Preparation of magnetorheological elastomers and their applications in precision machining: A review

-

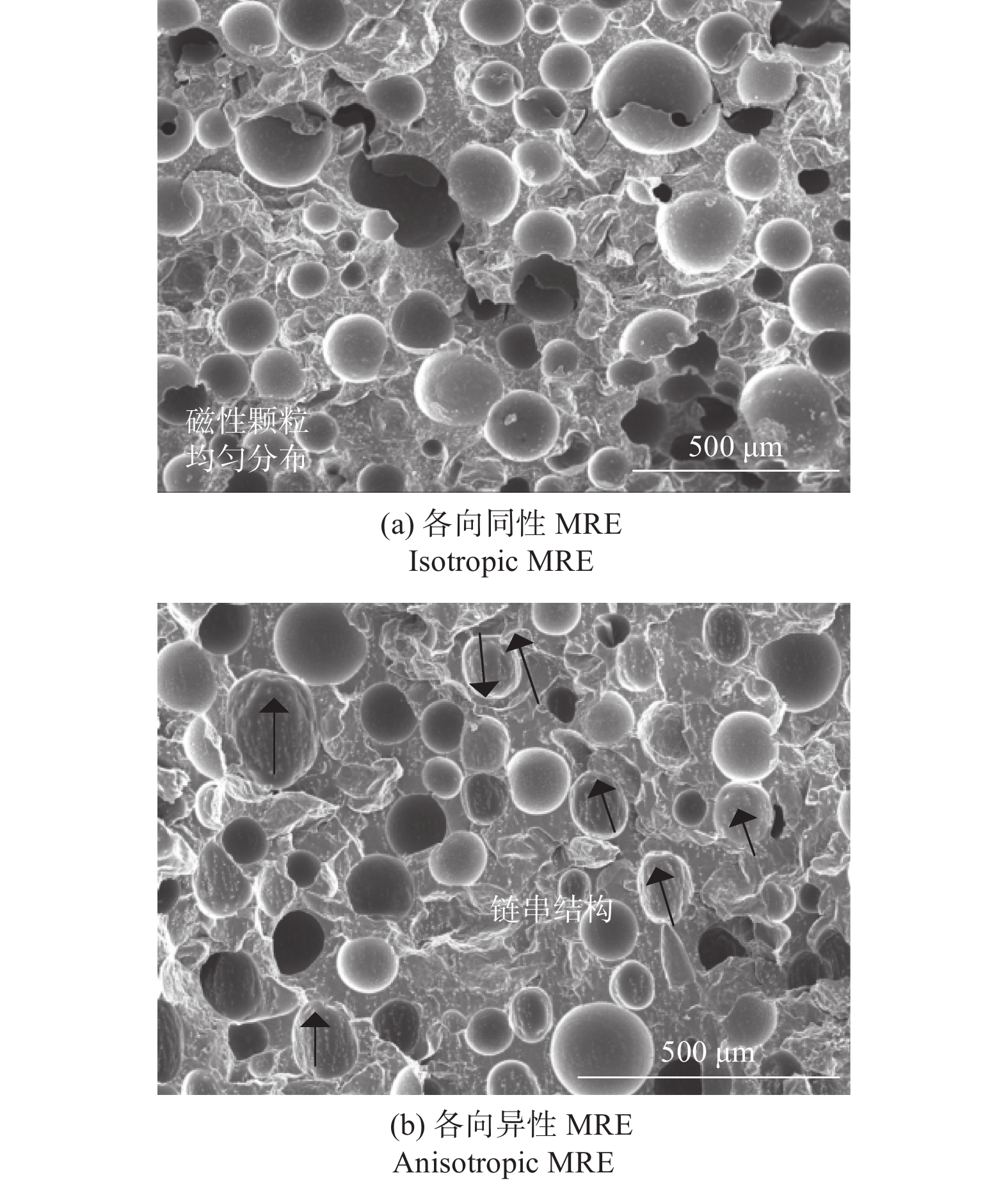

摘要: 磁流变弹性体(magnetorheological elastomer,MRE)是一种磁控智能材料,可通过调节外加磁场强度对其机械性能(如刚度、弹性模量、固有频率、阻尼能力等)进行连续、可逆的控制,在振动控制、机械工程、土木工程等领域得到了广泛的研究和应用。将MRE作为一种磨抛工具,利用磁场改变其刚度等性能来控制磨抛过程的机械去除,有望在精密加工领域得到广泛的应用。本文介绍了MRE的制备材料、制备方法和工艺,分析了外场(磁场和温度场)对MRE性能的影响规律,阐述了基于磁偶极子理论和宏观力学的本构模型,为MRE制备研究和实际工程应用提供指导,综述了MRE在精密加工领域的应用状况和未来发展方向。利用MRE的磁控性能变化可以较好地应用于精密加工,具有很好的发展前景。Abstract: Magnetorheological elastomer (MRE) is a magnetically controlled intelligent material, whose mechanical properties (such as stiffness, elastic modulus, intrinsic frequency, damping capacity, etc.) can be continuously and reversibly controlled by adjusting the strength of the applied magnetic field. It is now widely studied and applied in the fields of vibration control, mechanical engineering, civil engineering, etc. When MRE is made into grinding or polishing tools, the mechanical removal of the process can be controlled by changing the stiffness and other properties of MRE in a magnetic field, which is expected to be widely used in the field of precision machining. In this paper, the materials, the methods and the processes to prepare MRE are introduced, and the influencing rules of external field (including magnetic and temperature fields) on the performance of MRE are analyzed. The intrinsic structure model is described based on magnetic dipole theory and macromechanics, which provides guidance for MRE preparation and practical engineering applications. Besides, the application status and future development direction of MRE in the field of precision machining are reviewed. The variation of magnetically controlled properties using MRE can be better applied to precision machining and has a good development prospect.

-

表 1 部分MRE基体及性能对比

Table 1. Comparison of some MRE substrates and properties

基体类型 性能 参考文献 硅橡胶 600 mT磁场强度下获得了500%的磁流变效应 [8] 硅橡胶 磁流变效应达到1672% [13] 硅橡胶 800 mT磁场强度下储能模量G$ ^\prime $从1增加到420 kPa,磁流变效应达41900% [14] 硅橡胶 剪切模量提高20%,压缩模量提高25% [26] 聚氨酯、硅橡胶 磁流变效应达到99.8% [27] 聚氨酯 磁流变效应达到100% [28] 聚氨酯 含CIPs的MRE拉伸应力增加758% [29] 聚氨酯、环氧树脂 形成IPN结构,磁流变效应达691% [15] 聚氨酯海绵骨架 磁流变效应达到820% [18,30] 聚氨酯、环氧树脂 形成IPN结构,磁流变效应为200% [16] 天然橡胶 磁流变效应达到67% [22] 天然橡胶 磁流变效应为34.85% [31] 天然橡胶 磁流变效应为392%,损耗因子为0.14 [32] 天然橡胶 通过磁性颗粒包覆制备出更高的MRE储能模量和损耗模量 [33] 聚二甲基硅氧烷 弹性模量为55.7 kPa的MRE对应的磁流变效应高达17286% [34] 聚二甲基硅氧烷 磁流变效应为55% [35] 丁苯橡胶、丁腈橡胶

以及丙烯腈磁流变效应达到50% [23-24] -

[1] JAAFAR M F, MUSTAPHA F, MUSTAPHA M. Review of current research progress related to magnetorheological elastomer material [J]. Journal of Materials Research and Technology,2021,15:5010-5045. doi: 10.1016/j.jmrt.2021.10.058 [2] BASTOLA A K, PAUDEL M, Li L, et al. Recent progress of magnetorheological elastomers: A review [J]. Smart Materials and Structures,2020,29(12):123002. doi: 10.1088/1361-665X/abbc77 [3] KHANOUKI M A, SEDAGHATI R, HEMMATIAN M. Multidisciplinary design optimization of a novel sandwich beam-based adaptive tuned vibration absorber featuring magnetorheological elastomer [J]. Materials,2020,13(10):2261. doi: 10.3390/ma13102261 [4] GU X, YU Y, LI Y, et al. Experimental study of semi-active magnetorheological elastomer base isolation system using optimal neuro fuzzy logic control [J]. Mechanical Systems and Signal Processing,2019,119:380-398. doi: 10.1016/j.ymssp.2018.10.001 [5] ALKHALAF A, HOOSHIAR A, DARGAHI J. Composite magnetorheological elastomers for tactile displays: Enhanced MR-effect through bi-layer composition [J]. Composites Part B: Engineering,2020,190:107888. doi: 10.1016/j.compositesb.2020.107888 [6] SHIGA T, OKADA A, KURAUCHI T. Magnetroviscoelastic behavior of composite gels [J]. Journal of Applied Polymer Science,1995,4(58):787-792. [7] DO X P, CHOI S B. A state-of-the-art on smart materials actuators over the last decade: Control aspects for diverse applications [J]. Smart Materials and Structures,2022,31(5):53001. doi: 10.1088/1361-665X/ac5b1e [8] 李剑锋, 龚兴龙, 张先舟, 等. 硅橡胶基磁流变弹性体的研制 [J]. 功能材料,2006,37(6):1003-1005,1012. doi: 10.3321/j.issn:1001-9731.2006.06.046LI Jianfeng, GONG Xinglong, ZHANG Xianzhou, et al. Research on magnetorheological elastomer based on silicone rubber [J]. Journal of Functional Materials,2006,37(6):1003-1005,1012. doi: 10.3321/j.issn:1001-9731.2006.06.046 [9] YOON J H, LEE S W, BAE S H, et al. Effect of alignment of magnetic particles on the rheological properties of natural rubber composite [J]. Journal of Polymer Research,2021,28(10):1-7. [10] ENTEZAM M, ZAREI I, KHONAKDAR H A. Effect of accelerator solubility on the curing characteristics and physico-mechanical properties of SBR/NBR blends: Correlation with feeding sequence and blend composition [J]. Polymer Bulletin,2022,79:1501-1519. [11] CHEN K, REN Q, LI J, et al. A highly stretchable and self-healing hydroxy-terminated polybutadiene elastomer [J]. Journal of Saudi Chemical Society,2020,24(12):1034-1041. doi: 10.1016/j.jscs.2020.11.002 [12] XIE A, MAO S W, CHEN T J, et al. Microstructure and properties of cerium oxide/polyurethane elastomer composites [J]. Rare Metals,2021,40:3685-3693. doi: 10.1007/s12598-021-01714-3 [13] DARGAHI A, SEDAGHATI R, RAKHEJA S. On the properties of magnetorheological elastomers in shear mode: Design, fabrication and characterization [J]. Composites Part B: Engineering,2019,159:269-283. doi: 10.1016/j.compositesb.2018.09.080 [14] CHERTOVICH A V, STEPANOV G V, KRAMARENKO E Y, et al. New composite elastomers with giant magnetic response [J]. Macromolecular Materials and Engineering,2010,295(4):336-341. doi: 10.1002/mame.200900301 [15] 游仕平, 曾德长, 游世辉, 等. 硅橡胶基尼龙帘线增强型磁敏橡胶的研究 [J]. 弹性体,2011,21(1):1-5. doi: 10.3969/j.issn.1005-3174.2011.01.001YOU Shiping, ZENG Dechang, YOU Shihui, et al. Study on the nylon cord reinforced magnetorheological rubber based on the silicone rubber [J]. China Elastomerics,2011,21(1):1-5. doi: 10.3969/j.issn.1005-3174.2011.01.001 [16] QI S, YU M, FU J, et al. Stress relaxation behavior of magnetorheological elastomer: Experimental and modeling study [J]. Journal of Intelligent Material Systems and Structures,2017,29:205-213. [17] YU M, QI S, FU J, et al. A high-damping magnetorheological elastomer with bi-directional magnetic-control modulus for potential application in seismology [J]. Applied Physics Letters,2015,107(11):111901. doi: 10.1063/1.4931127 [18] GE L, GONG X, WANG Y, et al. The conductive three dimensional topological structure enhanced magnetorheological elastomer towards a strain sensor [J]. Composites Science and Technology,2016,135:92-99. doi: 10.1016/j.compscitech.2016.09.015 [19] JU B X, YU M, FU J, et al. A novel porous magnetorheological elastomer: Preparation and evaluation [J]. Smart Materials and Structures,2012,21(3):35001. doi: 10.1088/0964-1726/21/3/035001 [20] JU B, TANG R, ZHANG D, et al. Temperature-dependent dynamic mechanical properties of magnetorheological elastomers under magnetic field [J]. Journal of Magnetism and Magnetic Materials,2015,374:283-288. doi: 10.1016/j.jmmm.2014.08.012 [21] JU B X, YU M, FU J, et al. Study on the properties of porous magnetorheological elastomers under shock effect [J]. Journal of Physics: Conference Series,2013,412:12039. [22] TAO Y, RUI X, YANG F, et al. Design and experimental research of a magnetorheological elastomer isolator working in squeeze/elongation-shear mode [J]. Journal of Intelligent Material Systems and Structures,2018,29(7):1418-1429. doi: 10.1177/1045389X17740436 [23] LOKANDER M, STENBERG B. Improving the magnetorheological effect in isotropic magnetorheological rubber materials [J]. Polymer Testing,2003,22(6):677-680. doi: 10.1016/S0142-9418(02)00175-7 [24] LOKANDER M, STENBERG B. Performance of isotropic magnetorheological rubber materials [J]. Polymer Testing,2003,22(3):245-251. doi: 10.1016/S0142-9418(02)00043-0 [25] YUNUS N A, MAZLAN S A, Ubaidillah, et al. Thermal stability and rheological properties of epoxidized natural rubber-based magnetorheological elastomer [J]. International Journal of Molecular Sciences,2019,20(3):746. doi: 10.3390/ijms20030746 [26] LENG D, WU T, LIU G, et al. Tunable isolator based on magnetorheological elastomer in coupling shear–squeeze mixed mode [J]. Journal of Intelligent Material Systems and Structures,2018,29(10):2236-2248. doi: 10.1177/1045389X18758205 [27] BICA I, ANITAS E M, AVERIS L M E. Tensions and deformations in composites based on polyurethane elastomer and magnetorheological suspension: Effects of the magnetic field [J]. Journal of Industrial and Engineering Chemistry,2015,28:86-90. doi: 10.1016/j.jiec.2015.02.003 [28] KOZLOWSKA J, BOCZKOWSKA A, CZULAK A, et al. Novel MRE/CFRP sandwich structures for adaptive vibration control [J]. Smart Materials and Structures,2016,25(3):35025. doi: 10.1088/0964-1726/25/3/035025 [29] ELÍAS-ZÚñIGA A, PALACIOS-PINEDA L M, PERALES-MARTÍNEZ I A, et al. Investigating the mullins effect and energy dissipation in magnetorheological polyurethane elastomers [J]. International Journal of Molecular Sciences,2020,21(15):5318. doi: 10.3390/ijms21155318 [30] 葛琳. 三维网状结构增强磁流变弹性体的研究 [D]. 合肥: 中国科学技术大学, 2016.GE Lin. Study on three dimensional structure enchanced magnetorheological elastomer [D]. Hefei: University of Science and Technology of China, 2016. [31] SHI G, WANG W, LU H, et al. Study of crosslink structure and dynamic mechanical properties of magnetorheological elastomer: Effect of vulcanization system [J]. Journal of Intelligent Material Systems and Structures,2019,30(8):1189-1199. doi: 10.1177/1045389X19835940 [32] 陈琳. 磁流变弹性体的研制及其力学行为的表征[D]. 合肥: 中国科学技术大学, 2009.CHEN Lin. The development and mechanical characterization of magnetorheological elastomers [D]. Hefei: University of Science and Technology of China, 2009. [33] AN J S, KWON S H, CHOI H J, et al. Modified silane-coated carbonyl iron/natural rubber composite elastomer and its magnetorheological performance [J]. Composite Structures,2017,160:1020-1026. doi: 10.1016/j.compstruct.2016.10.128 [34] YAO J, SUN Y, WANG Y, et al. Magnet-induced aligning magnetorheological elastomer based on ultra-soft matrix [J]. Composites Science and Technology,2018,162:170-179. doi: 10.1016/j.compscitech.2018.04.036 [35] WINGER J, SCHÜMANN M, KUPKA A, et al. Influence of the particle size on the magnetorheological effect of magnetorheological elastomers [J]. Journal of Magnetism and Magnetic Materials,2019,481:176-182. doi: 10.1016/j.jmmm.2019.03.027 [36] MITSUMATA T, FURUKAWA K, JULIAC E, et al. Compressive modulus of ferrite containing polymer gels [J]. International Journal of Modern Physics B,2002,16(17/18):2419-2425. [37] MASUD M, BREZNAK C, LOCKETTE P, et al. On the electric and magnetic alignment of magnetoactive barium hexaferrite-PDMS composites [J]. International Society for Optics and Photonics,2017,10165:1016513. [38] KRAMARENKO E Y, CHERTOVICH A V, STEPANOV G V, et al. Magnetic and viscoelastic response of elastomers with hard magnetic filler [J]. Smart Materials and Structures,2015,24(3):35002. doi: 10.1088/0964-1726/24/3/035002 [39] PADALKA O, SONG H J, WERELEY N M, et al. Stiffness and damping in Fe, Co, and Ni nanowire-based magnetorheological elastomeric composites [J]. IEEE Transactions on Magnetics,2010,46(6):2275-2277. doi: 10.1109/TMAG.2010.2044759 [40] HAPIPI N, AZIZ S A A, MAZLAN S A, et al. The field-dependent rheological properties of plate-like carbonyl iron particle-based magnetorheological elastomers [J]. Results in Physics,2019,12:2146-2154. doi: 10.1016/j.rinp.2019.02.045 [41] JOLLY M R, CARLSON J D, MUñOZ B C, et al. The magnetoviscoelastic response of elastomer composites consisting of ferrous particles embedded in a polymer matrix [J]. Journal of Intelligent Material Systems and Structures,1996,7(6):613-622. doi: 10.1177/1045389X9600700601 [42] XU Y, GONG X, XUAN S, et al. A high-performance magnetorheological material: Preparation, characterization and magnetic-mechanic coupling properties [J]. Soft Matter,2011,7(11):5246. doi: 10.1039/c1sm05301a [43] CHEN D, YU M, ZHU M, et al. Carbonyl iron powder surface modification of magnetorheological elastomers for vibration absorbing application [J]. Smart Materials and Structures,2016,25(11):115005. doi: 10.1088/0964-1726/25/11/115005 [44] CHOI S, CHUNG K, KWON S, et al. Effect of surface treated magneto-responsible particle on the property of magneto-rheological elastomer based on silicone rubber [J]. Elastomers and Composites,2016,51(2):113-121. doi: 10.7473/EC.2016.51.2.113 [45] LI J, GONG X, ZHU H, et al. Influence of particle coating on dynamic mechanical behaviors of magnetorheological elastomers [J]. Polymer Testing,2009,28(3):331-337. doi: 10.1016/j.polymertesting.2009.01.008 [46] YU M, QI S, FU J, et al. Understanding the reinforcing behaviors of polyaniline-modified carbonyl iron particles in magnetorheological elastomer based on polyurethane/epoxy resin IPNs matrix [J]. Composites Science and Technology,2017,139:36-46. doi: 10.1016/j.compscitech.2016.12.010 [47] KHAIRI M H A, FATAH A Y A, MAZLAN S A, et al. Enhancement of particle alignment using silicone oil plasticizer and its effects on the field-dependent properties of magnetorheological elastomers [J]. International Journal of Molecular Sciences,2019,20(17):4085. doi: 10.3390/ijms20174085 [48] LI Y, LI J, LI W, et al. A state-of-the-art review on magnetorheological elastomer devices [J]. Smart Materials and Structures,2014,23(12):123001. doi: 10.1088/0964-1726/23/12/123001 [49] CHEN L, GONG X L, LI W H. Effect of carbon black on the mechanical performances of magnetorheological elastomers [J]. Polymer Testing,2008,27(3):340-345. doi: 10.1016/j.polymertesting.2007.12.003 [50] RAJHAN N H, HAMID H A, AZMI I, et al. Experimental study on mechanical properties of magnetorheological elastomer [J]. Journal Teknologi,2016,78:33-37. [51] 汪建晓, 孟光. 磁流变弹性体研究进展 [J]. 功能材料,2006,37(5):706-709. doi: 10.3321/j.issn:1001-9731.2006.05.009WANG Jianxiao, MENG Guang. Research progress In magnetorheological elastomers [J]. Journal of Functional Materials,2006,37(5):706-709. doi: 10.3321/j.issn:1001-9731.2006.05.009 [52] BASTOLA A K, HOANG V T, LI L. A novel hybrid magnetorheological elastomer developed by 3D printing [J]. Materials & Design,2017,114:391-397. [53] QI S, GUO H, FU J, et al. 3D printed shape-programmable magneto-active soft matter for biomimetic applications [J]. Composites Science and Technology,2020,188:107973. doi: 10.1016/j.compscitech.2019.107973 [54] KANIA A, BERENT K, MAZUR T, et al. 3D printed composites with uniform distribution of Fe3O4 nanoparticles and magnetic shape anisotropy [J]. Additive Manufacturing,2021,46:102149. doi: 10.1016/j.addma.2021.102149 [55] WOODS B K S, WERELEY N, HOFFMASTER R, et al. Manufacture of bulk magnetorheological elastomers using vacuum assisted resin transfer molding [J]. International Journal of Modern Physics B,2007,21(28/29):5010-5017. [56] GAO T, XIE R, CHUNG K. Microstructure and dynamic mechanical properties of magnetorheological elastomer based on ethylene/acrylic elastomer prepared using different manufacturing methods [J]. Micro & Nano Letters,2018,13(7):1026-1030. [57] 胡达. 单晶SiC磁流变弹性抛光垫制备及其抛光特性研究 [D]. 广州: 广东工业大学, 2022.HU Da. Preparation and Polishing Characteristics of Magnetorheological Elastic Polishing Pad for Single-crystal [D]. Guangzhou: Guangdong University of Technology, 2022. [58] WEN Q, SHEN L, LI J, et al. Temperature dependent magneto-mechanical properties of magnetorheological elastomers [J]. Journal of Magnetism and Magnetic Materials,2020,497:165998. doi: 10.1016/j.jmmm.2019.165998 [59] BERASATEGI J, SALAZAR D, GOMEZ A, et al. Anisotropic behaviour analysis of silicone/carbonyl iron particles magnetorheological elastomers [J]. Rheologica Acta,2020,59(7):469-476. doi: 10.1007/s00397-020-01218-4 [60] ROSENSWEIG R E. Directions in ferrohydrodynamics (invited) [J]. Journal of Applied Physics. 1985, 57(8): 4259-4264. [61] JOLLY M R, CARLSON J D, MUñOZ B C. A model of the behaviour of magnetorheological materials [J]. Smart Materials and Structures,1996,5(5):607-614. doi: 10.1088/0964-1726/5/5/009 [62] LANOTTE L, AUSANIO G, HISON C, et al. Particle dimension effects on magnetization and strain sensitivity for a composite of nickel particles in silicone matrix [J]. Journal of Magnetism and Magnetic Materials, 2004, 272–276, Part 2: 1533-1535. [63] LANOTTE L, AUSANIO G, IANNOTTI V, et al. Influence of particle pre-orientation on elastomagnetic effect in a composite material of ellipsoidal Ni microparticles in a silicone matrix [J]. Applied Physics A:Materials Science & Processing,2003,77(7):953-958. [64] LANOTTE L, AUSANIO G, HISON C, et al. The potentiality of composite elastic magnets as novel materials for sensors and actuators [J]. Sensors and Actuators A-Physical,2003,106(1–3):56-60. [65] YIN H M, SUN L Z. Magnetoelasticity of chain-structured ferromagnetic composites [J]. Applied Physics Letters,2005,86(26):261901. doi: 10.1063/1.1954895 [66] YIN H M, SUN L Z. Magnetoelastic modelling of composites containing randomly dispersed ferromagnetic particles [J]. Philosophical Magazine,2006,86(28):4367-4395. doi: 10.1080/14786430600724421 [67] COQUELLE E, BOSSIS G, SZABO D, et al. Micromechanical analysis of an elastomer filled with particles organized in chain-like structure [J]. Journal of Materials Science,2006,41(18):5941-5953. doi: 10.1007/s10853-006-0329-8 [68] STEPANOV G V, BORIN D Y, RAIKHER Y L, et al. Motion of ferroparticles inside the polymeric matrix in magnetoactive elastomers [J]. Journal of Physics: Condensed Matter,2008,20(20):204121. doi: 10.1088/0953-8984/20/20/204121 [69] KALETA J, KRÓLEWICZ M, LEWANDOWSKI D. Magnetomechanical properties of anisotropic and isotropic magnetorheological composites with thermoplastic elastomer matrices [J]. Smart Materials and Structures,2011,20(8):85006. doi: 10.1088/0964-1726/20/8/085006 [70] BILLER A M, STOLBOV O V, RAIKHER Y L. Modeling of particle interactions in magnetorheological elastomers [J]. Journal of Applied Physics,2014,116(11):114904. doi: 10.1063/1.4895980 [71] SHEN Y, GOLNARAGHI M F, HEPPLER G R. Experimental research and modeling of magnetorheological elastomers [J]. Journal of Intelligent Material Systems and Structures,2004,15(1):27-35. doi: 10.1177/1045389X04039264 [72] DANAS K, KANKANALA S V, TRIANTAFYLLIDIS N. Experiments and modeling of iron-particle-filled magnetorheological elastomers [J]. Journal of the Mechanics and Physics of Solids,2012,60(1):120-138. doi: 10.1016/j.jmps.2011.09.006 [73] HAN Y, HONG W, FAIDLEY L E. Field-stiffening effect of magneto-rheological elastomers [J]. International Journal of Solids and Structures,2013,50(14–15):2281-2288. [74] ZHU Y, GONG X, DANG H, et al. Numerical analysis on magnetic-induced shear modulus of magnetorheological elastomers based on multi-chain model [J]. Chinese Journal of Chemical Physics,2006,19(2):126-130. doi: 10.1360/cjcp2006.19(2).126.5 [75] 王奇, 董旭峰, 李芦钰, 等. 磁流变弹性体松弛行为的本构描述 [J]. 复合材料学报,2013,30(s1):138-141. doi: 10.13801/j.cnki.fhclxb.2013.s1.037WANG Qi, DONG Xufeng, LI Luyu, et al. Constitutive description for relaxation behavior of magnetorheological elastomer [J]. Journal of Composites,2013,30(s1):138-141. doi: 10.13801/j.cnki.fhclxb.2013.s1.037 [76] CHEN S W, LI R, ZHANG Z, et al. Micromechanical analysis on tensile modulus of structured magneto-rheological elastomer [J]. Smart Materials and Structures,2016,25(3):35001. doi: 10.1088/0964-1726/25/3/035001 [77] 朱俊涛, 徐赵东. 基于分数阶导数的磁流变弹性体参数模型 [J]. 工程力学,2012,29(8):45-49+79. doi: 10.6052/j.issn.1000-4750.2010.10.0779ZHU Juntao, XU Zhaodong. The parameter model of magnetorheological elastomers based on fractional derivatives [J]. Engineering Mechanics,2012,29(8):45-49+79. doi: 10.6052/j.issn.1000-4750.2010.10.0779 [78] GUO F, DU C, LI R. Viscoelastic parameter model of magnetorheological elastomers based on abel dashpot [J]. Advances in Mechanical Engineering,2014,6:629386. doi: 10.1155/2014/629386 [79] WANG J, WAN Y, SHI C, et al. Rigidity controllable polishing tool based on magnetorheological effect [C]. Bellingham: Proceedings of SPIE - The International Society for Optical Engineering, 2012. [80] 徐志强, 易理银, 张高峰, 等. 磁流变弹性体砂轮抛光镍基高温合金GH4169表面完整性研究 [J]. 宇航材料工艺,2020,50(5):51-57.XU Zhiqiang, YI Liyin, ZHANG Gaofeng, et al. Surface integrity of polishing nickel-based superalloys with magnetorheological elastomer grinding wheel [J]. Aerospace Materials Process,2020,50(5):51-57. [81] 易理银. 镍基高温合金磨削及其磁流变弹性体抛光试验研究 [D]. 湘潭: 湘潭大学, 2020.YI Liyin. Experimental study on grinding of nickel-based superalloy and polishing of magnetorheological elastomer [D]. Xiangtan: Xiangtan University, 2020. [82] XU Z, WANG J, WU H, et al. Effect of abrasive particles on mechanical properties of magnetorheological elastomer [J]. Polymers for Advanced Technologies,2021,32(2):630-640. doi: 10.1002/pat.5116 [83] XU Z, WANG Q, ZHU K, et al. Preparation and characterization of magnetorheological elastic polishing composites [J]. Journal of Intelligent Material Systems and Structures,2019,30(10):1481-1492. doi: 10.1177/1045389X19835960 [84] CHEN Y, HUANG W, ZHANG Y, et al. Novel high efficiency deterministic polishing method using magnetorheological elastomer [J]. Smart Materials and Structures,2020,29(11):114008. doi: 10.1088/1361-665X/abb989 [85] HU D, DENG J, LU J, et al. A study of the magneto-controlled mechanical properties and polishing performance for single-crystal SiC used as a magnetorheological-elastomer polishing pad [J]. Smart Materials and Structures,2022,31(3):35021. doi: 10.1088/1361-665X/ac4db6 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS