Experimental study on normal force of cutting sapphire with multi-wire swing reciprocating wire saw

-

摘要:

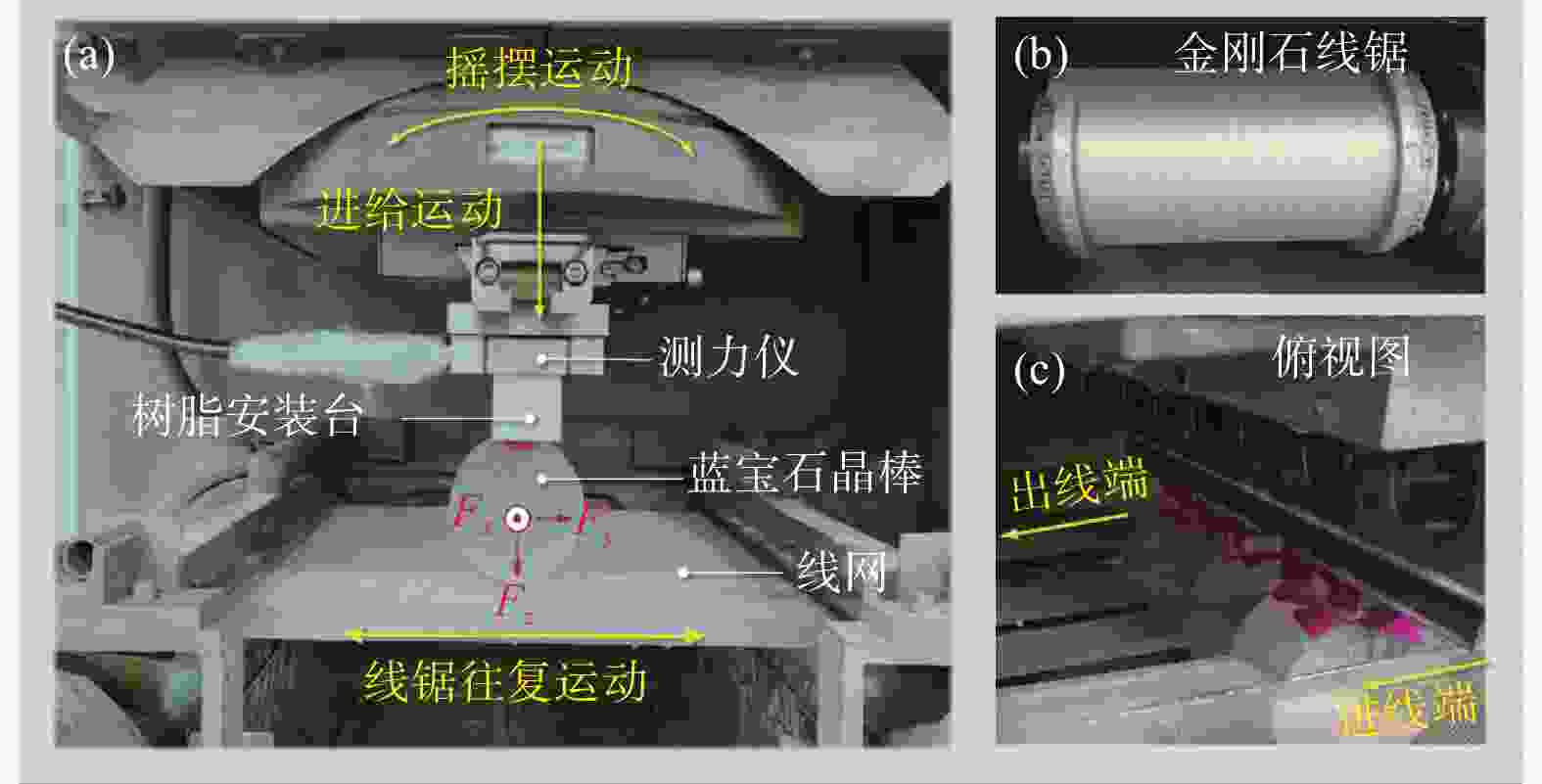

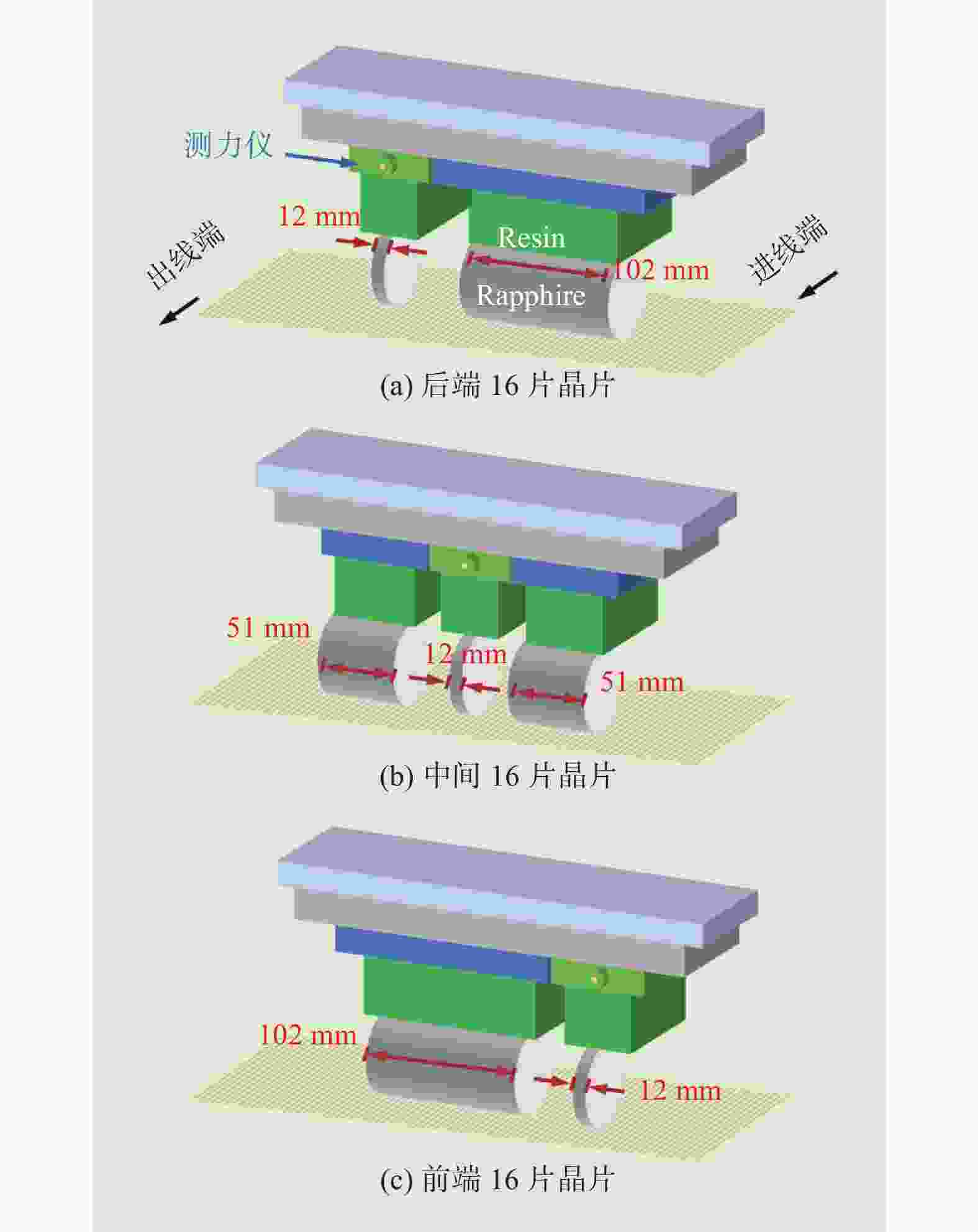

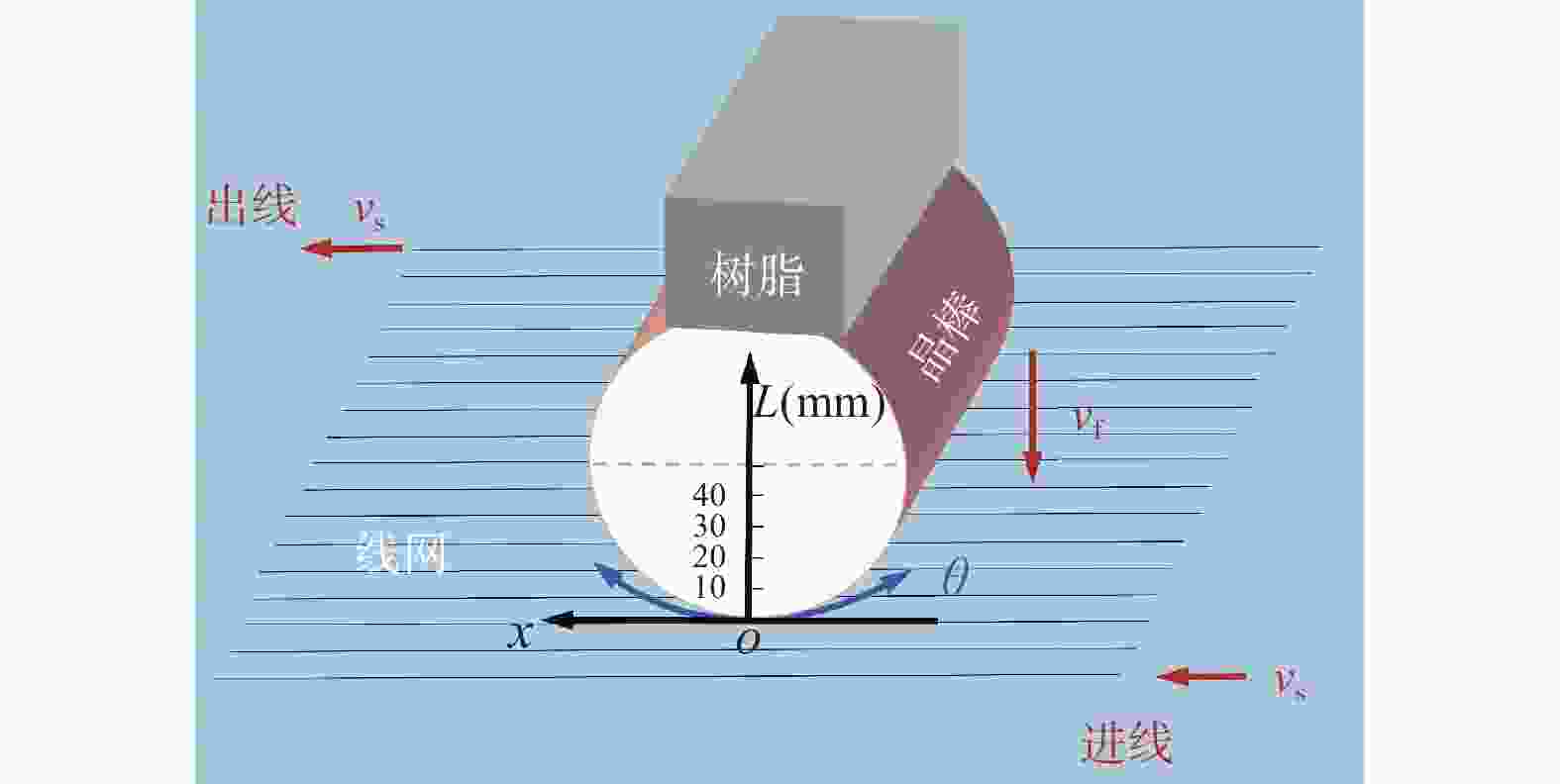

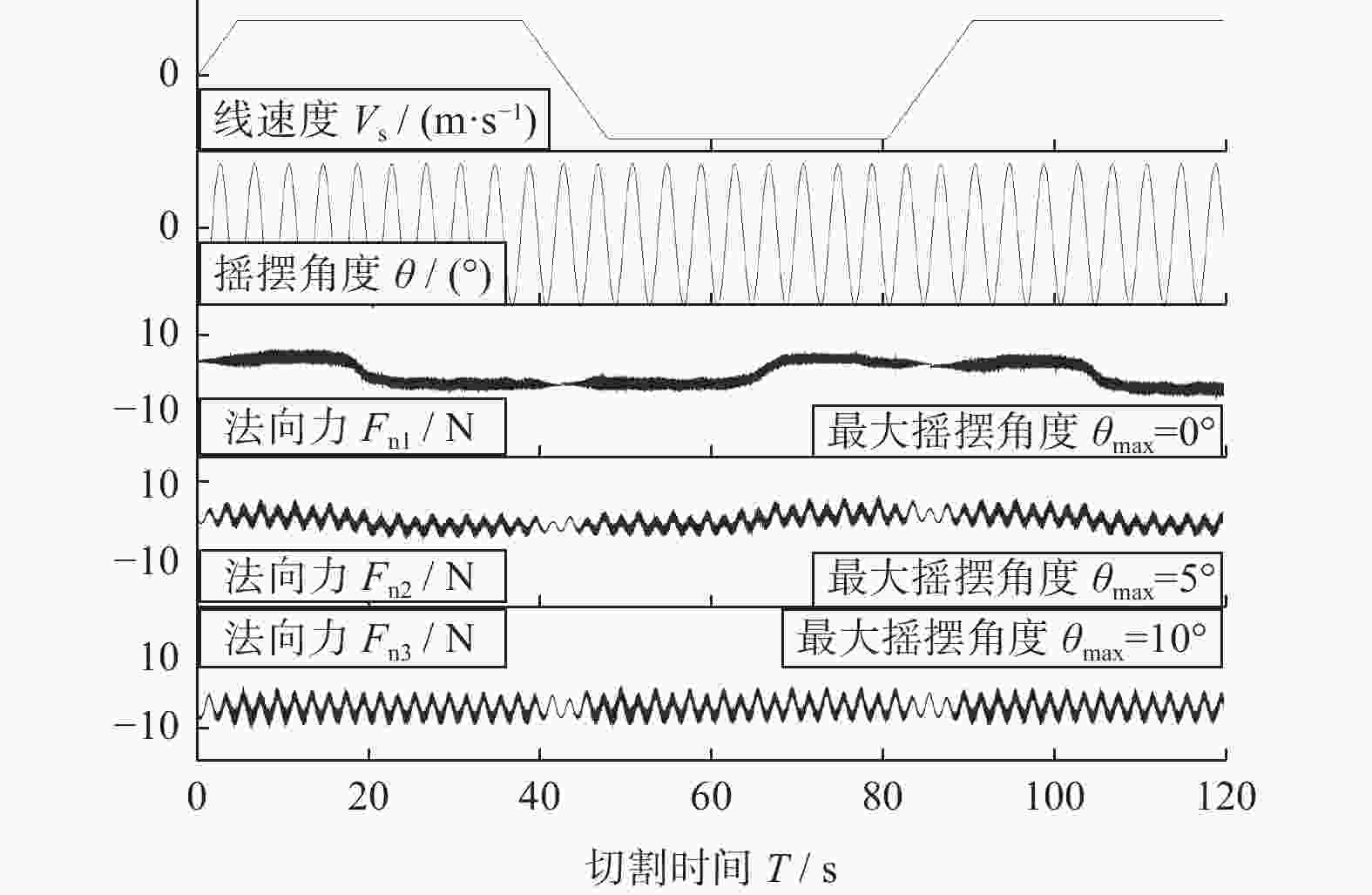

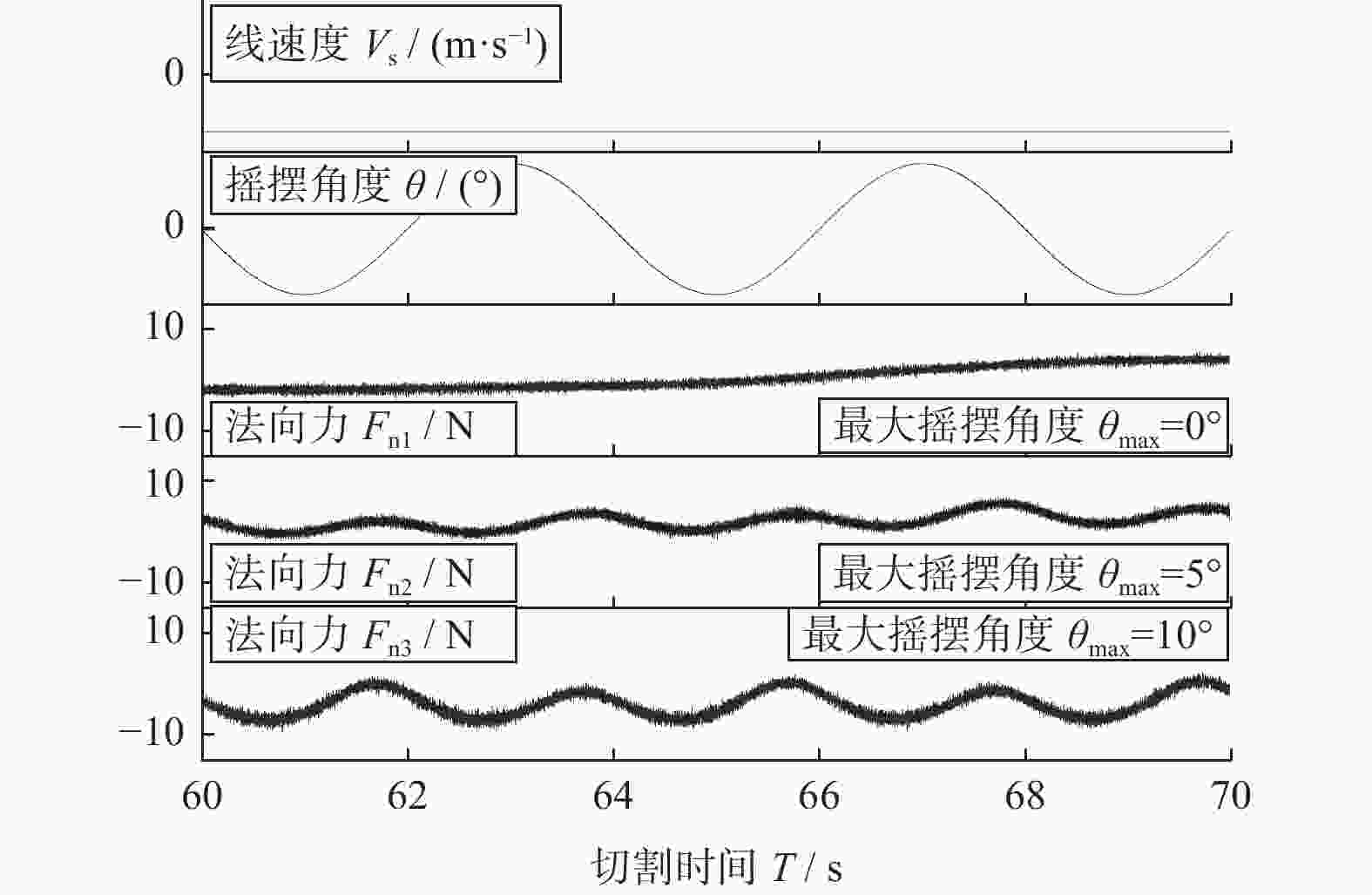

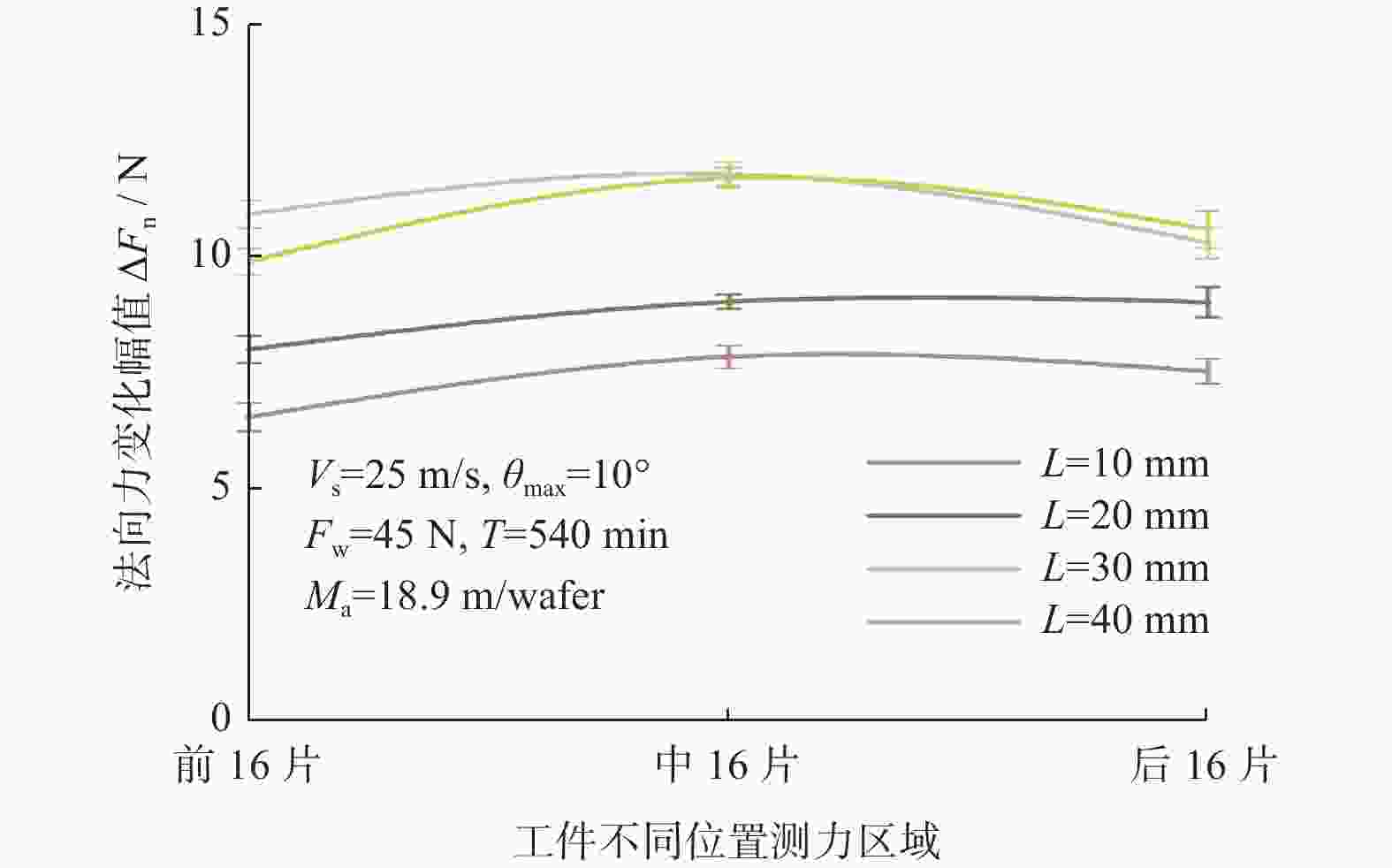

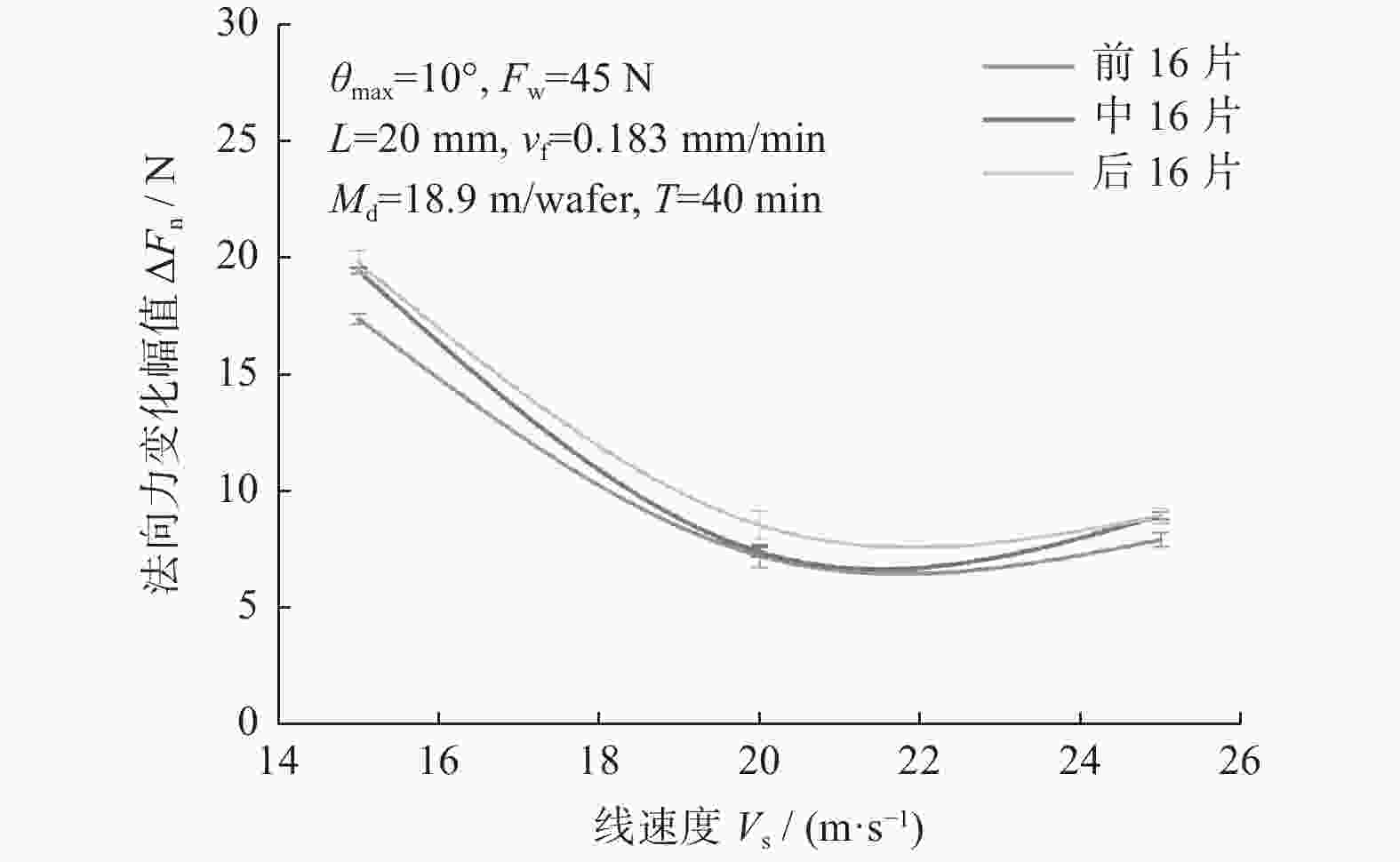

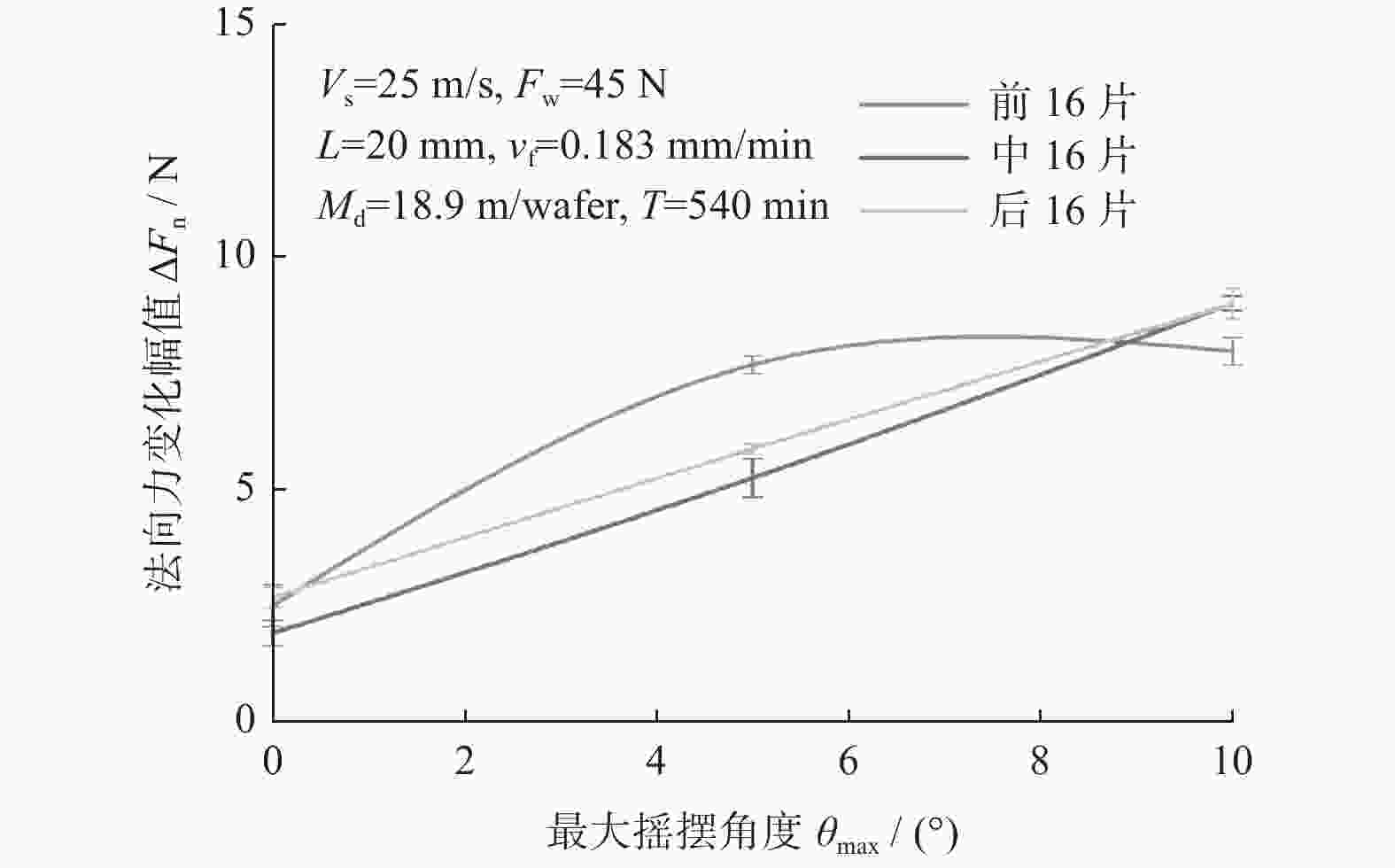

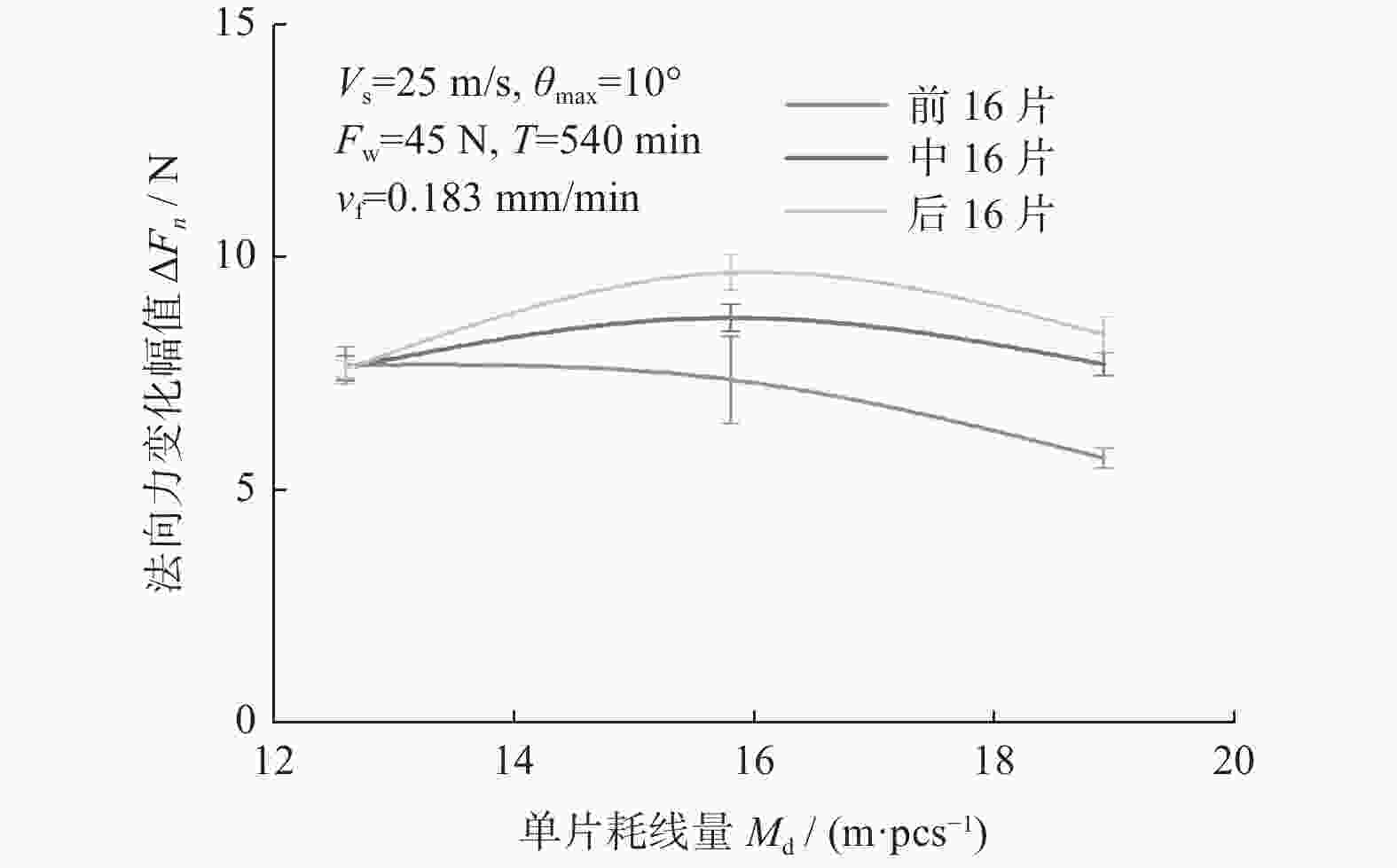

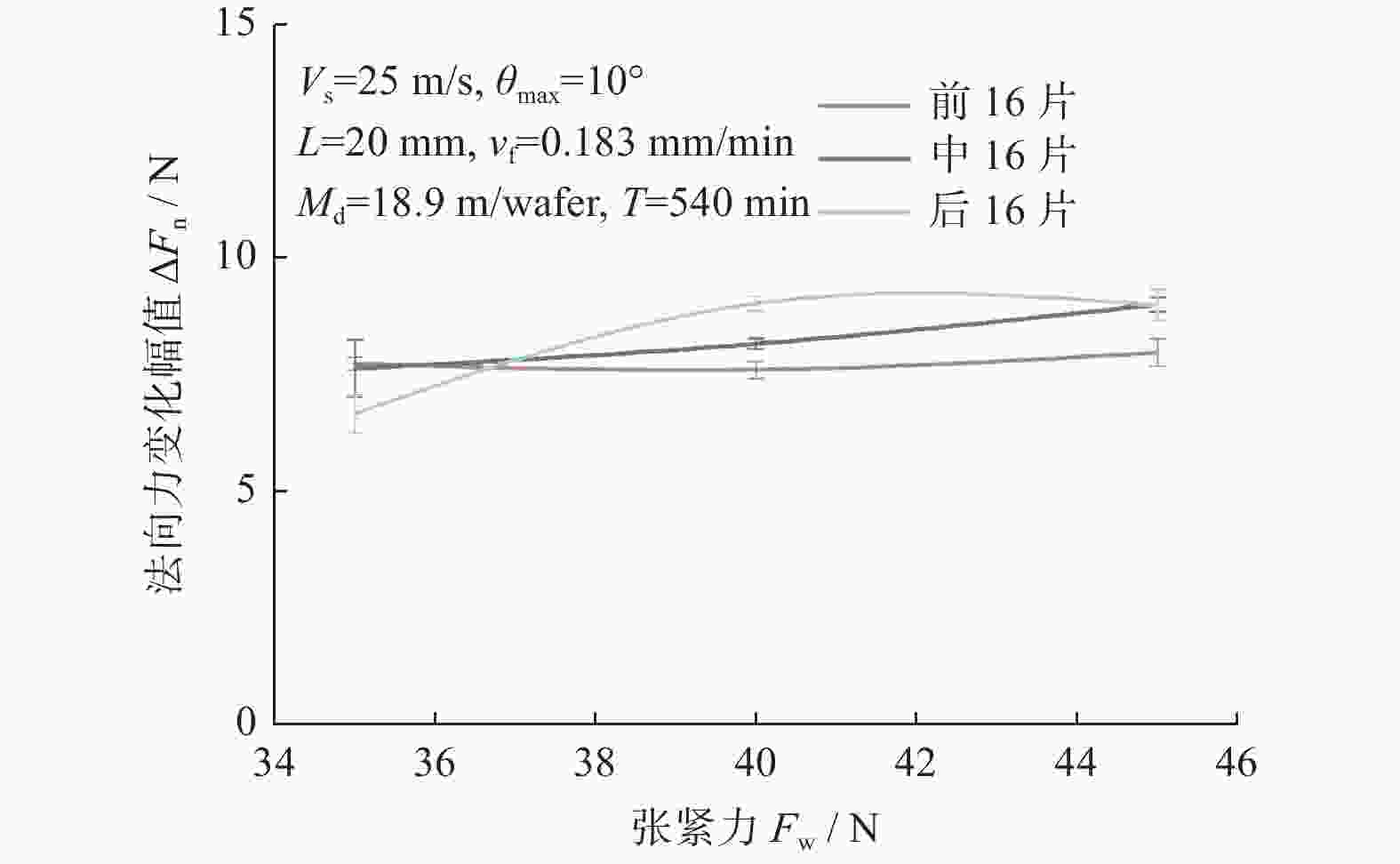

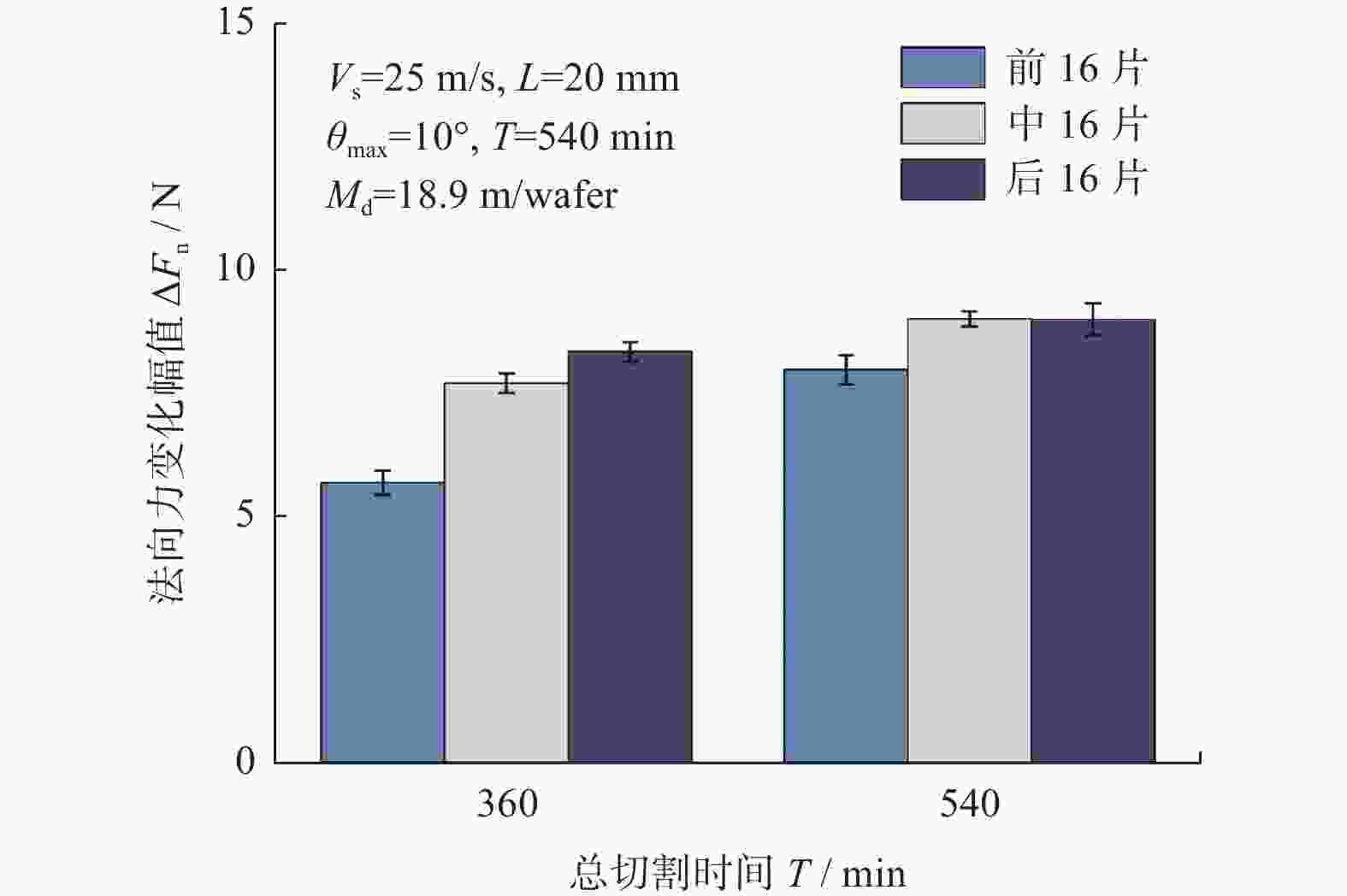

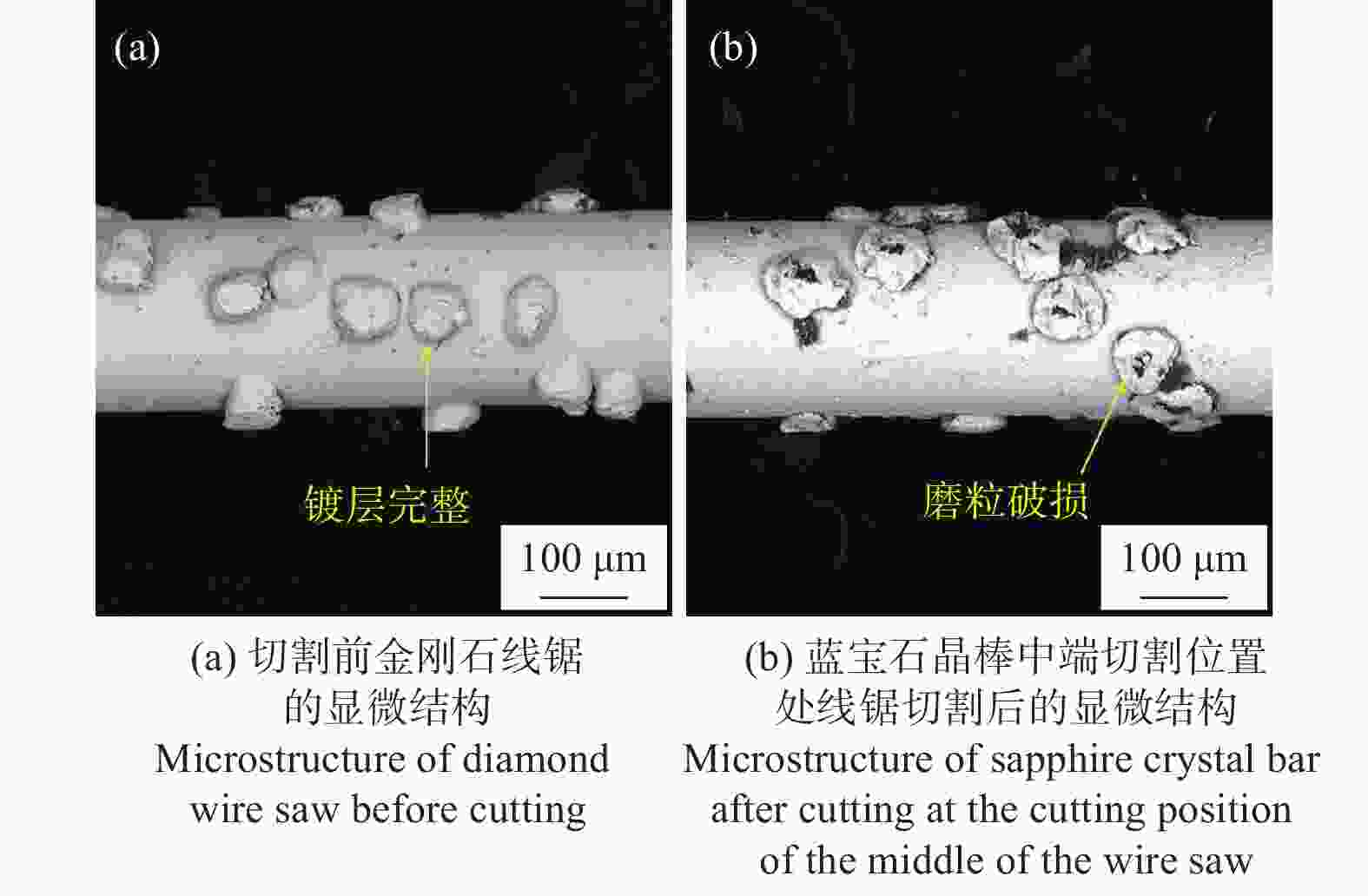

多线摇摆往复式线锯切割加工是目前将蓝宝石晶棒切割成晶圆衬底的主要加工方法,加工过程中法向切割力是反映加工过程稳定性的重要指标。测量了多线摇摆往复式线锯切割蓝宝石晶棒过程中产生的法向力Fn,跟踪了晶棒不同位置和不同切割深度下法向力的变化规律,以法向力变化幅值ΔFn为指标,探究各种工艺参数对加工过程稳定性的影响。试验结果表明:法向力Fn与线锯的往复运动、工件的摇摆运动有明确的对应关系,晶棒前端的ΔFn与中后端的有明显的不同。线速度vs、最大摇摆角度θmax、单片耗线量Md、张紧力Fw、总切割时间T等工艺参数对ΔFn有着不同的影响。ΔFn的波动程度与线锯磨损有着密切的关系。

-

关键词:

- 多线摇摆往复式线锯切割 /

- 蓝宝石 /

- 法向力 /

- 磨损 /

- 加工稳定性

Abstract:Multi-wire swing reciprocating sawing technology is the main machining method used to cut sapphire crystal bars into wafer substrates, while normal force is an important index that reflects the processing stability. In this paper, the normal force (Fn) during multi-wire swing reciprocating wire saw cutting sapphire crystal bars was measured, and the change in normal force at different positions and cutting depths of the sapphire crystal bars was tracked. The influence of various process parameters on the stability of the machining process was tracked by using the rangeability of normal force Fn as the index. The experimental results show that Fn is closely correlated with the reciprocating motion of the wire saw and the rocking motion of the workpiece, and ΔFn in the front of the sapphire crystal bar is significantly different from that in the middle and back. Process parameters such as the wire saw speed(vs), maximum swing angle (θmax), single piece wire consumption (Md), tensioning force (Fw), and total cutting time (T) have different effects on ΔFn. The fluctuation degree of ΔFn is closely related to the wear of the wire saw.

-

表 1 工艺参数

Table 1. Technological parameter

试验

序号线锯稳定切割

速度 Vs/(m·s−1)最大摇摆

角度

θmax/ (°)张紧力

Fw

/N单片耗

线量Md

/(m·wafer−1)总切割时间

T/min1 25 10 45 18.9 360 2 25 10 45 15.8 360 3 25 10 45 12.6 360 4 25 10 45 18.9 540 5 25 5 45 18.9 540 6 25 0 45 18.9 540 7 25 10 40 18.9 540 8 25 10 35 18.9 540 9 20 10 45 18.9 540 10 15 10 45 18.9 540 -

[1] WU H. Wire sawing technology a state-of-the-art review [J]. Precision Engineering,2016,(43:1-9. doi: 10.1016/j.precisioneng.2015.08.008 [2] 高航, 孔维邈. 脆性材料用固结金刚石线锯切割技术研究进展 [J]. 金刚石与磨料磨具工程,2019,39(4):97-102.GAO Hang, KONG Weimiao. Development of consolidated diamond wire saw cutting technology for brittle materials [J]. Diamond & Abrasives Engineering,2019,39(4):97-102. [3] ANSPACH O, HURKA B, SUNDER K. Structured wire: From single wire experiments to multi-crystalline silicon wafer mass production [J]. Solar Energy Materials and Solar Cells,2014(131):58-63. doi: 10.1016/j.solmat.2014.06.008 [4] 张强. 固结磨料多线切割设备的设计与研究 [D]. 苏州: 苏州大学, 2019.ZHANG Qiang. Design and Research of Fixed Abrasive Multi-wire Cutting Equipment [D]. Suzhou: Soochow University, 2019. [5] LIU Y H, GAO Y F, YANG C F. Analysis of sawing characteristics of fine diamond wire slicing multicrystalline silicon [J]. Diamond and Related Materials,2021(48):17335-17342. [6] GE M R, CHEN Z B, WANG P Z, et al. Crack damage control for diamond wire sawing of silicon the selection of processing parameters [J]. Materials Science in Semiconductor Processing,2022,148:106838-106846. doi: 10.1016/j.mssp.2022.106838 [7] LIU Y H, ZHU Z F. Experimental investigation on diamond wire sawing of Si3N4 ceramics considering the evolution of wire cutting performance [J]. Ceramics International,2022(48):17335-17342. doi: 10.1016/j.ceramint.2022.02.296 [8] HUANG H, LI X X, XU X P. An Experimental research on the force and energy during the sapphire sawing using reciprocating electroplated diamond wire saw [J]. ASME International,2017,139(12):121011-121015. [9] COSTA E C, WEINGAERTNER W L, XAVIER F A. Influence of single diamond wire sawing of photovoltaic monocrystalline silicon on the feed force, surface roughness and micro-crack depth [J]. Materials Science in Semiconductor Processing,2022(143):106525-106535. doi: 10.1016/j.mssp.2022.106525 [10] WANG P Z, GE P Q, GAO Y F, et al. Prediction of sawing force for single-crystal silicon carbide with fixed abrasive diamond wire saw [J]. Materials Science in Semiconductor Processing,2017(63):25-32. doi: 10.1016/j.mssp.2017.01.014 [11] WANG P Z, GE P Q, LI Z Q, et al. A scratching force model of diamond abrasive particles in wire sawing of single crystal SiC [J]. Materials Science in Semiconductor Processing,2017(68):21-29. doi: 10.1016/j.mssp.2017.05.032 [12] WANG Y, ZHANG S, DONG G J, et al. Theoretical study on sawing force of ultrasonic vibration assisted diamond wire sawing (UAWS) based on abrasives wear [J]. Wear,2022(496/497):204291-204301. [13] WANG Y, LI D L, DING Z J, et al. Modeling and verifying of sawing force in ultrasonic vibration assisted diamond wire sawing (UAWS) based on impact load [J]. International Journal of Mechanical Sciences,2019(164):105161-105170. doi: 10.1016/j.ijmecsci.2019.105161 [14] 李茜茜. 线锯切割光电材料的锯切力及锯切质量的试验研究[D]. 厦门: 华侨大学, 2017.LI Xixi. Experimental study on force and surface quality of photoelectric material with fixed abrasive diamond wire [D]. Xiamen: Huaqiao University, 2017. [15] 麻磊. 金刚石线锯切割力的分析与控制研究[D]. 西安: 西安理工大学, 2017.MA Lei. Study on cutting force analysis and control of diamond wire saw [D]. Xi’an: Xi’an University of Technology, 2017. [16] 纪磊磊. 固结金刚石磨粒线锯振动对切片表面形貌影响的研究[D]. 西安: 西安理工大学, 2018.JI Leilei. Study on effect of vibration of fixed diamond A-Brasive grain saw on surface morphology of slice[D]. Xi’an: Xi’an University of Technology, 2018. [17] KIM H, KIM D, KIM C, et al. Multi-wire sawing of sapphire crystals with reciprocating motion of electroplated diamond wires [J]. CIRP Annals-Manufacturing Technology,2013(62):335-338. doi: 10.1016/j.cirp.2013.03.122 [18] KIM D, KIM H, LEE S, et al. Effect of initial deflection of diamond wire on thickness variation of sapphire wafer in multi-wire saw [J]. Springer Science and Business Media LLC,2015(2):117-121. [19] KAO I, PRASAD V, LI J, et al. Wafer slicing and wire saw manufacturing technology[C]// Proceedings of the 1997 NSF Design & Manufacturing Grantees Conference. Washington: University of Washington, 1997: 239-240. [20] 杨沁. 多线摇摆往复式线锯切割大尺寸单晶碳化硅的试验研究 [D]. 厦门: 华侨大学, 2020.YANG Qin. Experimental study on cutting large-size single-crystalline silicon carbide with multi-wire swing reciprocating wire saw [D]. Xiamen: Huaqiao University, 2020. [21] 杨沁, 黄辉, 郑生龙. 多线摇摆往复式线锯切割加工运动的理论及试验研究 [J]. 机械工程学报,2020,56(11):219-228. doi: 10.3901/JME.2020.11.219YANG Qin, HUANG Hui, ZHENG Shenglong. Theoretical and experimental research on machining movement of multi-wire sawing with rocking and reciprocating [J]. Journal of Mechanical Engineering,2020,56(11):219-228. doi: 10.3901/JME.2020.11.219 [22] YANG Z X, HUANG H, LIAO X J. Influence of cutting parameters on wear of diamond wire during multi-wire rocking sawing with reciprocating motion [J]. Frontiers in Mechanical Engineering,2022(8):1-12. [23] 王兰青. 多线摇摆往复式线锯切割蓝宝石的晶片质量及锯切力试验研究[D]. 厦门: 华侨大学, 2021.WANG Lanqing. Experimental research on sapphire wafer quality and cutting force in multi-wire swing reciprocating wire saw cutting[D]. Xiamen: Huaqiao University, 2021. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS