Effect of Cr on microstructure and properties of brazed diamond with Ni-based boron free solder

-

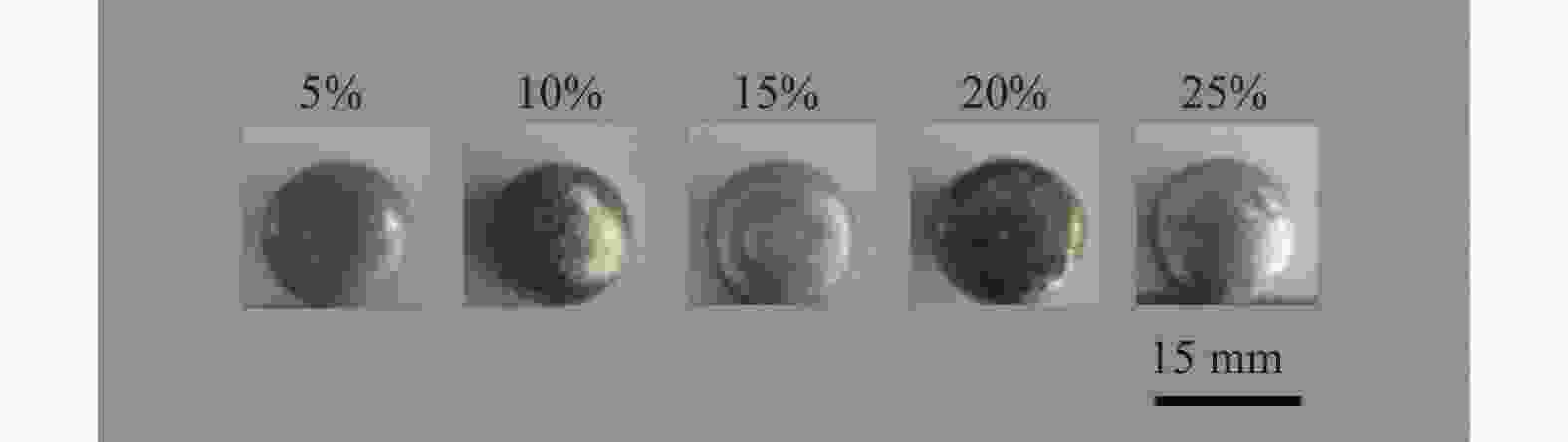

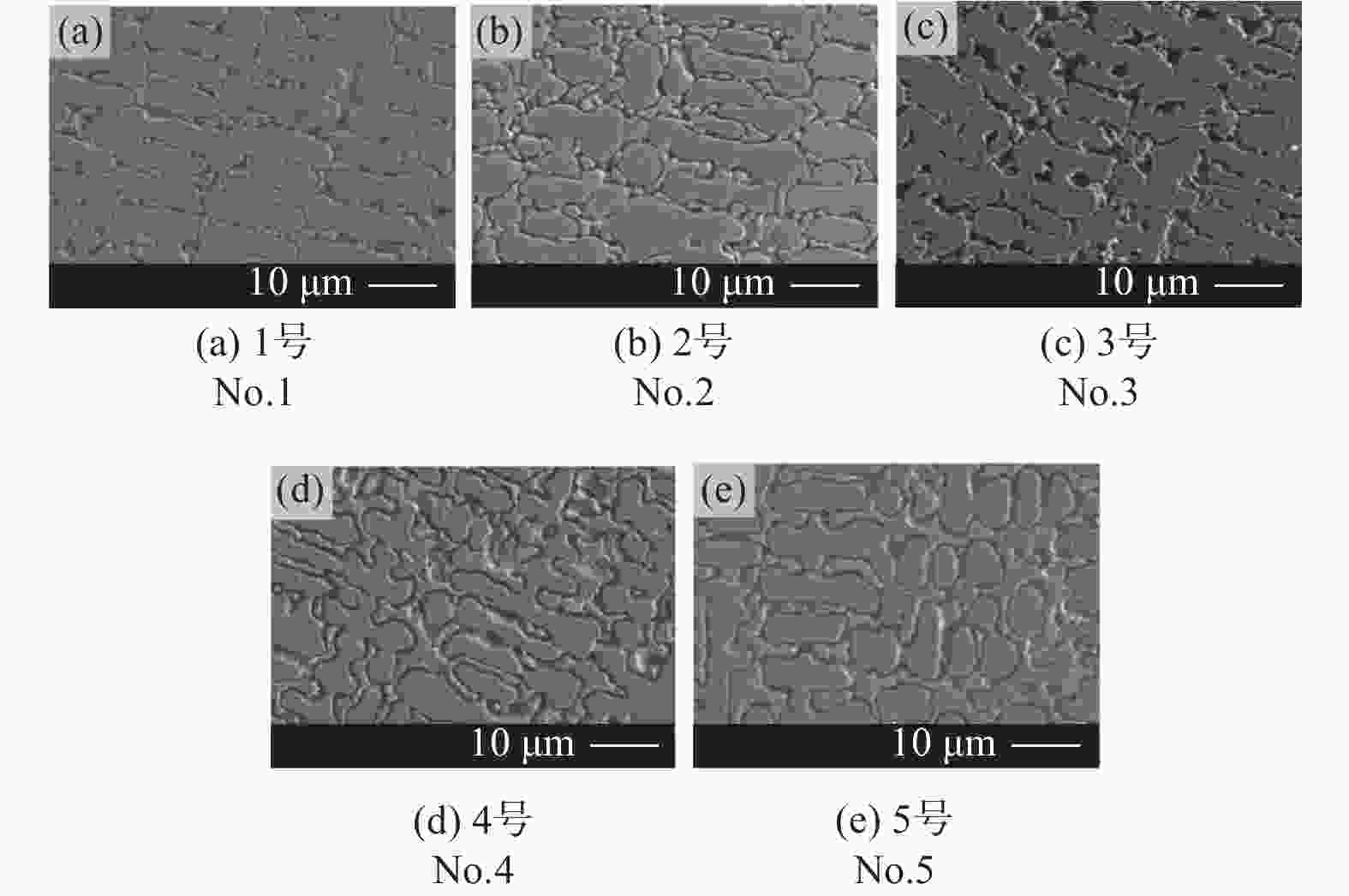

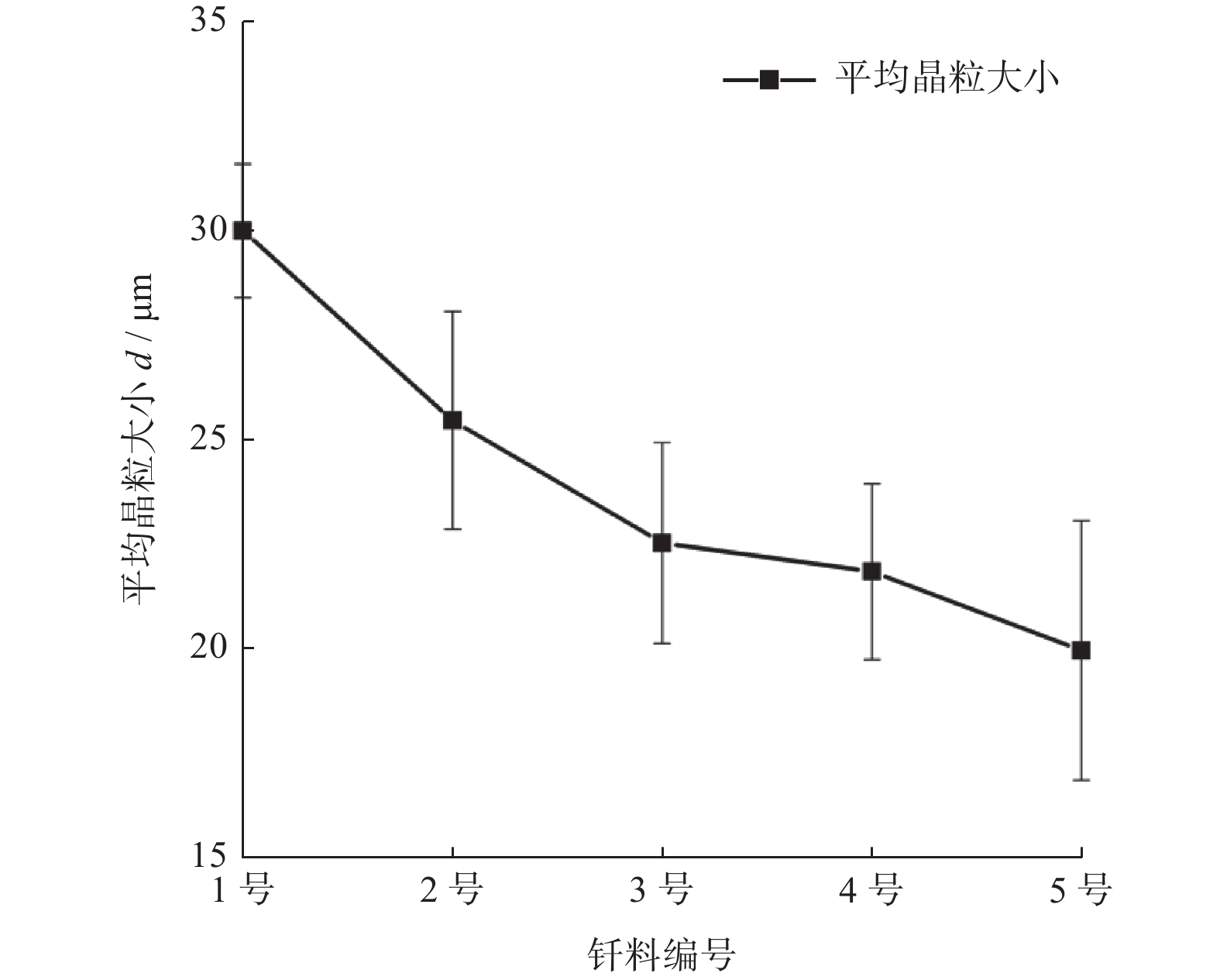

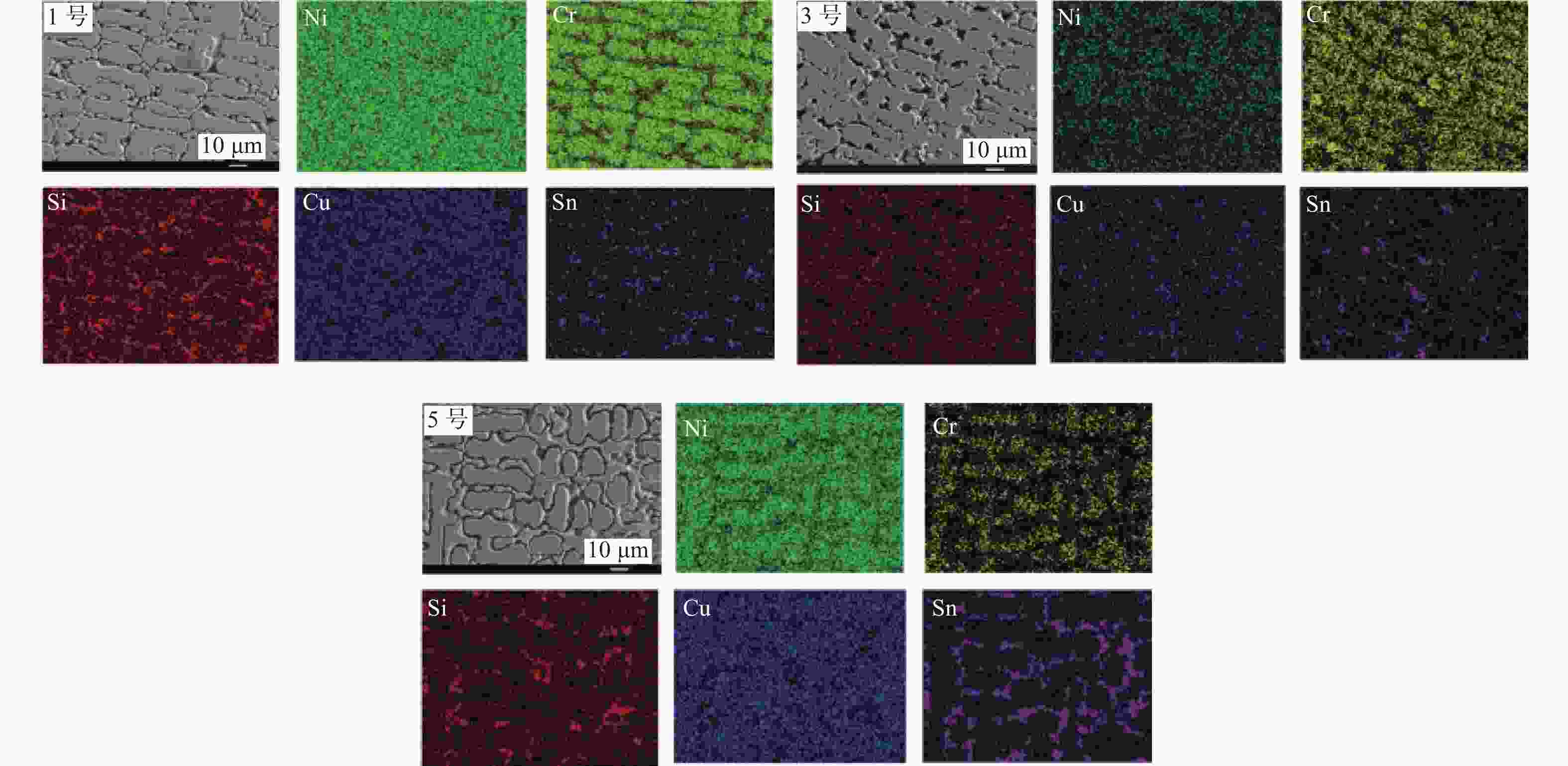

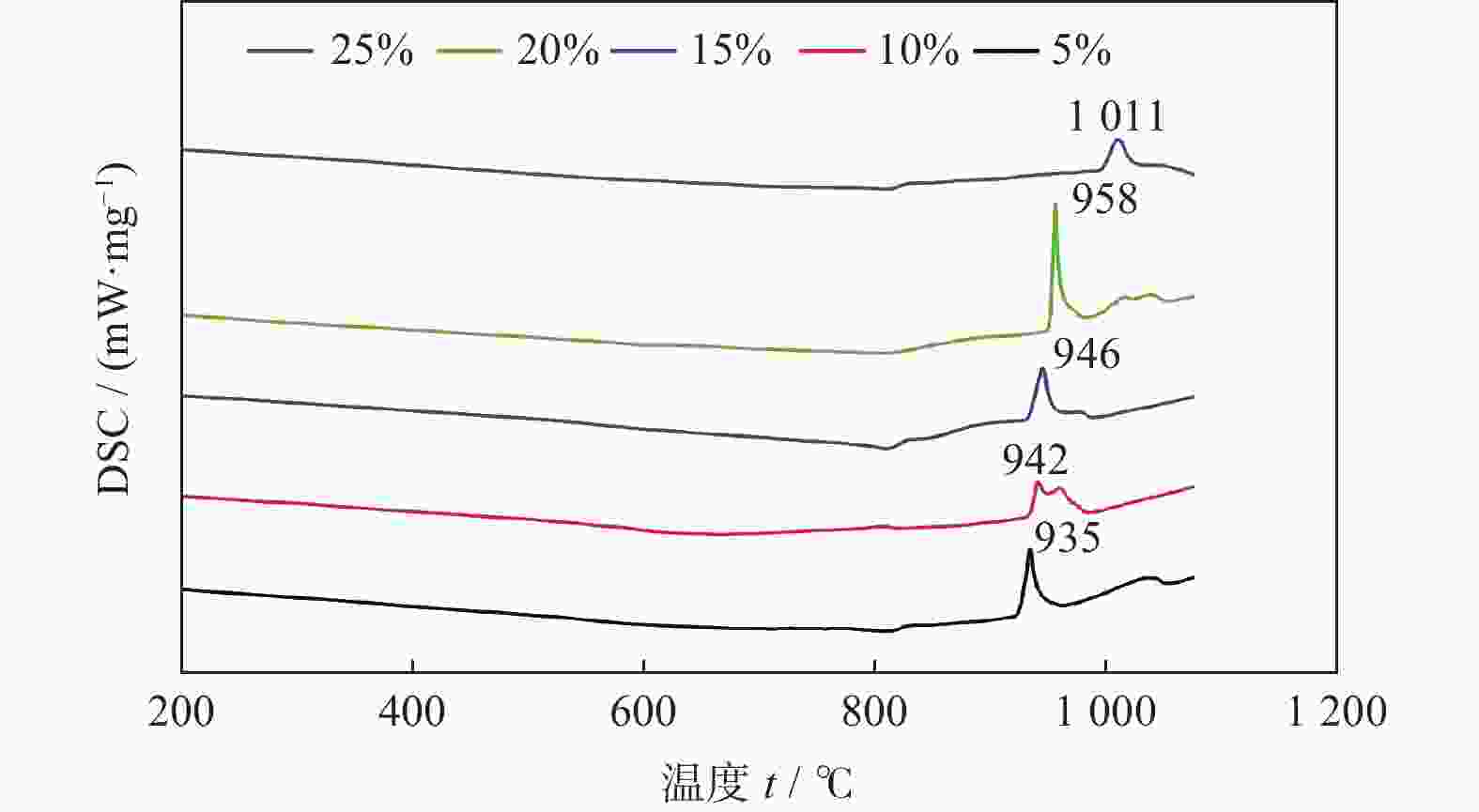

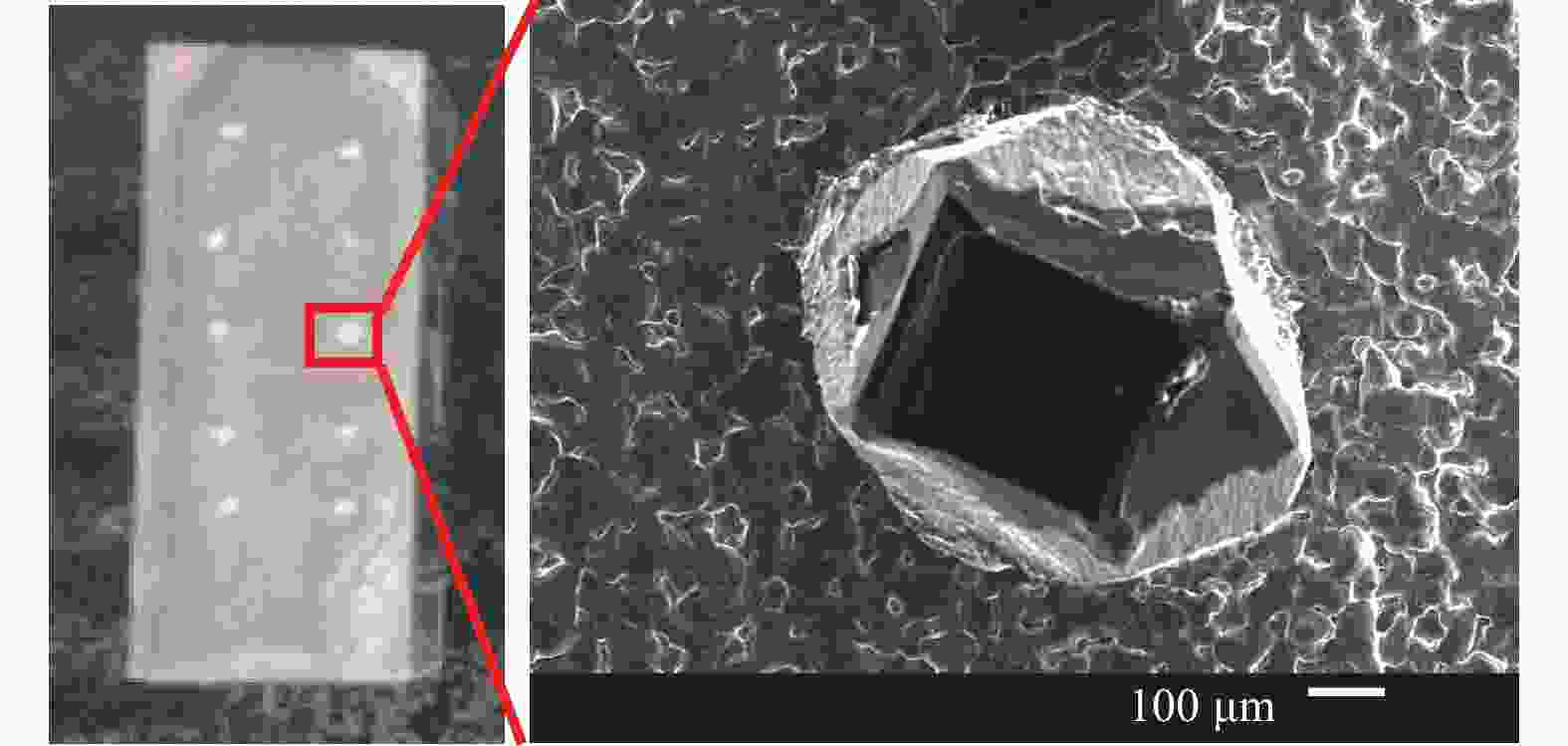

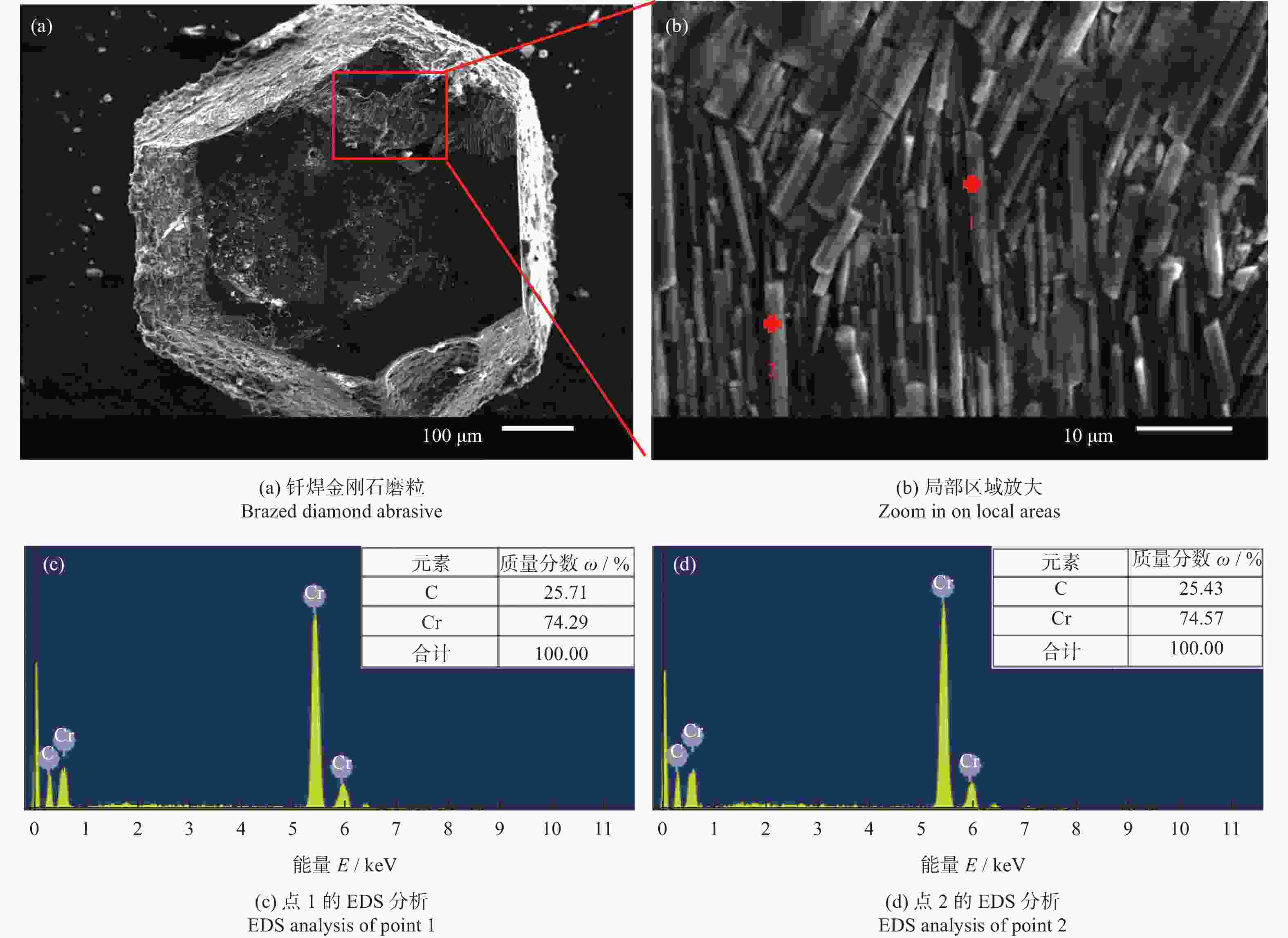

摘要: 针对B元素易使钎焊金刚石接头出现较多硬脆相的问题,制备一种新型Ni–Cr–Si–Cu–Sn无硼活性钎料,分析Cr元素对钎料组织和钎焊金刚石试样性能的影响规律。结果表明:Cr元素具有细化钎料晶粒和调控钎料中各元素分布的作用,可以提高钎料合金的显微硬度。当Cr元素质量分数过高时,会使钎料的熔点升高,钎料的润湿性能下降。综合来说,含有质量分数为15%的Cr的无硼钎料性能最佳,钎焊金刚石试样的磨削性能较优良,接头处出现多种形状的Cr7C3相,实现了钎料对金刚石的高强度连接。Abstract: In view of the problem that B element is easy to cause more hard and brittle phases in brazed diamond joints, a new type of Ni–Cr–Si–Cu–Sn boron free active solder was prepared, and the effects of Cr element on the microstructure of solder and the properties of brazed diamond were analyzed. The results show that Cr element can refine the solder grain and regulate the distribution of elements in the solder, which can improve the microhardness of the solder alloy. Excessive Cr addition will cause the melting point of the solder to increase and the wettability of the solder to decrease. In general, the boron free solder containing 15% Cr has the best performance, the grinding performance of brazed diamond is better, and Cr7C3 phases of various shapes appear at the joint, realizing the high-strength connection of the solder to the diamond.

-

Key words:

- brazing /

- diamond /

- new Ni-based boron free solder /

- active element /

- mechanical property

-

表 1 新型无硼钎料成分表

Table 1. Composition of new boron free solder

钎料编号 Cr 质量

分数

ωCr / %Sn质量

分数

ωSn / %Cu质量

分数

ωCu / %Si质量

分数

ωSi / %Ni质量

分数

ωNi / %1号 5 5 20 5 余量 2号 10 5 20 5 余量 3号 15 5 20 5 余量 4号 20 5 20 5 余量 5号 25 5 20 5 余量 -

[1] 龙伟民, 郝庆乐, 傅玉灿, 等. 金刚石工具钎焊用连接材料研究进展 [J]. 材料导报, 2020, 34(23): 23138-23144.LONG Weimin, HAO Qingyue, FU Yucan, et al. Research progress of bonding materials for diamond tool brazing [J]. Materials Reports, 2020, 34(23): 23138-23144. [2] CHEN N, YUAN Y, GUO C, et al. Design, optimization and manufacturing of polycrystalline diamond micro-end-mill for micro-milling of GH4169 [J]. Diamond and Related Materials,2020,108:107915. doi: 10.1016/j.diamond.2020.107915 [3] SUN B J, MA H L, LIAO S L. Wear characteristics of brazed diamond saw blade in cutting 304 stainless steel [J]. Diamond and Related Materials,2022,123:108869. doi: 10.1016/j.diamond.2022.108869 [4] DUAN D Z, HAN F, DING J J, et al. Microstructure and performance of brazed diamonds with multilayer graphene-modified Cu–Sn–Ti solder alloys [J]. Ceramics International,2021,47(16):22854-22863. doi: 10.1016/j.ceramint.2021.04.304 [5] SI S H, DING Z C, ZUO R Z, et al. Adding Hf element to improve the strength and wear resistance of diamond brazed with Ni-based boron-free brazing filler metal [J]. Diamond and Related Materials,2022,121:108723. doi: 10.1016/j.diamond.2021.108723 [6] LONG W M, LIU D S, WU A P, et al. Influence of laser scanning speed on the formation property of laser brazing diamond coating [J]. Diamond and Related Materials,2020,110:108085. doi: 10.1016/j.diamond.2020.108085 [7] HUANG G Q, WANG Y D, ZHANG M Q, et al. Brazing diamond grits onto AA7075 aluminium alloy substrate with Ag–Cu–Ti filler alloy by laser heating [J]. Chinese Journal of Aeronautics,2020,110:108085. [8] LI H L, CHEN J, CUI B, et al. Effects of Ga on mechanical properties and microstructure of Cu–Sn–Ti filler [J]. Physica Status Solidi A,2022,219:2100203. doi: 10.1002/pssa.202100203 [9] CUI B, ZHAO W X, ZUO R Z, et al. The abrasion resistance of brazed diamond using Cu–Sn–Ti composite alloys reinforced with boron carbide [J]. Diamond and Related Materials,2022,124:108926. doi: 10.1016/j.diamond.2022.108926 [10] ZHAO J, GUO M, HU S P, et al. Brazing of large synthetic diamond grits using graphene nanoplatelets reinforced Ni–Cr composite fillers [J]. Diamond and Related Materials, 2020, 109: 108004. [11] 李杨, 卢金斌, 穆云超, 等. Cu–P–Sn对镍基钎料真空钎焊金刚石的影响 [J]. 热加工工艺,2018,47(9):58-61,66. doi: 10.14158/j.cnki.1001-3814.2018.09.014LI Yang, LU Jinbin, MU Yunchao, et al. Effect of Cu–P–Sn on brazing diamond with Ni-based filler alloy [J]. Hot Working Technology,2018,47(9):58-61,66. doi: 10.14158/j.cnki.1001-3814.2018.09.014 [12] ZHANG L. Filler metals, brazing processing and reliability for diamond tools brazing: A review [J]. Journal of Manufacturing Processes,2021,66:651-668. doi: 10.1016/j.jmapro.2021.04.015 [13] 印有胜. 镍基钎料的钎缝脆性及其影响因素 [J]. 焊接学报, 1997(3): 6-12.YIN Yousheng. Brazing joint brittleness of nickel base solder and its influencing factors [J]. Transactions of the China Welding Institution, 1997 (3): 6-12. [14] HARDWICK L, RODGERS P, PICKERING E, et al. Development of a novel Ni-based multi-principal element alloy filler metal, using an alternative melting point depressant [J]. Metallurgical and Materials Transactions A,2021,59:2534-2548. [15] 闾川阳, 陈刚强, 唐夏焘, 等. BNi71CrSi钎料钎焊Hastelloy N合金的接头组织和性能 [J]. 航空学报,2022,43(2):90-101.LU Chuanyang, CHEN Gangqiang, TANG Xiatao, et al. Structure and mechanical properties of Hastelloy N superalloy joints brazed using BNi71CrSi filler alloy [J]. Journal of Aeronautics,2022,43(2):90-101. [16] ZHU W B, ZHANG W W, ZHOU W, et al. Improved microstructure and mechanical properties for SnBi solder alloy by addition of Cr powders [J]. Journal of Alloys and Compounds,2019,789:805-813. doi: 10.1016/j.jallcom.2019.03.027 [17] TAO Y, XUE S B, LIU H, et al. Effect of Cr addition on microstructure and properties of AuGa solder [J]. Metals,2020,10(11):1449. doi: 10.3390/met10111449 [18] DONG H G, YANG J, XIA Y Q, et al. Effect of Cr content in Ni-based amorphous filler on microstructure and shear strength of K4169 nickel-based alloy brazed joint [J]. Journal of Materials Processing Technology,2021,290:116975. doi: 10.1016/j.jmatprotec.2020.116975 [19] 张绍昆. Ni基非晶钎料炉中钎焊金刚石微粉及其加工性能的研究 [D]. 青岛: 青岛科技大学, 2018.ZHANG Shaokun. Study on brazing diamond powder in Ni based amorphous solder furnace and its machinability [D]. Qingdao: Qingdao University of Science and Technology, 2018. [20] 卢金斌, 徐九华. 真空钎焊金刚石界面碳化物的形貌 [J]. 中国有色金属学报,2007(7):1143-1148. doi: 10.3321/j.issn:1004-0609.2007.07.020LU Jinbin, XU Jiuhua. Morphology of carbides at the interface of vacuum brazing diamond [J]. Chinese Journal of Nonferrous Metals,2007(7):1143-1148. doi: 10.3321/j.issn:1004-0609.2007.07.020 [21] 苏仕超, 肖冰, 王树义, 等. Ni–Cr合金钎焊镀W金刚石的微观结构分析 [J]. 金刚石与磨料磨具工程, 2021, 41(1): 32-37.SU Shicao, XIAO Bing, WANG Shuyi, et al. Microstructure analysis of Ni–Cr alloy brazed and plated with W diamond [J]. Diamond & Abrasives Engineering, 2021, 41(1): 32-37. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS