Effect of double-sided polishing on surface morphology of quartz mask blanks

-

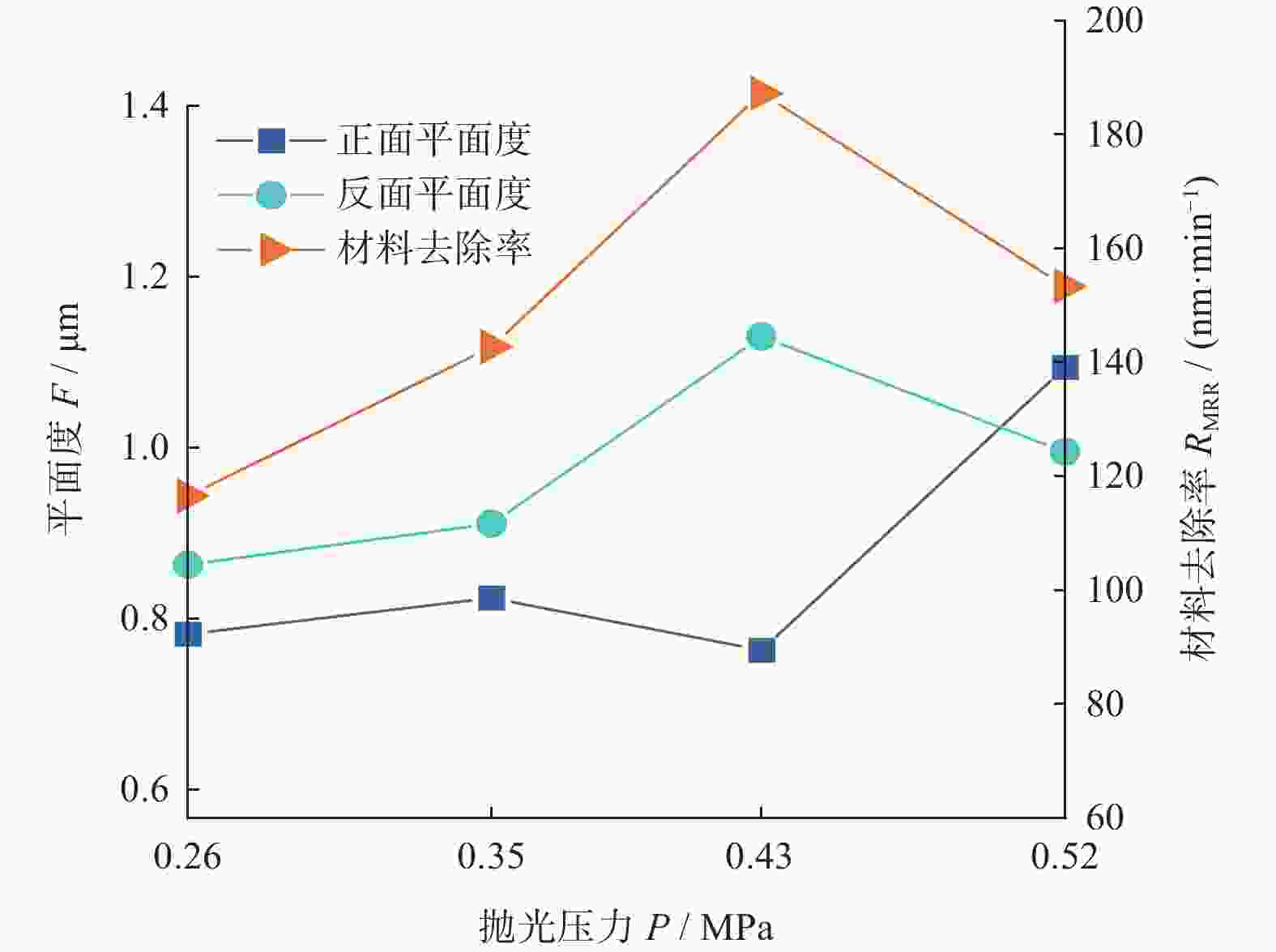

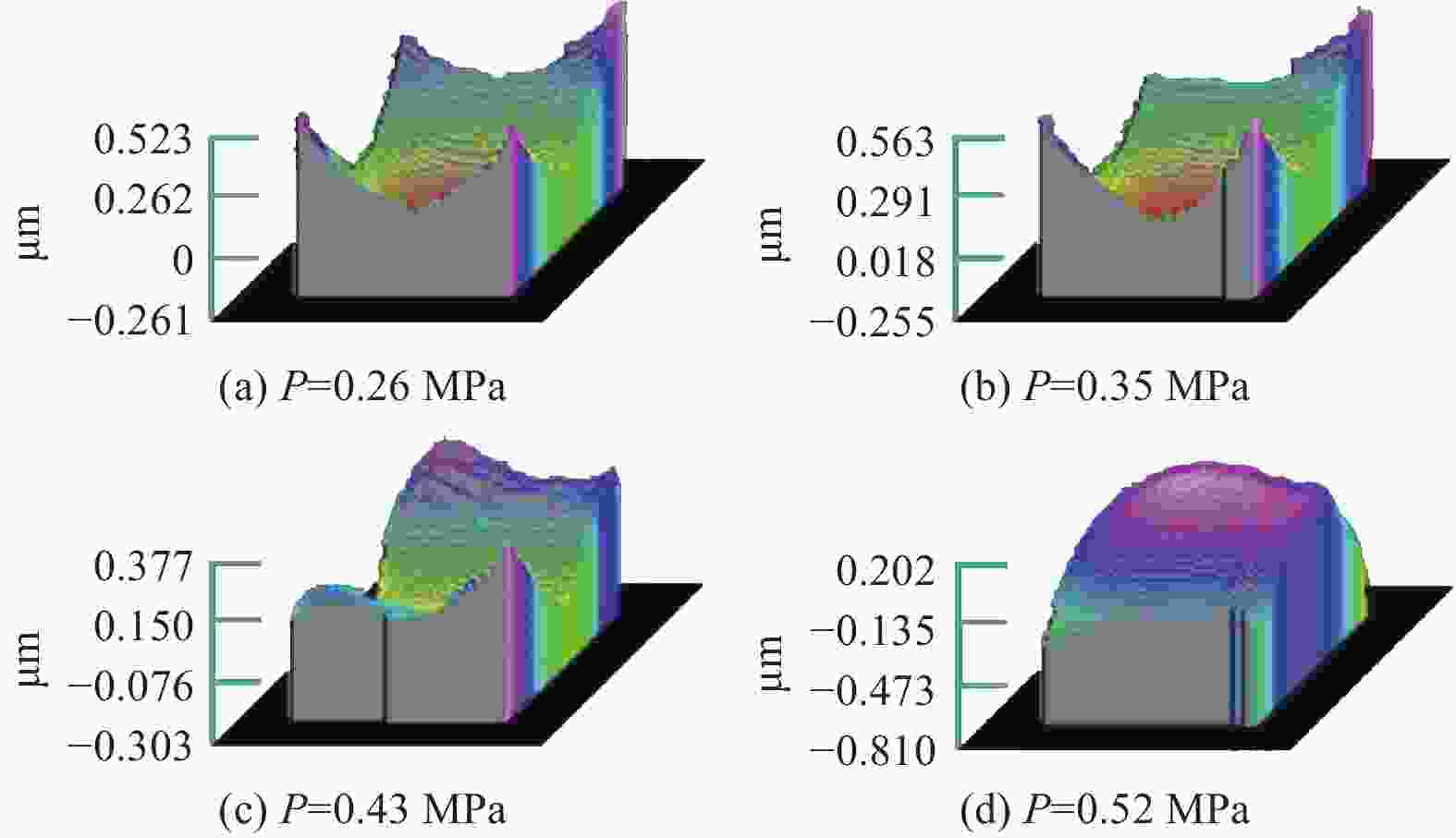

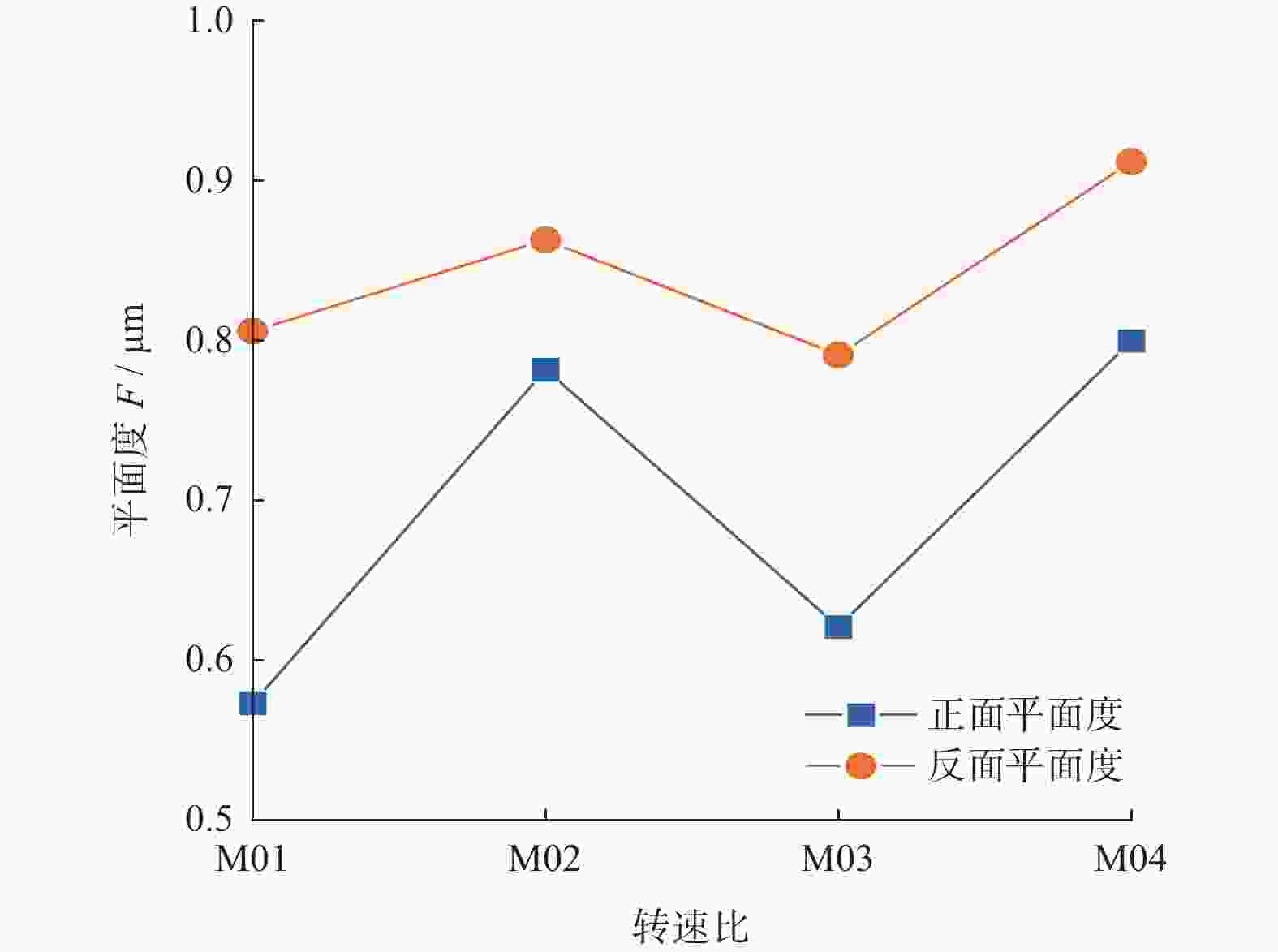

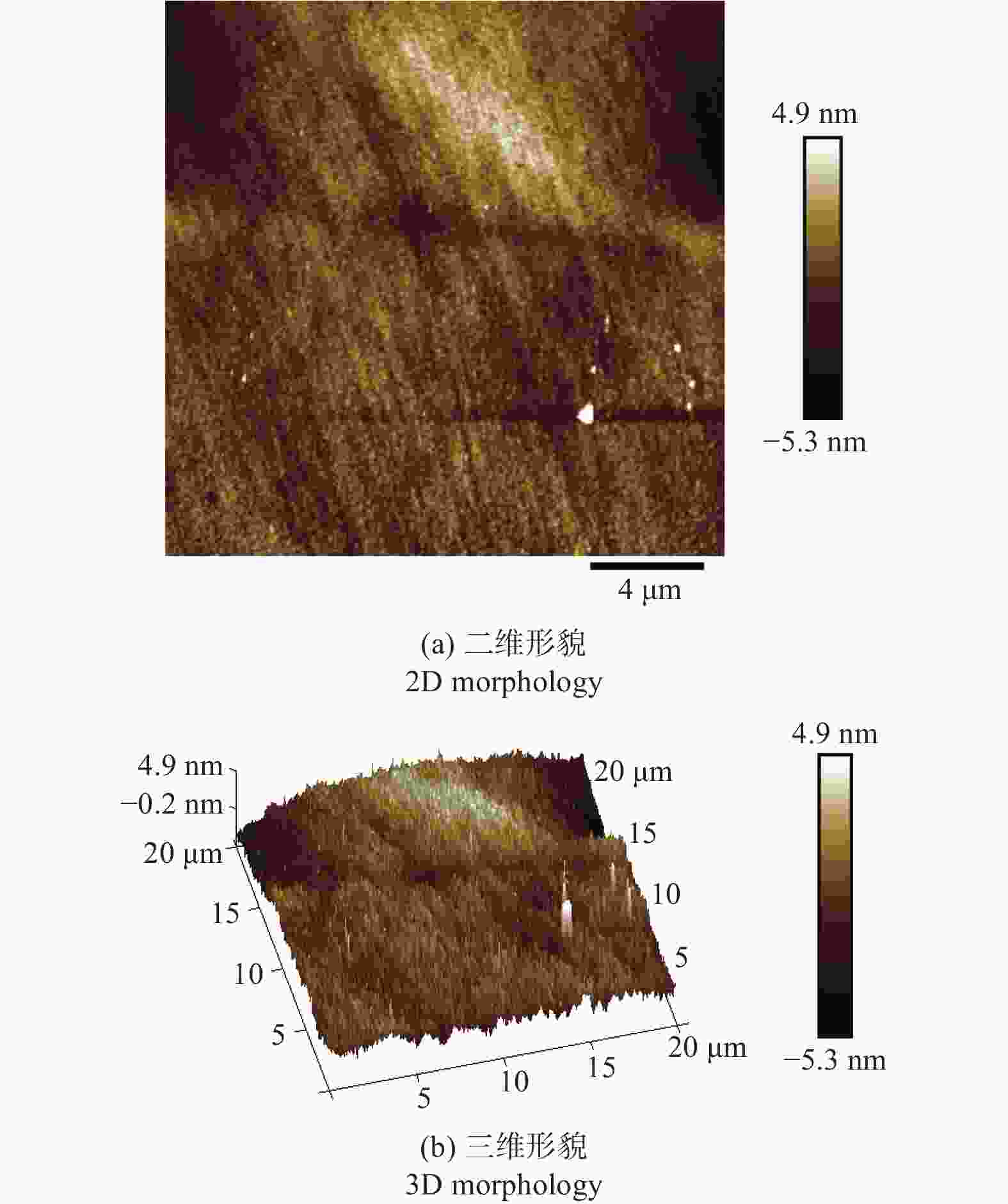

摘要: 随着集成电路关键尺寸的缩小,晶体管密度和芯片性能持续提升。同时,随着集成电路工艺制程的不断演进,掩模基板的平坦化加工要求也日益严苛。为揭示双面化学机械抛光对石英掩模基板的抛光去除机理,利用CeO2磨料自制抛光液,对6025石英玻璃进行双面抛光加工,考察抛光粉粒径、抛光液浓度、抛光压力、齿圈与太阳轮转速组合对石英掩模基板材料去除率、表面形貌、平面度以及表面粗糙度的影响。结果表明,使用粒径为0.823 μm的CeO2抛光粉抛光后,石英玻璃表面粗糙度比使用粒径为1.231 μm的CeO2抛光粉降低40%;随着抛光液浓度的增大,正面平面度呈现先下降后上升的趋势,当质量分数达到14%时结果最优,而材料去除率持续增大;在0.26~0.43 MPa的压力范围内,材料去除率与压力呈线性关系,然而如果压力进一步增大,材料去除率反而减小。使用等效粒径D50为0.823 μm的抛光粉,配制成14%浓度的CeO2抛光液,在0.43 MPa的抛光压力下,选取齿圈与太阳轮转速分别为6.54和3.08 r/min,抛光后6025石英玻璃的表面光滑(平面度为0.573 μm,表面粗糙度Ra最低为0.96 nm),几乎没有划痕、中位裂纹等表面损伤,平面度和表面质量最佳。Abstract:

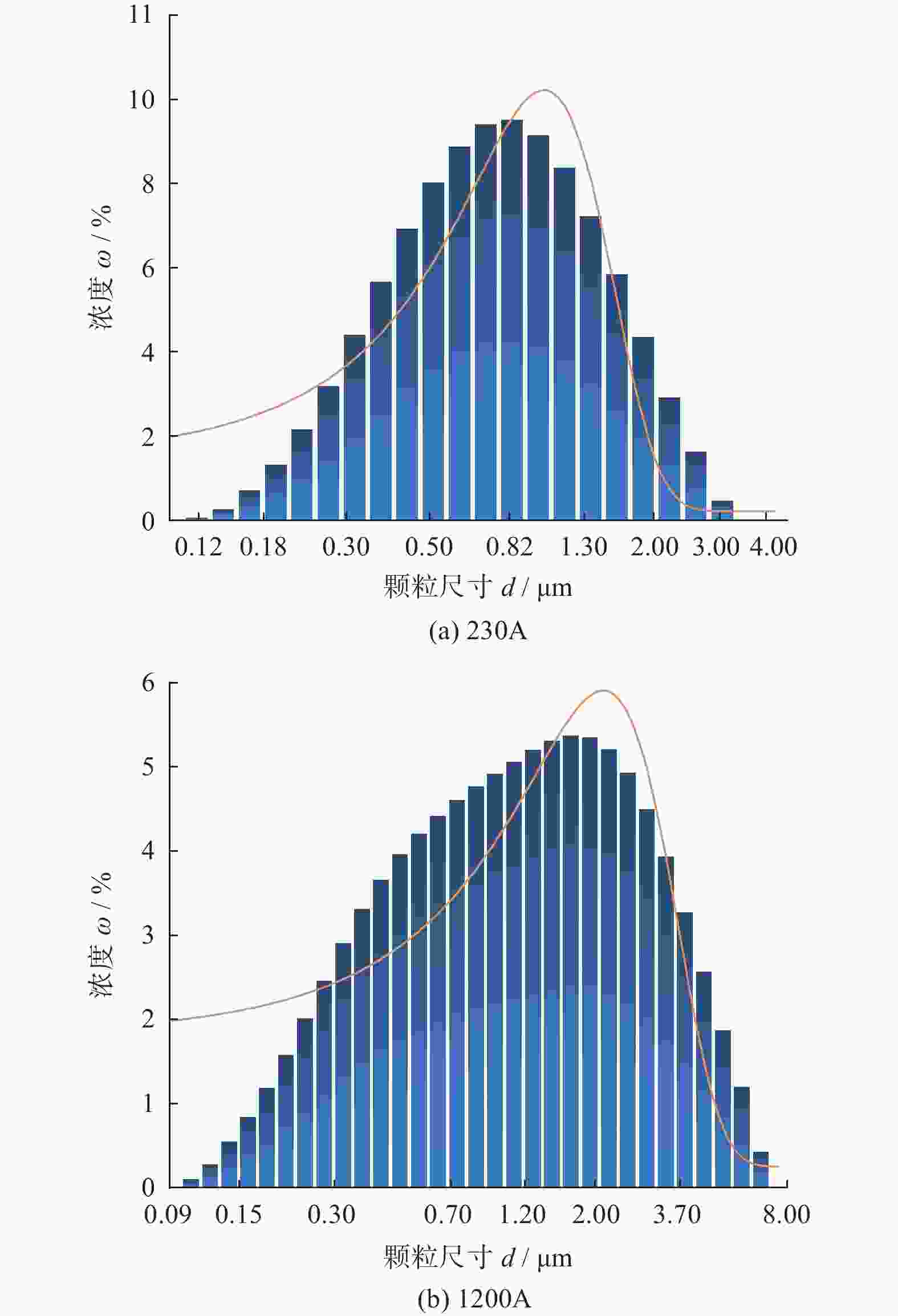

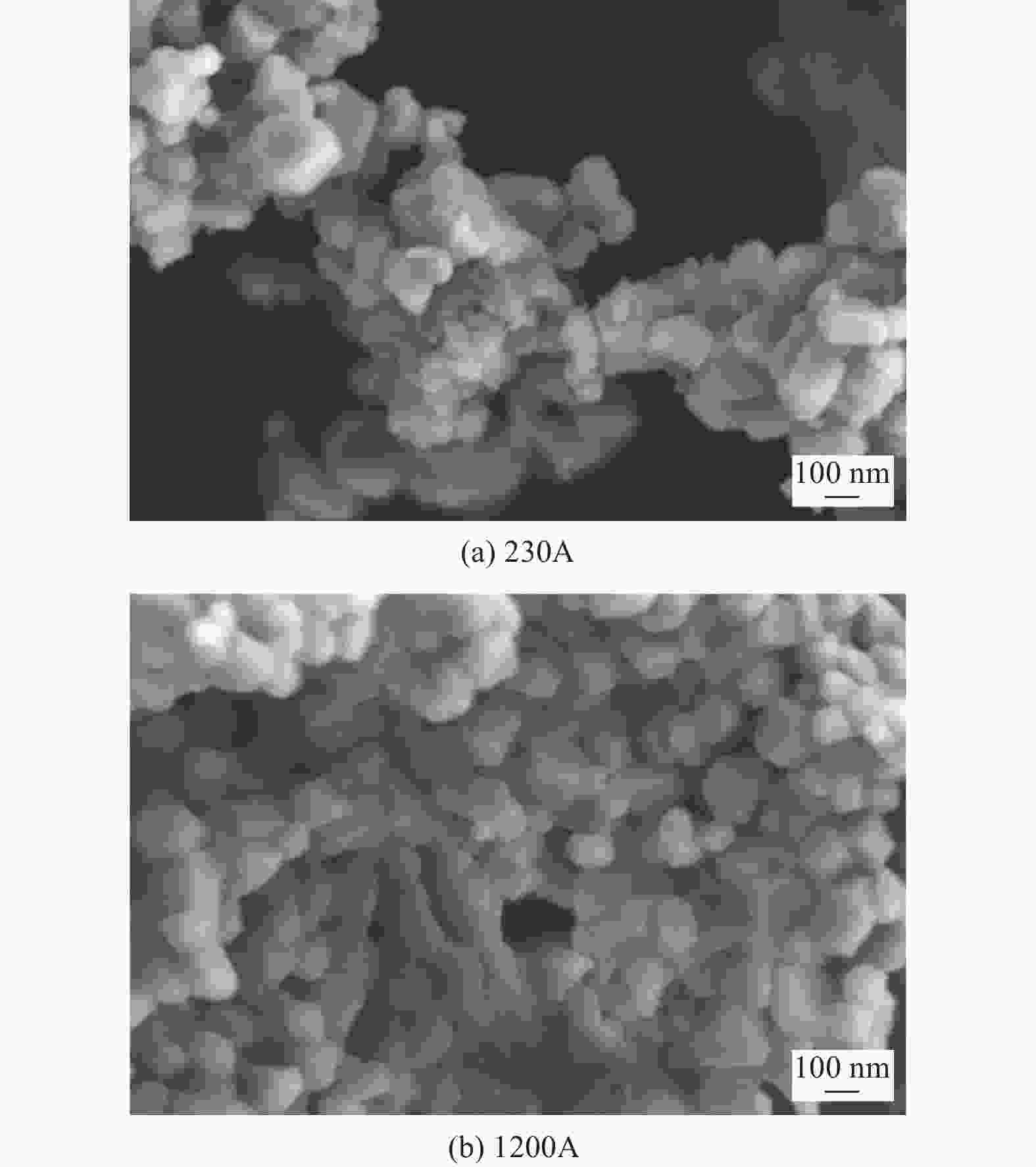

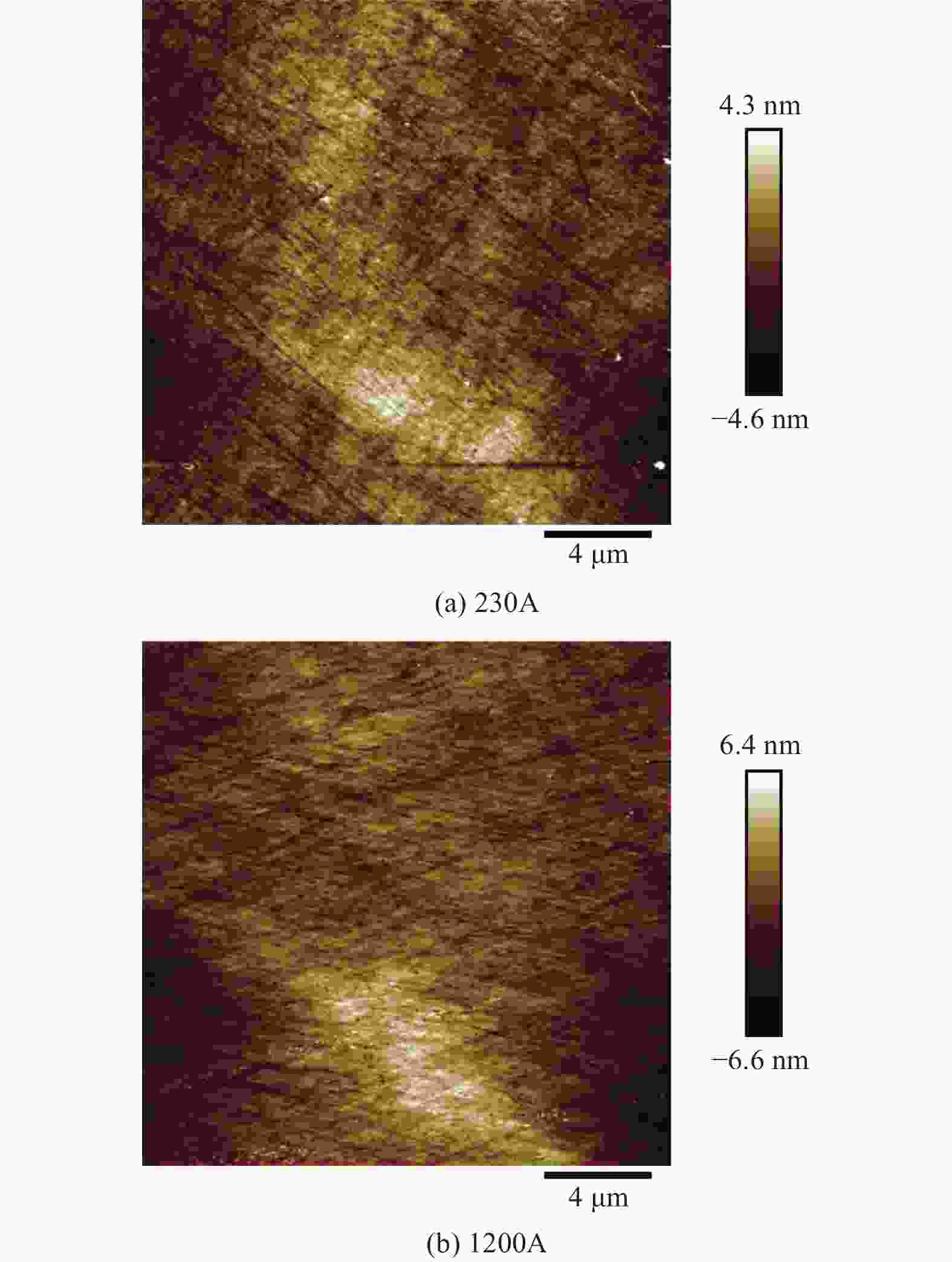

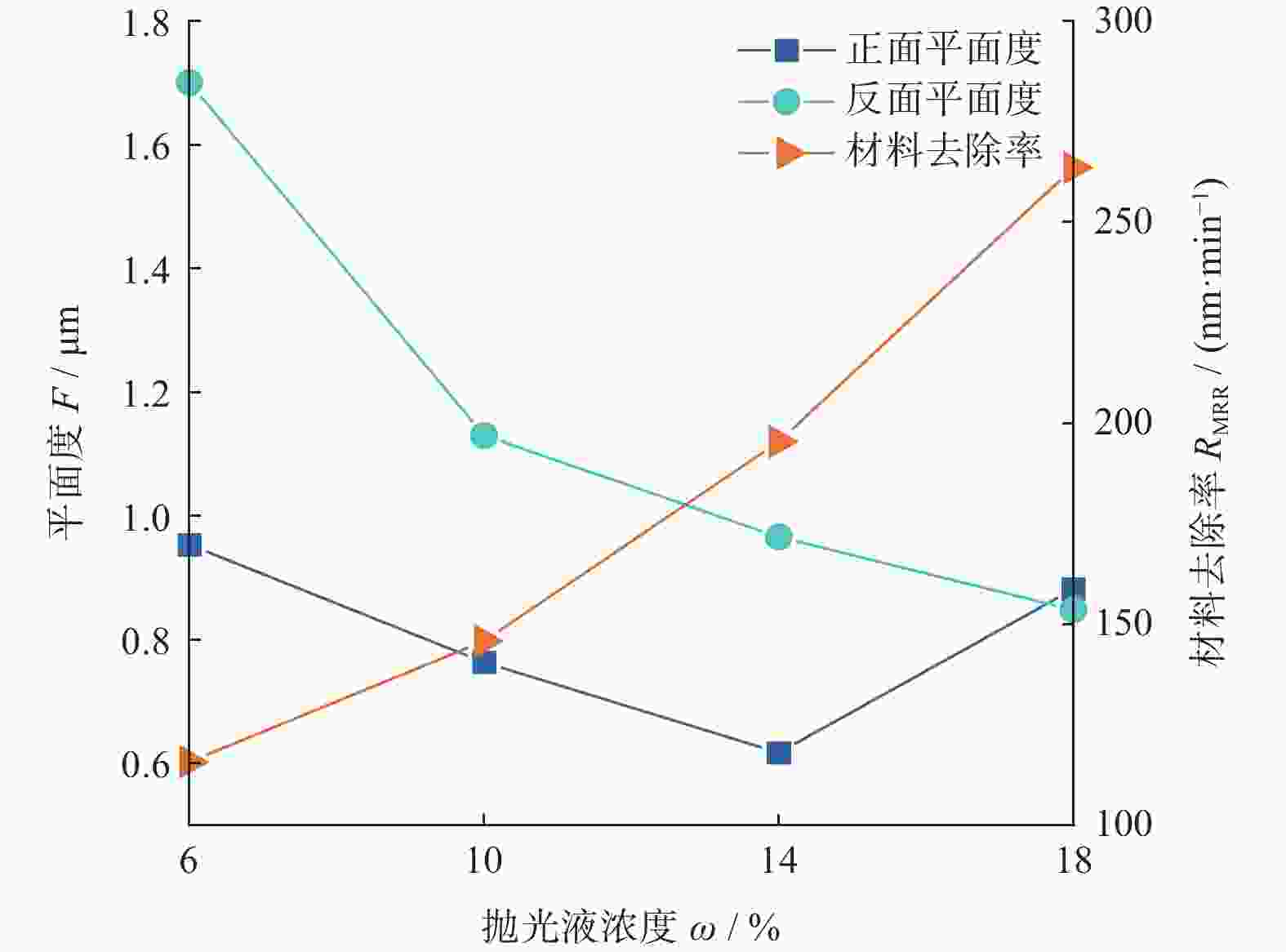

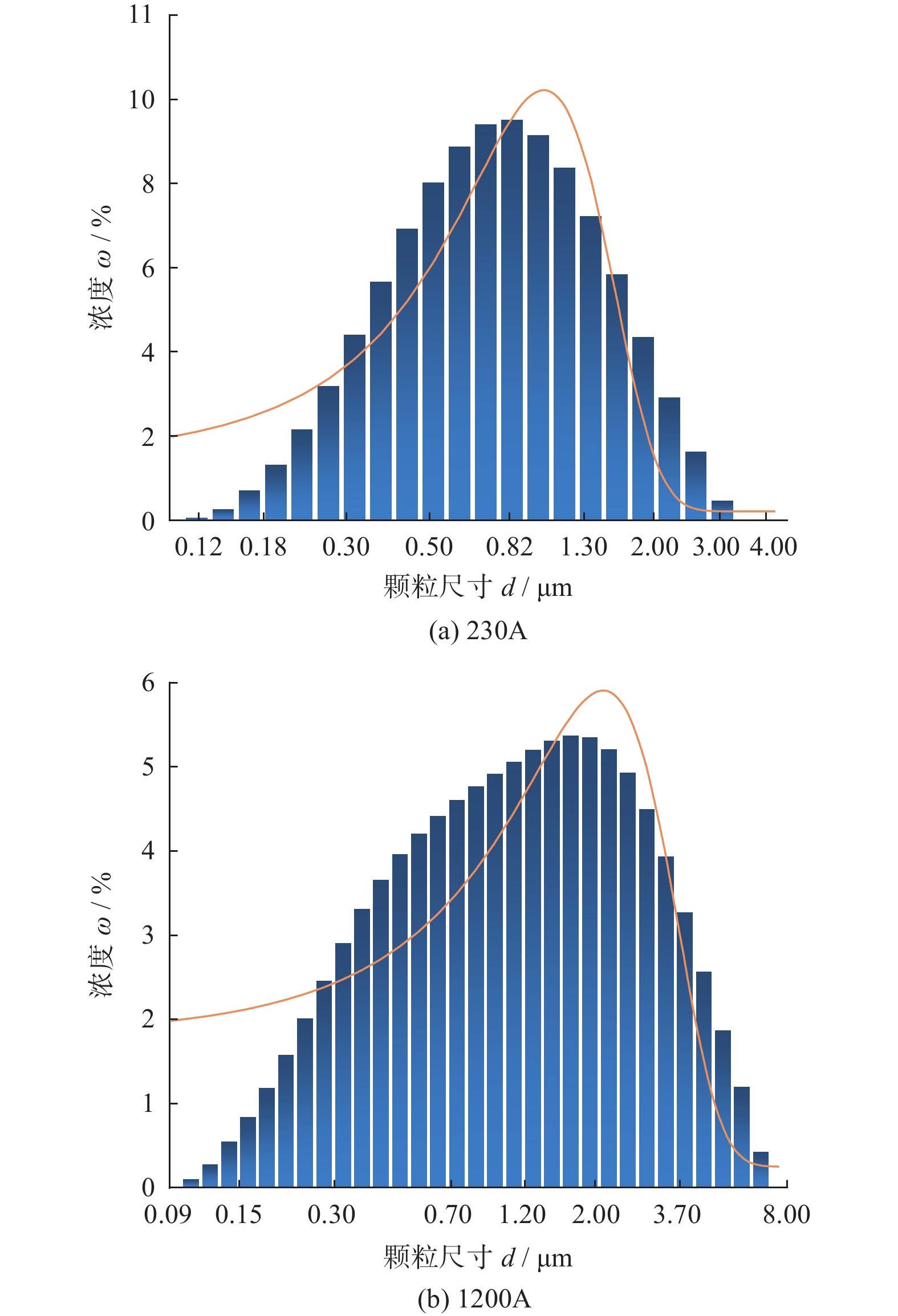

Objectives As the critical dimensions in integrated circuit structures continue to shrink, transistor density and chip performance keep improving. At the same time, the continuous evolution of integrated circuit manufacturing processes increasingly demands stricter flatness requirements for mask blanks. To reveal the polishing removal mechanism of double-sided chemical mechanical polishing on quartz mask substrates, a polishing solution is made using CeO2 abrasive to perform double-sided polishing on 6025 quartz mask substrates. Methods (1) CeO2 polishing powders with particle size distributions D50 of 0.823 and 1.231 μm respectively are placed in a beaker with deionized water. Under mechanical stirring, a certain amount of a mixture of sodium hexametaphosphate and sodium citrate is added as a dispersant, and an appropriate amount of polyacrylate as a surfactant. The pH value is adjusted using a weak alkali substance. Based on the content of CeO2, polishing liquids with mass fractions of 6%, 10%, 14%, and 18% are prepared. (2) The CMP experiment is conducted on a 22B double-sided polisher using an LP66 polyurethane polishing pad to polish 6025 synthetic quartz substrate grinding discs. The same set of polishing parameters is used to polish 12 pieces of 6025 simultaneously, and then the flatness and roughness of the 12 pieces of glass are averaged. For the polishing slurry, experiments are conducted with two types of polishing powder particle sizes and four types of polishing slurry concentrations. The surface morphology of different particle size CeO2 polishing powders is observed using a Zeiss Sigma field emission scanning electron microscope. The particle size distribution of the polishing powders is analyzed using a Mastersize 2000 laser particle size analyzer. The flatness of the quartz substrates before and after polishing is measured using a Tropel® UltraFlat™ flatness tester from CORNING. The change in thickness of the quartz substrates before and after polishing is measured using a KEYENCE displacement sensor to calculate the polishing rate. The roughness of the quartz substrates after polishing is measured using a Dimension ICON atomic force microscope from Bruker Germany. Results The flatness can reach 0.573 μm, and the surface roughness Ra is 0.96 nm under the following conditions: equivalent particle size D50 of CeO2 0.823 μm, mass fraction of CeO2 14%, polishing pressure 0.43 MPa, and a gear ring and sun gear speed of 6.54 and 3.08 r/min, respectively. Conclusions (1) The surface roughness of quartz glass after polishing with fine-grained 230A is reduced by 40% compared to that after polishing with 1200A. (2) With the increase in the concentration of the polishing solution, the flatness of the front surface initially shows a decreasing trend. It reaches a minimum value at a mass fraction of 14%. However, if the concentration is further increased, the flatness actually increases. The removal rate of the quartz glass increases continuously with the concentration of the polishing solution. (3) As the polishing pressure increases within the range of 0.26-0.43 MPa, the removal rate basically changes linearly. However, if the pressure is further increased, the removal rate actually decreases. (4) Using abrasive particles with an equivalent diameter D50 of 0.823 μm, a polishing solution with a concentration of 14% CeO2 is prepared. Under a polishing pressure of 0.43 MPa, and a ring gear and sun gear speed of 6.54 and 3.08 r/min, respectively, the surface of the 6025 quartz glass is polished to be smooth with almost no scratches or median cracks, achieving smaller flatness and better surface quality. -

Key words:

- CeO2 /

- double-sided polishing /

- mask blanks /

- surface topography

-

表 1 不同粒径CeO2对抛光性能的影响

Table 1. Effect of different particle size CeO2 on polishing

指标 230A 1200A 粒度分布 D50 / μm 0.823 1.231 去除量 h / nm 9 048 11 867 材料去除率 RMRR / (nm·min−1) 150.8 197.8 抛光后平面度 F / μm 0.953 0.987 抛光表面 表面光滑,无划伤,

光洁表面表面光滑,但局部

有点状划伤表 2 抛光转速差

Table 2. Polishing speed differential

r·min−1 转速差编号 齿圈转速 n1 太阳轮转速 n2 转速差 Δn M01 6.54 3.08 3.46 M02 6.80 4.23 2.57 M03 5.52 4.23 1.29 M04 4.23 4.23 0 -

[1] 韦亚一. 超大规模集成电路先进光刻理论与应用 [M]. 北京: 科学出版社, 2016.WEI Yayi. Advanced photolithography theory and applications in ultra-large-scale integrated circuits [M]. Beijing: Science Press, 2016. [2] SUKBAE J, LIANG H. Tribology for scientists and engineers: Tribology in chemical-mechanical planarization [M]. New York: Springer, 2013. [3] TZENG J, LEE B, LU J, et al. The effect between mask blank flatness and wafer print process window in ArF 6% att. PSM mask [C]//Photomask Technology 2006. Monterey, CA. SPIE, 2006: 634954. [4] 伍强, 胡华勇, 何伟明, 等. 衍射极限附近的光刻工艺 [M]. 2版. 北京: 清华大学出版社, 2024.WU Qiang, HU Huayong, HE Weiming, et al. Photolithography process near the diffraction limit [M]. 2nd ed. Beijing: Tsinghua University Press, 2024. [5] 许宁, 马家辉, 刘琦. CeO2基磨粒在化学机械抛光中的研究进展 [J]. 中国稀土学报, 2022, 40(2): 181-193. doi: 10.11785/S1000-4343.20220202XU Ning, MA Jiahui, LIU Qi. Research progress of CeO2-based abrasive particles in chemical mechanical polishing [J]. Journal of the Chinese Society of Rare Earths, 2022, 40(2): 181-193. doi: 10.11785/S1000-4343.20220202 [6] 张楷亮. CMP纳米抛光液及抛光工艺相关技术研究 [D]. 上海: 中国科学院研究生院(上海微系统与信息技术研究所), 2006.ZHANG Kailiang. Study on CMP nano-slurry and technology [D]. Shanghai: Shanghai Institute of Microsystem and Information Technology, Chinese Academy of Sciences, 2006. [7] HU Z H, AN D Q, ZHANG L, et al. Effect of CeO2 nanoparticle sizes on catalytic performances of sulfated CeO2/Al2O3 catalyst in NH3-SCR reaction [J]. Journal of Rare Earths, 2024, 42(3): 515-522. doi: 10.1016/j.jre.2023.02.004 [8] 阎秋生, 李基松, 潘继生. 熔融石英玻璃衬底的平面研磨加工实验研究 [J]. 金刚石与磨料磨具工程, 2019, 39(1): 60-65. doi: 10.13394/j.cnki.jgszz.2019.1.0011YAN Qiusheng, LI Jisong, PAN Jisheng. Experimental research on plane lapping of fused silica glass substrate [J]. Diamond & Abrasives Engineering, 2019, 39(1): 60-65. doi: 10.13394/j.cnki.jgszz.2019.1.0011 [9] LI W, HU X D, JIN Y F, et al. A study of double sided polishing process for ultra-smooth surface of silicon wafer [J]. Materials Science Forum, 2006(532/533): 472-475. doi: 10.4028/www.scientific.net/MSF.532-533.472 [10] 金程, 李伟. 双面抛光机内外齿圈齿比的研究 [J]. 轻工机械, 2011, 29(5): 28-30. doi: 10.3969/j.issn.1005-2895.2011.05.007JIN Cheng, LI Wei. Study on inner and outer gears ratio of double-sided polishing machine [J]. Light Industry Machinery, 2011, 29(5): 28-30. doi: 10.3969/j.issn.1005-2895.2011.05.007 [11] 王也, 张保国, 吴鹏飞, 等. 用于光学玻璃CMP的高效稀土抛光液研究 [J]. 润滑与密封, 2023, 48(5): 79-84. doi: 10.3969/j.issn.0254-0150.2023.05.012WANG Ye, ZHANG Baoguo, WU Pengfei, et al. Research on high-efficiency rare earth polishing slurry for CMP of optical glass [J]. Lubrication Engineering, 2023, 48(5): 79-84. doi: 10.3969/j.issn.0254-0150.2023.05.012 [12] CHEN C D, ZHAO S Y, LI X P, et al. Preparation of CeO2 particles via ionothermal synthesis and its application to chemical mechanical polishing [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2024, 694: 134194. doi: 10.1016/j.colsurfa.2024.134194 [13] PRESTON F W. The theory and design of plate glass polishing machine [J]. Society of Glass Technology, 1927, 11(44): 214-256. [14] 杜来林, 宋述稳. 平面阀门的快速研磨工艺 [J]. 机械制造, 2004, 42(12): 45-46. doi: 10.3969/j.issn.1000-4998.2004.12.019DU Lailin, SONG Shuwen. Rapid grinding technology of plane valve [J]. Machinery, 2004, 42(12): 45-46. doi: 10.3969/j.issn.1000-4998.2004.12.019 [15] 白林山, 王金普, 储向峰. 二氧化铈抛光液化学机械抛光微晶玻璃的机理及优化 [J]. 金刚石与磨料磨具工程, 2017, 37(2): 1-5,10. doi: 10.13394/j.cnki.jgszz.2017.2.0001BAI Linshan, WANG Jinpu, CHU Xiangfeng. Mechanism and optimization of chemical-mechanically polishing ceramic glass substrate with CeO2 slurry [J]. Diamond & Abrasives Engineering, 2017, 37(2): 1-5,10. doi: 10.13394/j.cnki.jgszz.2017.2.0001 [16] 杨昌明, 朱利, 张冒. 研磨机研磨运动轨迹分析 [J]. 机床与液压, 2012, 40(15): 7-9. doi: 10.3969/j.issn.1001-3881.2012.15.002YANG Changming, ZHU Li, ZHANG Mao. Analysis of grinding trajectory of lapping machine [J]. Machine Tool & Hydraulics, 2012, 40(15): 7-9. doi: 10.3969/j.issn.1001-3881.2012.15.002 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS