Ultra-low temperature grinding process and surface integrity of SiCp/Al material

-

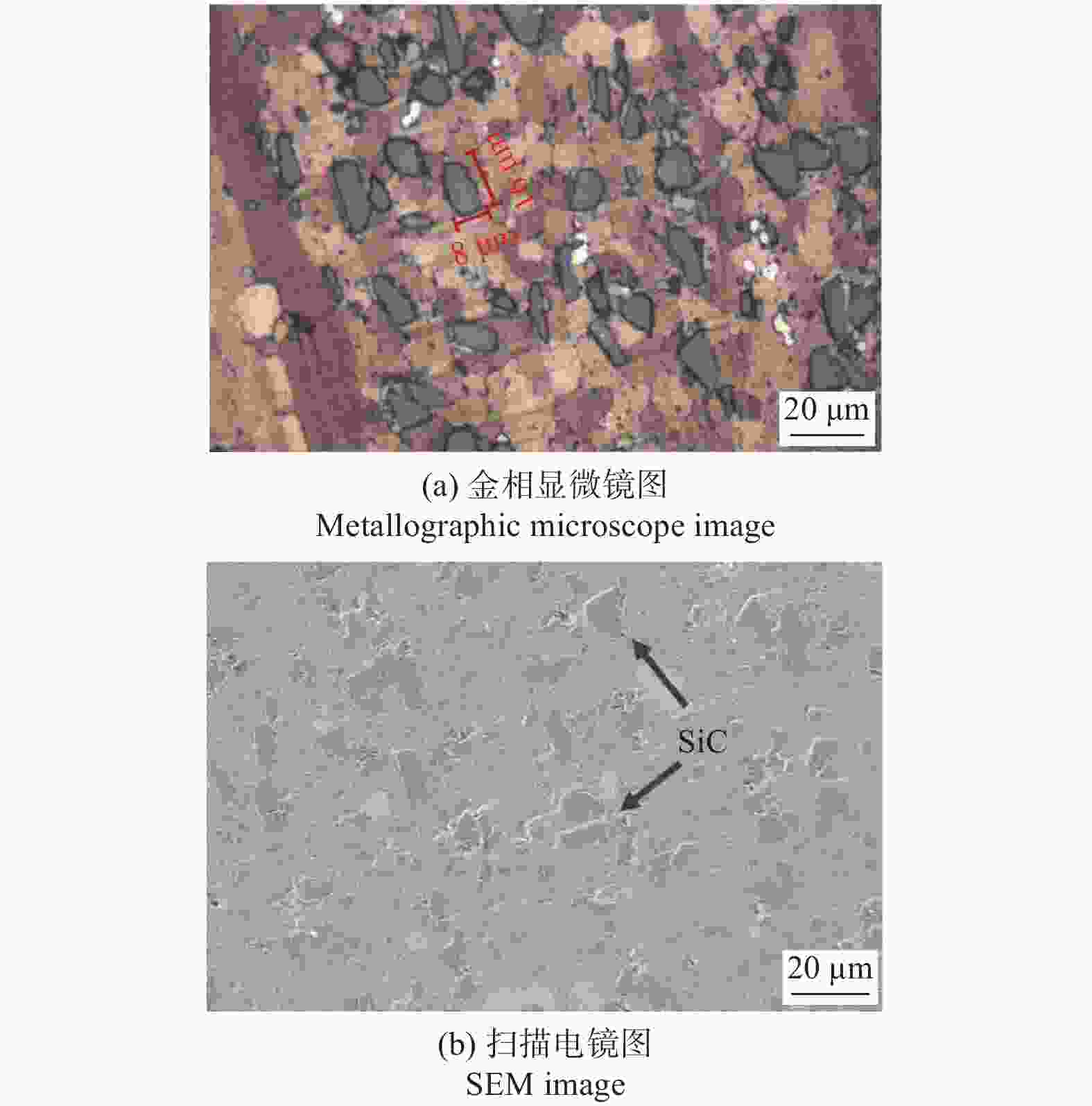

摘要: SiCp/Al作为一种典型的颗粒增强金属基复合材料,凭借其优异的综合性能在航空航天、精密电子等领域得到了广泛应用,但其物理特性与可加工性能仍有提升空间。针对20%体积分数的SiCp/Al复合材料进行液氮超低温与室温风冷磨削实验,对比2种冷却介质下工艺参数对其磨削力、表面损伤的影响,并分析其表面粗糙度、残余应力和显微硬度的变化规律。结果表明:SiCp/Al的超低温磨削力和表面完整性变化趋势与室温风冷磨削时的相近;超低温增加了铝基体的致密性与均匀性,提高了材料整体和界面结合强度,使其磨削力较室温风冷时的更大,且能有效抑制铝基体和SiC颗粒的磨削损伤,降低材料表面粗糙度,提高材料的残余压应力和硬度,从而综合提升材料表面质量。Abstract:

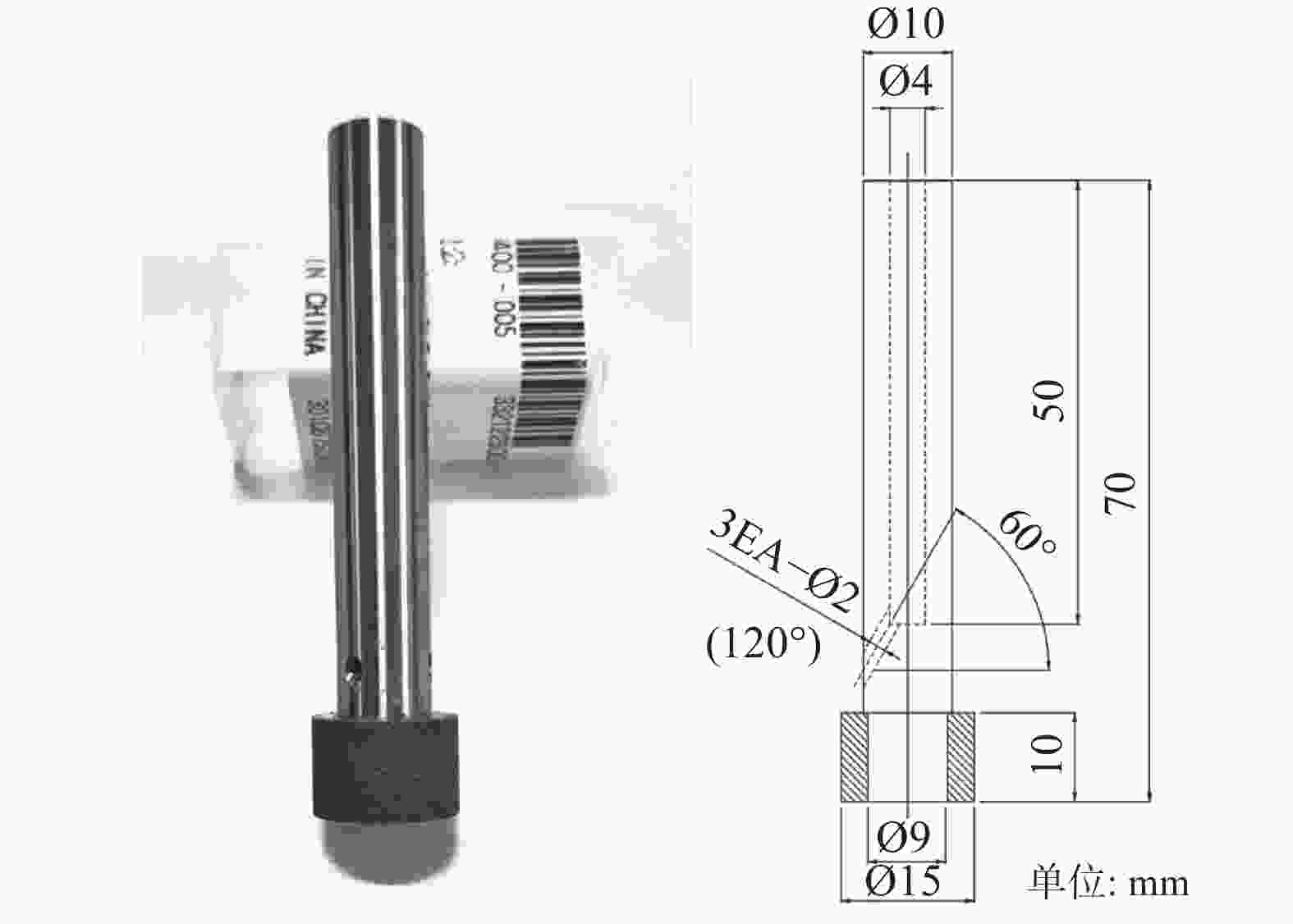

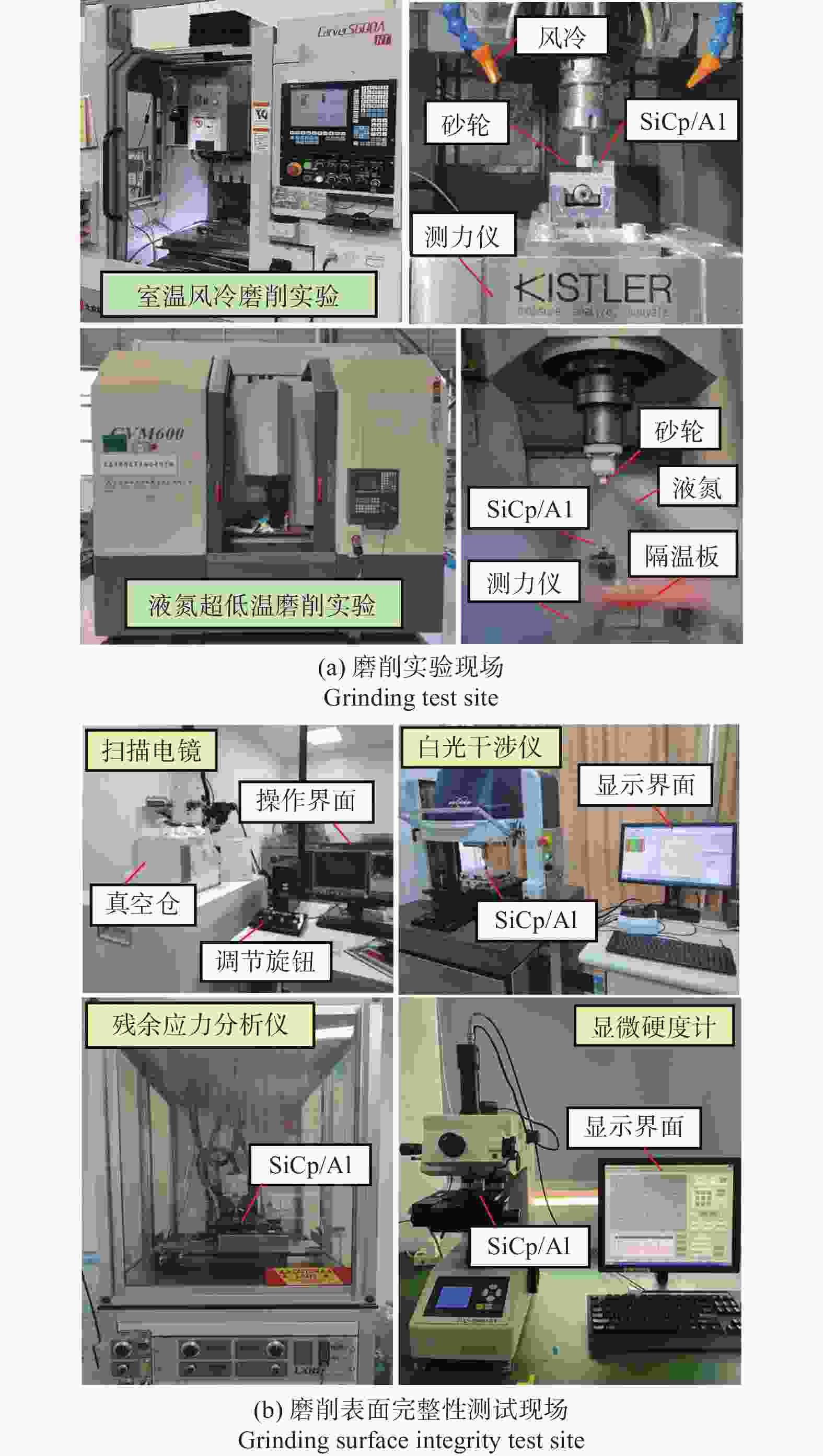

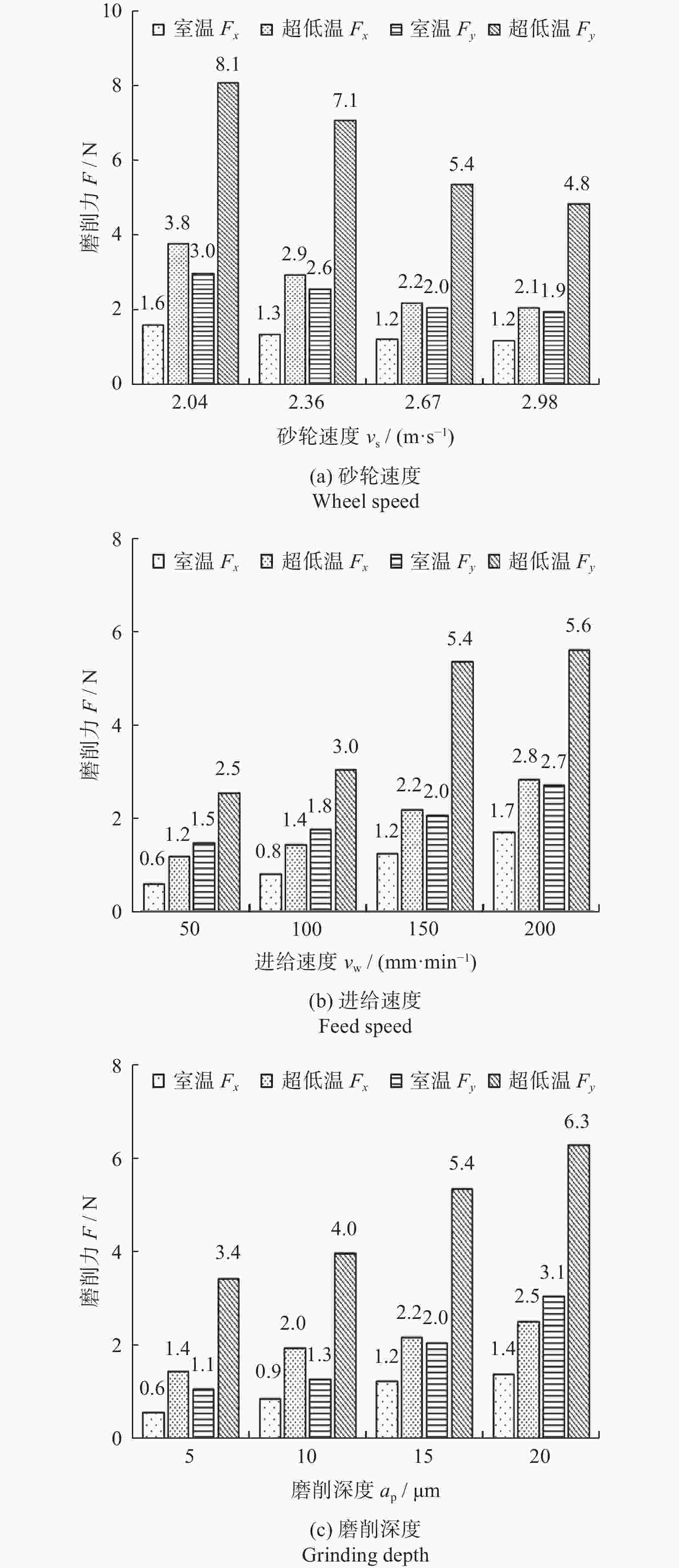

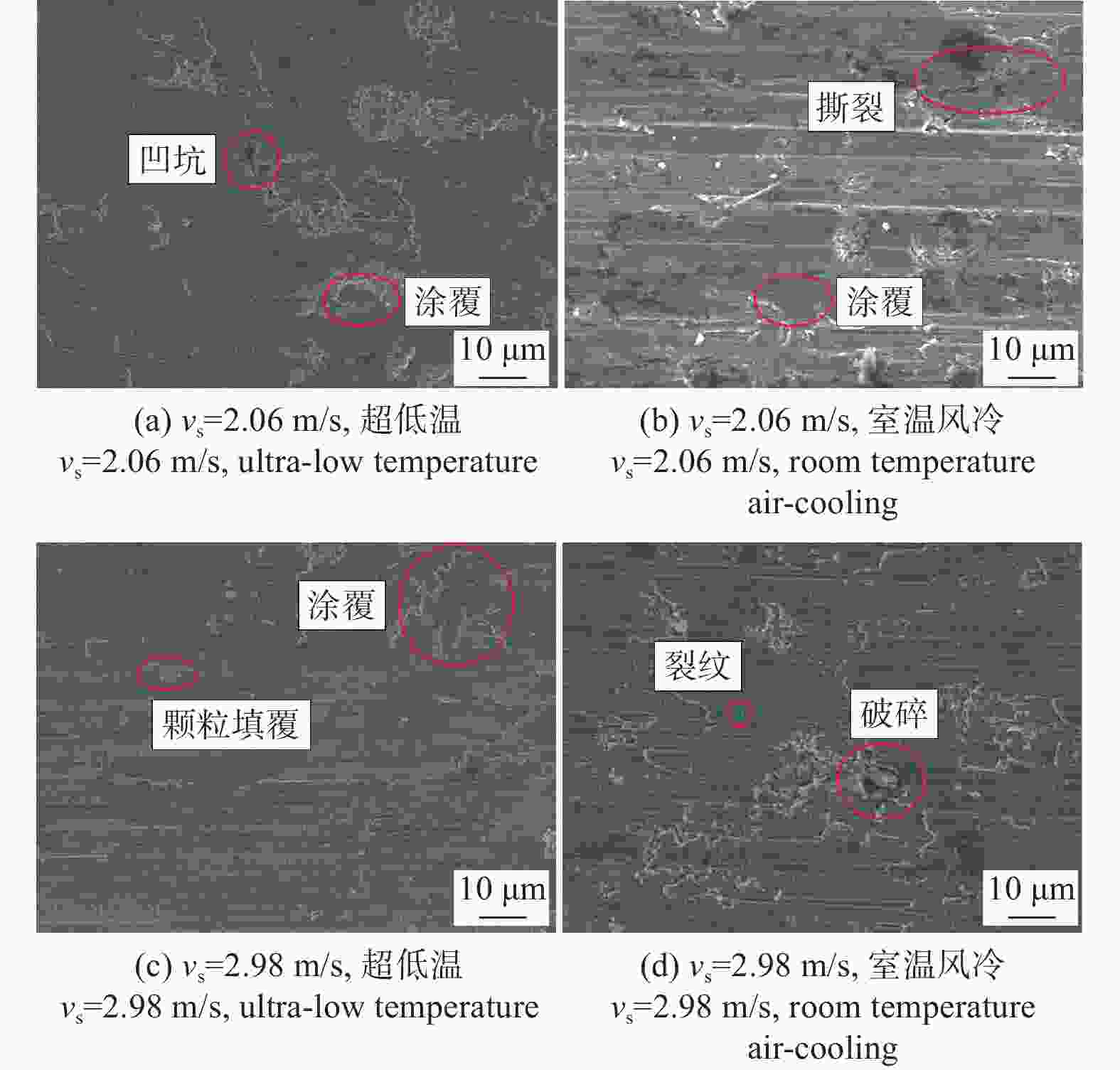

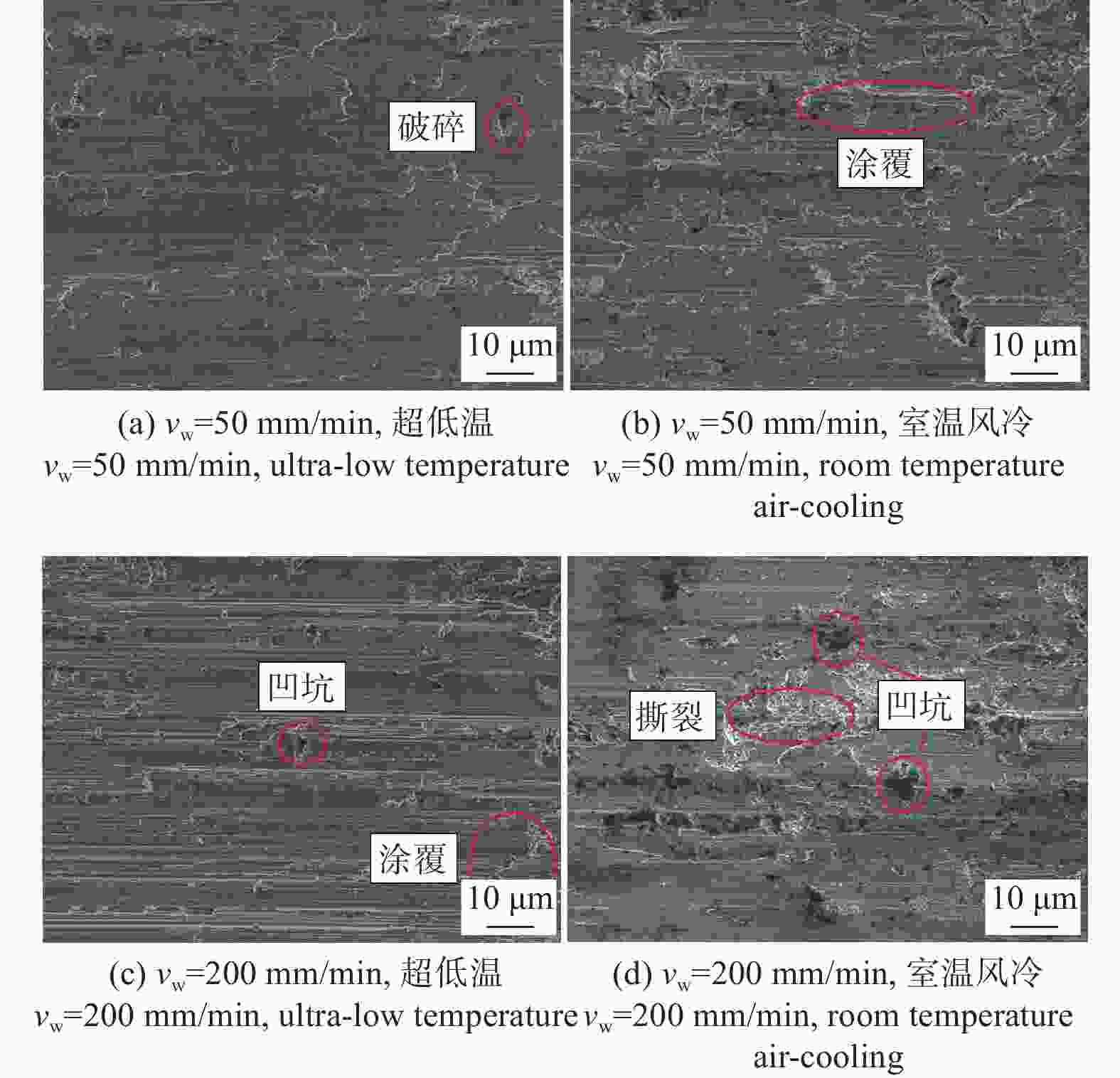

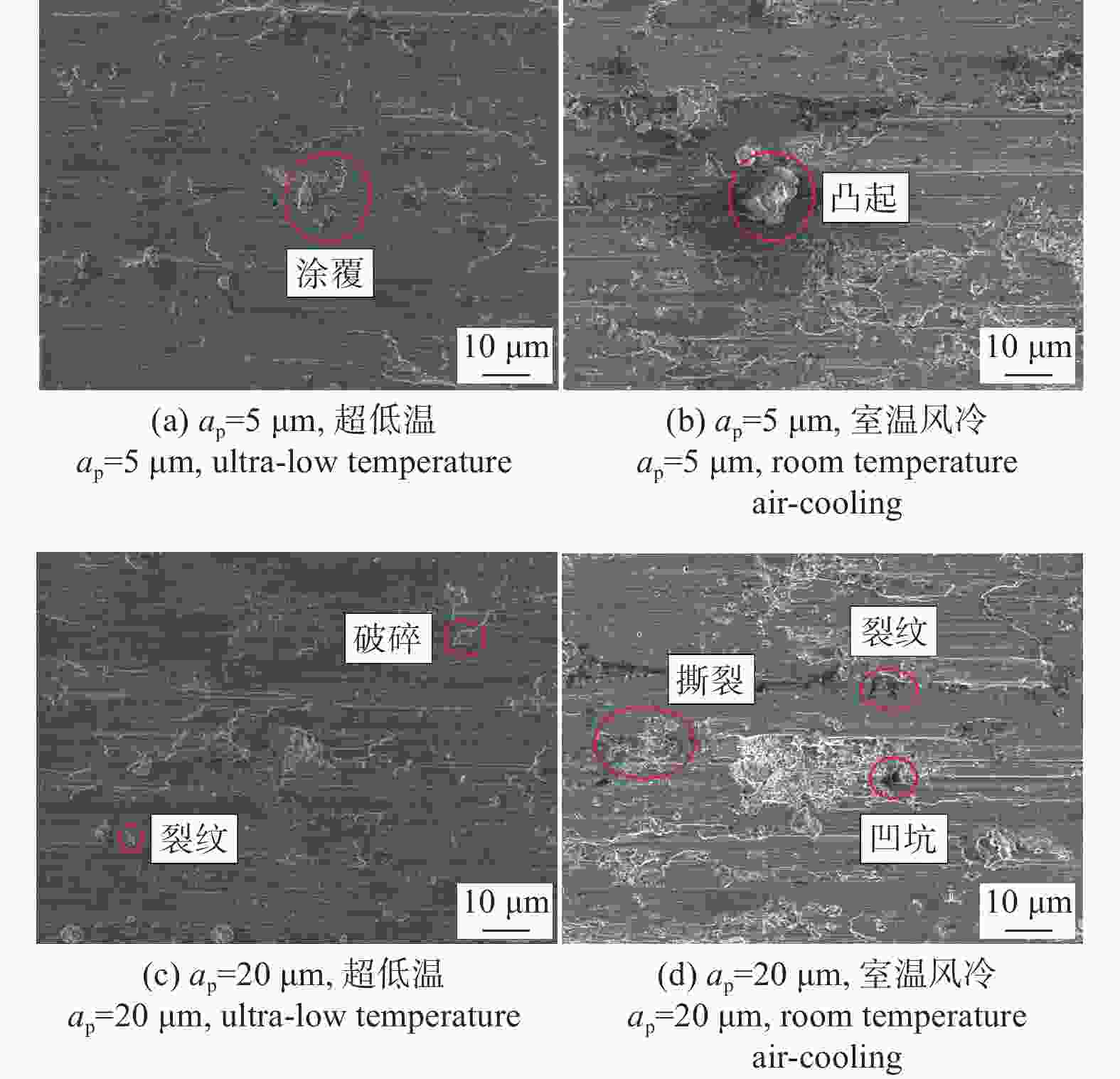

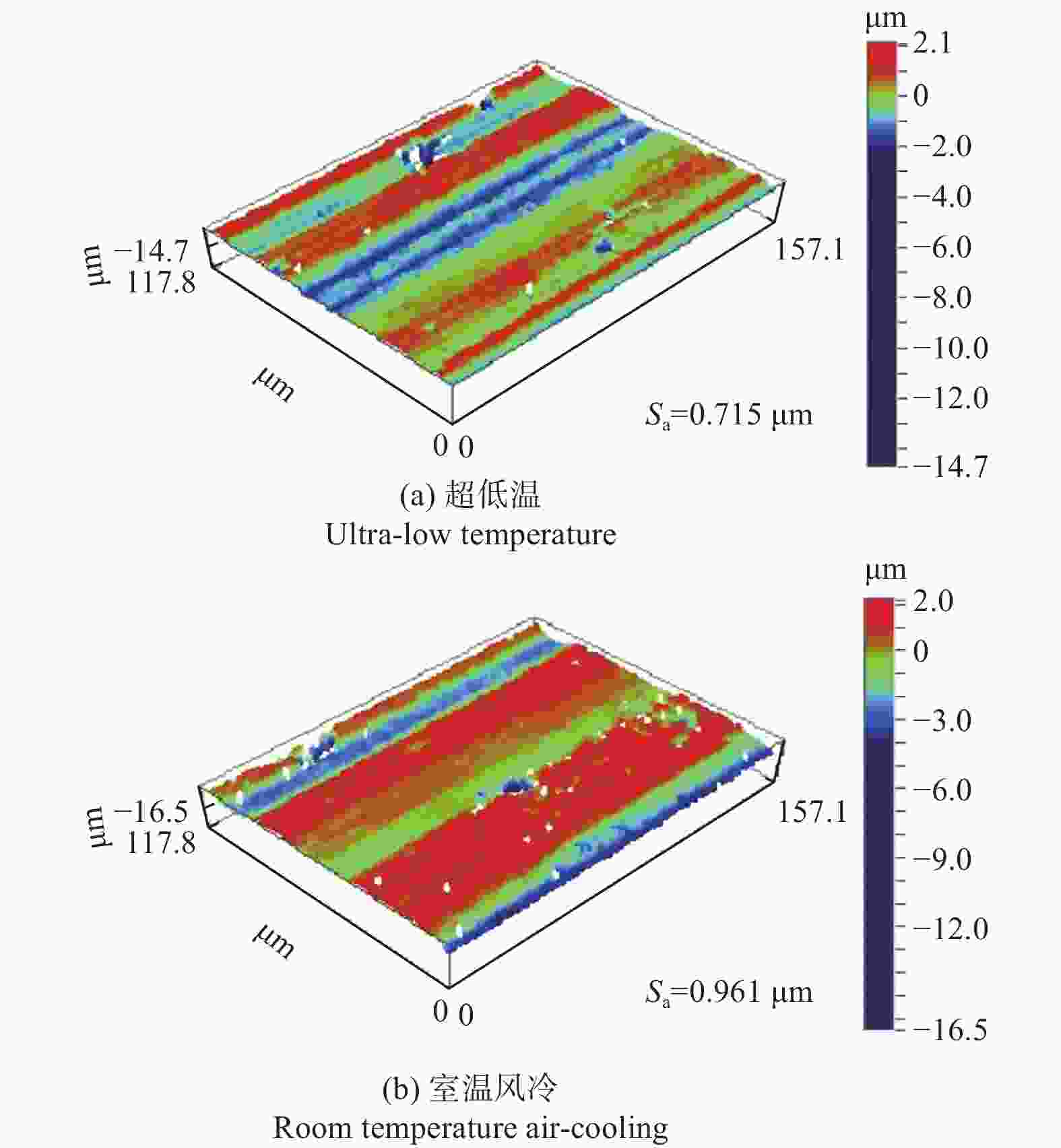

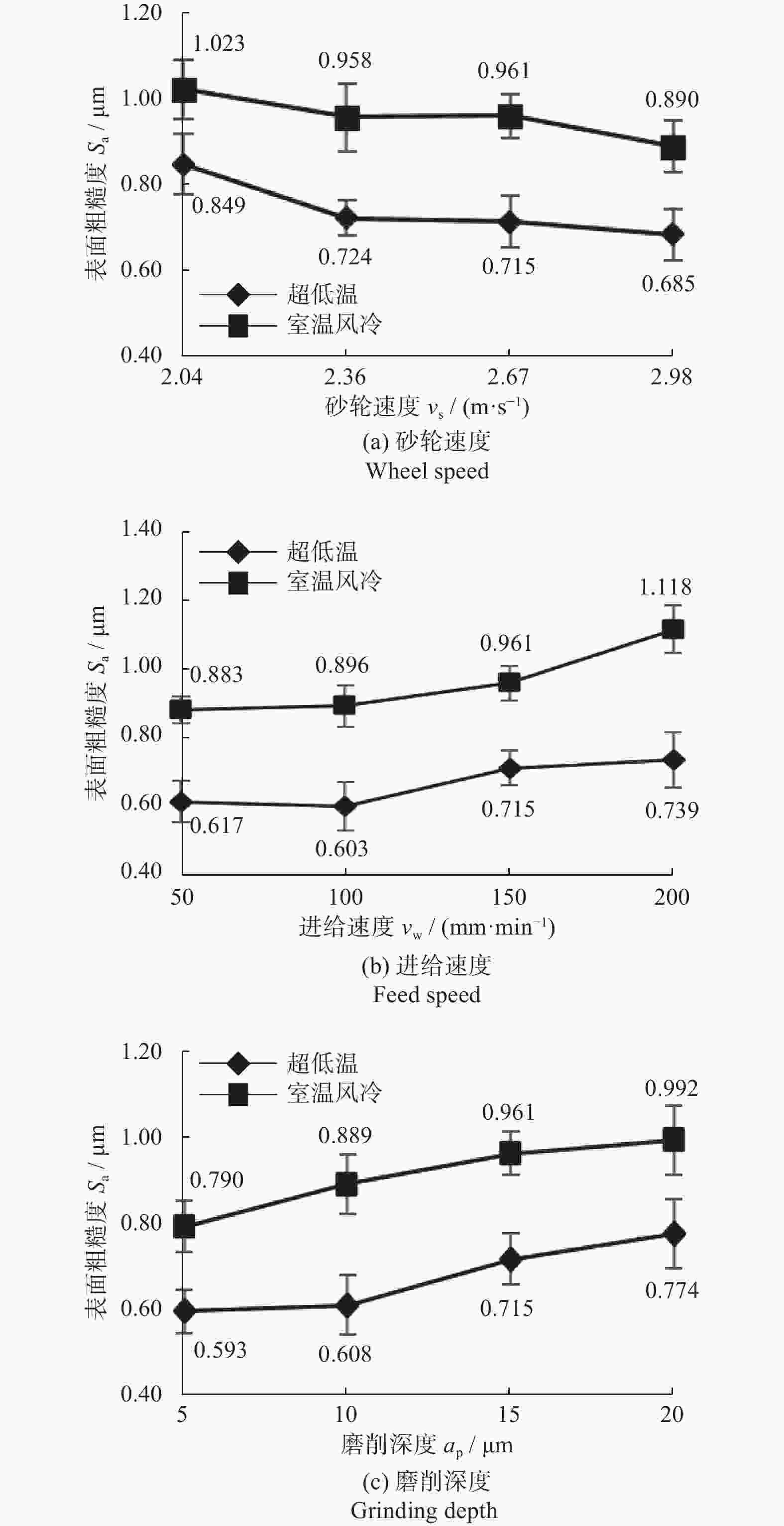

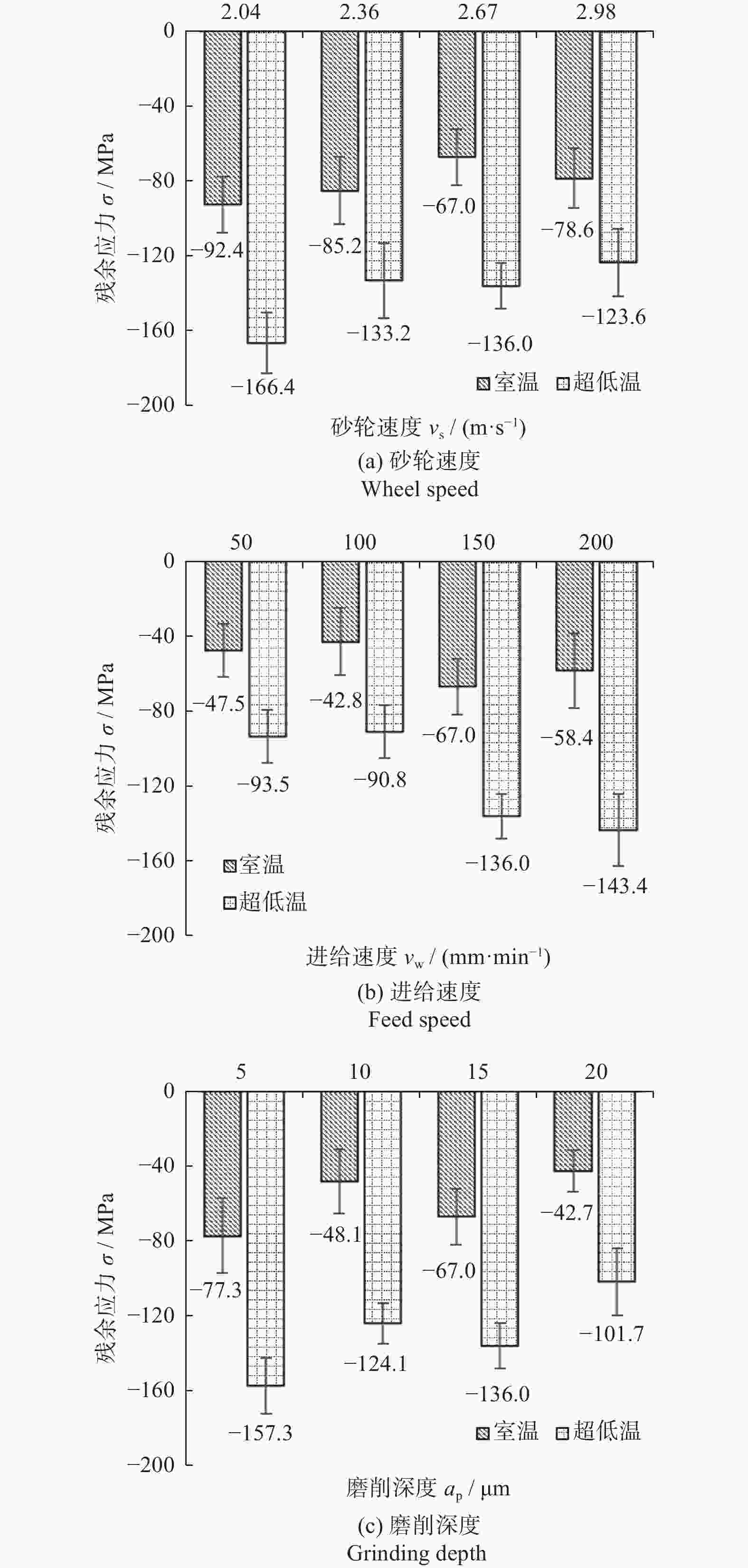

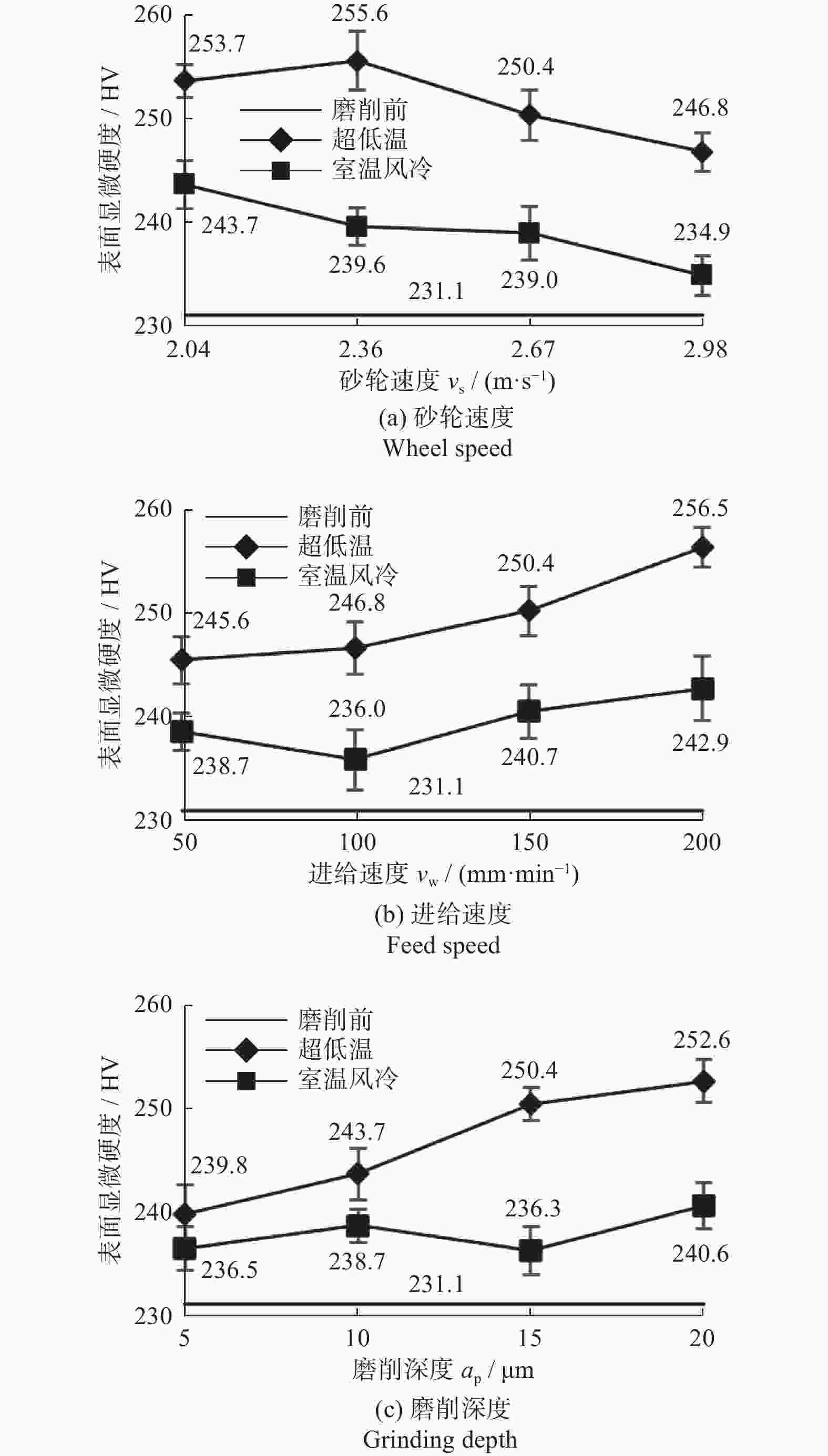

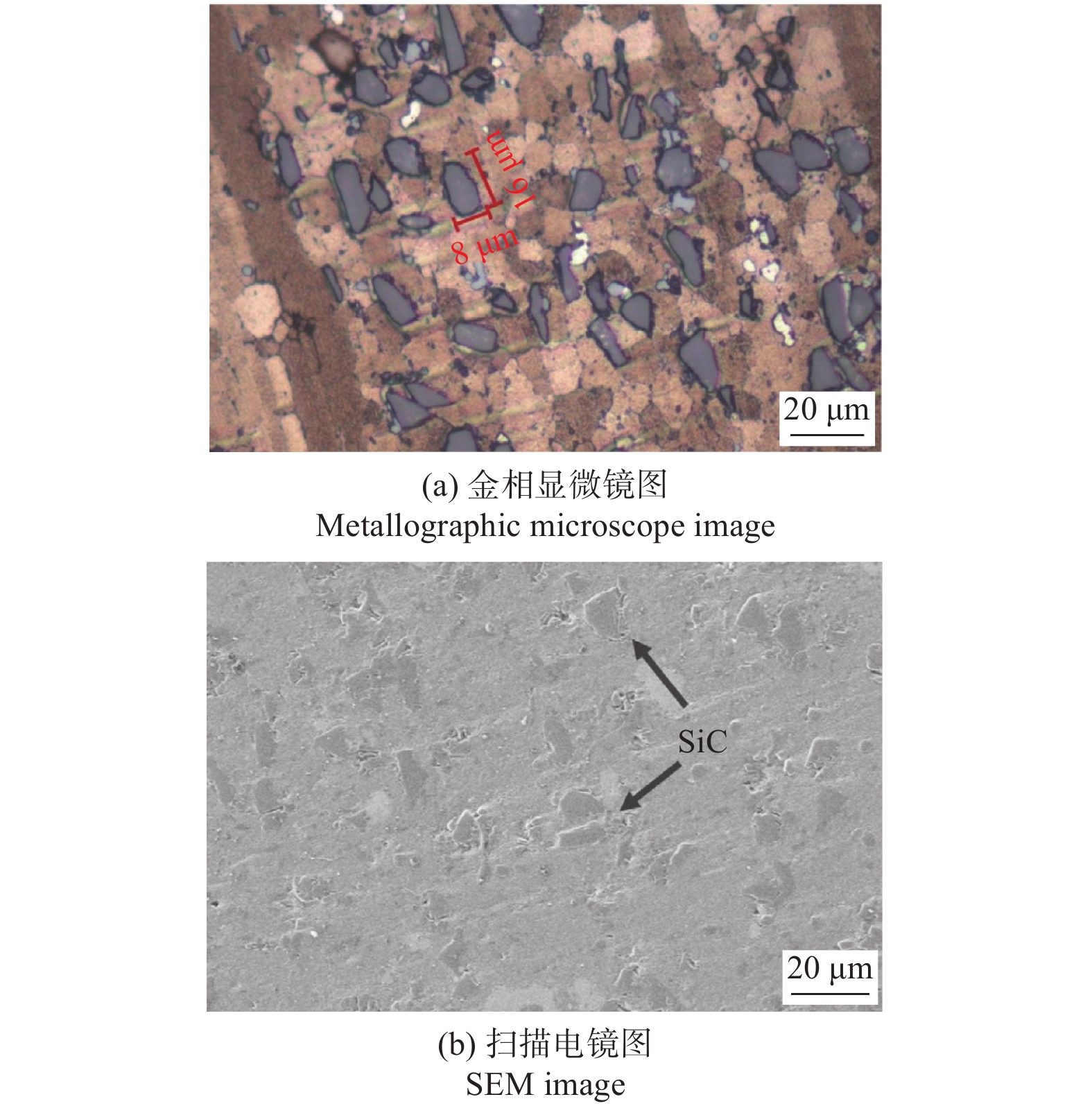

Objectives As a new-generation high-performance structural material, silicon carbide particle-reinforced aluminum matrix composites (SiCp/Al) exhibit outstanding specific strength, wear resistance, and thermal stability, making them highly valuable in aerospace precision components, electronic packaging substrates, and other advanced manufacturing fields. However, common machining-induced damage issues such as matrix smearing and particle fragmentation severely compromise surface integrity and service performance. This study focuses on 20% SiCp/Al composites, systematically investigating the effects of process parameters on grinding force evolution, surface damage mechanisms, and surface integrity by comparing liquid nitrogen ultra-low temperature and room temperature air-cooling grinding conditions. The aim is to reveal the regulatory mechanisms of ultra-low temperature environments on composite machining performance and provide theoretical guidance for precision process optimization. Methods Grinding experiments are conducted on 20% SiCp/Al composites using diamond grinding wheels under single-factor conditions. The ultra-low temperature grinding experiments are performed on a vertical machining center with internal liquid nitrogen jet cooling, while conventional room temperature air-cooling serves as the control group. Process parameters includes wheel speed 2.04 to 2.98 m/s, feed rate 50 to 200 mm/min, grinding depth 5 to 20 μm, and grinding width 6 mm. A dynamometer monitored normal and tangential grinding forces in real time. Surface roughness is measured via white light interferometry, residual stress measured via X-ray diffraction analysis, and microhardness measured via a microhardness tester. Surface and subsurface damage is characterized using scanning electron microscopy. Results (1) Under both cooling conditions, grinding forces decreases with increased wheel speed and increases linearly with feed rate and grinding depth. The ultra-low temperature environment significantly enhances material yield strength and interfacial bonding strength, resulting in average grinding forces 1.7 to 2.7 times higher than those under room temperature air-cooling conditions. While room temperature grinding forces shows minor variations with parameter changes, wheel speed and feed rate exerts substantial impacts in ultra-low temperature grinding. (2) Grinding-induced damage in SiCp/Al primarily manifests as matrix smearing/tearing and SiC particle fracture/pullout. Despite higher grinding forces under ultra-low temperature conditions, surface damage is consistently less severe than under room temperature cooling. In ultra-low temperature grinding, reduced thermal effects and increased material strength/hardness promotes localized stress concentration, leading to minor matrix smearing and particle fracture. In contrast, room temperature grinding induces extensive matrix tearing, particle pullout, and associated cracks/pits. (3) Ultra-low temperature grinding effectively suppresses matrix smearing, pits, and crack propagation, achieving surface roughness values 16% to 42% lower than those under room temperature air-cooling conditions. Higher grinding forces under ultra-low temperature conditions enhances plastic deformation strengthening, while liquid nitrogen cooling minimizes thermal softening effects. Consequently, ultra-low temperature grinding generates larger residual compressive stress magnitudes and higher surface microhardness compared to room temperature grinding. Conclusions The liquid nitrogen ultra-low temperature environment significantly improves the mechanical properties of the SiCp/Al matrix and interfaces through cryogenic strengthening. Although grinding forces increase, this approach effectively suppresses machining damage, substantially reduces surface roughness, and generates enhanced residual compressive stress fields and uniform hardened layers. The influence of process parameters on grinding forces and surface integrity follows similar trends under both cooling conditions. Optimal parameter combinations with higher wheel speeds and smaller depths of cut enable efficient, low-damage machining. The transition in damage mechanisms and improvements in surface integrity validate that ultra-low temperature environments optimize material removal processes through thermo-mechanical coupling suppression and mechanical property enhancement, offering a novel pathway for precision machining of particle-reinforced composites. -

Key words:

- SiCp/Al /

- ultra-low temperature /

- grinding /

- material damage /

- surface integrity

-

表 1 SiCp/Al复合材料的主要化学成分

Table 1. Main chemical compositions of SiCp/Al

成分 质量分数 ω / % SiC 19.50 Mg 1.25 Si 0.22 Ti < 0.03 Fe 0.08 Cu 3.36 Al 余量 表 2 SiCp/Al复合材料的机械物理性能

Table 2. Mechanical and physical properties of SiCp/Al

参数 取值 抗拉强度 σ1 / MPa 560 屈服强度 σ2 / MPa 370 密度 ρ / (g·cm−3) 2.84 泊松比 ε 0.38 弹性模量 E / GPa 105 热导率 K / (W·m−1·K−1) 178 线膨胀系数 λ / K−1 1.51 × 10−6 -

[1] 武高辉, 匡泽洋. 装备升级换代背景下金属基复合材料的发展机遇和挑战 [J]. 中国工程科学, 2020, 22(2): 79-90. doi: 10.15302/J-SSCAE-2020.02.012WU Gaohui, KUANG Zeyang. Opportunities and challenges for metal matrix composites in the context of equipment upgrading [J]. Strategic Study of CAE, 2020, 22(2): 79-90. doi: 10.15302/J-SSCAE-2020.02.012 [2] GU P, ZHU C, SUN Y, et al. Surface roughness prediction of SiCp/Al composites in ultrasonic vibration-assisted grinding [J]. Journal of Manufacturing Processes, 2023, 101: 687-700. doi: 10.1016/j.jmapro.2023.05.093 [3] WANG H, ZHANG H, ZHOU M, et al. Study of surface defect detection techniques in grinding of SiCp/Al composites [J]. Applied Sciences, 2023, 13(21): 11961. doi: 10.3390/app132111961 [4] 王永青, 郭东明, 郭立杰, 等. 超低温加工技术的研究现状及发展趋势 [J]. 上海航天(中英文), 2020, 37(3): 11-21. doi: 10.19328/j.cnki.1006-1630.2020.03.002WANG Yongqing, GUO Dongming, GUO Lijie, et al. Research status and development trend of ultra-low temperature machining technology [J]. Aerospace Shanghai (Chinese & English), 2020, 37(3): 11-21. doi: 10.19328/j.cnki.1006-1630.2020.03.002 [5] ZHU C, GU P, LIU D, et al. Evaluation of surface topography of SiCp/Al composite in grinding [J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(9/10/11/12): 2807-2821. doi: 10.1007/s00170-019-03362-5 [6] YIN G, GONG Y, LI Y, et al. Modeling and evaluation in grinding of SiCp/Al composites with single diamond grain [J]. International Journal of Mechanical Sciences, 2019, 163: 105137. doi: 10.1016/j.ijmecsci.2019.105137 [7] 尹逊雨, 高奇, 陈野, 等. 20%SiCp/Al复合材料磨削机理及表面粗糙度研究 [J]. 制造技术与机床, 2022(12): 107-112. doi: 10.19287/j.mtmt.1005-2402.2022.12.017YIN Xunyu, GAO Qi, CHEN Ye, et al. Study on micro-grinding mechanism and surface quality of 20% SiCp/Al composites [J]. Technology and Manufacture, 2022(12): 107-112. doi: 10.19287/j.mtmt.1005-2402.2022.12.017 [8] 范磊, 王娜, 尹国强. 基于单颗磨粒磨削的SiCp/Al材料去除机理研究 [J]. 组合机床与自动化加工技术, 2024(10): 126-131. doi: 10.13462/j.cnki.mmtamt.2024.10.025FAN Lei, WANG Na, YIN Guoqiang. Research on the material removal mechanism of SiCp/Al based on single grain grinding [J]. Modular Machine Tool & Automatic Manufacturing Technique, 2024(10): 126-131. doi: 10.13462/j.cnki.mmtamt.2024.10.025 [9] 李爽, 牛秋林, 李常平, 等. 涂层刀具低温铣削SiCp/Al 复合材料表面质量研究 [J]. 宇航材料工艺, 2021, 51(2): 68-72. doi: 10.12044/j.issn.1007-2330.2021.02.011LI Shuang, NIU Qiulin, LI Changping, et al. Surface quality of SiCp/Al composites milled by coated tools at low temperature [J]. Aerospace Materials & Technology, 2021, 51(2): 68-72. doi: 10.12044/j.issn.1007-2330.2021.02.011 [10] YU W, CHEN J, MING W, et al. Feasibility of supercritical CO2-based minimum quantity lubrication to improve the surface integrity of 50% SiCp/Al composites [J]. Journal of Manufacturing Processes, 2022(73): 364-374. doi: 10.1016/j.jmapro.2021.11.022 [11] ROSS N S, MANASEA S B J A, NAGARAJAN S, et al. Novel use of ultra-low temperature cooling conditions in improving the machining performance of Al 8011/nano-SiC composites [J]. The International Journal of Advanced Manufacturing Technology, 2023, 129(3): 1703-1715. doi: 10.1007/s00170-023-12382-1 [12] LAGHARI R A, HE N, JAMIL M, et al. Tribological and machining characteristics of milling SiCp/Al MMC composites under sustainable cooling conditions [J]. The International Journal of Advanced Manufacturing Technology, 2023, 128(5/6): 2613-2630. doi: 10.1007/s00170-023-12083-9 [13] ABBAS C A, HUANG C, BINGHAI L, et al. Research on ultra-low temperature high-speed drilling performance of metal matrix composite materials (Al/SiC) using ultra-low temperatureally treated drills [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2024, 46(8): 448. doi: 10.1007/s40430-024-05007-5 [14] 温雪龙, 王承宝, 巩亚东, 等. 涂层微磨具的制备及磨削表面质量实验研究 [J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. doi: 10.12068/j.issn.1005-3026.2022.05.011WEN Xuelong, WANG Chengbao, GONG Yadong, et al. Preparation of coated micro-grinding tools and experimental research on grinding surface quality [J]. Journal of Northeastern University (Natural Science), 2022, 43(5): 681-688. doi: 10.12068/j.issn.1005-3026.2022.05.011 [15] 郭维诚, 吴杰, 郭淼现, 等. SiCp/Al超低温材料流动行为和本构模型构建 [J]. 材料导报, 2025, 39(4): 204-211. doi: 10.11896/cldb.23110133GUO Weicheng, WU Jie, GUO Miaoxian, et al. Ultra-low temperature flow behavior of SiCp/Al composite and construction of constitutive model [J]. Materials Reports, 2025, 39(4): 204-211. doi: 10.11896/cldb.23110133 [16] 王少雷, 张丽影, 梁尤宇, 等. 磨削工艺参数对SiCp/Al三维粗糙度的影响 [J]. 制造技术与机床, 2024(4): 63-70. doi: 10.19287/j.mtmt.1005-2402.2024.04.010WANG Shaolei, ZHANG Liying, LIANG Youyu, et al. Influence of the grinding process parameters on the SiCp/Althree-dimensional Roughness [J]. Manufacturing Technology & Machine Tool, 2024(4): 63-70. doi: 10.19287/j.mtmt.1005-2402.2024.04.010 [17] 林洁琼, 于行, 周岩, 等. 超声振动辅助车削SiCp/Al切屑形成机理及表面粗糙度研究 [J]. 表面技术, 2024, 53(6): 144-156. doi: 10.16490/j.cnki.issn.1001-3660.2024.06.013LIN Jieqiong, YU Xing, ZHOU Yan, et al. Chip formation mechanism and surface roughness of SiCp/Al composites by ultrasonic vibration-assisted turning [J]. Surface Technology, 2024, 53(6): 144-156. doi: 10.16490/j.cnki.issn.1001-3660.2024.06.013 [18] ZHANG H, QU L, DING C. Study of Surface integrity of SiCp/Al composites using high-speed milling under ultra-low temperature liquid nitrogen conditions [J]. Machines, 2023, 11(6): 608. doi: 10.3390/machines11060608 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS