Effect of multi-arc ion plating process on coating performance of cemented carbide PCB milling cutter

-

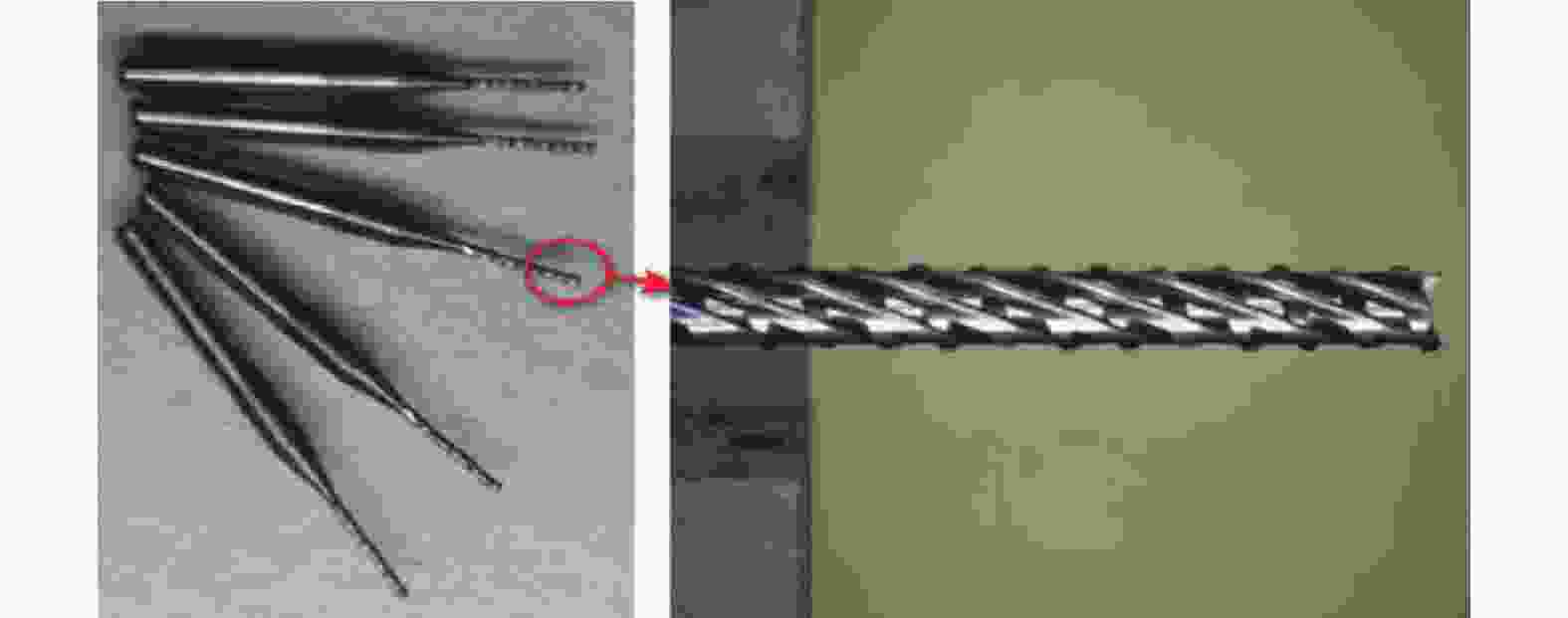

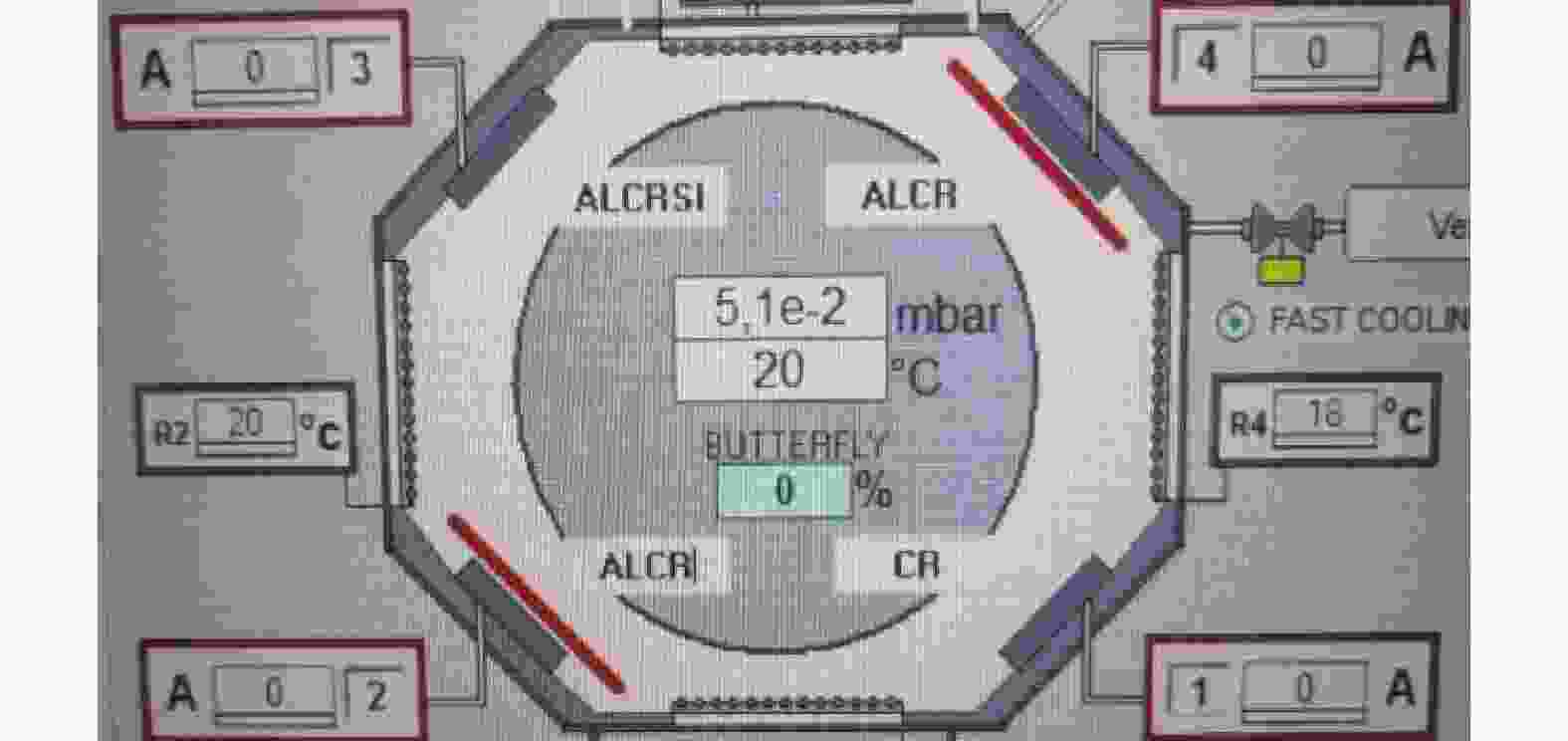

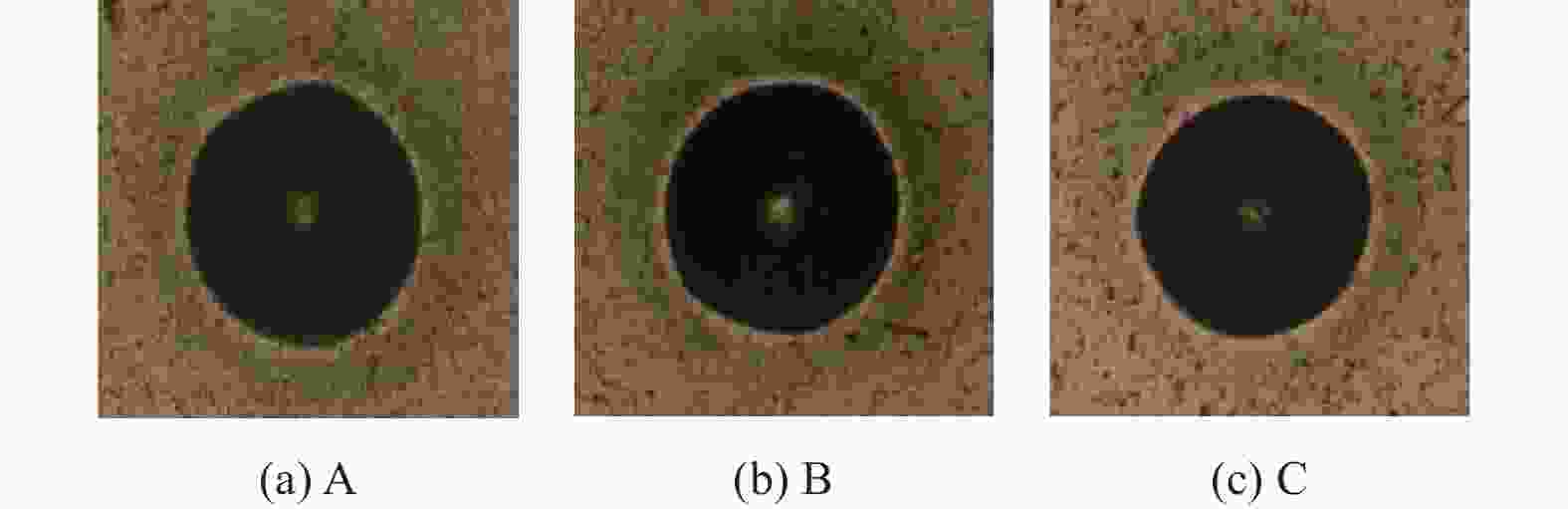

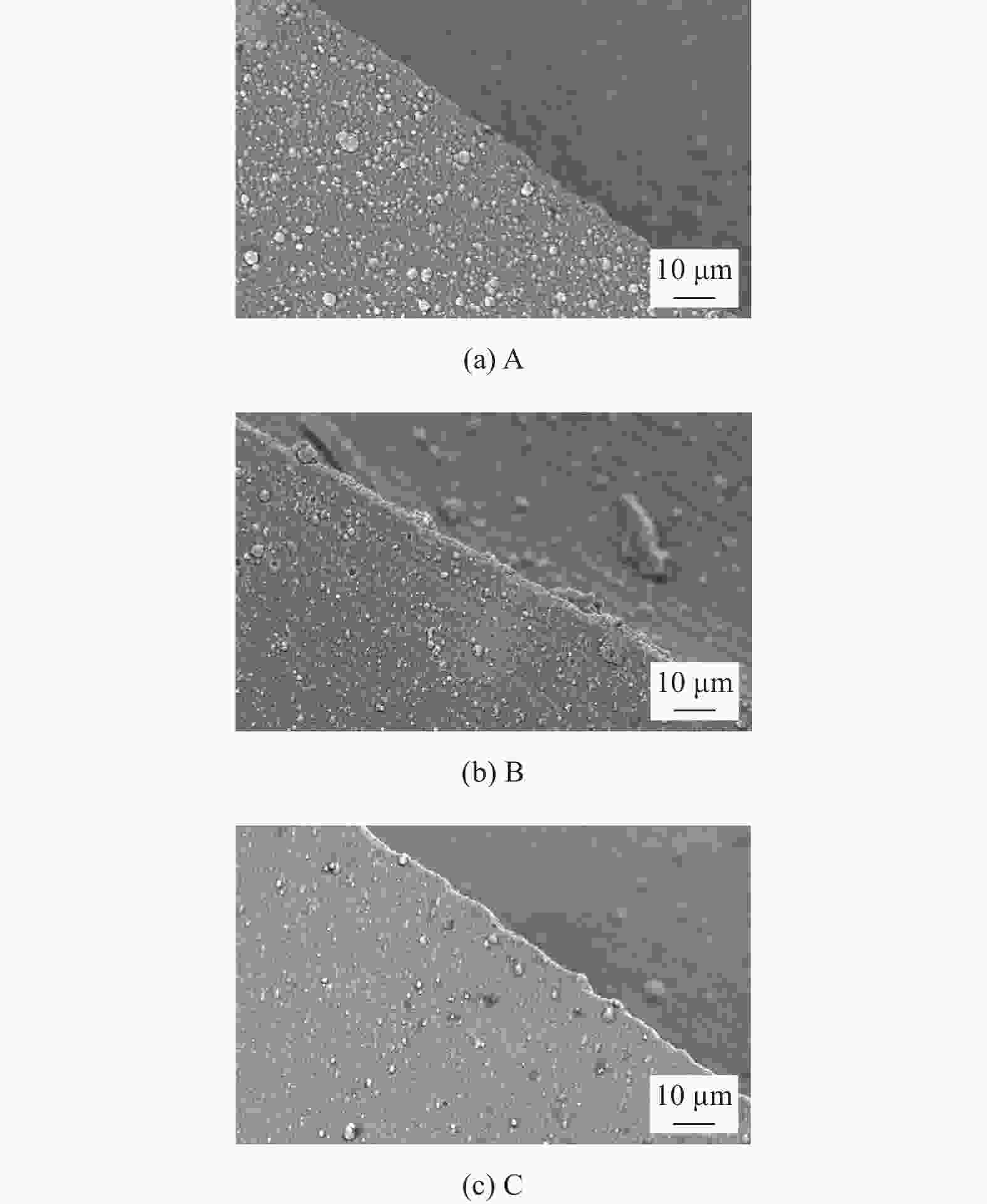

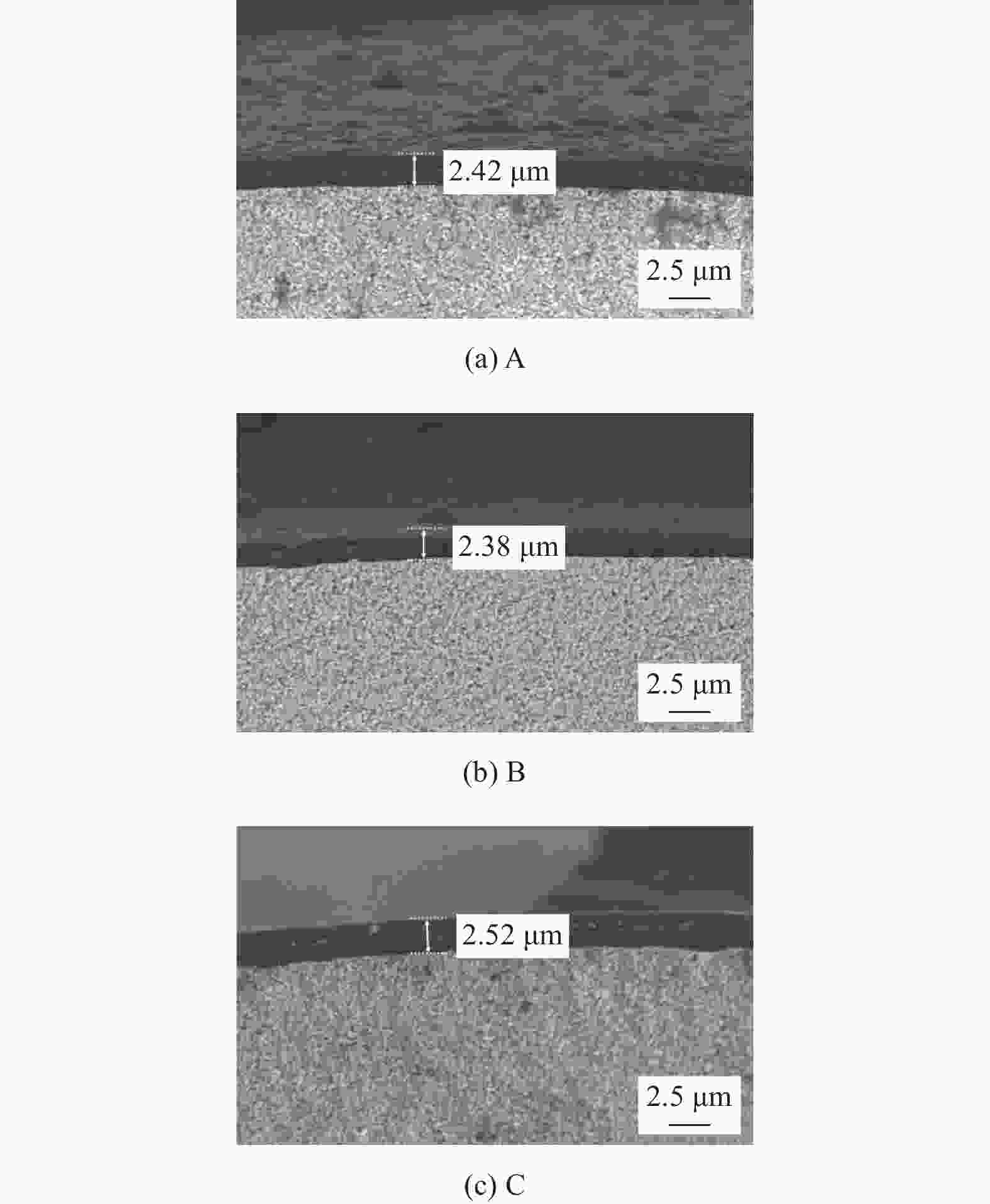

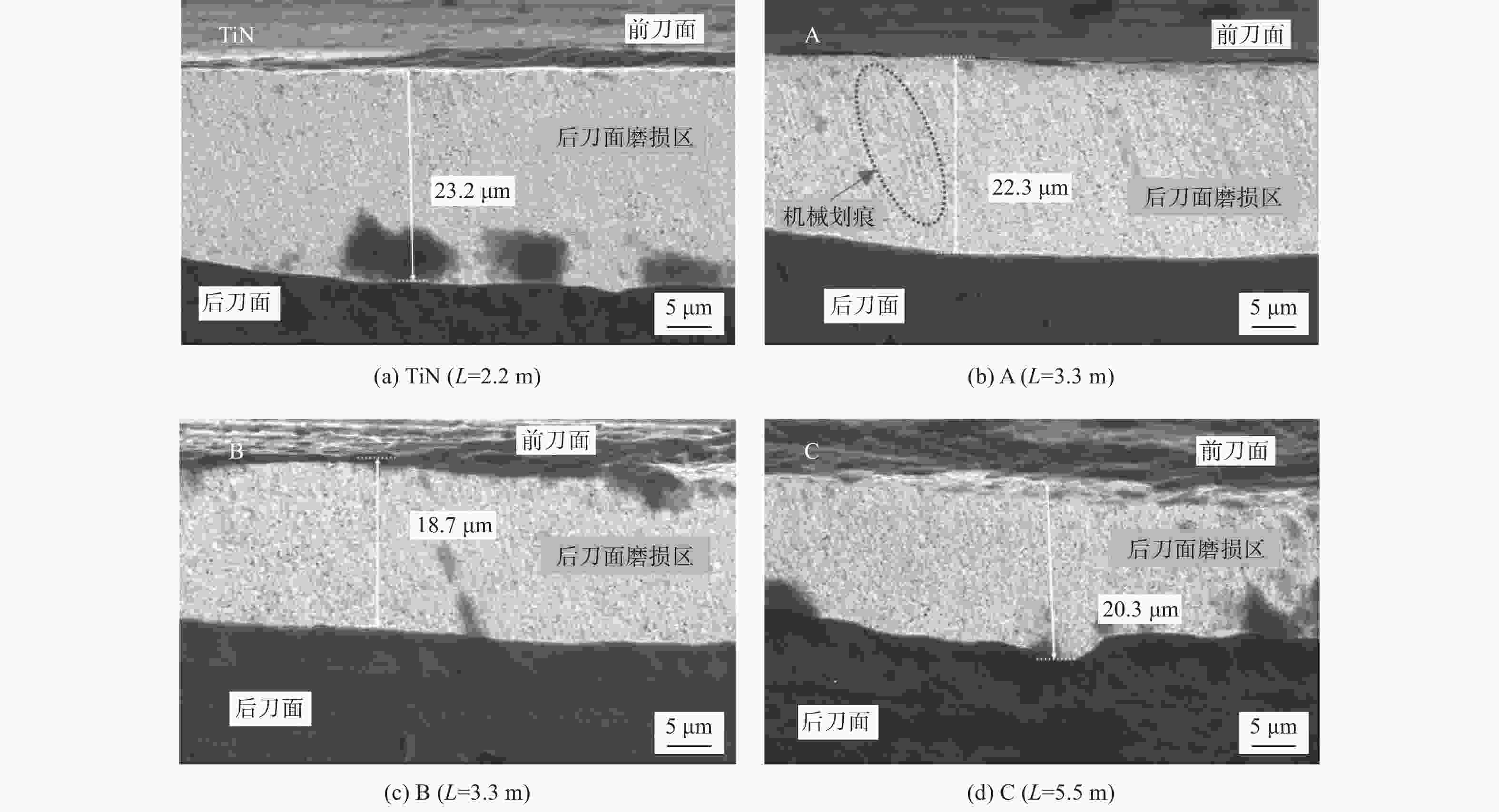

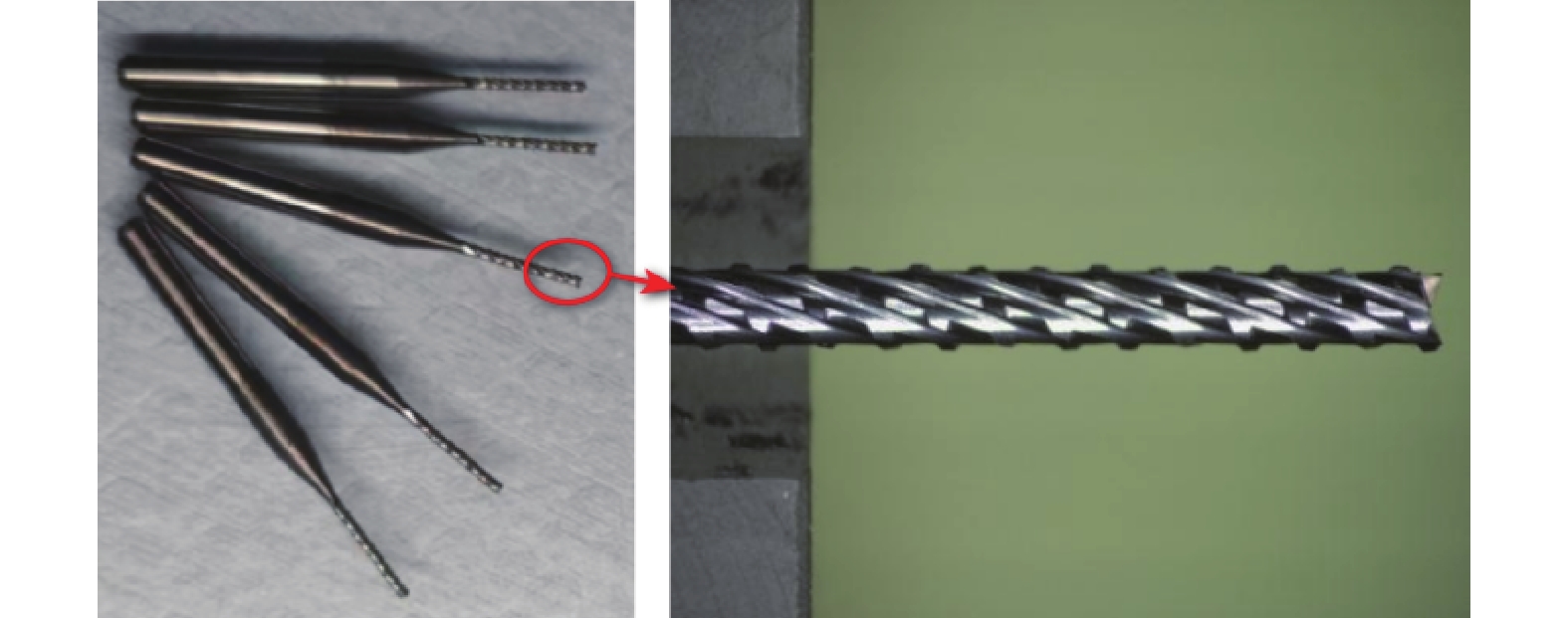

摘要: 在硬质合金PCB(printed circuit board)铣刀表面制备高性能的硬质涂层,可以改善切削过程中刀具快速磨损的问题。采用多弧离子镀涂层技术在YG06硬质合金试片及PCB铣刀基体上分别制备AlCrN单涂层、CrN/AlCrN复合涂层以及AlCrSiN/AlCrN纳米复合涂层,利用压痕仪及扫描电镜分析观察3种涂层的力学性能及形貌特征,且在相同条件下对3种PCB涂层铣刀进行涂层性能对比试验,分析刀具磨损机理。结果表明:3种工艺方案的涂层均有较好的膜基结合力;AlCrSiN/AlCrN纳米复合涂层铣刀使用寿命最长,约为CrN/AlCrN复合涂层铣刀的1.5倍,AlCrN单涂层铣刀的1.9倍;且其涂层的致密性和表面质量最好,更适用于IT158覆铜板的高速切削加工。

-

关键词:

- PCB /

- 多弧离子镀 /

- AlCrSiN/AlCrN纳米复合涂层 /

- 铣削 /

- 刀具寿命

Abstract: The preparation of a high-performance hard coating on the surface of a carbide PCB (Printed Circuit Board) milling cutter can address the issue of rapid tool wear during cutting. In this study, AlCrN single coating, CrN/AlCrN composite coating and AlCrSiN/AlCrN composite coating were prepared on YG06 cemented carbide specimens and PCB milling cutter substrates by a multi-arc ion plating process, respectively. The mechanical properties and morphological characteristics of the three coatings were observed and analyzed using an indenter and a scanning electron microscope. The above three coated milling cutters were tested under the same conditions, and the coating performance and the tool wear mechanism were compared and analyzed. The results show that the coatings prepared by the above three processes exhibit good film-base adhesion, with the AlCrSiN/AlCrN composite coating milling cutter having the longest service life — approximately 1.5 times that of the CrN/AlCrN coating milling cutter and 1.9 times that of the AlCrN single coating milling cutter. The AlCrSiN/AlCrN composite coating demonstrates the best compactness and surface quality, making it more suitable for high-speed machining of PCB (IT158 copper-clad laminate).-

Key words:

- PCB /

- multi-arc ion plating /

- AlCrSiN/AlCrN nano composite coating /

- milling /

- tool life

-

表 1 刀具基体信息表

Table 1. Base parameters of tools

刀具规格

(刃径 ×

刃长 ×

全长)刀具

基体

材料刀具参数 齿数

n螺旋角 (右)

α/(°)圆周前角

β /(°)圆周后角

γ /(°)ϕ1.0 mm×

9.0 mm×

38.1 mmYG06 6 30

−3 15 表 2 沉积工艺参数

Table 2. Deposition process parameters

方

案沉积

时间

t

min工作

压强

p

Pa基体偏压

(负值)

U

VN2

流量

q

cm3/min靶材电流

I

ACr AlCr AlCrSi AlCr A 90 4 40~150 250 150 150 B 60 4 40~150 250 90 150 150 C 60 4 40~150 250 150 200 150 表 3 PCB的铣削加工条件

Table 3. Milling conditions of PCB milling cutter

加工参数 取值 主轴转速 n / (r·min−1) 42×103 行刀速度 vf / (mm·s−1) 4 下刀速度 vd / (m·min−1) 0.3 退刀速度 vt / ( m·min−1) 10 切削深度 ap / mm 6 切削方式 槽铣 冷却方式 气冷 -

[1] 高阳华, 何云, 雷学林. PCB微钻不同金刚石涂层加工性能的研究 [J]. 硬质合金,2018,35(3):202-211.GAO Yanghua, HE Yun, LEI Xuelin. Research on machining properties of different diamond coatings for pcb micro drills [J]. Cemented Carbide,2018,35(3):202-211. [2] LU B Y, MA F, MA D Y. Microstructure and mechanical properties of thick Cr/CrN multilayer coatings by multi-arc ion plating [J]. Rare Metal Materials and Engineering,2022,51(5):1558-1564. [3] 段佳妮, 李文正, 赵春蕾, 等. 多弧离子镀制备TiAlCN和TiAlN涂层的结构和摩擦磨损性能 [J]. 表面技术,2022,51(4):139-148.DUAN Jiani, LI Wenzheng, ZHAO Chunlei, et al. Structure and tribological property of TiAlCN and TiAlN coatings prepared by multi-arc ion plating [J]. Surface Technology,2022,51(4):139-148. [4] 冉龙姣, 郑思婷, 范洪远, 等. 气体离子源辅助电弧离子镀在硬质合金表面制备AlCrN涂层的性能 [J]. 稀有金属与硬质合金,2021,49(6):94-98.RAN Longjiao, ZHENG Siting, FAN Hongyuan, et al. Properties of AlCrN coatings on cemented carbide prepared by arc ion plating assisted by gas ion source [J]. Rare Metals and Cemented Carbides,2021,49(6):94-98. [5] 蔡飞, 高营, 蔡习军, 等. 硬质合金刀具高能离子源增强多弧镀AlCrTiSiN梯度涂层制备及性能研究 [J]. 机械工程学报,2019,55(19):213-220. doi: 10.3901/JME.2019.19.213CAI Fei, GAO Ying, CAI Xijun, et al. Study on preparation and properties of gradient AlCrTiSiN coated cemented carbide tools deposited by ion source enhanced multi-arc ion plating technology [J]. Journal of Mechanical Engineering,2019,55(19):213-220. doi: 10.3901/JME.2019.19.213 [6] 吴雁, 王冰, 王犁, 等. PVD纳米涂层致硬机理研究现状及发展 [J]. 表面技术,2020,49(7):90-97.WU Yan, WANG Bing, WANG Li, et al. Research status and development of hardening mechanism of PVD nano-coatings [J]. Surface Technology,2020,49(7):90-97. [7] 王成勇, 邓阳, 何醒荣, 等. 微细钻铣刀具表面涂层制备及应用研究进展(I) [J]. 硬质合金,2019,36(1):1-13.WANG Chengyong, DENG Yang, HE Xingrong, et al. Fabrication and application research of surface coatings on micro-drills and micro-milling tools (I) [J]. Cemented Carbide,2019,36(1):1-13. [8] 杨小璠, 李友生, 李凌祥, 等. CVD金刚石涂层工艺对硬质合金立铣刀铣削CFRP性能的影响 [J]. 金刚石与磨料磨具工程,2018,38(2):37-41.YANG Xiaofan, LI Yousheng, LI Lingxiang, et al. Influence of CVD diamond coating process on performance of carbide end mill for cutting CFRP [J]. Diamond & Abrasives Engineering,2018,38(2):37-41. [9] 汪鹏, 许昌庆, 蔡飞, 等. 多弧离子镀TiAlSiN梯度涂层制备及切削性能 [J]. 中国表面工程,2019,32(2):34-43.WANG Peng, XU Changqing, CAI Fei, et al. Preparation and machining properties of TiAlSiN gradient coating by multi-arc ion plating [J]. China Surface Engineering,2019,32(2):34-43. [10] WOLFGANG T, MARKUS D. Influence of Si content on mechanical and tribological properties of TiAlSiN PVD coatings at elevated temperatures[J]. Surface & Coatings Technology, 2017: 448-454. [11] MARINA V, ALEXEY V, NIKOLAY A, et al. Improvement of the performance properties of cutting tools using the multilayer composite wear-resistant coatings based on nitrides of Cr, Mo, Zr, Nb, and Al [J]. Materials Today:Proceedings,2021,38(4):1421-1427. [12] SHARMA V, KUMAR M, SHUKLA V N. Tribo-behavior of nano-structured coatings deposited by various techniques: A review [J]. Materials Today:Proceedings,2021,44(6):4097-4101. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS