improve the magnetic induction intensity and promote a more uniform distribution of abrasives. The results show that this approach addresses the challenges of poor abrasive fluidity and the inability of abrasives to tumble effectively. Additionally, the simultaneous grinding of both sides of the workpiece enhances processing efficiency, effectively removes the surface defects of the workpiece, and improves the grinding efficiency and surface quality. Results: The application of involute-lined magnets with a relative angle for double-sided MAF yields improved processing results under the following test conditions: magnetic pole group speed of 600 r/min, processing gap of 2 mm, magnetic abrasives size of 150 μm, and a relative angle of 10°. After 30 minutes of grinding, the surface roughness of the front side of the titanium alloy is reduced from Ra 0.458 μm to Ra 0.116 μm, and the surface height variation decreases from 43.3 μm to 7.8 μm. The reverse side also shows improvements, with surface roughness decreasing from Ra 0.434 μm to Ra 0.111 μm, and surface height variation reducing from 44.2 μm to 8.4 μm. Conclusions: The use of involute-lined magnets to create a relative angle for double-sided grinding effectively improves surface defects, such as scratches and grooves, on the workpiece. This method also significantly enhances grinding efficiency compared to single-sided grinding. The involute arrangement of magnets minimizes variations in magnetic induction intensity, which improves grinding efficiency and ensures a more uniform distribution of the magnetic field. This uniformity results in better adsorption of magnetic abrasives and enhanced grinding quality. When grinding at a relative angle of 10°, the magnetic field gradient changes significantly, covering a wider area with stronger magnetic induction. This variation in magnetic field gradient faciliates the tumbling of magnetic abrasives and the timely renewal of cutting edges, ultimately improving processing performance.

-

表 1 磁场模拟仿真参数

Table 1. Parameters of magnetic field simulation

参数名称 数值或类型 磁极组Ⅰ转速 n1 / (r·min−1) 600 磁极组Ⅱ转速 n2 / (r·min−1) 600 磁极组转向 顺时针 两侧磁极组距离 s / mm 4 初始相对角度 λ / (°) 10 表 2 磁场模拟仿真参数

Table 2. Parameters of magnetic field simulation

参数名称 数值或类型 磁极组Ⅰ转速 n1 / (r·min−1) 600 磁极组Ⅱ转速 n2 / (r·min−1) 600 磁极组转向 顺时针 两侧磁极组距离 s / mm 4 参考线长度 a / mm 40 初始相对角度 λ / (°) 0、10、20 表 3 试验条件

Table 3. Test conditions

参数名称 数值或类型 工件材料 钛合金TC4板 工件尺寸 / mm 100.0 × 100.0 × 0.8 加工间隙 l / mm 2 研磨液 劳力恩SR-9911水基式研磨液6 mL 磁性磨粒 Fe与Al2O3混合烧结磨料,粒径为150 μm 磁极组Ⅰ转速 n1 / (r·min−1) 600 磁极组Ⅱ转速 n2 / (r·min−1) 600 磁极组转向 顺时针 初始相对角度 λ / (°) 0、10、20 磨粒填充量 Q / g 30 加工时间 t / min 30 -

[1] 张应鹏, 祁宇星. 钛合金助力航空海工装备新发展: 先进钛合金结构材料分论坛侧记 [J]. 中国材料进展,2021,40(10):790-791. doi: 10.7502/j.issn.1674-3962.2021.10.zgcljz202110010ZHANG Yingpeng, QI Yuxing. Titanium alloy contributes to the new development of aviation and marine engineering equipment: Sidelights of the sub forum on advanced titanium alloy structural materials [J]. China Materials Progress,2021,40(10):790-791. doi: 10.7502/j.issn.1674-3962.2021.10.zgcljz202110010 [2] 李军, 陈祥宝. 通用航空复合材料的发展现状与挑战 [J]. 材料导报,2022,36(14):206-211. doi: 10.11896/cldb.21110268LI Jun, CHEN Xiangbao. Development status and challenges of general aviation composites [J]. Materials Bulletin,2022,36(14):206-211. doi: 10.11896/cldb.21110268 [3] YOU K Y, YAN G P, LUO X C, et al. Advances in laser assisted machining of hard and brittle materials [J]. Journal of Manufacturing Processes,2020,58:677-692. doi: 10.1016/j.jmapro.2020.08.034 [4] LIU L P, LIN B, FANG F Z. Monitoring of tool wear in rotary ultrasonic machining of advanced ceramics [J]. Advanced Materials Research,2011( 314/315/316):1754-1759. doi: 10.4028/www.scientific.net/AMR.314-316.1754 [5] 邢绍美. 毛刺发生机理与形态及去除方法的探讨 [J]. 航天返回与遥感,2000(2):40-45,49.XING Shaomei. Discussion on burr generation mechanism, morphology and removal method [J]. Aerospace Return and Remote Sensing,2000(2):40-45,49. [6] 冯薇. 精密与超精密磨削的发展现状 [J]. 精密制造与自动化,2009(2):8-9. doi: 10.3969/j.issn.1009-962X.2009.02.002FENG Wei. Current development of precision and ultra-precision grinding [J]. Precise Manufacturing & Automation,2009(2):8-9. doi: 10.3969/j.issn.1009-962X.2009.02.002 [7] 张占立, 熊明照, 王恒迪, 等. 氮化硅陶瓷滚子磁流变、化学与超声复合抛光工艺试验 [J]. 轴承,2016(2):14-19. doi: 10.3969/j.issn.1000-3762.2016.02.006ZHANG Zhanli, XIONG Mingzhao, WANG Hengdi, et al. Polishing processing test for silicon nitride ceramic rollers based on magnetorheological and chemo-ultrasonic compound technology [J]. Bearing,2016(2):14-19. doi: 10.3969/j.issn.1000-3762.2016.02.006 [8] 高永超, 程好, 杨淑平, 等. 金属基带的连续非接触式电化学抛光 [J]. 表面技术,2014,43(2):105-108. doi: 10.16490/j.cnki.issn.1001-3660.2014.02.020GAO Yongchao, CHENG Hao, YANG Shuping, et al. Non-contact and continuous electrochemical polishing of the metal strip [J]. Surface Technology,2014,43(2):105-108. doi: 10.16490/j.cnki.issn.1001-3660.2014.02.020 [9] NGUYEN N T, TRAN T N, YIN S H, et al. Multi-objective optimization of improved magnetic abrasive finishing of multi-curved surfaces made of SUS202 material [J]. International Journal of Advanced Manufacturing Technology,2017,88:381-391. doi: 10.1007/s00170-016-8773-3 [10] 张坤领. 硬脆材料加工技术发展现状 [J]. 组合机床与自动化加工技术,2008(5):1-6,15. doi: 10.3969/j.issn.1001-2265.2008.05.001ZHANG Kunling. Overview the machining technology for hard and brittle materials [J]. Modular Machine Tool and Automatic Processing Technology,2008(5):1-6,15. doi: 10.3969/j.issn.1001-2265.2008.05.001 [11] XUE B, GENG Y Q, WANG D, et al. Improvement in surface quality of microchannel structures fabricated by revolving tip-based machining [J]. Nanomanufacturing and Metrology,2019,2(1):26-35. doi: 10.1007/s41871-018-0032-9 [12] 刘文浩, 陈燕, 李文龙, 等. 磁粒研磨加工技术的研究进展 [J]. 表面技术,2021,50(1):47-61. doi: 10.16490/j.cnki.issn.1001-3660.2021.01.004LIU Wenhao, CHEN Yan, LI Wenlong, et al. Research progress of magnetic abrasive finishing technology [J]. Surface Technology,2021,50(1):47-61. doi: 10.16490/j.cnki.issn.1001-3660.2021.01.004 [13] 刘宁, 赵玉刚, 高跃武, 等. CBN磁性磨料磁力研磨TC4钛合金工艺参 数优化 [J]. 组合机床与自动化加工技术,2020(3):131-135. doi: 10.13462/j.cnki.mmtamt.2020.03.031LIU Ning, ZHAO Yugang, GAO Yuewu, et al. Optimization of process parameters for magnetic abrasive finishing TC4 titanium alloy by CBN magnetic abrasive [J]. Modular Machine Tool & Automatic Manufacturing Technique,2020(3):131-135. doi: 10.13462/j.cnki.mmtamt.2020.03.031 [14] TIAN Y B, ANG Y J, ZHONG Z W. Chemical mechanical polishing of glass disk substrates: Preliminary experimental investigation [J]. Materials and Manufacturing Processes,2013,28(4/5/6):488-494. doi: 10.1080/10426914.2011.654161 [15] 朱子俊, 韩冰, 李奎, 等. 超声辅助磁粒研磨TC4平面的光整试验研究 [J]. 电镀与精饰,2020,42(10):6-11. doi: 10.3969/j.issn.1001⁃3849.2020.10.002ZHU Zijun, HAN Bing, LI Kui, et al. Experimental study on ultrasonic-assisted magnetic particle grinding of TC4 plane [J]. Plating and Finishing,2020,42(10):6-11. doi: 10.3969/j.issn.1001⁃3849.2020.10.002 [16] LIU Z B, LI J, NIE M, et al. Modeling and simulation of workpiece surface flatness in magnetorheological plane finishing processes [J]. The International Journal of Advanced Manufacturing Technology,2020,111:2637-2651. doi: 10.1007/s00170-020-06267-w [17] 潘明诗, 陈燕, 张东阳. 仿形磁极头对电磁研磨管件内表面形成的影响 [J]. 中国表面工程,2022,35(6):274-285. doi: 10.11933/j.issn.1007-9289.20220119001PAN Mingshi, CHEN Yan, ZHANG Dongyang. Effect of profiling magnetic pole head on the inner surface of electromagnetic finishing pipe fittings [J]. China Surface Engineering,2022,35(6):274-285. doi: 10.11933/j.issn.1007-9289.20220119001 [18] 张旭. 烧结磁性磨料制备过程分析及工艺优化[D]. 鞍山: 辽宁科技大学, 2014.ZHANG Xu. Mechanism study and process control of sintering magnetic abrasive [D]. Anshan: University of Science and Technology Liaoning, 2014. [19] 姚新改, 轧刚, 丁艳红. 旋转磁场磁力光整内表面研磨机理研究[C]//中国机械工程学会特种加工分会. 2007年中国机械工程学会年会之第12届全国特种加工学术会议论文集. 《机械工程学报》编辑部, 2007: 377-380.YAO Xingai, YA Gang, DING Yanhong. Research on the mechanism of rotating magnetic field magnetic brightening inner surface grinding [C]//Chinese Society of Mechanical Engineering, Special Processing Branch. 2007 Proceedings of the 12th National Special Processing Academic Conference of Chinese Society of Mechanical Engineering Annual Meeting. Journal of Mechanical Engineering, 2007: 377-380. [20] 杨子彧, 焦安源, 丁浩东, 等. 渐开线槽磁极改进磁粒研磨毛刺效果的试验研究 [J]. 表面技术,2023,52(4):329-337. doi: 10.16490/j.cnki.issn.1001-3660.2023.04.029YANG Ziyu, JIAO Anyuan, DING Haodong, et al. Experimental study on improving grinding burrs effect by magnetic abrasive finishing using magnetic pole with involute grooves [J]. Surface Technology,2023,52(4):329-337. doi: 10.16490/j.cnki.issn.1001-3660.2023.04.029 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS