Mechanical properties and rock-breaking effects of ridge-shaped PDC teeth

-

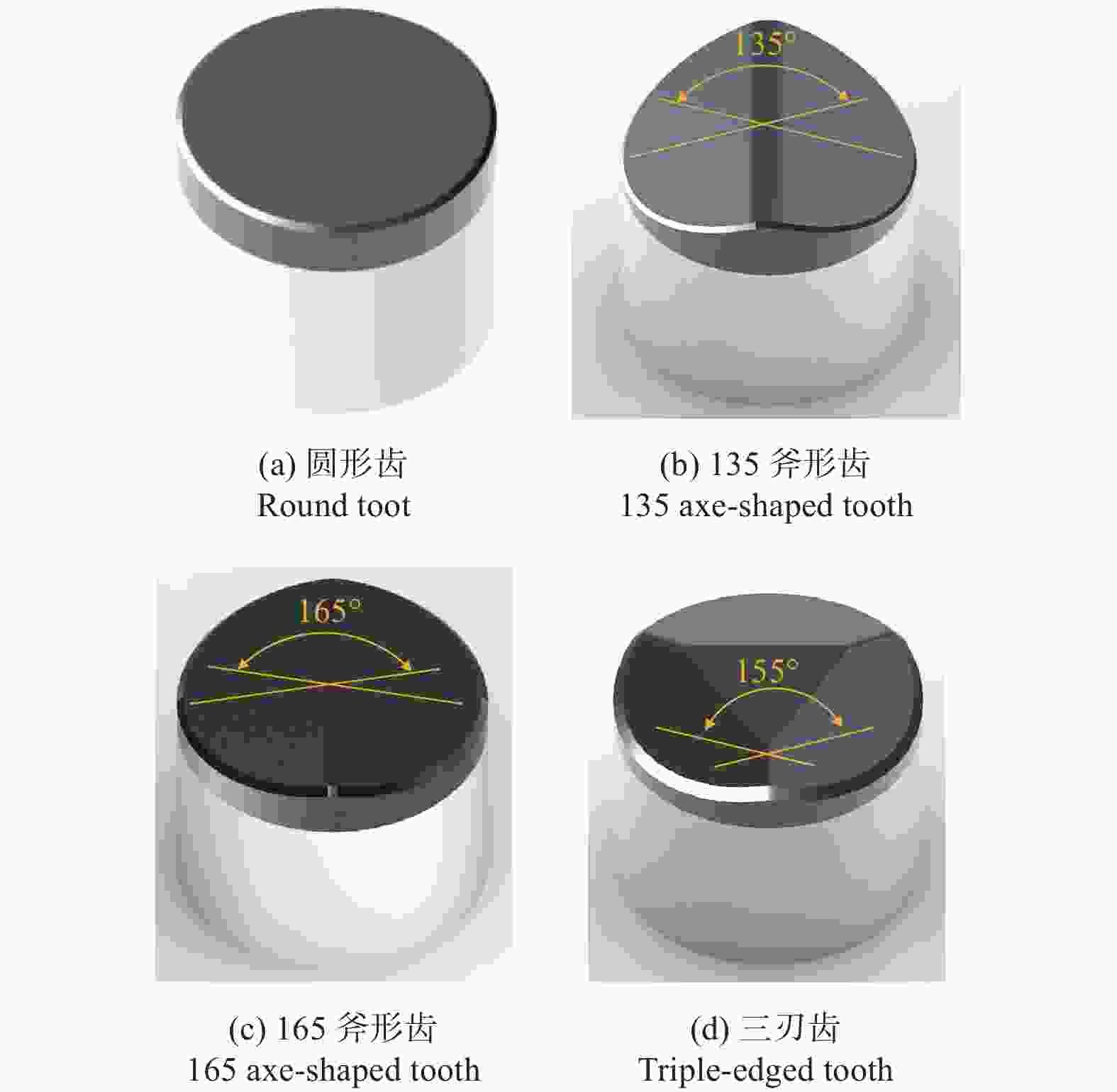

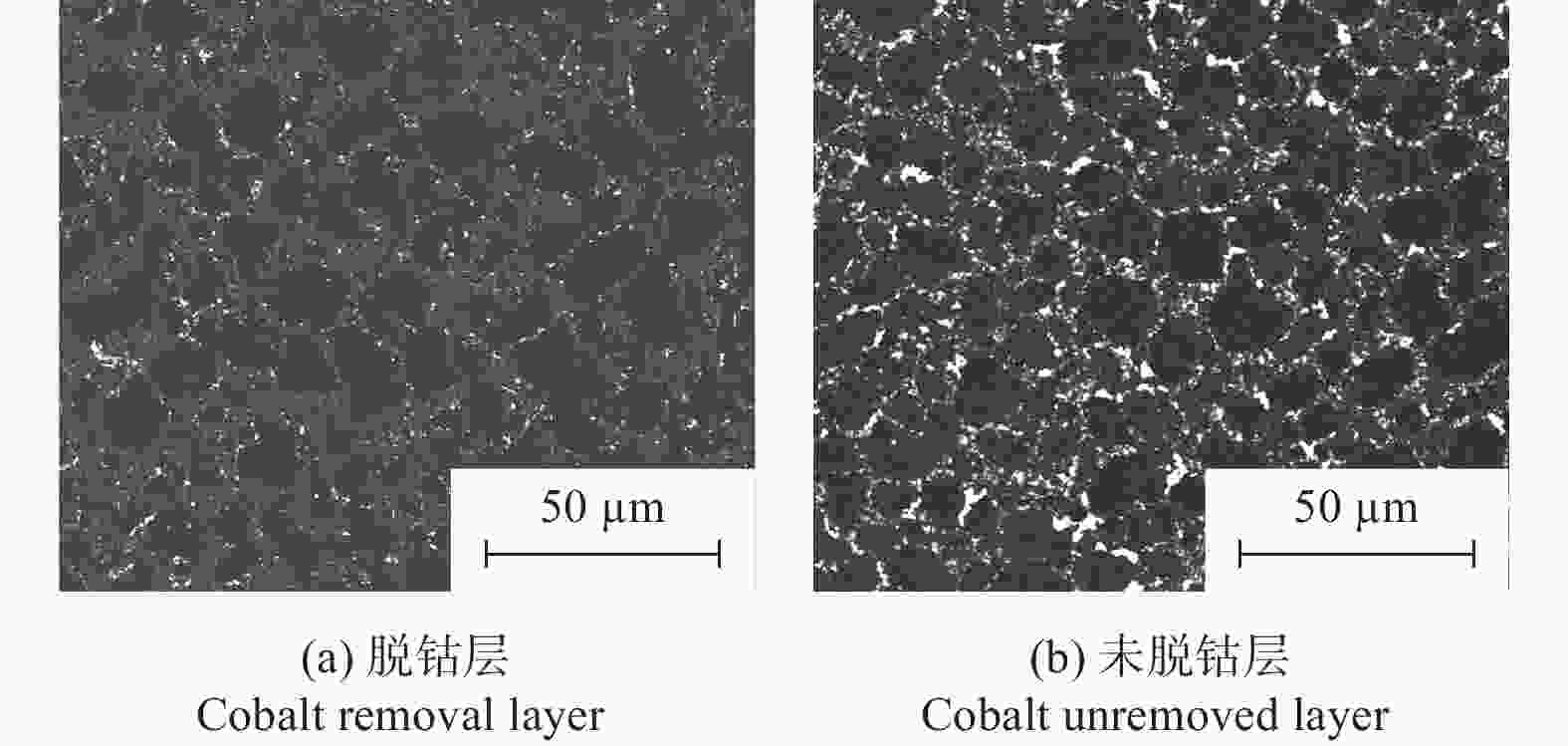

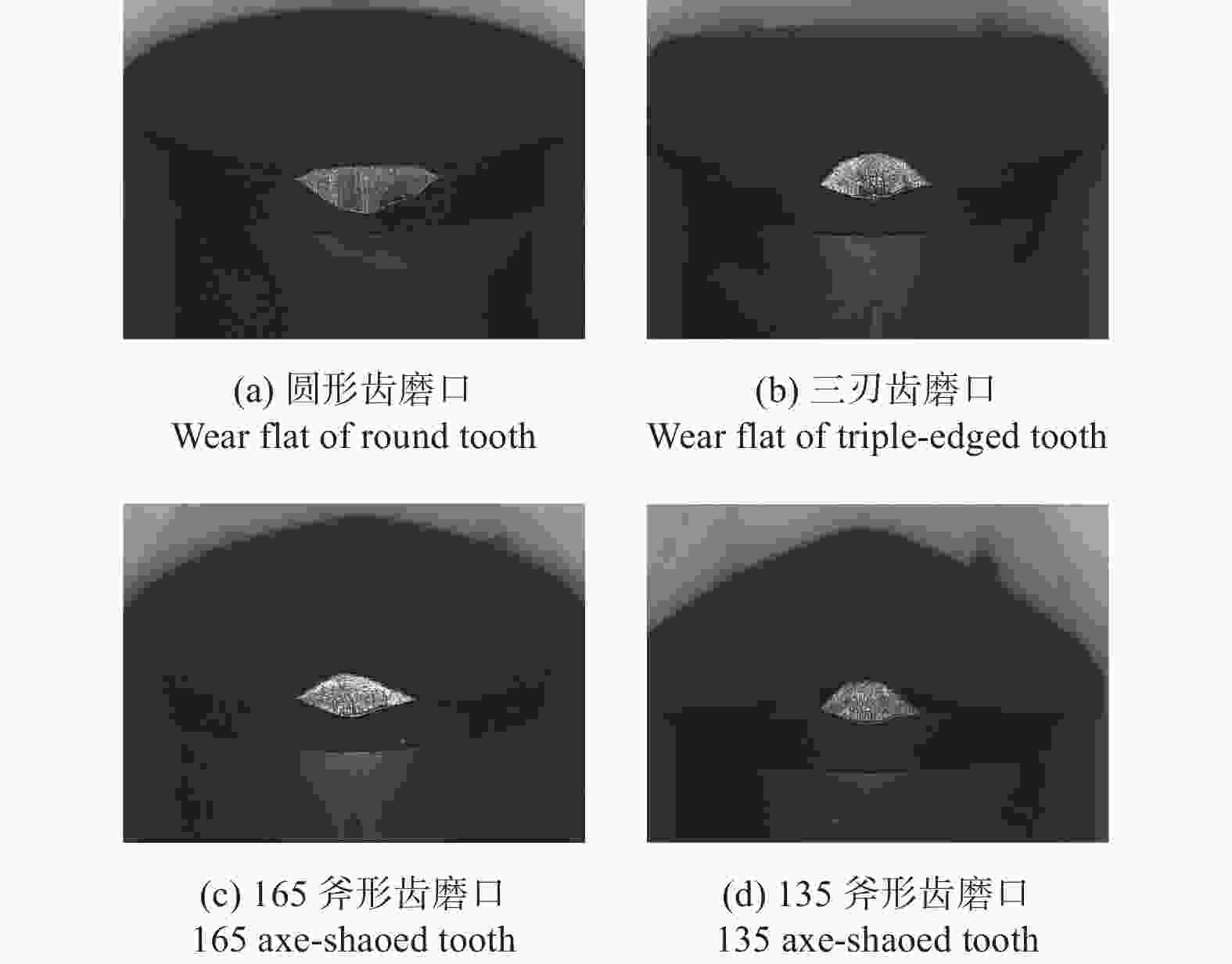

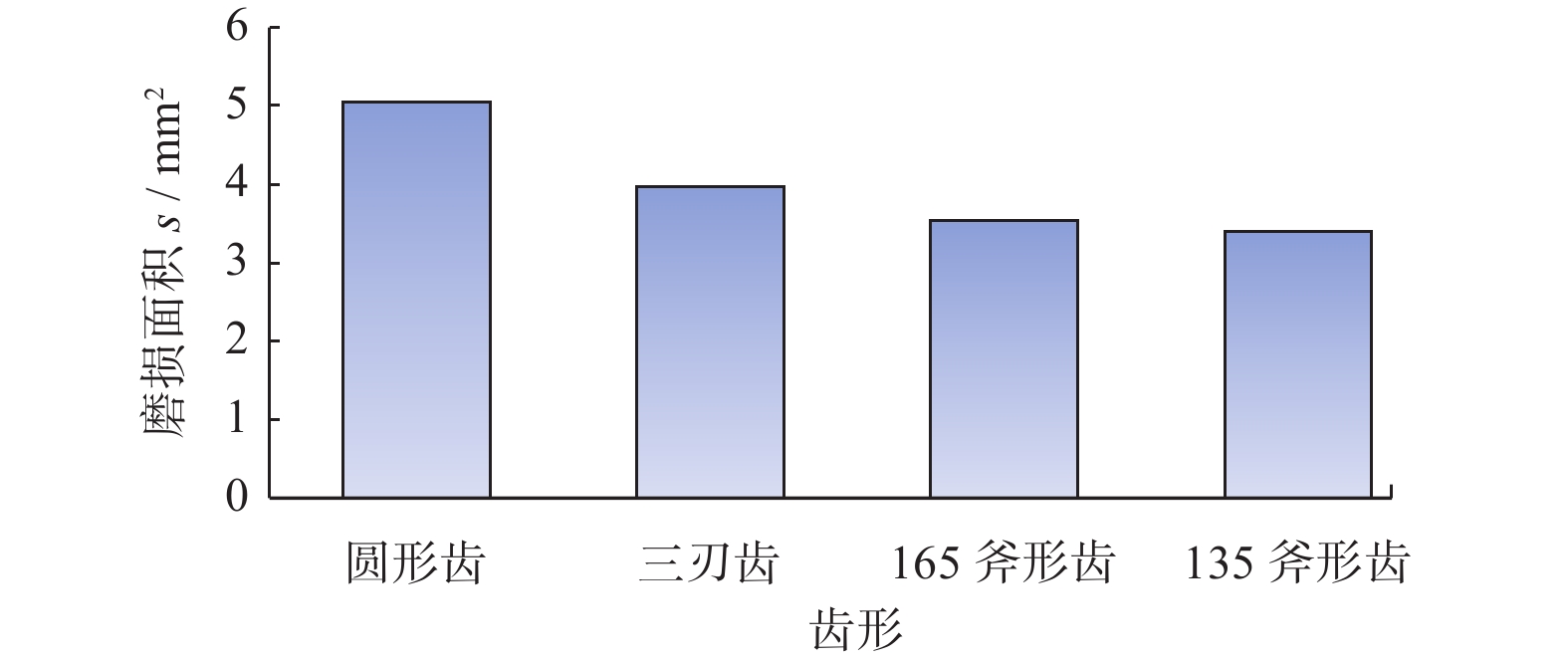

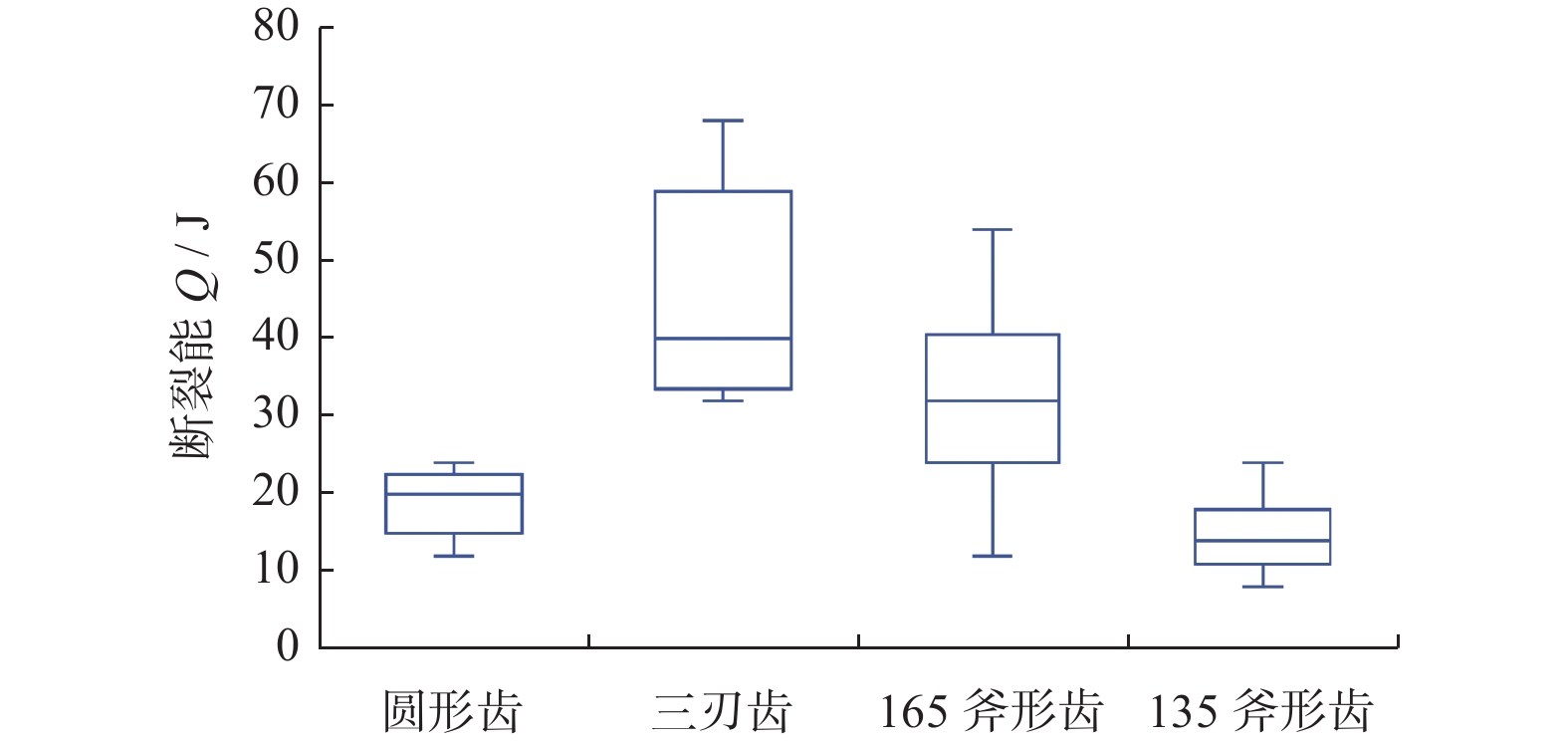

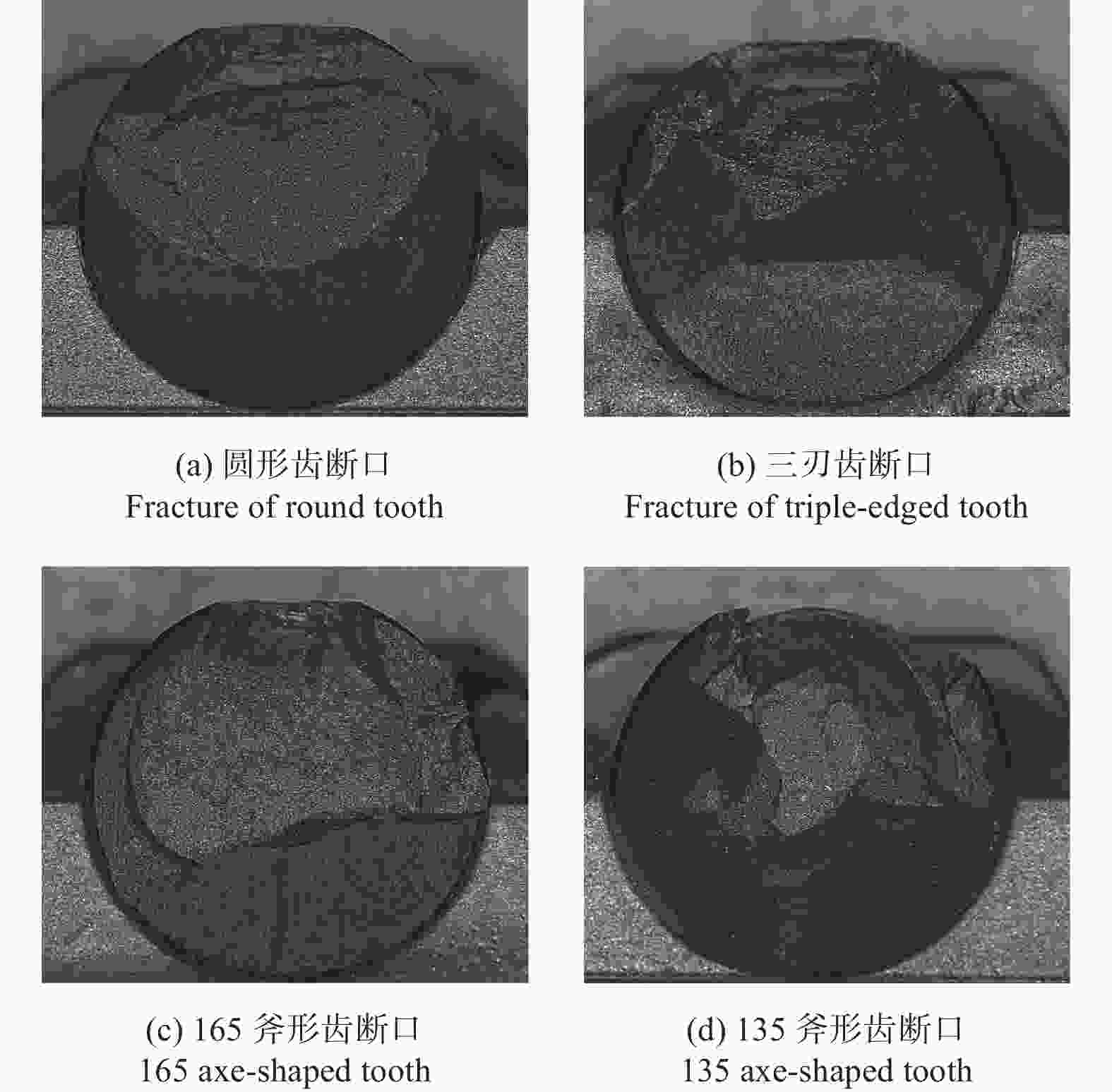

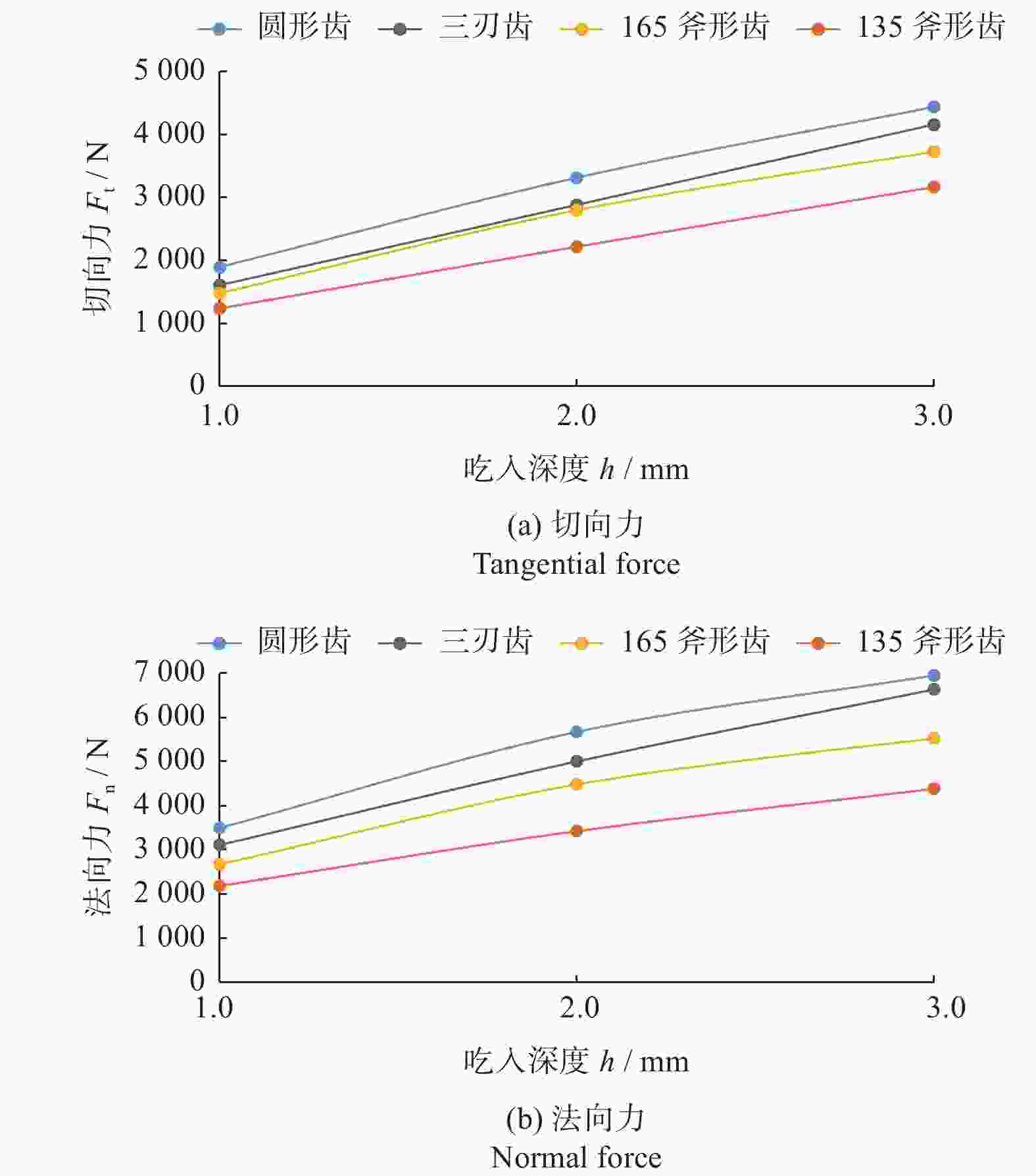

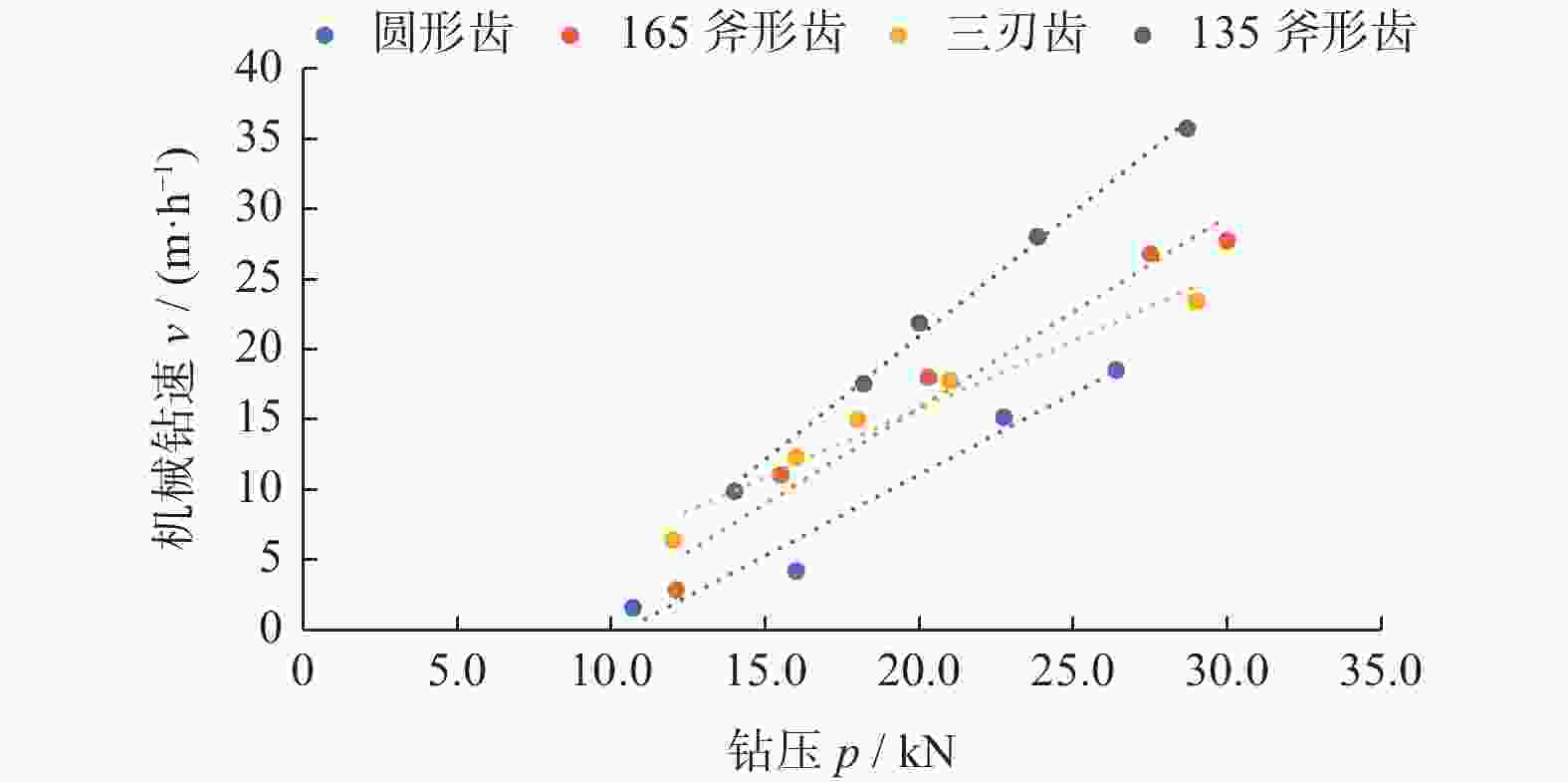

摘要: 以地层特性为依据有针对性地选择PDC异形齿,可以降低其失效的概率并提高其机械钻速和进尺。为了综合对比脊形PDC齿的机械性能和破岩效果,对165斧形、135斧形、三刃3种脊形PDC齿的耐磨性能和抗冲击性能进行测试,随后选择花岗岩进行3个吃入深度的单齿切削试验和不同压力下的全尺寸钻头模拟钻进试验,并与普通圆形齿的结果进行对比。结果表明:3种脊形PDC齿的耐磨性能均优于圆形齿的;165斧形齿与三刃齿的抗冲击性能优于圆形齿的,而135斧形齿的冲击点缺少材料支撑,其抗冲击性能较差。在相同吃入深度下,脊形齿的切向力与法向力均低于圆形齿的相应力,且脊角越小切削力越小。135斧形齿的机械钻速最快且适合高钻压;与165斧形齿比较,三刃齿在≤20.0 kN的低钻压下机械钻速较快,在>20.0 kN的高钻压下机械钻速较慢;圆形齿的机械钻速最慢,所适合的钻压也较低。同时,当脊形齿的脊角变化时,其冲击点的材料支撑也发生改变,进而影响其抗冲击性能;且脊角变化会改变前方岩石内部的应力集中,进而改变其破岩效果。Abstract: Objectives: With the depletion of easily recoverable oil reservoirs, the focus of oil and gas exploration and development in China has shifted to "two deeps and non-conventional" oil and gas fields. This transformation is not only accompanied by a significant increase in well depth and more complex formation challenges but also presents more stringent requirements for the design and construction of drilling engineering, which directly leads to a significant extension of the drilling cycle. The length of the drilling cycle is a key factor in determining drilling costs. Therefore, for a long time, scholars have been committed to improving the mechanical penetration rate and the durability of polycrystalline diamond composite (PDC) bits. The main purpose of this study is to analyze geological characteristics in depth, accurately match and optimize the design of special-shaped teeth in PDC drill bits, in order to significantly reduce the risk of drill bit failure and greatly improve mechanical drilling speed and footage. Given the wide application of PDC bits in hard rock drilling and their key impact on the cost and efficiency of drilling operations, this study focuses on the design and optimization of ridge-shaped PDC teeth, aiming to explore more suitable tooth structures for specific geological conditions through scientific testing and comparative analysis. This will promote innovation and efficiency improvements in drilling technology. Methods: Based on round teeth, the wear resistance, impact resistance, and rock-breaking effect of three types of ridge-shaped teeth were systematically tested. First, the wear resistance and impact resistance of three typical ridge-shaped PDC teeth—namely the 165 axe-shaped, 135 axe-shaped, and three-edged cutters—were tested to quantitatively evaluate their mechanical properties. Subsequently, granite was selected as the representative rock sample, and the single-tooth cutting tests were conducted with three different penetration depths to simulate the cutting effect under various drilling pressures during actual drilling. Additionally, a full-size bit simulation drilling test was designed to evaluate the drilling performance of each tooth shape under different pressures, and the data were compared with those of round teeth. This series of tests aimed to fully reveal the advantages and disadvantages of ridge-shaped PDC teeth in terms of wear resistance, impact resistance, and rock-breaking effectiveness. Results: The test results show that the three ridge-shaped PDC cutters significantly outperform the round teeth in terms of wear resistance. The 135 axe-shaped cutter, with the smallest ridge angle, exhibited the greatest improvement in wear resistance, indicating that the ridge design enhances the durability of PDC cutters and bits. In terms of impact resistance, the 165 axe-shaped cutter and the three-edged cutter performed excellently and could effectively withstand high impact loads, while the 135 axe-shaped cutter had relatively weaker impact resistance due to insufficient support at the impact point. Further analysis of the cutting force data revealed that the tangential force and normal forces of ridge-shaped cutters were lower than those of round cutters at the same cutting depth. The smaller the ridge angle, the smaller the cutting force, which indicates that the ridge design helps reduce cutting resistance and improve drilling efficiency. The full-size drill bit simulation drilling test results showed that the 135 axe-shaped cutter achieved the fastest mechanical drilling speed and is suitable for high-pressure operations. The three-edged cutter performed better in the low-pressure range (≤ 20 kN), while the round teeth had the slowest drilling speed and a lower suitable drilling pressure range. Additionally, the variation in ridge tooth angle not only affects the impact resistance but also directly influences the rock-breaking effect by altering the stress distribution within the rock. Conclusions: Through systematic testing and comparative analysis, this study has verified the significant advantages of ridge-shaped PDC cutters in improving drilling efficiency and reducing the risk of drill bit failure. Specifically, the ridge design effectively enhances the wear resistance and impact resistance of the drill bit while reducing cutting force and increasing mechanical drilling speed. The performance differences of the various ridge-shaped cutters under different drilling pressure conditions provide a scientific basis for the flexible selection of drill bit types based on formation conditions during drilling operations. In the future, further optimization of ridge-shaped PDC cutter designs, especially for specific formation conditions, will be an important direction for improving mechanical drilling speeds and reducing operational costs.

-

Key words:

- PDC bit /

- special-shaped teeth /

- ridge-shaped teeth /

- mechanical property /

- rock-breaking effect

-

表 1 花岗岩岩样的基本力学性能参数

Table 1. Basic mechanical property parameters of granite samples

参数 取值 密度 ρ / (g·cm−3) 2.6 单轴抗压强度 σ / MPa 204.41 弹性模量 E1 / GPa 40.37 泊松比 ε 0.28 黏聚力 E2 / MPa 44.12 内摩擦角 θ / (°) 53.51 -

[1] SCOTT D. A bit of history: Overcoming early setbacks, PDC bits now drill 90%-plus of worldwide footage [J]. Drilling Contractor,2015,71(4):60-68. [2] 张明杰, 李国军, 郭书生, 等. 随钻测压技术在高温高压大斜度气井中的应用 [J]. 新疆石油天然气,2012,8(3):45-47. doi: 10.3969/j.issn.1673-2677.2012.03.010ZHANG Mingjie, LI Guojun, GUO Shusheng, et al. Application of formation pressure testing while drilling in HTHP high deviated gas well in south sea [J]. Xinjang Oil and Gas,2012,8(3):45-47. doi: 10.3969/j.issn.1673-2677.2012.03.010 [3] 王扩军, 孙浮, 石明江, 等. 超深井稠油试油技术开发与应用 [J]. 新疆石油天然气,2008(1):59-63,111. doi: 10.3969/j.issn.1673-2677.2008.01.014WANG Kuojun, SUN Fu, SHI Mingjiang, et al. Technology development of heavy oil testing in ultra-deep well and its application [J]. Xinjang Oil and Gas,2008(1):59-63,111. doi: 10.3969/j.issn.1673-2677.2008.01.014 [4] 冯国良, 解忠义. 高温高压超深探井钻井技术在费尔干纳盆地的研究与应用 [J]. 新疆石油天然气,2011,7(4):21-27. doi: 10.3969/j.issn.1673-2677.2011.04.006FENG Guoliang, XIE Zhongyi. Research on drilling engineering technology under high temperature and high pressure at extra deep exploration well in fergana basin and its application [J]. Xinjang Oil and Gas,2011,7(4):21-27. doi: 10.3969/j.issn.1673-2677.2011.04.006 [5] 王赞, 王晓琪, 陈立强, 等. 渤海油田钻井降本增效技术现状与展望 [J]. 新疆石油天然气,2022,18(1):66-72. doi: 10.12388/j.issn.1673-2677.2022.01.011WANG Zan, WANG Xiaoqi, CHEN Liqiang, et al. Status and prospect of technologies to reduce cost and increase efficiency for drilling in bohai oilfield [J]. Xinjang Oil and Gas,2022,18(1):66-72. doi: 10.12388/j.issn.1673-2677.2022.01.011 [6] MIESS D, RAI G. Fracture toughness and thermal resistance of polycrystalline diamond compacts [J]. Materials Science and Engineering A,1996,209(1/2):270-276. doi: 10.1016/0921-5093(95)10105-5 [7] FLOOD G M. Dense packing particle size distribution for PDC cutters: US11279002B2 [P]. 2022-03-22. [8] 孙伟, 赵海峰, 张天翔, 等. 提高金刚石复合片抗冲击性能的试验研究 [J]. 钻采工艺,2018,41(6):87. doi: 10.3969/J.ISSN.1006-768X.2018.06.25SUN Wei, ZHAO Haifeng, ZHANG Tianxiang, et al. Experimental study on how to improve impact resistance of polycrystalline diamond compact [J]. Drilling and Production Technology,2018,41(6):87. doi: 10.3969/J.ISSN.1006-768X.2018.06.25 [9] RAHMANI R, PASTUSEK P, YUN G, et al. Investigation of geometry and loading effects on PDC cutter structural integrity in hard rocks [J]. SPE Drilling and Completion,2020,36(1):199598. doi: 10.2118/199598-MS [10] 刘伟吉, 阳飞龙, 董洪铎, 等. 异型PDC齿混合切削破碎花岗岩特性研究 [J]. 工程力学,2023,40(3):245-256. doi: 10.6052/j.issn.1000-4750.2021.10.0761LIU Weiji, YANG Feilong, DONG Hongze, et al. Investigate on the mixed-cutting of specially-shaped pdc cutters in granite [J]. Engineering Mechanics,2023,40(3):245-256. doi: 10.6052/j.issn.1000-4750.2021.10.0761 [11] 杨灿, 王鹏, 饶开波, 等. 大港油田页岩油水平井钻井关键技术 [J]. 石油钻探技术,2020,48(2):34-41. doi: 10.11911/syztjs.2020036YANG Can, WANG Peng, RAO Kaibo, et al. Key technologies for drilling horizontal shale oil wells in the dagang oilfield [J]. Petroleum Drilling techniques,2020,48(2):34-41. doi: 10.11911/syztjs.2020036 [12] 邹德永, 潘龙, 崔煜东, 等. 斧形PDC切削齿破岩机理及试验研究 [J]. 石油机械,2022,50(1):34-40. doi: 10.16082/j.cnki.issn.1001-4578.2022.01.005ZOU Deyong, PAN Long, CUI Yudong, et al. Rock breaking mechanism and experimental study of axe-shaped pdc cutter [J]. Petroleum Machinery,2022,50(1):34-40. doi: 10.16082/j.cnki.issn.1001-4578.2022.01.005 [13] CRANE D, ZHANG Y, DOUGLAS C, et al. Innovative PDC cutter with elongated ridge combines shear and crush action to improve PDC bit performance: SPE middle east oil & gas show and conference [C]. Chengdu: SPE, 2017. [14] 孔栋梁. 底砾岩地层PDC钻头损坏机理及钻头优化设计研究 [D]. 青岛: 中国石油大学(华东), 2011.KONG Dongliang. Research on damage mechanism and optimization design of PDC bit in bottom conglomerate formation [D]. Qingdao: China University of Petroleum (East China), 2011. [15] 赵东鹏, 马姗姗, 牛同健, 等. 石油钻探用非平面聚晶金刚石复合片的开发 [J]. 金刚石与磨料磨具工程,2017,37(6):49-52. doi: 10.13394/j.cnki.jgszz.2017.6.0009ZHAO Dongpeng, MA Shanshan, NIU Tongjian. Research of polycrystalline diamond compact having non-planar surface for oil drilling [J]. Diamond and Abrasives Engineering,2017,37(6):49-52. doi: 10.13394/j.cnki.jgszz.2017.6.0009 [16] 刘建华, 令文学, 王恒. 非平面三棱形PDC齿破岩机理研究与现场试验 [J]. 石油钻探技术,2021,49(5):46-50. doi: 10.11911/syztjs.2021040LIU Jianhua, LING Wenxue, WANG Heng. Study on rock breaking mechanism and field test of triangular prismatic PDC cutters [J]. Petroleum Drilling Techniques,2021,49(5):46-50. doi: 10.11911/syztjs.2021040 [17] 李宁, 周波, 文亮, 等. 塔里木油田库车山前砾石层提速技术研究 [J]. 钻采工艺,2020,43(2):143. doi: 10.3969/J.ISSN.1006-768X.2020.02.39LI Ning, ZHOU Bo, WEN Liang, et al. Research on speed-increasing technology of gravel layer in Kuqa piedmont of Tarim Oilfield [J]. Drilling and Production Technology,2020,43(2):143. doi: 10.3969/J.ISSN.1006-768X.2020.02.39 [18] HUANG H, ZHAO B, WEI W, et al. Effect of cobalt content on the performance of polycrystalline diamond compacts [J]. International Journal of Refractory Metals and Hard Materials,2020,92:105312. doi: 10.1016/j.ijrmhm.2020.105312 [19] WESTRAADT J E, SIGALAS I, NEETHLING J H. Characterisation of thermally degraded polycrystalline diamond [J]. International Journal of Refractory Metals and Hard Materials,2015,48:286-292. doi: 10.1016/j.ijrmhm.2014.08.008 [20] WEI J, LIU W, GAO D. Effect of cutter shape on the resistance of PDC cutters against tip impacts [J]. SPE Journal,2022,27(5):3035-3050. doi: 10.2118/209809-PA -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS