Ultra-precision machining test of diamond sand belt for Si3N4 ceramic cylindrical roller

-

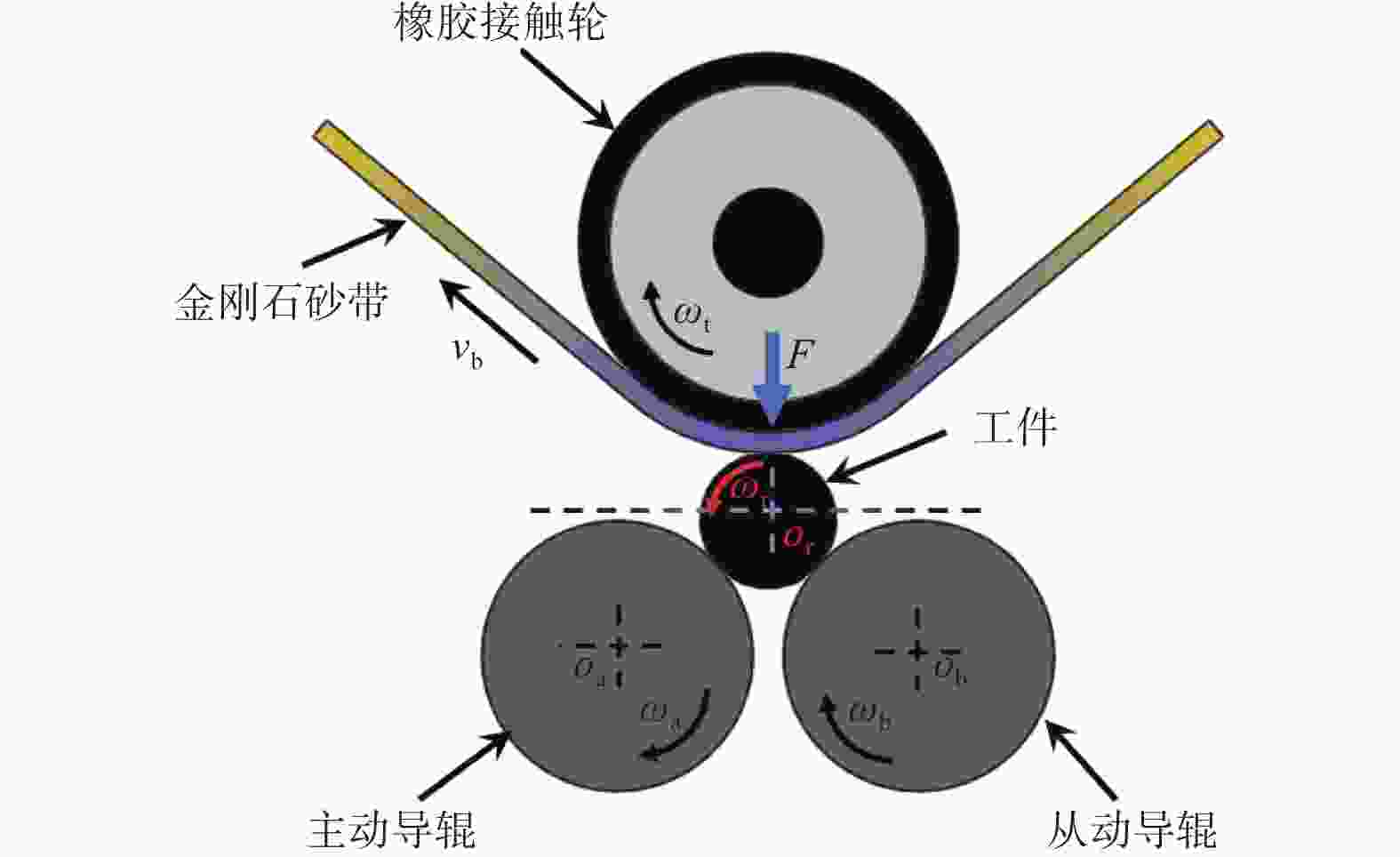

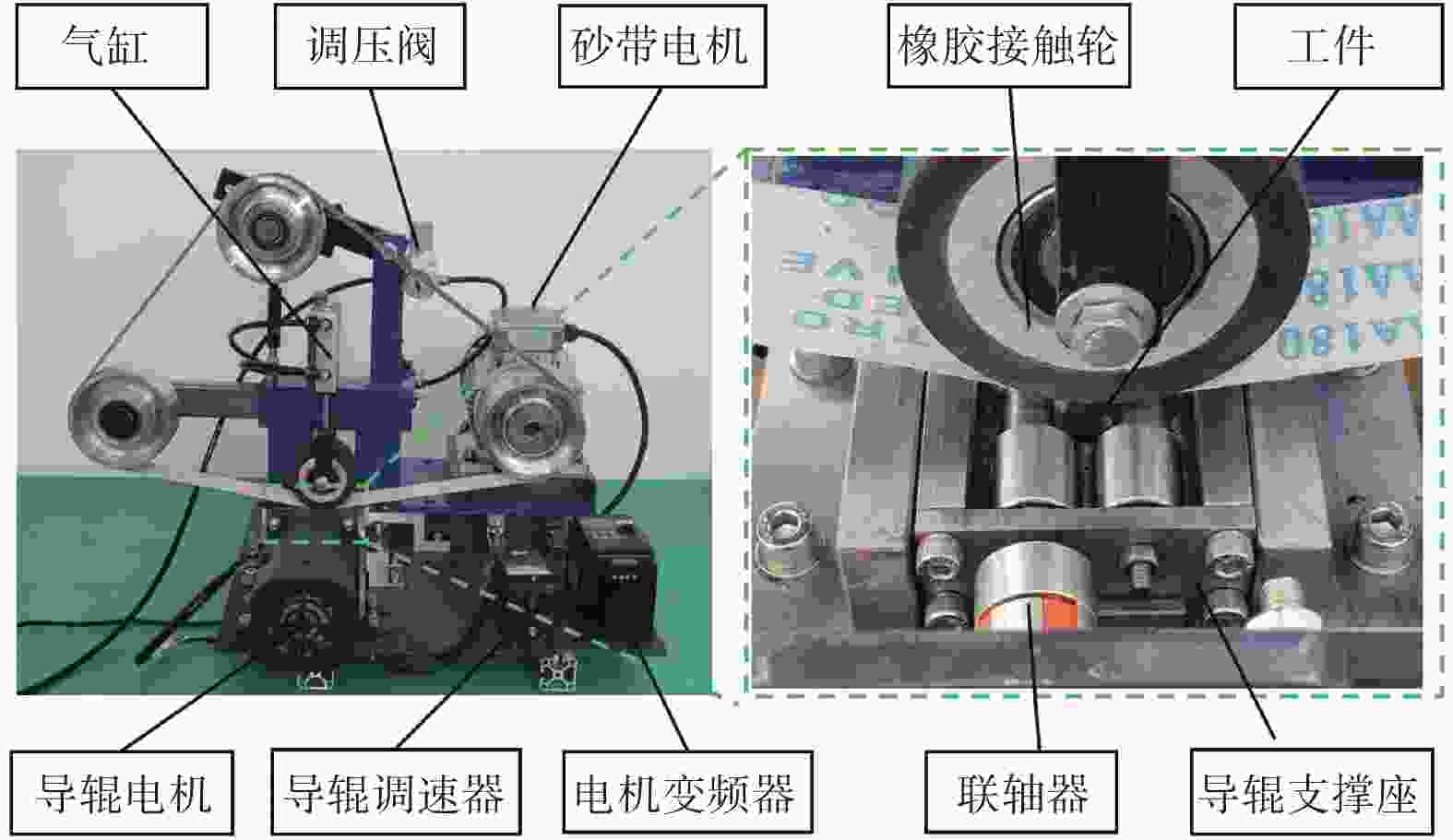

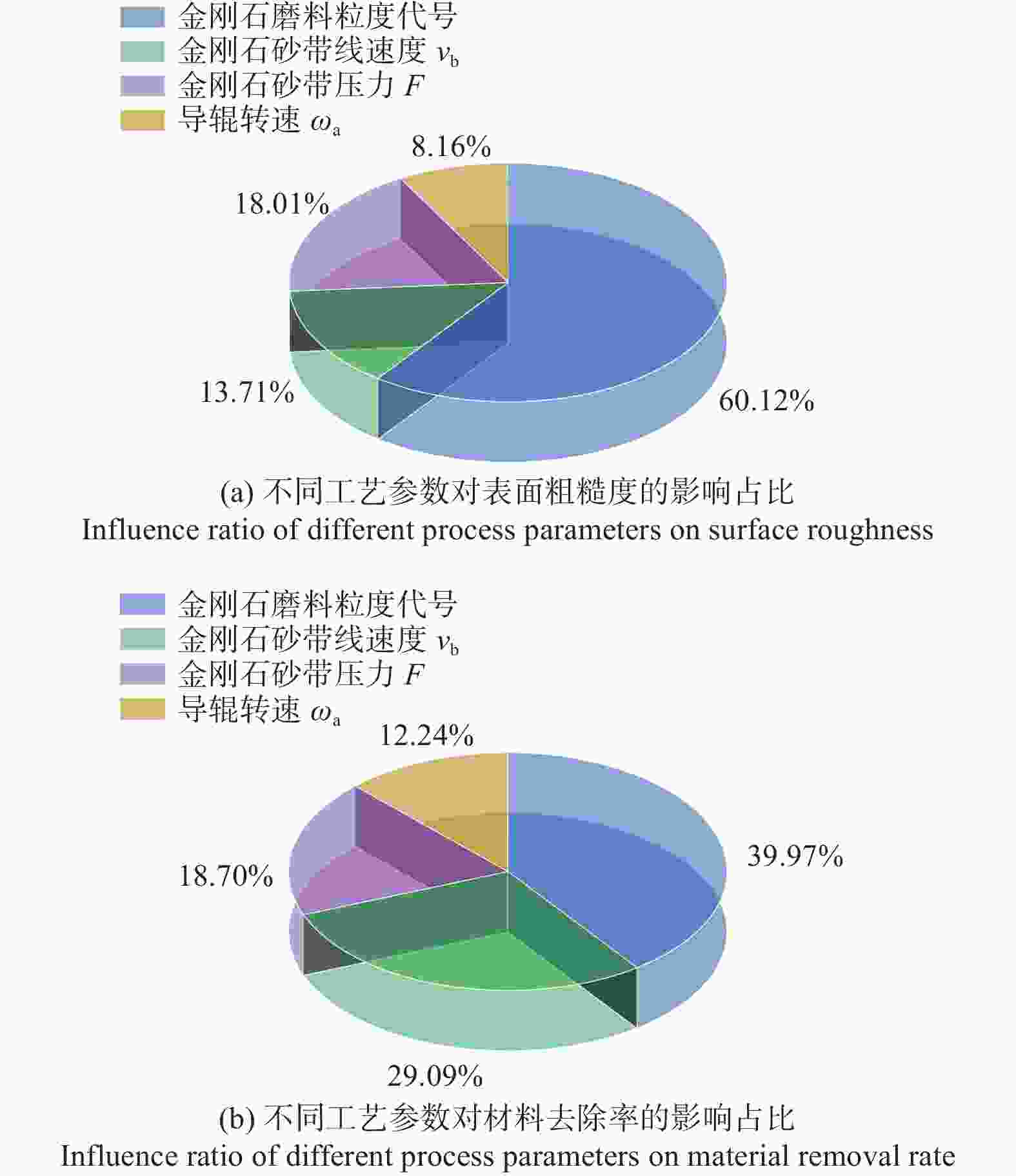

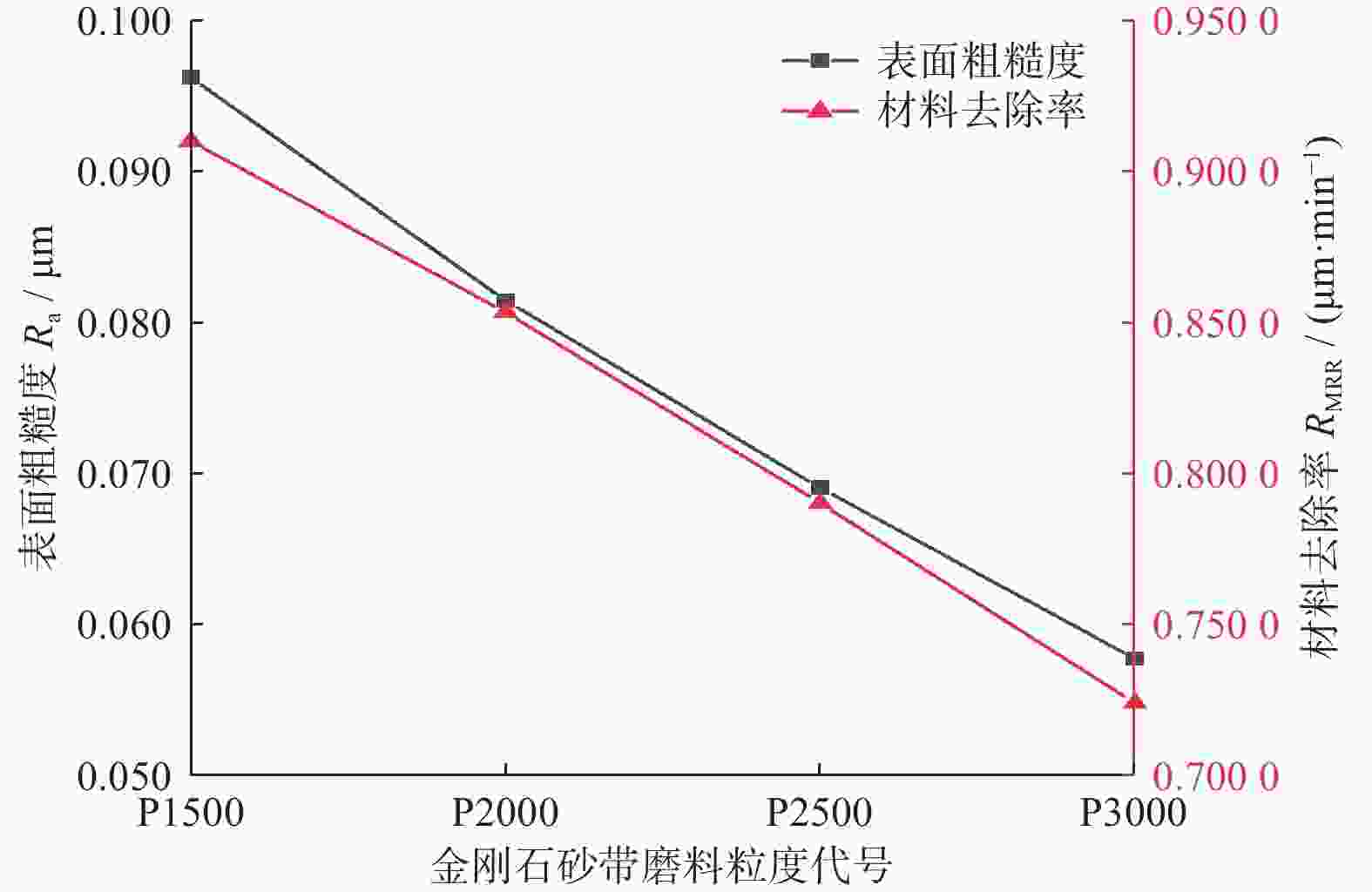

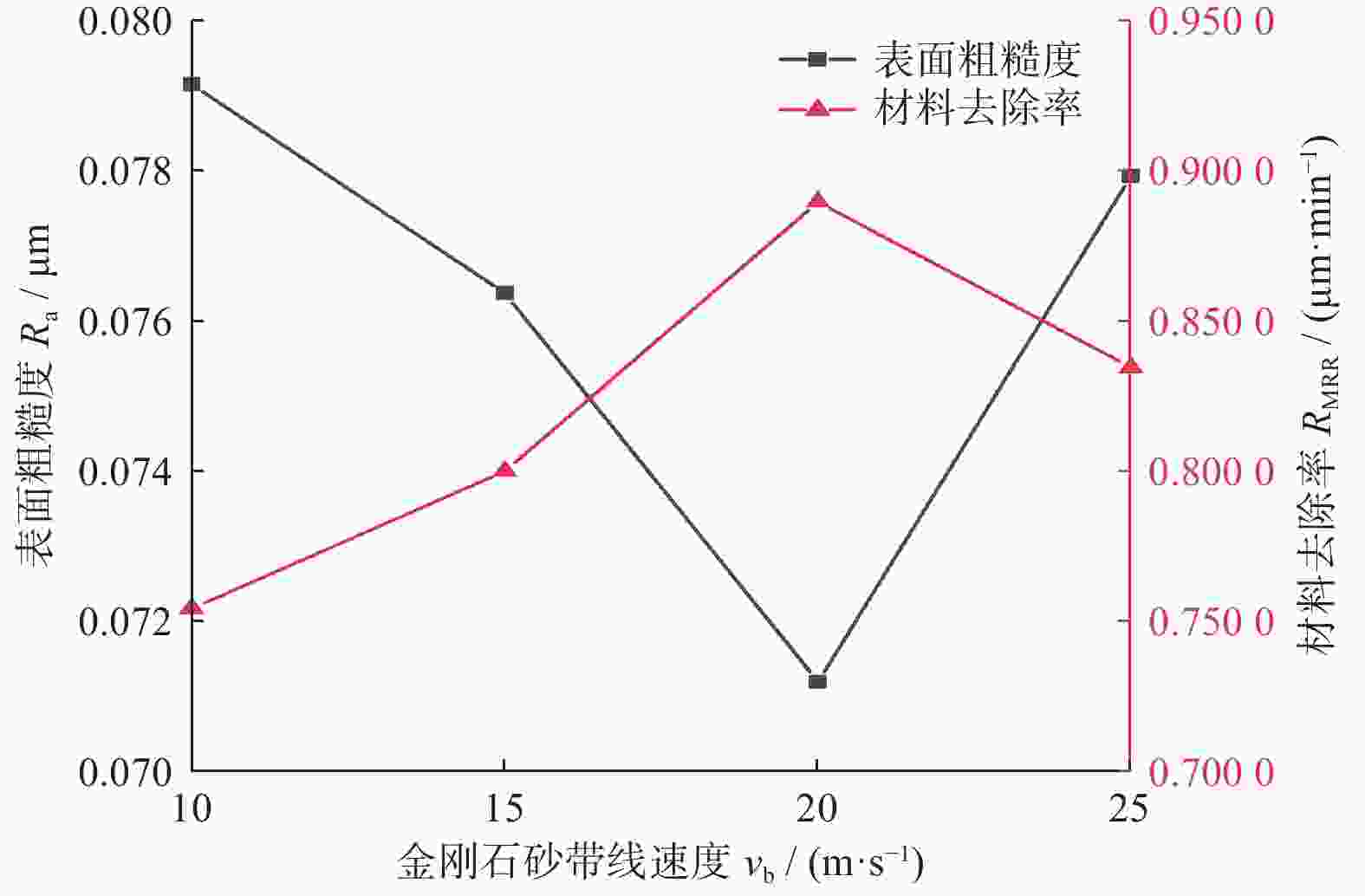

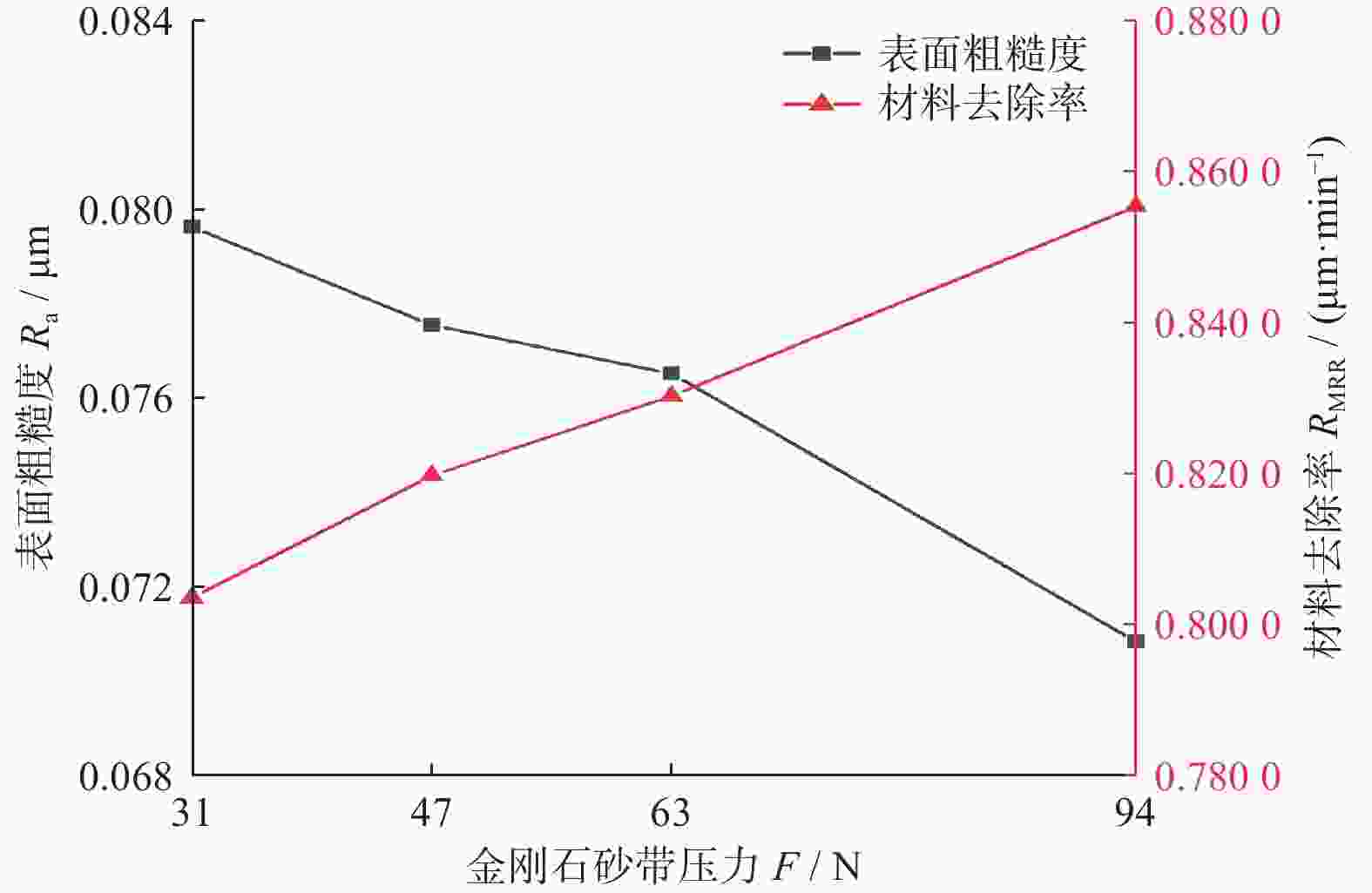

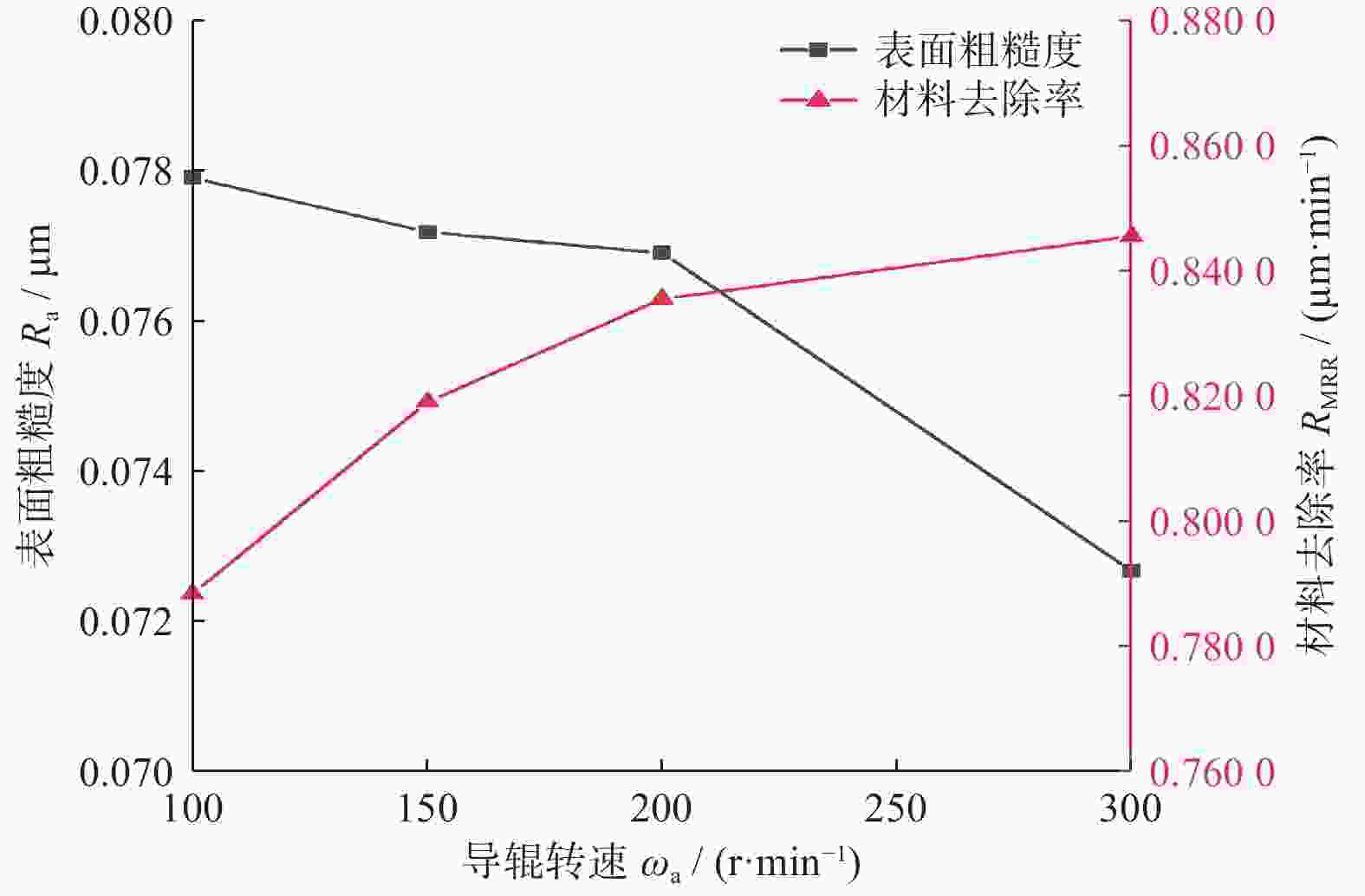

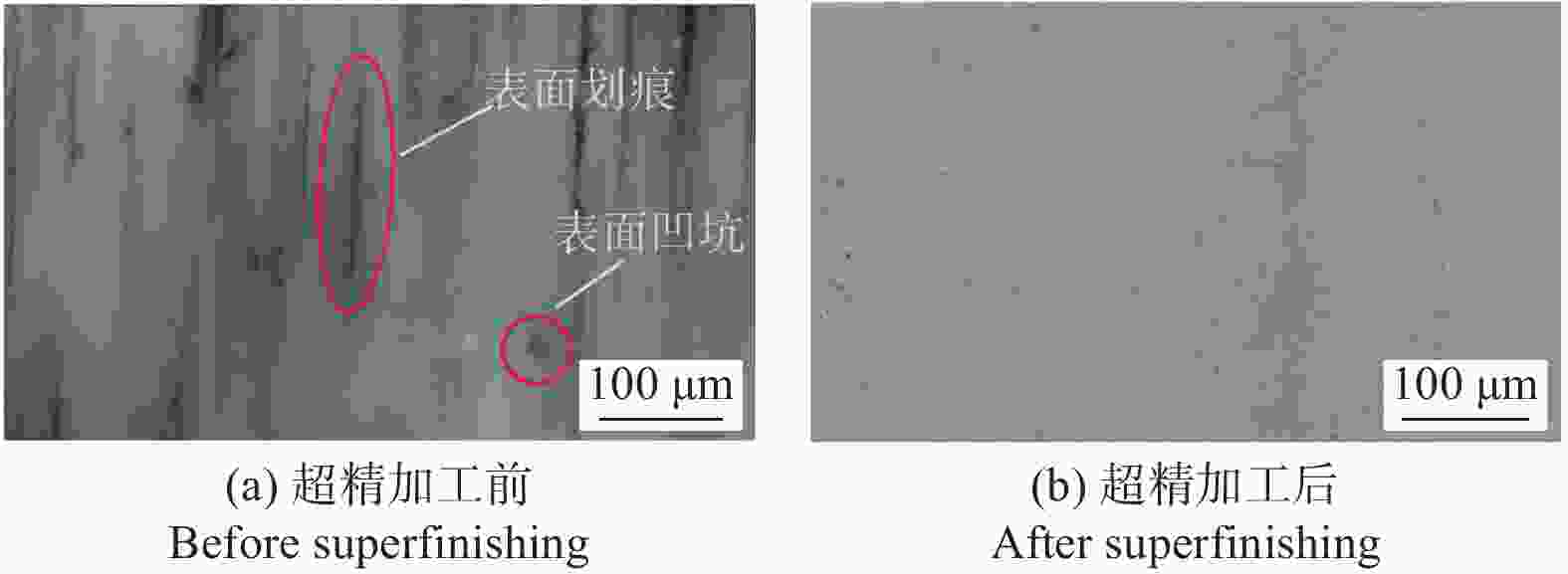

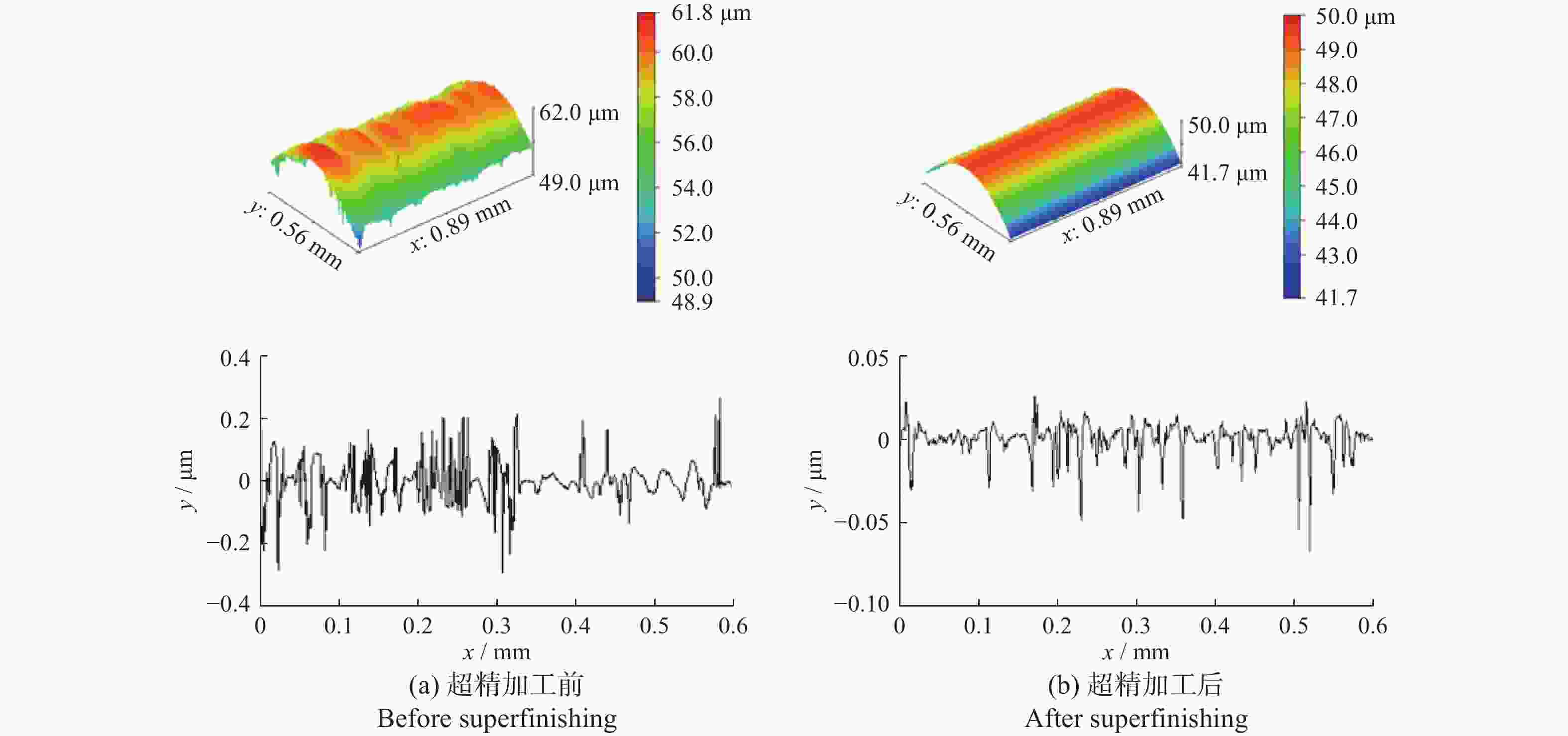

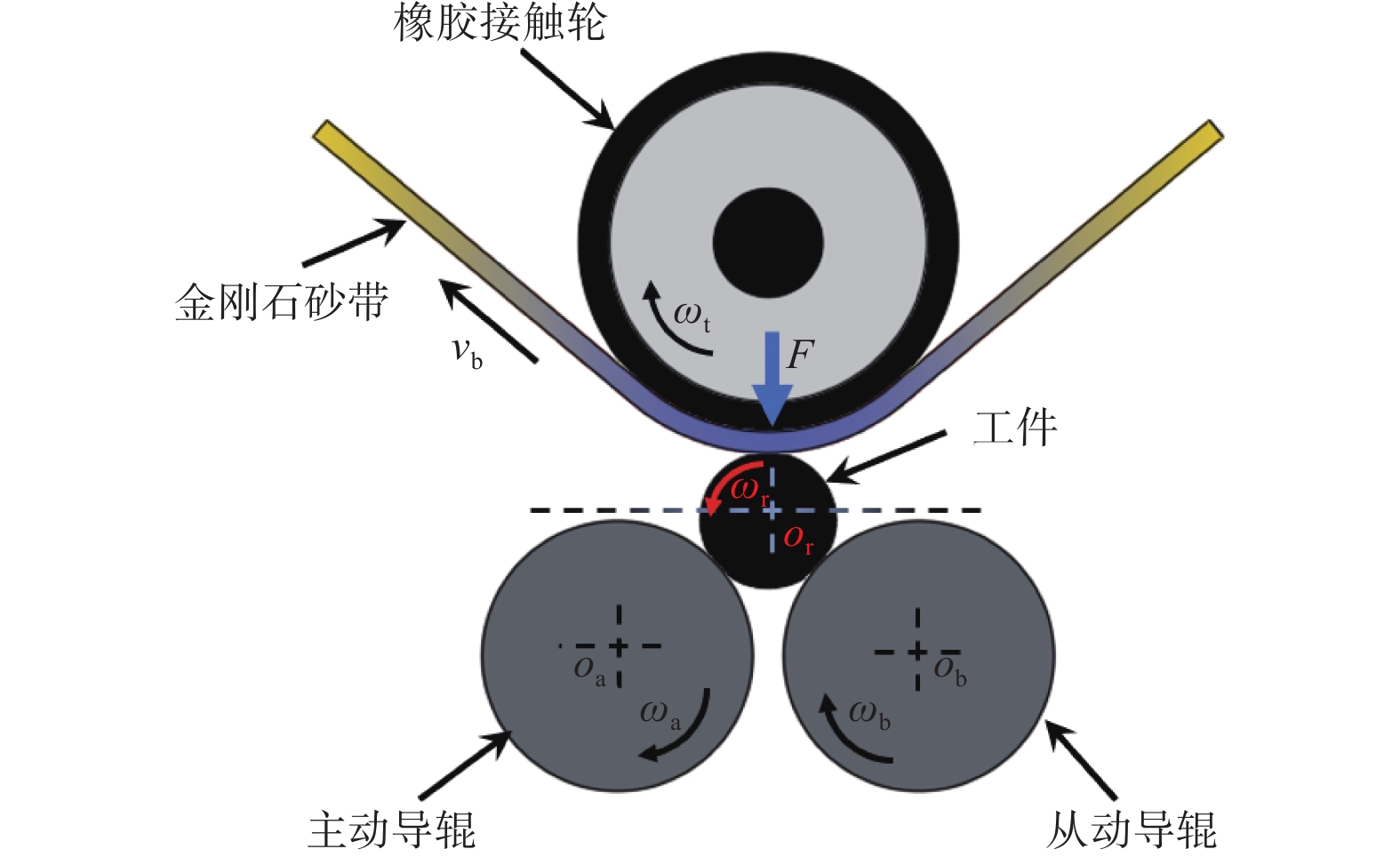

摘要: Si3N4陶瓷圆柱滚子在极端工况中表现出优异的服役性能,但其硬脆特性等导致加工困难。为实现Si3N4陶瓷圆柱滚子高质量、高柔性的加工,提出金刚石砂带超精加工方法。通过搭建金刚石砂带超精加工试验平台,设计正交试验并对试验数据进行水平响应分析和方差分析,研究金刚石砂带磨料粒度、砂带线速度、砂带压力、导辊转速对Si3N4陶瓷圆柱滚子工件(ϕ10 mm × 12 mm)表面粗糙度Ra和材料去除率RMRR的影响规律。结果表明:金刚石砂带磨料粒度对工件表面粗糙度和材料去除率的影响均最显著,砂带压力相较于砂带线速度和导辊转速对工件表面粗糙度的影响较大,而砂带线速度相较于砂带压力和导辊转速对材料去除率的影响较大。当金刚石砂带磨料粒度代号为P3000、砂带线速度为10 m/s、砂带压力为94 N、导辊转速为300 r/min时,工件表面粗糙度最小值为0.045 2 μm;当金刚石砂带磨料粒度代号为P2000、砂带线速度为20 m/s、砂带压力为94 N、导辊转速为200 r/min时,材料去除率最大值为1.075 31 μm/min。采用金刚石砂带超精加工方法,可有效提高Si3N4陶瓷圆柱滚子的表面质量。

-

关键词:

- Si3N4陶瓷圆柱滚子 /

- 金刚石砂带 /

- 表面粗糙度 /

- 超精密加工

Abstract:Objectives Si3N4 ceramic cylindrical rollers show excellent service performance in extreme working conditions, but their hardness and brittleness and other characteristics lead to difficulties in machining. To realize high-quality and highly flexible machining and manufacturing of Si3N4 ceramic cylindrical rollers, a diamond abrasive belt super-finishing machining method for Si3N4 ceramic cylindrical rollers is proposed. Methods By building an ultra precision machining experimental platform with a diamond abrasive belt, designing orthogonal experiments, and conducting horizontal response analysis and ANOVA on the experimental data, the influences of abrasive particle size in the diamond abrasive belt, abrasive belt linear velocity, abrasive belt pressure and guide roller speed on the surface roughness Ra and the material removal rate RMRR of Si3N4 ceramic cylindrical roller workpieces (ϕ 10 mm × 12 mm) are studied. Results The effects of abrasive grain size in the diamond abrasive belt on both surface roughness and material removal rate of the workpiece are the most significant. The effects of diamond abrasive belt pressure on the surface roughness of the workpiece are larger compared to those of diamond abrasive belt linear speed and guide roller rotational speed, while the effects of diamond abrasive belt linear speed on material removal rate are larger compared to those of diamond abrasive belt pressure and guide roller rotational speed. The minimum value of surface roughness of the workpiece is 0.0452 μm when the grain size code of the diamond belt is P3000, the linear speed of the diamond belt is 10 m/s, the pressure of the diamond belt is 94 N, and the rotational speed of the guide roller is 300 r/min; the minimum surface roughness of the workpiece is also 0.045 2 μm when the grain size code of the diamond belt is P2000, the linear speed of the diamond belt is 20 m/s, the pressure of the diamond belt is 94 N, the rotational speed of the guide roller is 200 r/min. When the rotational speed is 200 r/min, the maximum material removal rate is 1.075 31 μm/min.Conclusions The surface quality of Si3N4 ceramic cylindrical rollers can be effectively improved by using the superfinishing method with a diamond abrasive belt. -

表 1 金刚石砂带磨削的参数及水平

Table 1. Parameters and levels of diamond sand belt grinding

水平 因素 砂带粒

度号砂带线速度

vb / (m·s−1)砂带压力

F / N导辊转速

ωa / (r·min−1)1 P1500 10 31 100 2 P2000 15 47 150 3 P2500 20 63 200 4 P3000 25 94 300 表 2 Si3N4陶瓷材料性能参数

Table 2. Performance parameters of Si3N4 ceramic material

参数 取值 密度 ρ / (g∙cm−3) 3.26 弹性模量 E / GPa 310 硬度 H / GPa 16 泊松比 ε 0.25 断裂韧性 KIC / (MPa∙m−2) 7.0 线膨胀系数 λ / K−1 3.2 × 10−6 表 3 正交试验结果

Table 3. Results of orthogonal experiments

实验

序号结果 磨料粒

度代号砂带线

速度

vb / (m·s−1)砂带

压力

F / N导辊转速

ωa /

(r·min−1)表面粗

糙度

Ra / μm材料去除率

RMRR/

(μm·min−1)1 P1500 10 31 200 0.098 2 0.803 91 2 P1500 15 47 300 0.092 0 1.017 65 3 P1500 20 63 100 0.086 6 0.946 53 4 P1500 25 94 150 0.088 2 0.872 35 5 P2000 10 47 100 0.082 1 0.680 57 6 P2000 15 31 150 0.079 4 0.804 38 7 P2000 20 94 200 0.069 6 1.075 31 8 P2000 25 63 300 0.074 9 0.854 37 9 P2500 10 63 150 0.071 1 0.826 54 10 P2500 15 94 100 0.060 5 0.723 56 11 P2500 20 31 300 0.058 6 0.803 45 12 P2500 25 47 200 0.066 2 0.808 32 13 P3000 10 94 300 0.045 2 0.706 42 14 P3000 15 63 200 0.053 6 0.654 32 15 P3000 20 47 150 0.050 0 0.733 15 16 P3000 25 31 100 0.062 4 0.803 45 -

[1] 何加群. 论我国重大技术装备轴承的自主安全可控 [J]. 轴承, 2022(1): 1-17. doi: 10.19533/j.issn1000-3762.2022.01.001HE Jiaqun. On the independent safety and control of bearings for major technical equipment in China [J]. Bearing, 2022(1): 1-17. doi: 10.19533/j.issn1000-3762.2022.01.001 [2] 姚齐水, 杨文, 余江鸿, 等. 弹性复合圆柱滚子轴承结构设计研究 [J]. 中国机械工程, 2012, 23(24): 2899-2902. doi: 10.3969/j.issn.1004-132X.2012.24.001YAO Qishui, YANG Wen, YU Jianghong, et al. Research on structure design of elastic composite cylindrical roller bearing [J]. China Mechanical Engineering, 2012, 23(24): 2899-2902. doi: 10.3969/j.issn.1004-132X.2012.24.001 [3] 魏延刚, 张松哲. 钢制和陶瓷圆柱滚子轴承高速性能的有限元分析 [J]. 机械设计, 2007(7): 48-50. doi: 10.3969/j.issn.1001-2354.2007.07.016WEI Yangang, ZHANG Songzhe. Finite element analysis of high-speed performance of steel and ceramic cylindrical roller bearings [J]. Mechanical Design, 2007(7): 48-50. doi: 10.3969/j.issn.1001-2354.2007.07.016 [4] REJITHA R, KESAVAN D, CHAKRAVARTHY P, et al. Bearings for aerospace applications [J]. Tribology International, 2023, 181: 1-24. doi: 10.1016/j.triboint.2023.108312 [5] GUO L, HENK M, THIJS N, et al. Study on the electric discharge behaviour of a single contact in EV motor bearings [J]. Tribology International, 2023, 187: 1-10. doi: 10.1016/j.triboint.2023.108743 [6] 李颂华, 魏超, 吴玉厚, 等. 面向极端工况的Si3N4全陶瓷轴承关键技术与研究进展 [J]. 轴承, 2023(9): 1-10. doi: 10.19533/j.issn1000-3762.2023.09.001LI Songhua, WEI Chao, WU Yuhou, et al. Key technology and research progress of Si3N4 all-ceramic bearings for extreme working conditions [J]. Bearing, 2023(9): 1-10. doi: 10.19533/j.issn1000-3762.2023.09.001 [7] ZHANG X C, WU D, XIA Z F, et al. Study on surface fatigue and metamorphic layer of raceway of hybrid ceramic ball bearing in high-speed spindle for machine tool [J]. Engineering Failure Analysis, 2023, 143: 106928. doi: 10.1016/j.engfailanal.2022.106928 [8] HUAN J, LI S H, XIA Z X, et al. Experimental study on electric corrosion damage of bearing and solution [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2022, 236(19): 10349-10358. doi: 10.1177/09544062221100328 [9] 刘丽斌, 于琦, 万磊, 等. 一种陶瓷圆柱滚子的生产加工方法: CN202010688210. X [P]. 2020-12-01.LIU Libin, YU Qi, WAN Lei, et al. A production and processing method of ceramic cylindrical roller: CN202010688210X [P]. 2020-12-01. [10] WANG X F, LI X H, MA X L, et al. Advance on surface finishing technology of precision bearing cylindrical rollers [J]. The International Journal of Advanced Manufacturing Technology, 2023, 131(5/6): 2341-2363. doi: 10.1007/s00170-023-11595-8 [11] 黄贺利, 李颂华, 吴玉厚, 等. 双平面研磨Si3N4圆柱滚子的表面质量 [J]. 金刚石与磨料磨具工程, 2023, 43(3): 371-378. doi: 10.13394/j.cnki.jgszz.2022.0165HUANG Heli, LI Songhua, WU Yuhou, et al. Surface quality of double plane ground Si3N4 cylindrical rollers [J]. Diamond and Abrasives Engineering, 2023, 43(3): 371-378. doi: 10.13394/j.cnki.jgszz.2022.0165 [12] HE C L, ZHANG J, GENG K, et al. Advances in ultra-precision machining of bearing rolling elements [J]. The International Journal of Advanced Manufacturing Technology, 2022, 122(9/10): 3493-3524. doi: 10.1007/s00170-022-10086-6 [13] 周兆忠, 李兴林, 居冰峰, 等. 陶瓷圆柱滚子超精研磨工艺试验 [J]. 轴承, 2015(12): 14-18. doi: 10.3969/j.issn.1000-3762.2015.12.004ZHOU Zhaozhong, LI Xinglin, JU Bingfeng, et al. Experiment on superfine grinding process of ceramic cylindrical roller [J]. Bearing, 2015(12): 14-18. doi: 10.3969/j.issn.1000-3762.2015.12.004 [14] LI S C, XIAO G J, WANG Y X, et al. Multi-dimensional ultrasonic-assisted belt grinding on the surface integrity of Inconel 718 [J]. Journal of Manufacturing Processes, 2023(102): 700-717. doi: 10.1016/j.jmapro.2023.08.005 [15] HUANG Y, LIU G, XIAO G J, et al. Abrasive belt grinding force and its influence on surface integrity [J]. Materials and Manufacturing Processes, 2023, 38(7): 888-897. doi: 10.1080/10426914.2022.2116042 [16] 刘志环, 王进保, 陆安. 超硬材料砂带的研究现状和发展趋势 [J]. 超硬材料工程, 2008, 20(6): 48-52. doi: 10.3969/j.issn.1673-1433.2008.06.012LIU Zhihuan, WANG Jinbao, LU An. Research status and development trends of superhard material abrasive belts [J]. Superhard Material Engineering, 2008, 20(6): 48-52. doi: 10.3969/j.issn.1673-1433.2008.06.012 [17] 黄云. 砂带磨削技术的研究现状和发展方向简介 [J]. 金刚石与磨料磨具工程, 2020, 40(3): 1-4. doi: 10.3969/j.issn.1006-852X.2020.03.001HUANG Yun. Brief introduction to the research status and development direction of abrasive belt grinding technology [J]. Diamond and Abrasives Engineering, 2020, 40(3): 1-4. doi: 10.3969/j.issn.1006-852X.2020.03.001 [18] 王光祖, 崔仲鸣, 冯常财. 金刚石砂带的工程应用 [J]. 超硬材料工程, 2021, 33(2): 35-38. doi: 10.3969/j.issn.1673-1433.2021.02.011WANG Guangzu, CUI Zhongming, FENG Changcai. Engineering application of diamond abrasive belts [J]. Superabrasives Engineering, 2021, 33(2): 35-38. doi: 10.3969/j.issn.1673-1433.2021.02.011 [19] 张叠, 黄云. ZrO2工程陶瓷砂带磨削实验及工艺研究 [J]. 机械科学与技术, 2015, 34(12): 1966-1970. doi: 10.13433/j.cnki.1003-8728.2015.1230ZHANG Die, HUANG Yun. Experimental and process research on belt grinding of ZrO2 engineering ceramics [J]. Mechanical Science and Technology, 2015, 34(12): 1966-1970. doi: 10.13433/j.cnki.1003-8728.2015.1230 [20] 高超, 王生, 吴国荣, 等. 电镀金刚石砂带磨削氧化铝陶瓷的试验研究 [J]. 工具技术, 2017, 51(10): 40-43. doi: 10.3969/j.issn.1000-7008.2017.10.010GAO Chao, WANG Sheng, WU Guorong, et al. Experimental study on grinding alumina ceramics with electroplated diamond abrasive belts [J]. Tool Technology, 2017, 51(10): 40-43. doi: 10.3969/j.issn.1000-7008.2017.10.010 [21] LI H, ZOU L, LI Z R, et al. Investigation on abrasive wear of electroplated diamond belt in grinding nickel-based superalloys [J]. The International Journal of Advanced Manufacturing Technology, 2022, 121(7/8): 4419-4429. doi: 10.1007/s00170-022-09468-7 [22] ZHOU K, XIAO G J, XU J Y, et al. Wear evolution of electroplated diamond abrasive belt and corresponding surface integrity of Inconel 718 during grinding [J]. Tribology International, 2023, 177: 1-14. doi: 10.1016/j.triboint.2022.107972 [23] GONG H, ZHANG Z G, LIAN M L, et al. Design and verification of flexible belt grinding system for SiC mirror [C]// Eighth Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 2021: 12169B.1-12169B.8. [24] STADNIK T, SIDOROV D, KHARCHENKO A. Investigation of diamond elastic belts characteristics effect on rotary belt grinding process output performance [J]. Procedia Engineering, 2017, 206: 1415-1418. doi: 10.1016/j.proeng.2017.10.654 [25] SYREYSHCHIKOVA N V, PIMENOV D Y, GUPTA M K, et al. Relationship between pressure and output parameters in belt grinding of steels and nickel alloy [J]. Materials (Basel), 2021, 14(4704): 1-14. doi: 10.3390/MA14164704 [26] ZHAO J B, WANG S, YIN H, et al. Investigation of influence function model and polished surface characteristics during belt polishing polycrystalline aluminate magnesium spinel (PAMS) ceramics [J]. Journal of Materials Processing Technology, 2023, 320: 1-17. doi: 10.1016/j.jmatprotec.2023.118129 [27] 黄云. 现代砂带磨削技术及工程应用 [M]. 重庆: 重庆大学出版社, 2009: 83-89.HUANG Yun. Modern belt grinding technology and engineering applications [M]. Chongqing: Chongqing University Press, 2009: 83-89. [28] 李伯民, 赵波. 现代磨削技术 [M]. 北京: 机械工业出版社, 2003.LI Bomin, ZHAO Bo. Modern grinding technology [M]. Beijing: China Machine Press, 2003. [29] 王生, 高超, 吴国荣, 等. 基于电镀金刚石砂带的钢化玻璃磨边试验研究 [J]. 工具技术, 2017, 51(11): 41-45. doi: 10.3969/j.issn.1000-7008.2017.11.009WANG Sheng, GAO Chao, WU Guorong, et al. Experimental study on tempered glass edging based on electroplated diamond abrasive belt [J]. Tool Technology, 2017, 51(11): 41-45. doi: 10.3969/j.issn.1000-7008.2017.11.009 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS