Analysis on the technology of preparing diamond tools by FDMS

-

摘要:

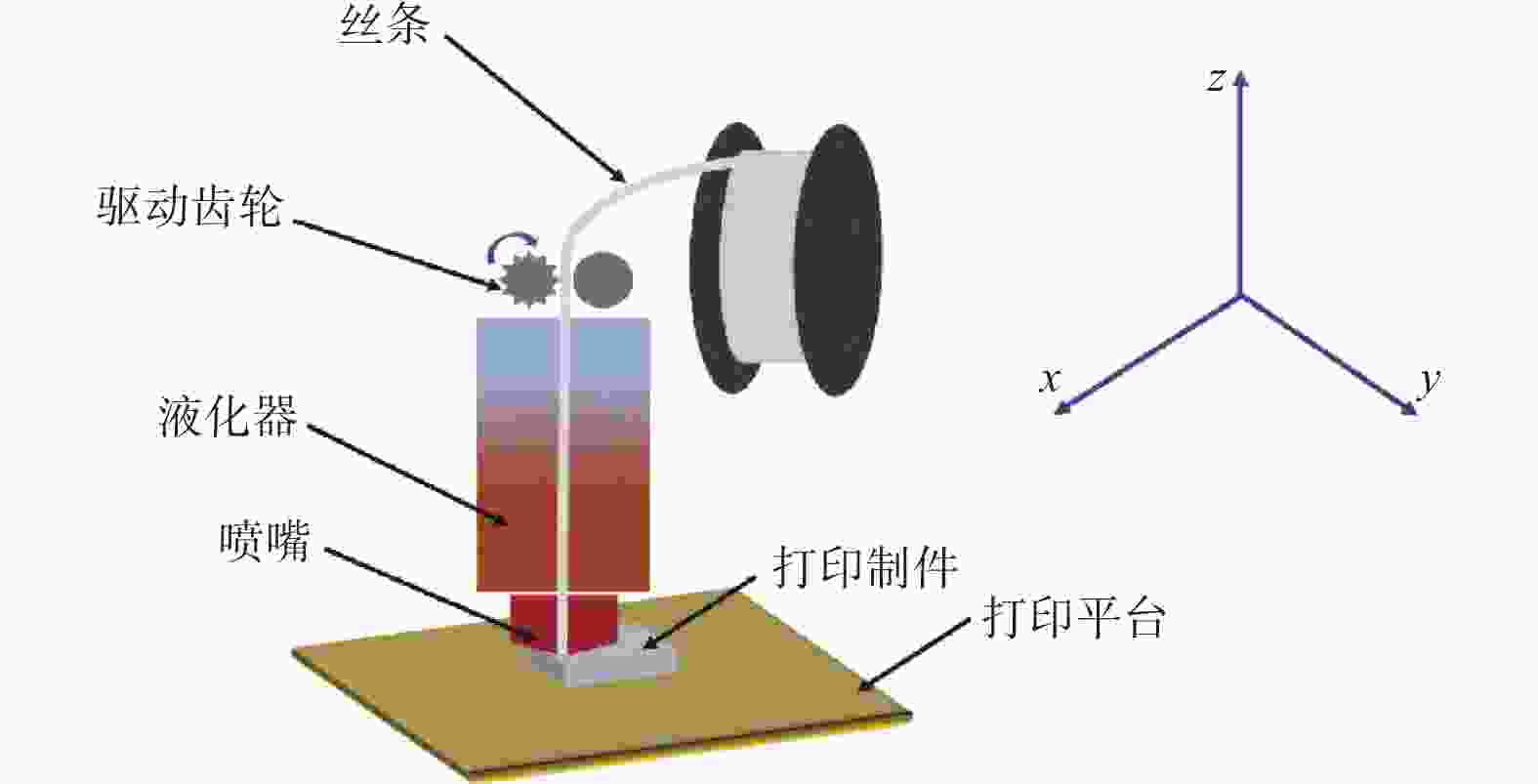

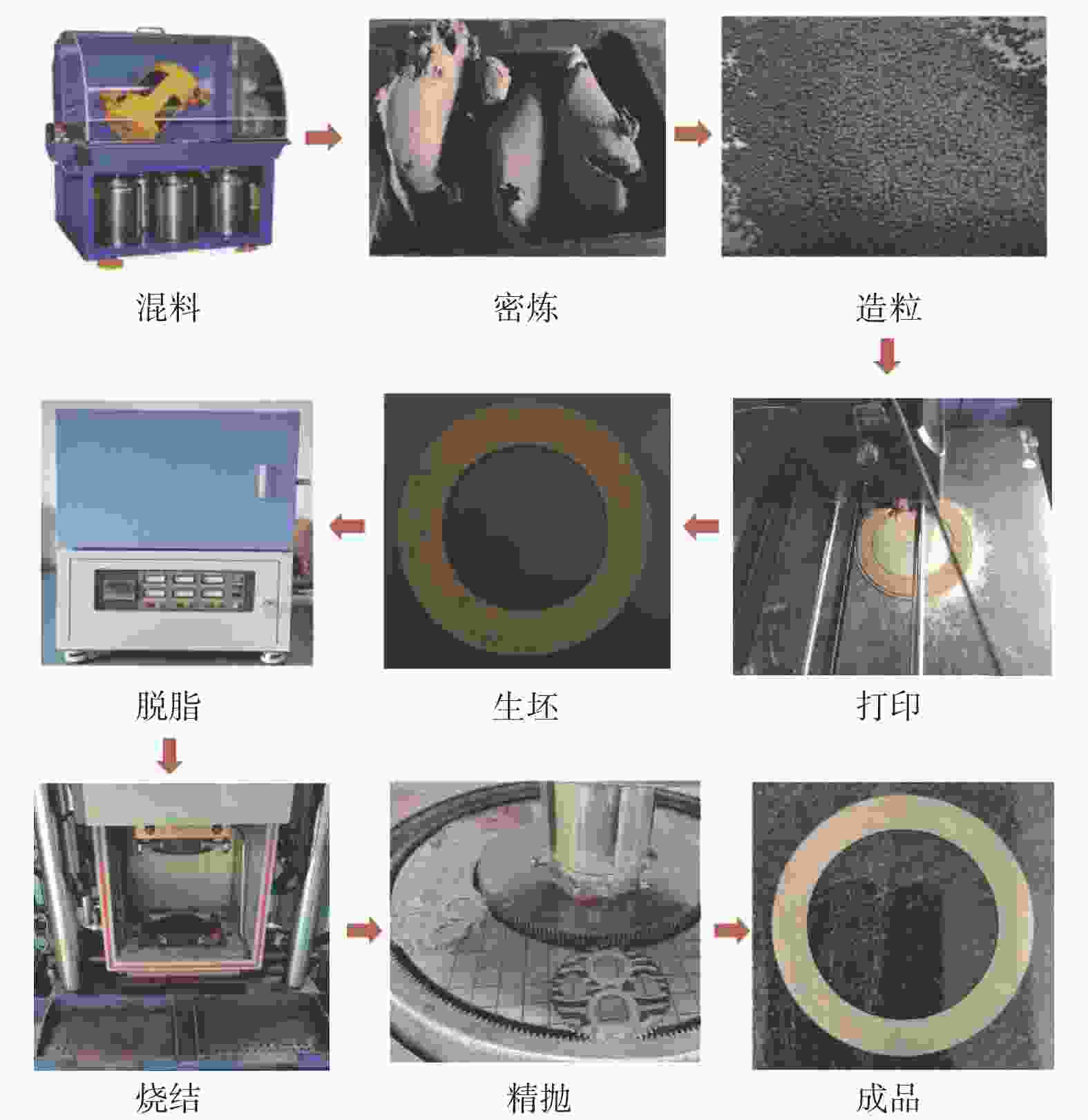

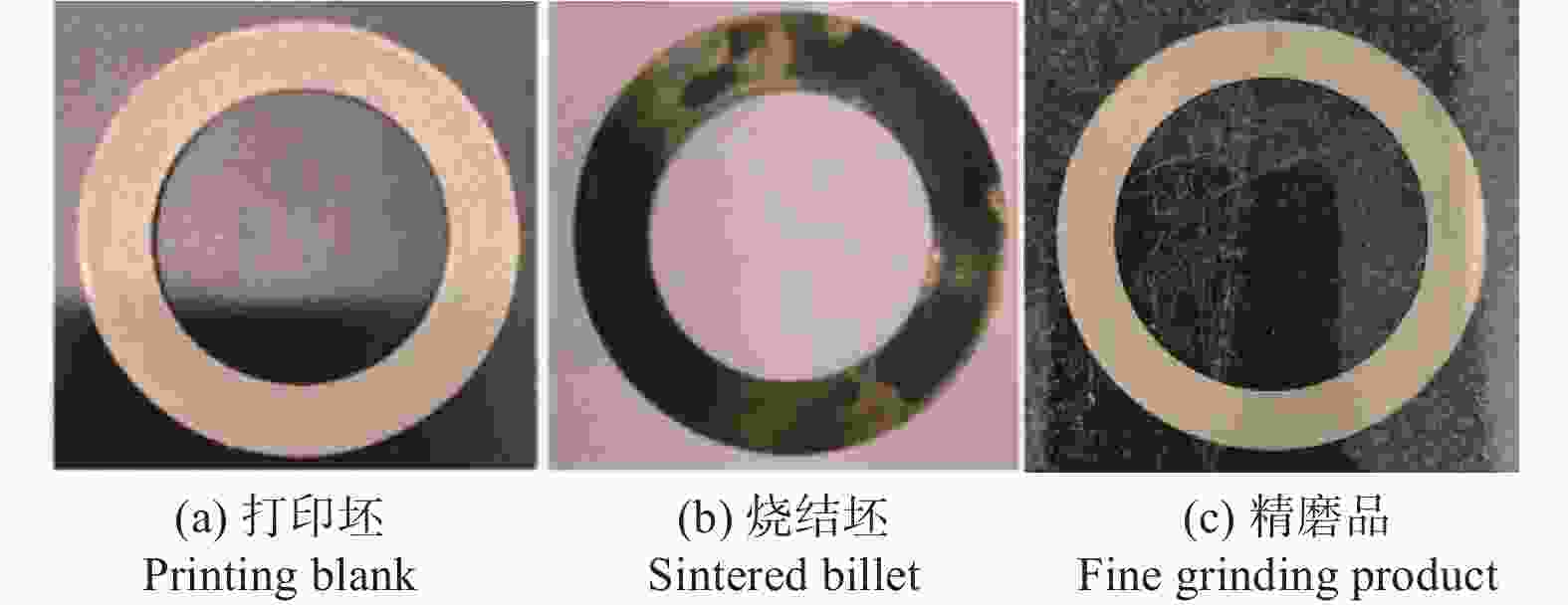

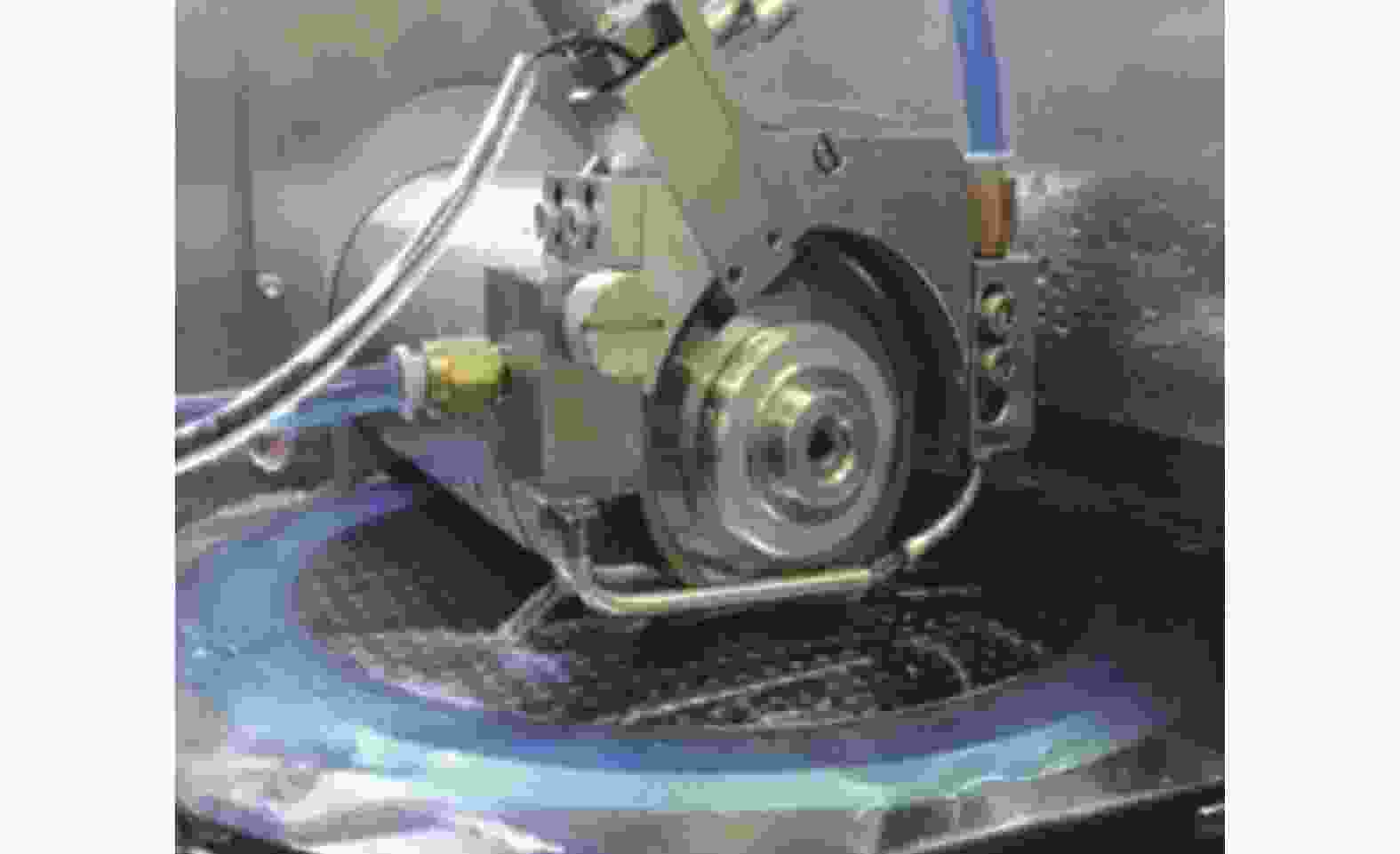

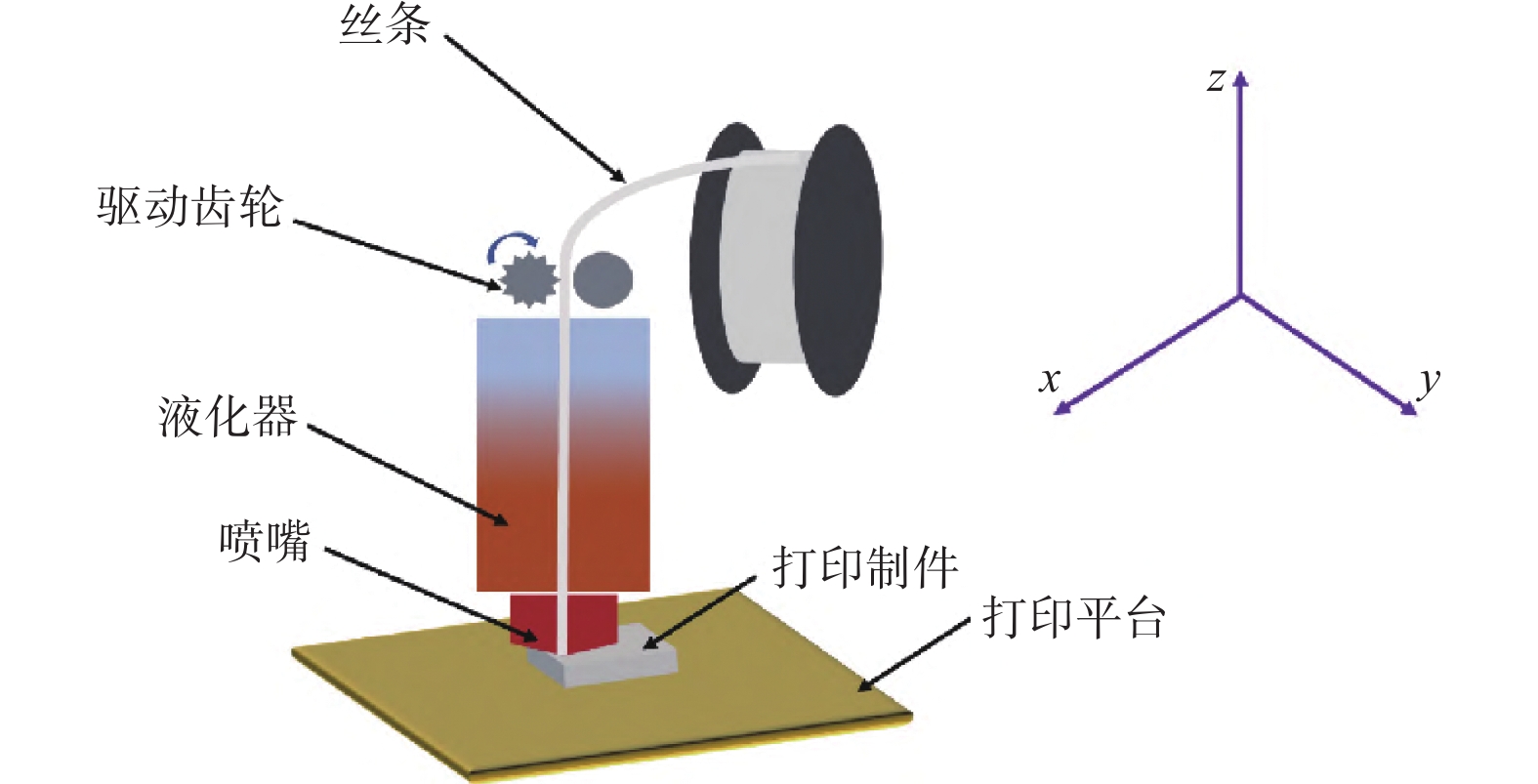

近些年,熔融沉积成形烧结(fused deposition modeling sintering,FDMS)技术迅猛发展,由于其具有能耗低、打印稳定性高、成形设备价格低廉和操作简单等优点,在金刚石工具的制造中具有巨大的发展潜力。对FDMS工艺制备金刚石工具的技术可行性进行了分析,系统论述了FDMS技术的制备工艺流程、打印参数优选以及打印设备优化设计等内容,列举了FDMS制造金刚石超薄片的研究成果,指出了FDMS技术在制造金刚石工具中的关键问题,并对其发展进行了展望。

-

关键词:

- 3D打印 /

- 熔融沉积成形烧结技术 /

- 金刚石工具 /

- 打印参数优选 /

- 设备优化

Abstract:The fused deposition modeling sintering (FDMS) technology has developed rapidly in recent years and has a great potential for development in the manufacture of diamond tools because of its advantages of low energy consumption, high printing stability, low cost of forming equipment and simple operation. The technical feasibility of preparing diamond tools by FDMS technology is analyzed. The preparation process flow, the printing parameter optimization and the printing equipment optimization design of FDMS technology are systematically discussed. The research results of manufacturing diamond ultra-thin blades by FDMS are listed. The key problems of FDMS technology in manufacturing diamond tools are pointed out, and its development is prospected.

-

[1] 张绍和. 金刚石与金刚石工具 [M]. 长沙: 中南大学出版社, 2005.ZHANG Shaohe. Diamond and diamond tools [M]. Changsha: Central South University Press, 2005. [2] 孙子文. 金属材料增材制造技术应用现状及发展趋势 [J]. 广东科技,2021,30(8):4. doi: 10.3969/j.issn.1006-5423.2021.08.029SUN Ziwen. Application status and development trend of additive manufacturing technology for metal materials [J]. Guangdong Science & Technology,2021,30(8):4. doi: 10.3969/j.issn.1006-5423.2021.08.029 [3] GIBSON I, ROSEN D, STUCKER B. Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing, second edition [M]. New York: Springer US, 2015. [4] CV A, MMT B, SSH C, et al. Fused deposition modelling: Current status, methodology, applications and future prospects [J]. Additive Manufacturing, 2021, 47:102378. [5] 冯淑莹, 张慧梅. 浅论熔融沉积成型工艺的研究进展 [J]. 科学技术创新,2020(24):177-178.FENG Shuying, ZHANG Huimei. Discussion on the research progress of melt deposition forming process [J]. Scientific and Technological Innovation,2020(24):177-178. [6] 张云鹤, 黄景銮, 宋运运, 等. 3D打印金刚石工具的研究进展 [J]. 金刚石与磨料磨具工程,2021,41(3):40-47. doi: 10.13394/j.cnki.jgszz.2021.3.0006ZHANG Yunhe, HUANG Jingluan, SONG Yunyun, et al. Research progress of 3D printing diamond tools [J]. Diamond & Abrasives Engineering,2021,41(3):40-47. doi: 10.13394/j.cnki.jgszz.2021.3.0006 [7] 曾光, 韩志宇, 梁书锦, 等. 金属零件3D打印技术的应用研究 [J]. 中国材料进展,2014,33(6):376-382.ZENG Guang, HAN Zhiyu, LIANG Shujin, et al. The applications and progress of manufacturing of metal parts by 3D printing technology [J]. Materials China,2014,33(6):376-382. [8] BANDYOPADHYAY A, ZHANG Y N, BOSE S. Recent developments in metal additive manufacturing [J]. Current Opinion in Chemical Engineering,2020,28:96-104. doi: 10.1016/j.coche.2020.03.001 [9] 林梓威. 高分子金属复合材料3D打印成型机理及工艺研究 [D]. 广州: 华南理工大学, 2019.LIN Ziwei. Study on 3D printing mechanism and process of polymer metal composites [D]. Guangzhou: South China University of Technology, 2019. [10] SWAPNIL V, SOHAM T, DEEPAK P, et al. Fused deposition modelling: A review [J]. Rapid Prototyping Journal,2020,26(1):176-201. doi: 10.1108/RPJ-04-2019-0106 [11] WANG S, MA Y, DENG Z, et al. Effects of fused deposition modeling process parameters on tensile, dynamic mechanical properties of 3D printed polylactic acid materials [J]. Polymer Testing, 2020, 86: 106483. [12] 杨钦杰, 李佳汶, 李明, 等. 熔融沉积3D打印设备研究进展 [J]. 中国塑料,2022,36(2):157-171.YANG Qinjie, LI Jiawen, LI Ming, et al. Research progress in fused deposition modeling 3D printing equipment [J]. China Plastics,2022,36(2):157-171. [13] 刘斌, 王玉香, 林梓威, 等. 316L/POM复合材料FDM成型件成型质量的研究 [J]. 塑料科技,2020,48(4):32-35. doi: 10.15925/j.cnki.issn1005-3360.2020.04.008LIU Bin, WANG Yuxiang, LIN Ziwei, et al. Research on forming quality of 316L/POM composite parts fabricated by fused deposition modeling [J]. Plastics Science and Technology,2020,48(4):32-35. doi: 10.15925/j.cnki.issn1005-3360.2020.04.008 [14] 张绍和, 苏舟, 刘磊磊, 等. SLS和FDMS制造超薄金刚石锯片对比研究 [J]. 金刚石与磨料磨具工程,2021,41(1):38-43. doi: 10.13394/j.cnki.jgszz.2021.1.0007ZHANG Shaohe, SU Zhou, LIU Leilei, et al. Comparative study on ultra-thin diamond saw blades made by SLS and FDMS [J]. Diamond & Abrasives Engineering,2021,41(1):38-43. doi: 10.13394/j.cnki.jgszz.2021.1.0007 [15] 王延庆, 沈竞兴, 吴海全. 3D打印材料应用和研究现状 [J]. 航空材料学报,2016,36(4):89-98. doi: 10.11868/j.issn.1005-5053.2016.4.013WANG Yanqing, SHEN Jingxing, WU Haiquan. Application and research status of alternative materials for 3D-printing technology [J]. Journal of Aeronautical Materials,2016,36(4):89-98. doi: 10.11868/j.issn.1005-5053.2016.4.013 [16] 孙聚杰. 3D打印材料及研究热点 [J]. 丝网印刷,2013(12):34-39.SUN Jujie. 3D printing materials and research hotspots [J]. Screen Printing,2013(12):34-39. [17] ZHANG P, WANG Z, LI J, et al. From materials to devices using fused deposition modeling: A state-of-art review [J]. Nanotechnology Reviews,2020,9(1):1594-1609. doi: 10.1515/ntrev-2020-0101 [18] GEBISA A W, LEMU H G. Influence of 3D printing FDM process parameters on tensile property of ULTEM 9085-sciencedirect [J]. Procedia Manufacturing,2019,30:331-338. doi: 10.1016/j.promfg.2019.02.047 [19] MOHAMED O, MASOOD S, BHOWMIK J. Optimization of fused deposition modeling process parameters: A review of current research and future prospects [J]. Advances in Manufacturing, 2015, 3(1): 42–53. [20] NIDAGUNDI V B, KESHAVAMURTHY R, PRAKASH C. Studies on parametric optimization for fused deposition modelling process [J]. Materials Today Proceedings,2015,2(4/5):1691-1699. [21] 董伟, 杨向东. 基于FDM的大尺寸薄壁类3D打印件硬度的工艺分析与研究 [J]. 塑料工业,2018,46(2):23-26. doi: 10.3969/j.issn.1005-5770.2018.02.006DONG Wei, YANG Xiangdong. Process analysis and research on hardness of large-sized and thin-walled 3D printing based on FDM [J]. China Plastics Industry,2018,46(2):23-26. doi: 10.3969/j.issn.1005-5770.2018.02.006 [22] DEY A, YODO N. A systematic survey of FDM process parameter optimization and their influence on part characteristics [J]. Journal of Manufacturing and Materials Processing,2019,3(3):64. doi: 10.3390/jmmp3030064 [23] MONTERO M, ROUNDY S, DAN O, et al. Material characterization of fused deposition modeling (FDM) ABS by designed experiments [J]. Society of Manufacturing Engineers, 2001, 10(13552540210441166): 1-21. [24] RUBEN K. A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters [J]. Open Engineering,2021,11(1):639-649. doi: 10.1515/eng-2021-0063 [25] 雷芳, 孟鑫沛, 张俊平, 等. 针对柔性材料的FDM型3D打印机的远程送料机构研究与设计 [J]. 装备制造技术, 2018(9): 128-130 , 157.LEI Fang, MENG Xinpei, ZHANG Junping, et al. Research and design of remote feeding mechanism for FDM 3D printer with flexible materials [J]. Equipment Manufacturing Technology, 2018(9): 128-130, 157. [26] 王春香, 张辉. FDM型3D打印机喷头结构的进展 [J]. 塑料,2021,50(3):93-98.WANG Chunxiang, ZHANG Hui. Development progress of FDM 3D printer nozzle structure [J]. Plastics,2021,50(3):93-98. [27] 李吉康. 熔融沉积式3D打印机喷头结构及常见问题分析 [J]. 南方农机,2018,49(13):181. doi: 10.3969/j.issn.1672-3872.2018.13.138LI Jikang. Analysis of nozzle structure and common problems of melt deposition 3D printer [J]. China Southern Agricultural Machinery,2018,49(13):181. doi: 10.3969/j.issn.1672-3872.2018.13.138 [28] 杨娜娜, 田玉琢, 白耀仙, 等. 基于PLA材料的FDM打印结构与性能的关系研究 [J]. 广东化工,2021,48(16):34-36. doi: 10.3969/j.issn.1007-1865.2021.16.015YANG Nana, TIAN Yuzhuo, BAI Yaocan, et al. Research on the relationship between FDM printing structure and performance based on PLA material [J]. Guangdong Chemical Industry,2021,48(16):34-36. doi: 10.3969/j.issn.1007-1865.2021.16.015 [29] 朱黎立, 周敏, 高强, 等. FDM 3D打印机喷头温度场分析与结构优化 [J]. 组合机床与自动化加工技术,2018(8):18-22 , 28.ZHU Lili, ZHOU Min, GAO Qiang, et al. FDM 3D printer nozzle temperature field analysis and structure optimization [J]. Modular Machine Tool & Automatic Manufacturing Technique,2018(8):18-22 , 28. [30] 唐庆瑞, 毕俊喜, 代志功, 等. FDM成型系统喷头温度控制方法研究 [J]. 机械研究与应用,2018,31(3):179-181. doi: 10.16576/j.cnki.1007-4414.2018.03.058TANG Qingrui, BI Junxi, DAI Zhigong, et al. Research on spray head temperature control of FDM molding system [J]. Mechanical Research & Application,2018,31(3):179-181. doi: 10.16576/j.cnki.1007-4414.2018.03.058 [31] 程雨, 罗福源, 刘传义. 基于OpenSceneGraph的3D打印切片软件的设计 [J]. 机械与电子,2019,37(12):3-8.CHENG Yu, LUO Fuyuan, LIU Chuanyi. Design of slicing software for 3D printing based on openscenegraph [J]. Machinery & Electronics,2019,37(12):3-8. [32] DEZAKI M L, ARIFFIN M K, SERJOUEI A, et al. Influence of infill patterns generated by CAD and FDM 3D printer on surface roughness and tensile strength properties [J]. Applied Sciences,2021,11(16):7272. doi: 10.3390/app11167272 [33] KUN K. Reconstruction and development of a 3D printer using FDM technology [J]. Procedia Engineering, 2016, 149: 203-211.. [34] TONG K, LEHTIHET E A, JOSHI S. Software compensation of rapid prototyping machines [J]. Precision Engineering,2004,28(3):280-292. doi: 10.1016/j.precisioneng.2003.11.003 [35] WASSERFALL F, HENDRICH N, ZHANG J. Adaptive slicing for the FDM process revisited, Xi'an, Aug 20-23, 2017 [C]. Trivandrum: IEEE Robotics and Automation Society, 2017: 49-54. [36] 苏舟. 制造超薄金刚石锯片的FDMS工艺研究 [D]. 长沙: 中南大学, 2022.SU Zhou. Research on FDMS process for manufacturing ultra-thin diamond saw blades [D]. Changsha: Central South University, 2022. -

下载:

下载:

邮件订阅

邮件订阅 RSS

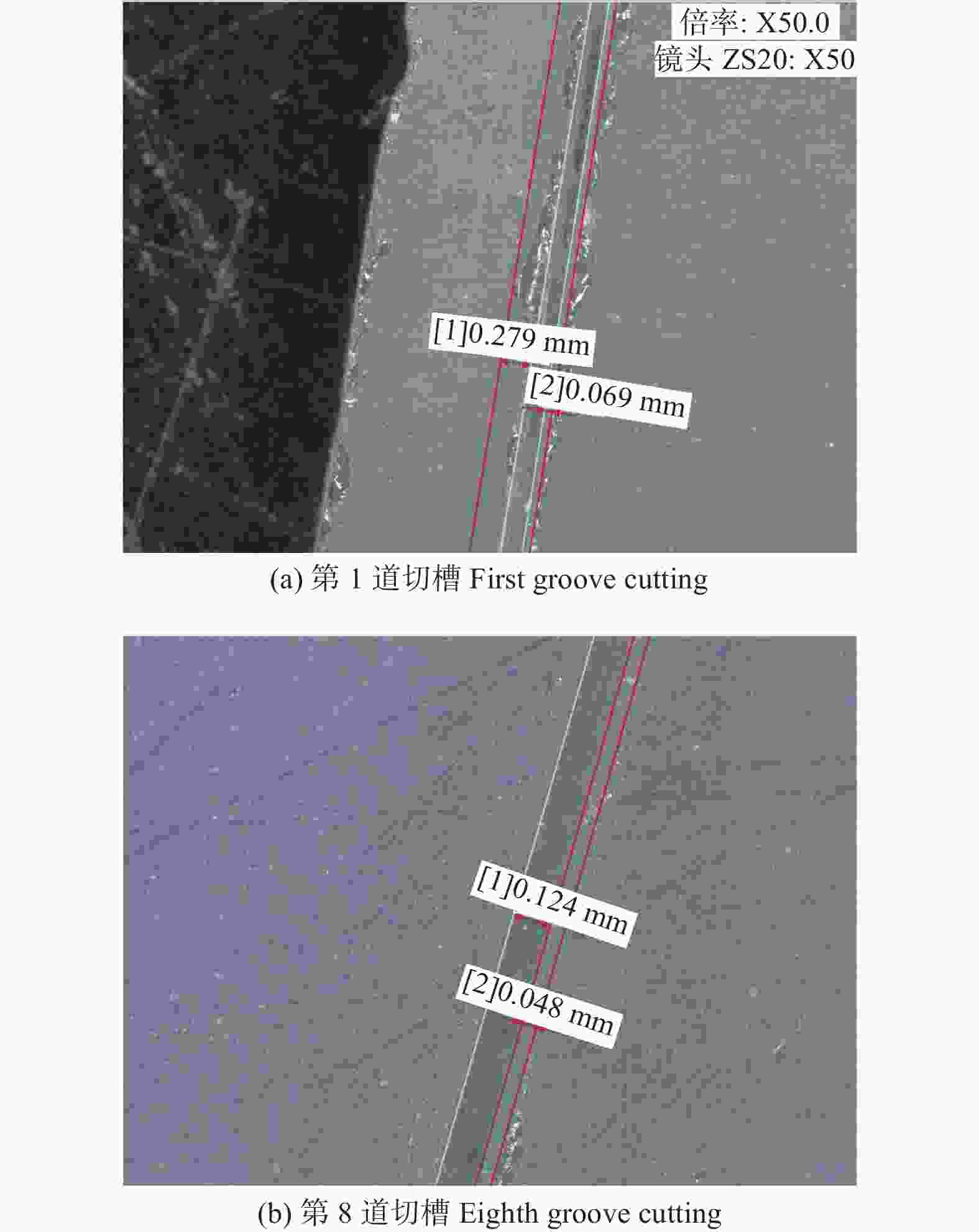

RSS