Preparation and properties of Mo2C-TiN0.3 composite materials at high temperature and high pressure

-

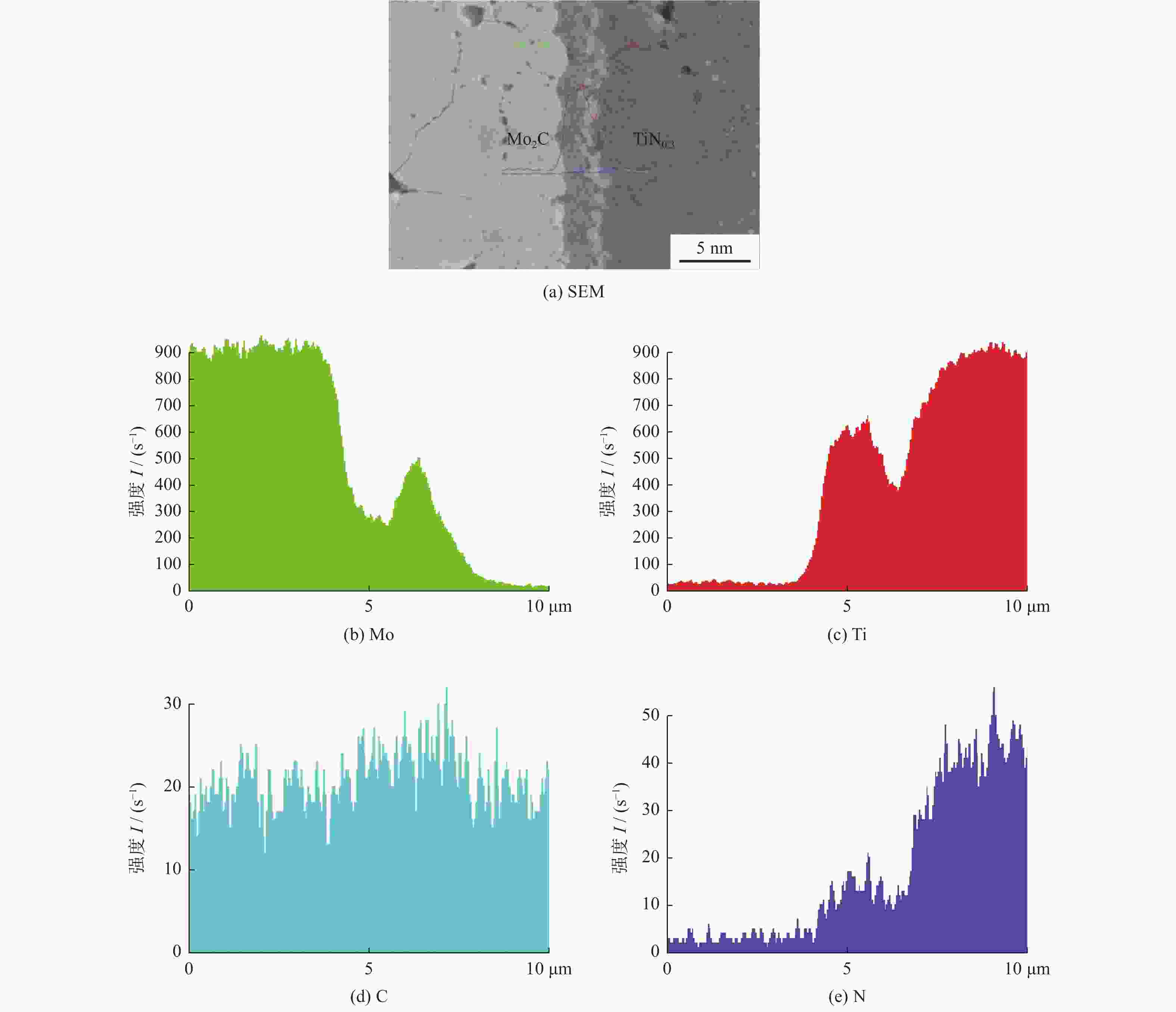

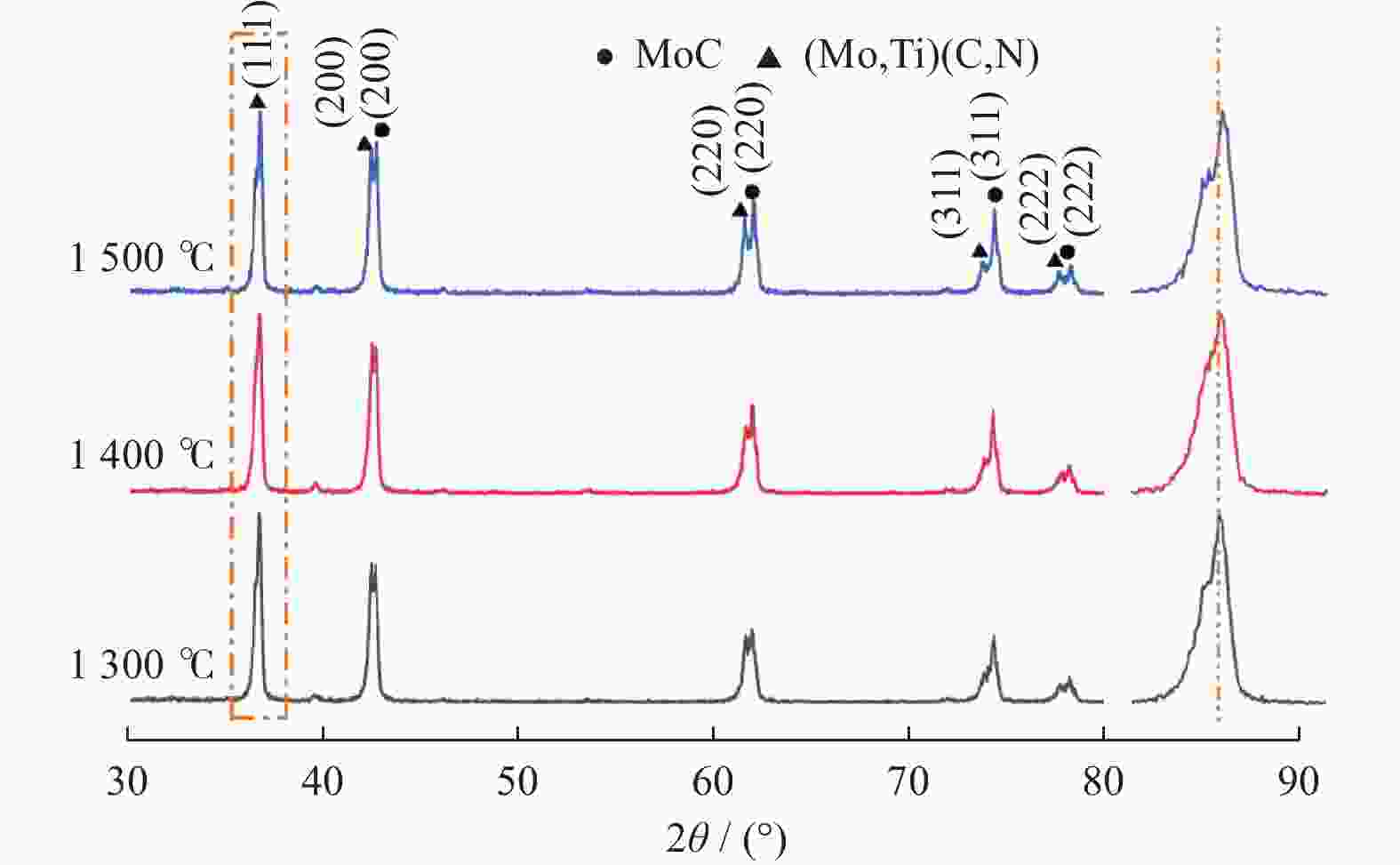

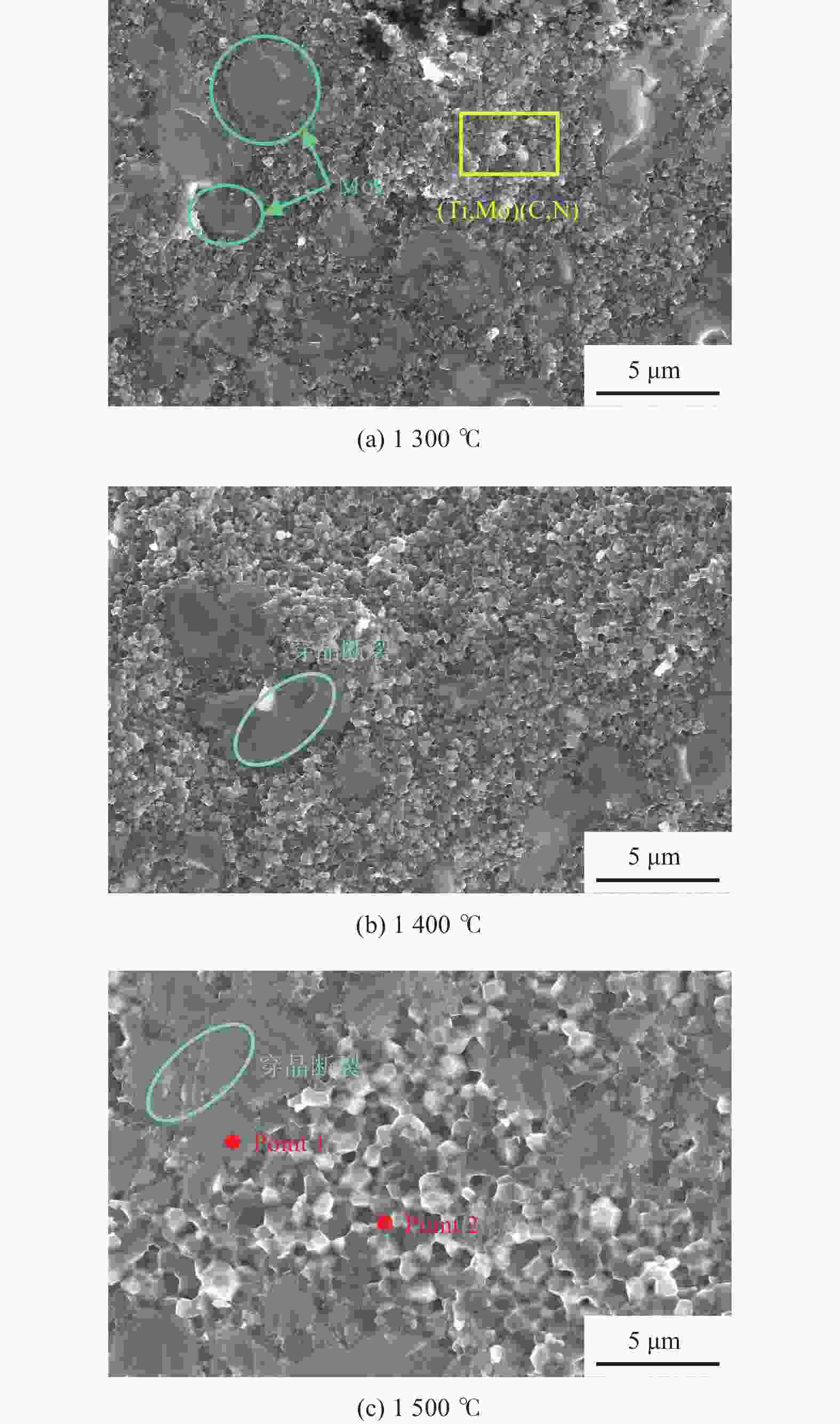

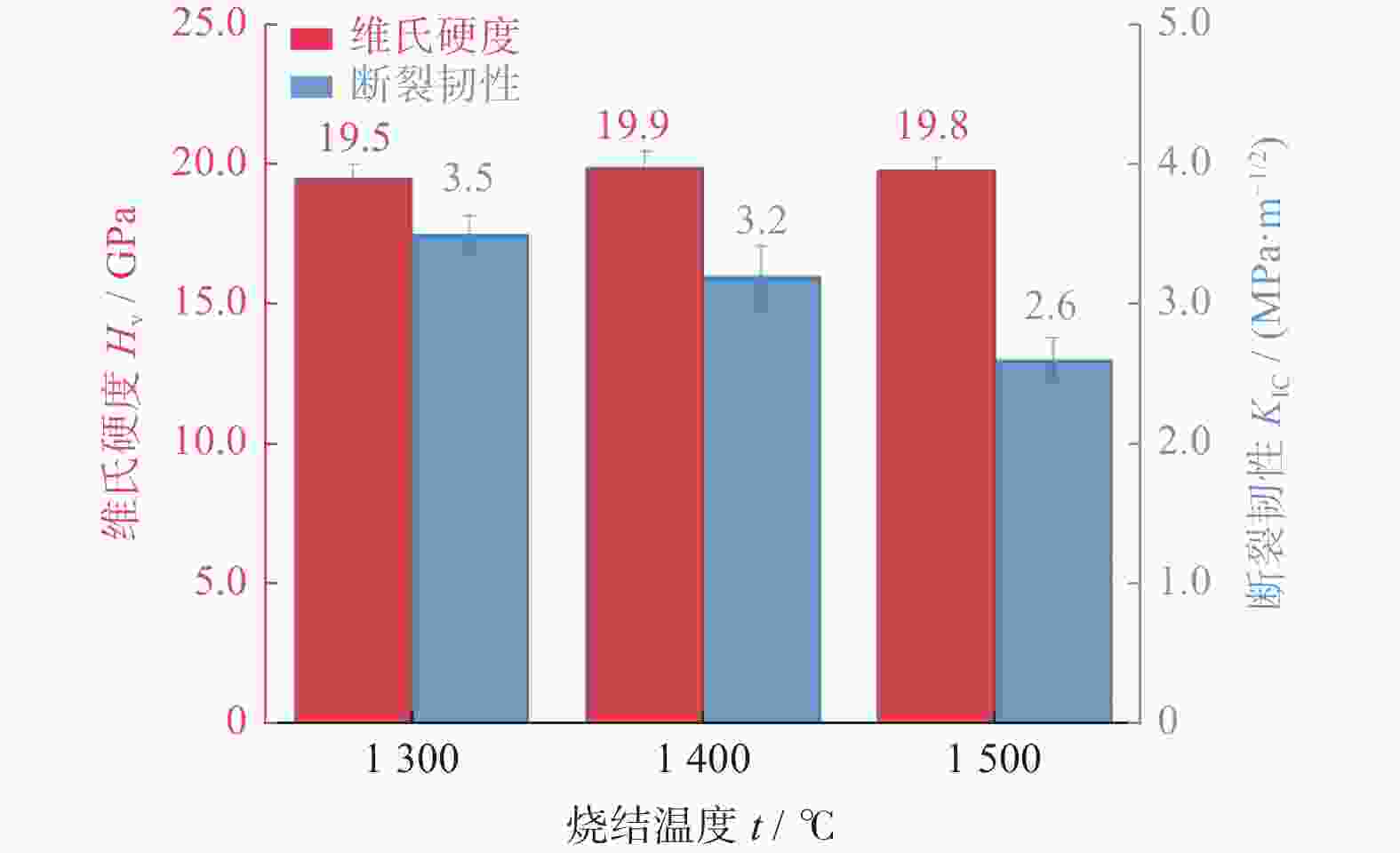

摘要: 将Mo2C和TiN0.3粉体采用机械合金化和高温高压烧结相结合的方法进行分层烧结,并制备30% Mo2C-70%TiN0.3的烧结体复合材料,分析Mo2C-TiN0.3烧结体的物相组成、微观组织结构及力学性能。结果表明:Mo2C和TiN0.3 间存在明显的相互扩散,且形成了2层不同的扩散层;随着烧结温度不断升高,Mo2C-TiN0.3烧结体的晶粒尺寸逐渐变大,会导致烧结体的机械性能变差;在烧结过程中有高硬高脆的MoC生成,能够维持Mo2C-TiN0.3烧结体的硬度在19.0~20.0 GPa,但会降低其断裂韧性。Abstract: Objectives: This study aims to prepare sintered bodies of Mo2C and TiN0.3 and explore their phase compositions, microstructures, and mechanical properties. Using a combined approach of mechanical alloying and high-temperature high-pressure sintering, the research investigates the stratified sintering process of Mo2C and TiN0.3 powders, analyzes the influence of different sintering temperatures on the sintered body performances, and aims to optimize the preparation process to enhance the comprehensive properties of the sintered bodies. Methods: This experiment employed a combination of mechanical alloying and high-temperature high-pressure sintering to prepare the sintered bodies. Initially, Mo2C and TiN0.3 powders were mechanically alloyed in a 7:3 volume ratio. The powders were thoroughly mixed using a high-energy ball mill to ensure uniform mixing. Subsequently, the mixed powders were subjected to high-temperature and high-pressure sintering using a six-sided top press under various temperature conditions to obtain sintered bodies with different sintering parameters. During the sintering process, the temperature and pressure were strictly controlled to study their effects on the microstructure and mechanical properties of the sintered bodies. The phase composition of the sintered bodies was analyzed using X-ray diffraction (XRD) to identify the presence and changes of various phases. The microstructure of the sintered bodies was observed using a scanning electron microscope (SEM) to analyze the grain size and morphology. To evaluate the mechanical properties of the sintered bodies, Vickers hardness tests and fracture toughness tests were conducted. These test methods were used to comprehensively analyze the overall performance of Mo2C and TiN0.3 sintered bodies under different sintering conditions. Results: The experimental results indicate significant mutual diffusion between Mo2C and TiN0.3 during the sintering process, forming two distinct diffusion layers. The formation of these diffusion layers markedly affects the phase composition and microstructure of the sintered body. As the sintering temperature increases, the grain size of the Mo2C-TiN0.3 sintered body gradually enlarges, leading to a deterioration in mechanical properties. Specifically, at lower sintering temperatures, the sintered body exhibits higher hardness, but as the temperature rises, the grain size increases, resulting in decreased hardness. Additionally, the formation of a highly hard and brittle MoC phase was detected during high-temperature sintering. In addition, MoC phase formation with high hardness and brittleness was detected during high temperature sintering. The presence of the MoC phase helps maintain the hardness of the sintered body within the range of 19.0 to 20.0 GPa, but also leads to a reduction in fracture toughness. The microstructure of the sintered body varies significantly with different sintering temperatures. Under low-temperature sintering conditions, the grains of the sintered body are small and evenly distributed, and the phase composition is relatively stable. However, with the increase of sintering temperature, the grains gradually grow, and the phase distribution becomes uneven, which leads to a decline in the mechanical properties of the sintered body. Furthermore, SEM analysis reveals the presence of numerous pores and cracks on the surface of the high-temperature sintered body, which are crucial factors affecting its mechanical performance. Conclusions: Through the study of 30% Mo2C-TiN0.3 sintered bodies, it is found that: (1) The mutual diffusion between Mo2C and TiN0.3 plays a crucial role in the formation of the sintered body, directly impacting its phase composition and microstructure. (2) As the sintering temperature increases, the grain size of the sintered body enlarges, leading to a decline in its mechanical properties, particularly in its hardness and fracture toughness. (3) The MoC phase generated in the sintering process helps to maintain the high hardness of the sintered body, but also reduces fracture toughness. Therefore, in practical applications, it is necessary to find a balance between hardness and toughness to optimize the overall performance of the sintered body. (4) Different sintering temperatures significantly affect the microstructure of the sintered body, highlighting the importance of optimizing sintering process parameters to enhance the performance of the sintered body. Others: The mechanical alloying and high-temperature and high-pressure sintering methods used in this study demonstrate the potential for producing high-performance Mo2C and TiN0.3 sintered bodies. By optimizing sintering process parameters, the performance of the sintered bodies can be further enhanced. Furthermore, future research could explore the effects of other additives on the performance of Mo2C-TiN0.3 sintered bodies to obtain higher performance hard and brittle materials.

-

Key words:

- TiN0.3 /

- Mo2C /

- diffusion /

- high-temperature high-pressure sintering /

- mechanical alloying(MA)

-

表 1 TiN0.3制备原料

Table 1. TiN0.3 preparation raw materials

构成 取值 Ti∶CH4N2O 摩尔比 R1 6∶1 Ti∶N 原子比 R2 3∶1 Ti 质量 m1 / g 33.08 CH4N2O质量 m2 / g 6.92 表 2 1 500 ℃下Mo2C-TiN0.3复合烧结体断口的点能谱分析结果

Table 2. Point energy spectrum analysis results of Mo2C-TiN0.3 composite sintered body at 1 500 ℃

位置 质量分数 ω / % Ti N C Mo Point 1 3.64 1.62 51.29 43.45 Point 2 28.56 50.94 11.22 9.28 -

[1] XUE J X, LIU H T, TANG Y, et al. Effect of sintering atmosphere on the densification behavior of hot pressed TiN ceramics [J]. Ceramics International, 2013, 39(7): 8531-8535. [2] CHÁVEZ J M M, MOSHTAGHIOUN B M, HERNÁNDEZ F L C, et al. Sintering kinetics, defect chemistry and room-temperature mechanical properties of titanium nitride prepared by spark plasma sintering [J]. Journal of Alloys and Compounds, 2019, 807: 151666. [3] TIAN L, LI Y M, JU P, et al. A novel approach to prepare reticulated porous TiN ceramics with high strength and high porosity by in-situ synthesis [J]. Journal of the European Ceramic Society, 2022, 42(6): 2718-2725. [4] ANSARI S A, KHAN N A, HASAN Z, et al. Electrochemical synthesis of titanium nitride nanoparticles onto titanium foil for electrochemical supercapacitors with ultrafast charge/discharge [J]. Sustainable Energy & Fuels, 2020, 4(5): 2480-2490. [5] KAWRANI S, NADA A A, BEKHEET M F, et al. Enhancement of calcium copper titanium oxide photoelectrochemical performance using boron nitride nanosheets [J]. Chemical Engineering Journal, 2020, 389: 124326. [6] ZHU J J, JIANG L, ZHAI L H, et al. Effect of TiN inclusions on oxidation behavior of austenitic stainless steels [J]. Materials Letters, 2023, 335: 133761. [7] LIN L Y, TIAN Y H, YU W X, et al. Corrosion and hardness characteristics of Ti/TiN-modified Ti6Al4V alloy in marine environment [J]. Ceramics International, 2022, 48(23): 34848-34854. [8] RONADSON, B J, VIJAYAN, K, SANMUGAM, S, et al. Improving dry machining performance of surface modified cutting tools through combined effect of texture and TiN-WS2 coating [J]. Journal of Manufacturing Processes, 2023, 85: 101-108. [9] GAO W J, MA F L, YIN Y H, et al. Robust and durable transparent superhydrophobic F-TNTs/TiN coating fabricated by structure tuning on surface of TiN hard coating [J]. Applied Surface Science, 2023, 613: 155967. [10] WANG S, KONG Y, CHEN L, et al. Initial oxidation on 12 grain boundaries in pure TiN coating and on (Al, Si, Cr) doped Σ3 (111) grain boundaries: A first-principles calculations [J]. Surfaces and Interfaces, 2023, 36: 102531. [11] PENG C, GAO X, WANG M Z, et al. Diffusion-controlled alloying of single-phase multi-principal transition metal carbides with high toughness and low thermal diffusivity [J]. Applied Physics Letters, 2019, 114(1): 011905-1-011905-5. [12] WANG Q S, SARKAR A, WANG D, et al. Multi-anionic and -cationic compounds: new high entropy materials for advanced Li-ion batteries [J]. Energy & Environmental Science, 2019, 12(8): 2433-2442. [13] ZHAI S, ROJAS J, AHLBORG N, et al. The use of poly-cation oxides to lower the temperature of two-step thermochemical water splitting [J]. Energy & Environmental Science, 2018, 11(8): 2172-2178. [14] VALLAURI D, ADRIÁN I C A, CHRYSANTHOU A. TiC–TiB2 composites: A review of phase relationships, processing and properties [J]. Journal of the European Ceramic Society, 2008, 28(8): 1697-1713. [15] MONTEVERDE F. Progress in the fabrication of ultra-high-temperature ceramics: “in situ” synthesis, microstructure and properties of a reactive hot-pressed HfB2-SiC composite [J]. Composites Science and Technology, 2005, 65(11/12): 1869-1879. [16] SHON I J. Enhanced mechanical properties of TiN-graphene composites rapidly sintered by high-frequency induction heating [J]. Ceramics International, 2017, 43(1): 890-896. [17] 战再吉, 程庭信, 李国伟, 等. 高熵陶瓷的制备与应用[J]. 燕山大学学报, 2022, 46(5): 377-384ZHAN Zaiji, CHENG Tingxin, LI Guowei, et al. Preparation and application of high-entropy ceramics [J]. Journal of Yanshan University, 2022, 46(5): 377-384. [18] LEI H Y, FENG P, ZHANG X M, et al. Effect of TiN addition on the microstructure and mechanical properties of Ti (C, N)-based cermets [J]. Advanced Materials Research, 2012, (602/603/ 604): 536-539. [19] RADAJEWSKI M, HENSCHEL S, GRÜTZNER S, et al. Microstructure and mechanical properties of bulk TiN-AlN composites processed by FAST/SPS [J]. Ceramics International, 2016, 42(8): 10220-10227. [20] SONG J P, JIANG L K, LIANG G X, et al. Strengthening and toughening of TiN-based and TiB2-based ceramic tool materials with HfC additive [J]. Ceramics International, 2017, 43(11): 8202-8207. [21] YANG Z L, LIU Z G, OUYANG J H, et al. Synthesis route and mechanical properties of reactive hot pressed TiN–TiB2 ceramics [J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 54-59. [22] WYZGA P, JAWORSKA L, BUCKO M M, et al. TiN-TiB2 composites prepared by various sintering techniques [J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 571-576. [23] DELBARI S A, NAYEBI B, GHASALI E, et al. Spark plasma sintering of TiN ceramics codoped with SiC and CNT [J]. Ceramics International, 2019, 45(3): 3207-3216. [24] MOGHANLOU F S, VAJDI M, JAFARZADEH H, et al. Spark plasma sinterability and thermal diffusivity of TiN ceramics with graphene additive [J]. Ceramics International, 2021, 47(7): 10057-10062. [25] KITIWAN M, ITO A, GOTO T. Spark plasma sintering of TiN-TiB2-hBN composites and their properties [J]. Ceramics International, 2015, 41(3, Part B): 4498-4503. [26] UEMATSU K, NAKAMURA M, KATO Z, et al. Hot isostatic pressing and thermoelectrical properties of non-stoichiometric titanium nitride [J]. Journal of the Ceramic Society of Japan, 1989, 97: 63-67. [27] SUAREZ-VAZQUEZ S, NANKO M. Preparation of dense TiN1−X (X=0~0.4) by pulsed electric current sintering: Densification and mechanical behavior [J]. International Journal of Refractory Metals and Hard Materials, 2014, 44: 54-59. [28] XU S, WANG M Z, QIAO L, et al. Enhancing the sintering ability of TiNx by introduction of nitrogen vacancy defects [J]. Ceramics International, 2015, 41(8): 9514-9520. [29] SUN J F, WANG M Z, ZHAO Y C, et al. Synthesis of titanium nitride powders by reactive ball milling of titanium and urea [J]. Journal of Alloys and Compounds, 2009, 482(1/2): L29-L31. [30] KOHICHI T. Evaluation of elastic/plastic indentation stress to determine fracture toughness [J]. Journal of the Japan Institute of Metals and Materials, 1984, 48: 1157-1162. [31] KARANAM M K, GULIVINDALA G, CHINTHAPENTA V R. Effect of anisotropy on the ductile fracture in metal reinforcements of brittle matrix composites [J]. Theoretical and Applied Fracture Mechanics, 2021, 112: 102923. [32] PINEAU A, BENZERGA A A, PARDOEN T. Failure of metals I: Brittle and ductile fracture [J]. Acta Materialia, 2016, 107: 424-483. [33] XIANG H M, XING Y, DAI F Z, et al. High-entropy ceramics: Present status, challenges, and a look forward [J]. Journal of Advanced Ceramics, 2021, 10(3): 385-441. [34] AKINRIBIDE O J, AKINWAMIDE S O, OLUBAMBI P A. Morphological analysis and high-temperature phase stability of spark plasma sintered TiN-MWCNTs ceramic composite [J]. Journal of the Australian Ceramic Society, 2023, 59(3): 521-532. [35] SONG J, JIANG L, LIANG G, et al. Strengthening and toughening of TiN-based and TiB2-based ceramic tool materials with HfC additive [J]. Ceramics International, 2017, 43(11): 8202-8207. [36] LI J, GAO L, GUO J, et al. Mechanical properties and electrical conductivity of TiN-Al2O3 nanocomposites [J]. Journal of the European Ceramic Society, 2003, 23(1): 69-74. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS