Preparation of vitrified bond diamond wheel based on Bi2O3-B2O3 glass system and its grinding performance on monocrystalline silicon

-

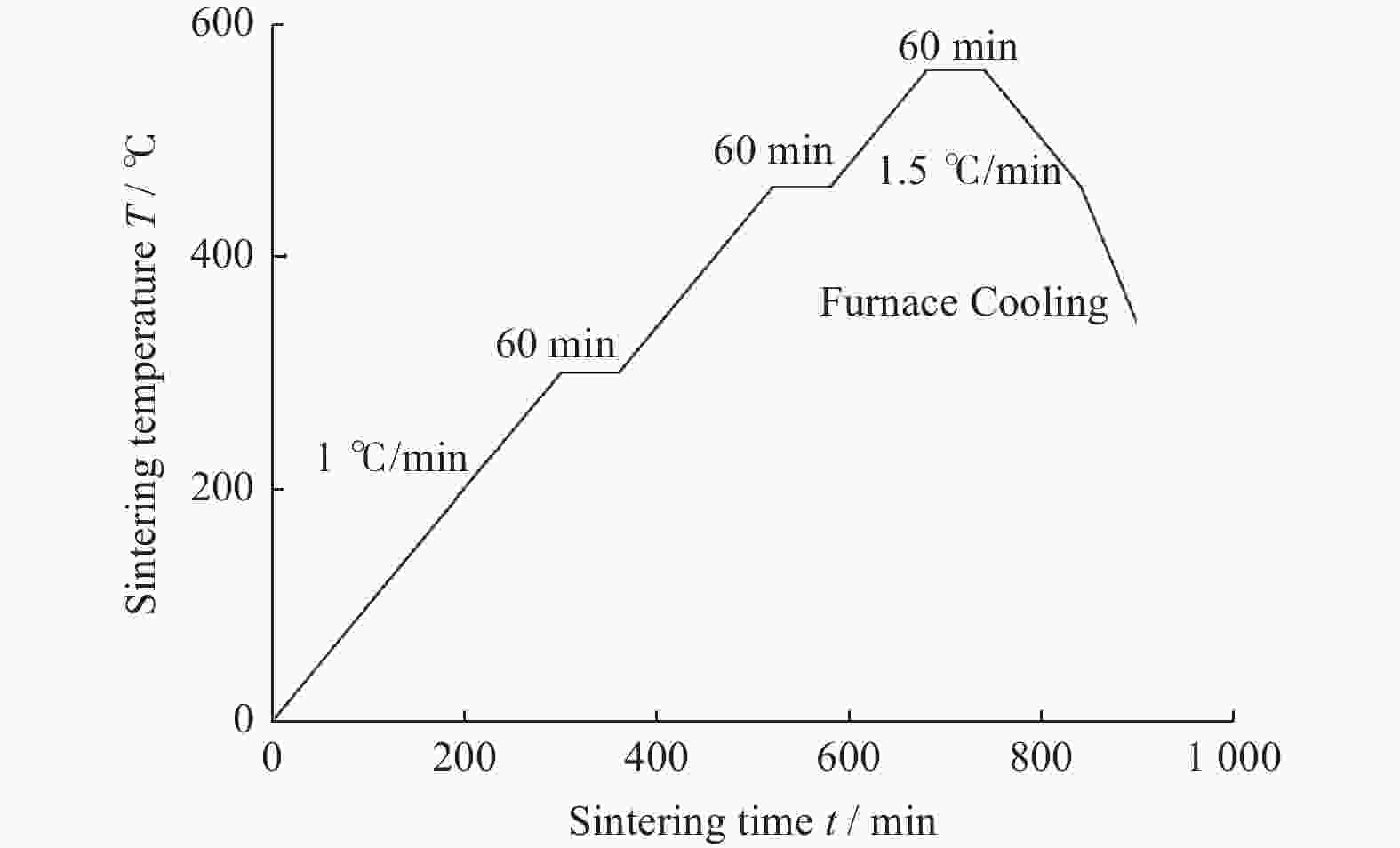

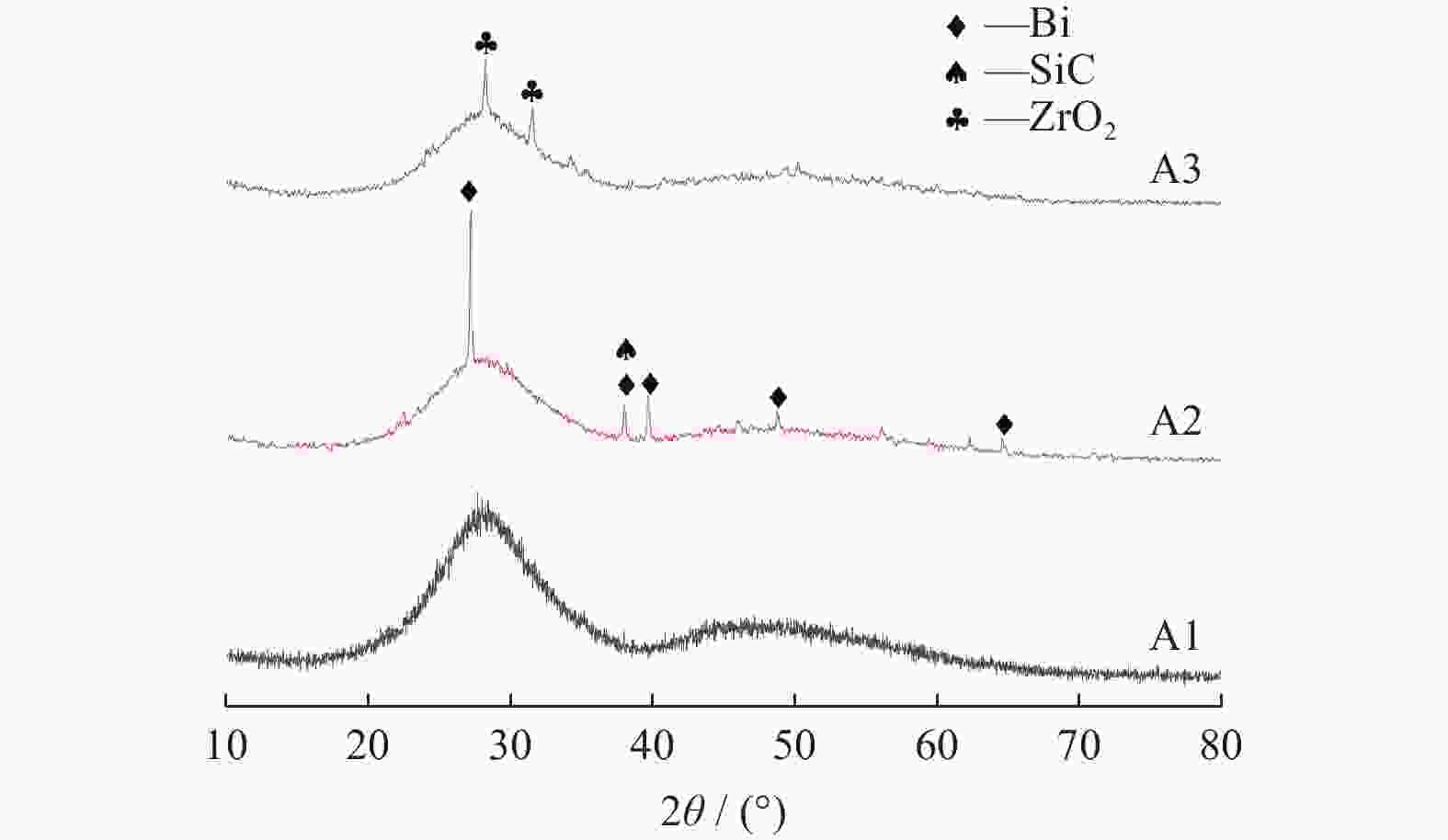

摘要: 针对陶瓷结合剂烧结温度高的问题,提出一种基于Bi2O3-B2O3的新型低温陶瓷结合剂。分析添加纳米SiC和纳米ZrO2对结合剂物相组成、流动性和力学性能的影响,并探索添加核桃壳粉造孔剂对金刚石砂轮微观形貌的影响;制备基于Bi2O3-B2O3体系的陶瓷结合剂金刚石杯形砂轮,测试其对单晶硅晶圆片的磨削性能。结果表明:添加纳米SiC会导致陶瓷结合剂中出现一定量的Bi单质,破坏结合剂的[BiO4]玻璃网络;添加纳米SiC及纳米ZrO2后,结合剂的流动性降低;随烧结温度上升,结合剂的流动性、抗弯强度和硬度有增大的趋势,在560 ℃烧结时结合剂的抗弯强度和硬度达到最大。随着造孔剂含量的增大,砂轮中大气孔的数量显著增多、尺寸显著增大。在砂轮线速度为12.56 m/s,工件转速为5.23 m/s,进给速度为0.1 μm/s条件下,使用以M10/20金刚石(粒度号为800目)制备的砂轮磨削加工单晶硅晶圆片,其磨削比为790,表面粗糙度为0.16 μm。

-

关键词:

- 陶瓷结合剂金刚石砂轮 /

- 单晶硅晶圆片 /

- 力学性能 /

- 磨削性能

Abstract: To solve the problem of high sintering temperature of vitrified bond, a novel low- temperature vitrified bond based on Bi2O3-B2O3 glass system was proposed. The effect of nano-SiC and nano-ZrO2 on the phase composition, fluidity and mechanical properties of the vitrified bond were analyzed. Additionally, the effect of adding walnut shell powder as a pore-forming agent on the microstructure of the vitrified bond diamond grinding wheel was explored. A vitrified bond diamond cup grinding wheel based on Bi2O3-B2O3 glass system was prepared, and its grinding performance on monocrystalline silicon wafer was tested. The results show that adding nano-SiC powder leads to the formation of Bi in the vitrified bond and destroys the [BiO4] glass network of vitrified bond. The fluidity of the vitrified bond decreases with the addition of nano-SiC and nano- ZrO2. Furthermore, the fluidity, flexural strength and hardness of the vitrified bond increase as the sintering temperature increases. The flexural strength and the hardness of the vitrified bond reach to their highest value at 560 ℃. With the increase of the content of the pore-forming agent, the amount of large pores in the grinding wheel increases significantly and the size becomes larger. The prepared Bi2O3-B2O3 vitrified bond diamond cup grinding wheel (800 mesh or M10/20) was used to grind monocrystalline silicon wafer under specific conditions (linear speed: 12.56 m/s, workpiece speed: 5.23 m/s, and feed speed: 0.1 μm/s). The grinding ratio reaches 790, and the surface roughness of the monocrystalline silicon wafer is 0.16 μm. -

表 1 Bi2O3-B2O3陶瓷结合剂成分

Table 1. Composition of Bi2O3-B2O3 vitrified bond

编号 Bi2O3

物质的

量分数

N1 / %B2O3

物质的

量分数

N2 / %SiO2

物质的

量分数

N3 / %Al2O3

物质的

量分数

N4 / %额外添加

(质量分数)A1 40 40 10 10 无 A2 40 40 10 10 5%纳米SiC

(100 nm)A3 40 40 10 10 5%纳米ZrO

(100 nm)2表 2 陶瓷结合剂金刚石砂轮配方

Table 2. Formula of vitrified bond diamond grinding wheel

序号 金刚石

质量分数

wd / %绿碳化硅

质量分数

ws / %结合剂

质量数

wb / %造孔剂

质量分数

wp / %1 35 35 29 1 2 35 34 29 2 3 35 33 29 3 -

[1] CHEN S P, LIU X P, WAN L, et al. Effect of V2O5 addition on the wettability of vitrified bond to diamond abrasive and grinding performance of diamond wheels [J]. Diamond and Related Materials,2019,102:107672. doi: 10.1016/j.diamond.2019.107672 [2] ZHANG X H, WANG Y H, ZANG J B, et al. Improvement of thermal stability of diamond by adding Ti powder during sintering of diamond/borosilicate glass composites [J]. Journal of the European Ceramic Society,2011,31(10):1897-1903. doi: 10.1016/j.jeurceramsoc.2011.04.009 [3] HOU Y G, QIAO G Y, SHANG Y, et al. Effect of porosity on the grinding performance of vitrified bond diamond wheels for grinding PCD blades [J]. Ceramics International,2012,38(8):6215-6220. doi: 10.1016/j.ceramint.2012.04.074 [4] ZHOU H, GUO M, WANG X. Ultraprecision grinding of silicon wafers using a newly developed diamond wheel [J]. Materials Science in Semiconductor Processing,2017,68:238-244. doi: 10.1016/j.mssp.2017.06.031 [5] 张红轩. 金刚石砂轮磨削蓝宝石晶片加工过程实验研究 [D]. 广州: 广东工业大学, 2020.ZHANG Hongxuan. Experimental study of sapphire wafer grinding process with diamond wheel [D]. Guangzhou: Guangdong University of Technology. 2020. [6] RABIEY M, JOCHUM N, KUSTER F. High performance grinding of zirconium oxide (ZrO2) using hybrid bond diamond tools [J]. CIRP Annals - Manufacturing Technology,2013,62(1):343-346. doi: 10.1016/j.cirp.2013.03.073 [7] 万明. RO及R2O对金刚石砂轮陶瓷结合剂性能的影响 [D]. 秦皇岛: 燕山大学, 2018.WANG Ming. Effect of RO and R2O on the properties of vitrified bond diamond wheel [D]. Qinhuangdao: Yanshan University, 2018. [8] GUO B J, HONG Y. Influence of Li2O addition on the performance of vitrified bond and vitrified diamond composites [J]. Journal of Wuhan University of Technology (Materials Science),2020,35(04):699-705. doi: 10.1007/s11595-020-2310-9 [9] WANG X Z, MA Z L, SUN X, et al. Effects of ZrO2 and Y2O3 on physical and mechanical properties of ceramic bond and ceramic CBN composites [J]. International Journal of Refractory Metals and Hard Materials,2018,75:18-24. doi: 10.1016/j.ijrmhm.2018.03.016 [10] LIN K H, PENG S F, LIN S T. Sintering parameters and wear performances of vitrified bond diamond grinding wheels [J]. International Journal of Refractory Metals & Hard Materials,2007,25(1):25-31. [11] 左宏森, 关春龙. 造孔剂对金属结合剂金刚石磨具力学性能的影响 [J]. 金刚石与磨料磨具工程,2009(5):82-85. doi: 10.3969/j.issn.1006-852X.2009.05.018ZUO Hongsen, GUAN Chunlong. Effect of pore-forming agent on mechanical properties of metal-bonded diamond abrasive tools [J]. Diamond & Abrasive Engineering,2009(5):82-85. doi: 10.3969/j.issn.1006-852X.2009.05.018 [12] LV X F, LI Z H, ZHU Y M, et al. Effect of PMMA pore former on microstructure and mechanical properties of vitrified bond CBN grinding wheels [J]. Ceramics International,2013,39(2):1893-1899. doi: 10.1016/j.ceramint.2012.08.038 [13] GUO W, FU L, HE P, et al. Low-temperature brazing of alumina ceramics with bismuth-borate glass in air [J]. Materials Characterization,2019,149:158-164. doi: 10.1016/j.matchar.2019.01.020 [14] LIN P P, LIN T, HE P, et al. Investigation of microstructure and mechanical property of Li–Ti ferrite/Bi2O3-B2O3-SiO2 glass/Li–Ti ferrite joints reinforced by FeBi5Ti3O15 whiskers [J]. Journal of the European Ceramic Society,2015,35(9):2453-2459. doi: 10.1016/j.jeurceramsoc.2015.03.019 [15] GUO W, WANG T, LIN T S, et al. Bismuth borate zinc glass braze for bonding sapphire in air [J]. Materials Characterization,2018,137:67-76. doi: 10.1016/j.matchar.2018.01.002 [16] CHEN H Y, REN X W, GUO W, et al. Microstructures and mechanical properties of brazed Al2O3/Cu joints with bismuth glass [J]. Ceramics International,2019,45(13):16070-16077. doi: 10.1016/j.ceramint.2019.05.123 [17] LIU Y, DONG L L, LU J W, et al. Microstructure and mechanical properties of SiC nanowires reinforced titanium matrix composites [J]. Journal of Alloys and Compounds,2020,819:152953. doi: 10.1016/j.jallcom.2019.152953 [18] 田英良, 孙诗兵. 新编玻璃工艺学 [M]. 北京: 中国轻工业出版社, 2009, 63-78.TIAN Yingliang, SUN Shibing. New glass technology [M]. Beijing: China Light Industry Press, 2009, 63-78. [19] 侯永改, 田久根, 马加加. 纳米氧化锆对金刚石磨具用陶瓷结合剂结构与性能的影响研究 [J]. 硅酸盐学报,2015,34(2):530-534. doi: 10.16552/j.cnki.issn1001-1625.2015.02.025HOU Yongai, TIAN Jiugen, MA Jiajia. Effect of nano-ZrO2 on properties and structure of vitrified bond for diamond grinding tools [J]. Journal of the Chinese Ceramic Society,2015,34(2):530-534. doi: 10.16552/j.cnki.issn1001-1625.2015.02.025 [20] AGARWAL S, RAO P V. A probabilistic approach to predict surface roughness in ceramic grinding [J]. International Journal of Machine Tools & Manufacture: Design, Research and Application,2005,45(6):606-616. doi: 10.1016/j.ijmachtools.2004.10.005 [21] HECHER R L, LIANG S Y. Predictive modeling of surface roughness in grinding [J]. International Journal of Machine Tools & Manufacture: Design, Research and Application,2003,43(8):755-761. doi: 10.1016/S0890-6955(03)00055-5 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS