Analysis of microstructure and properties of laser cladding diamond alloy coating on 45 steel surface

-

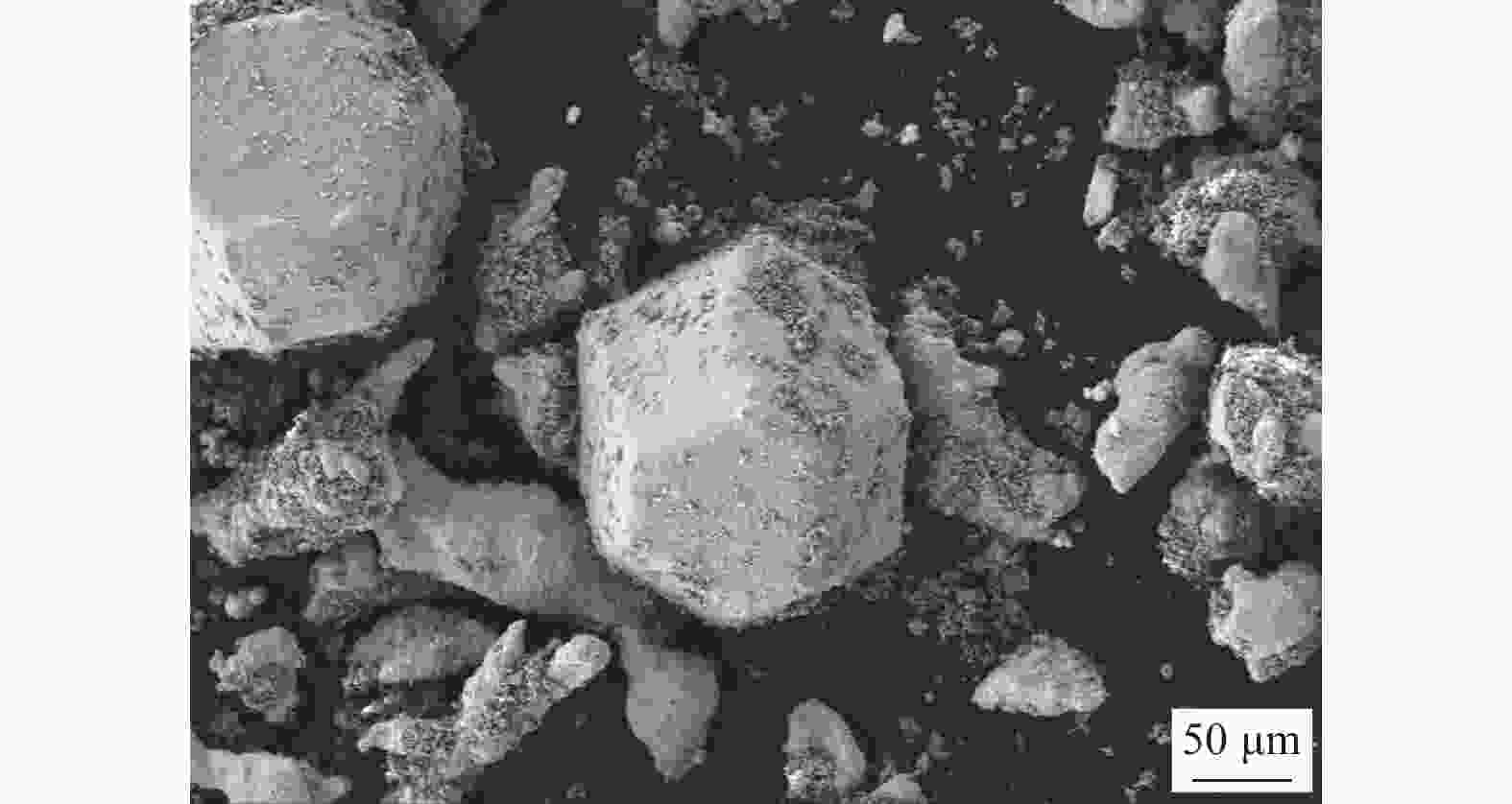

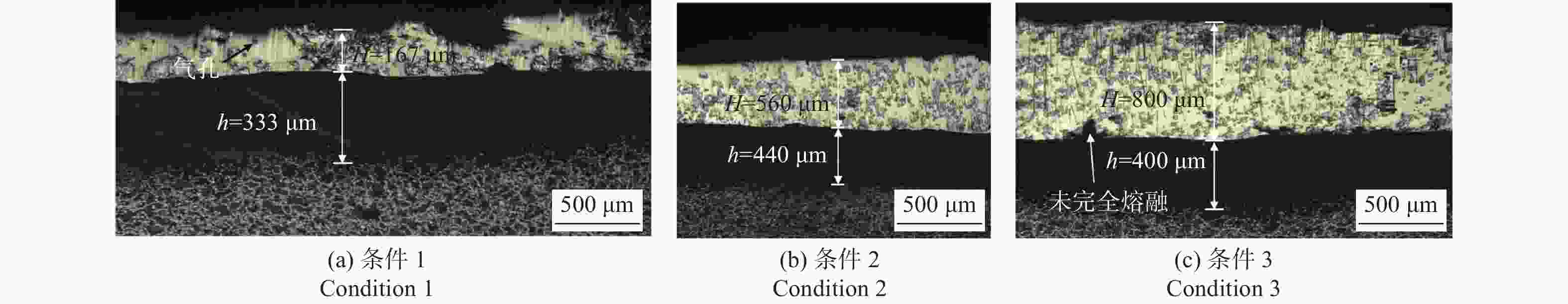

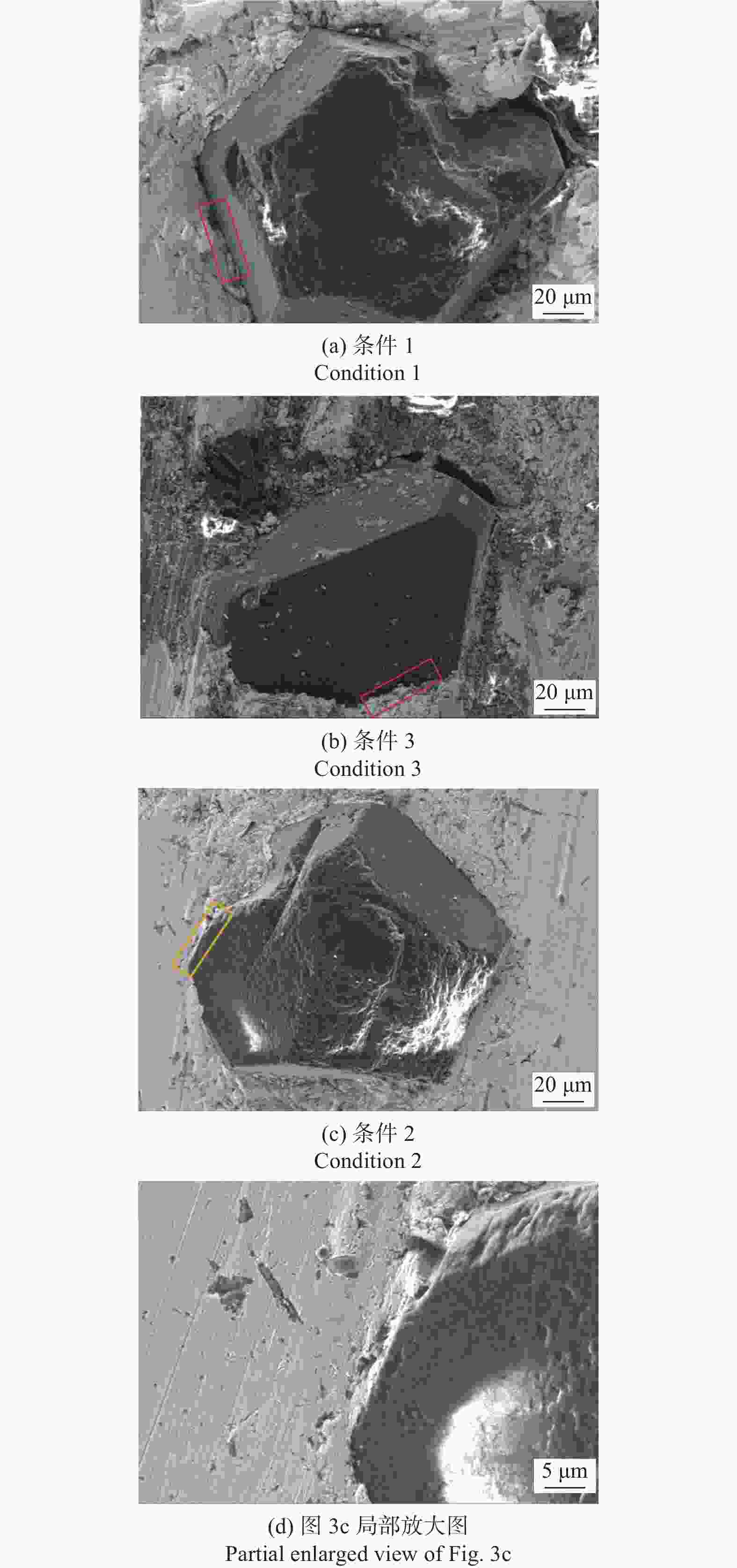

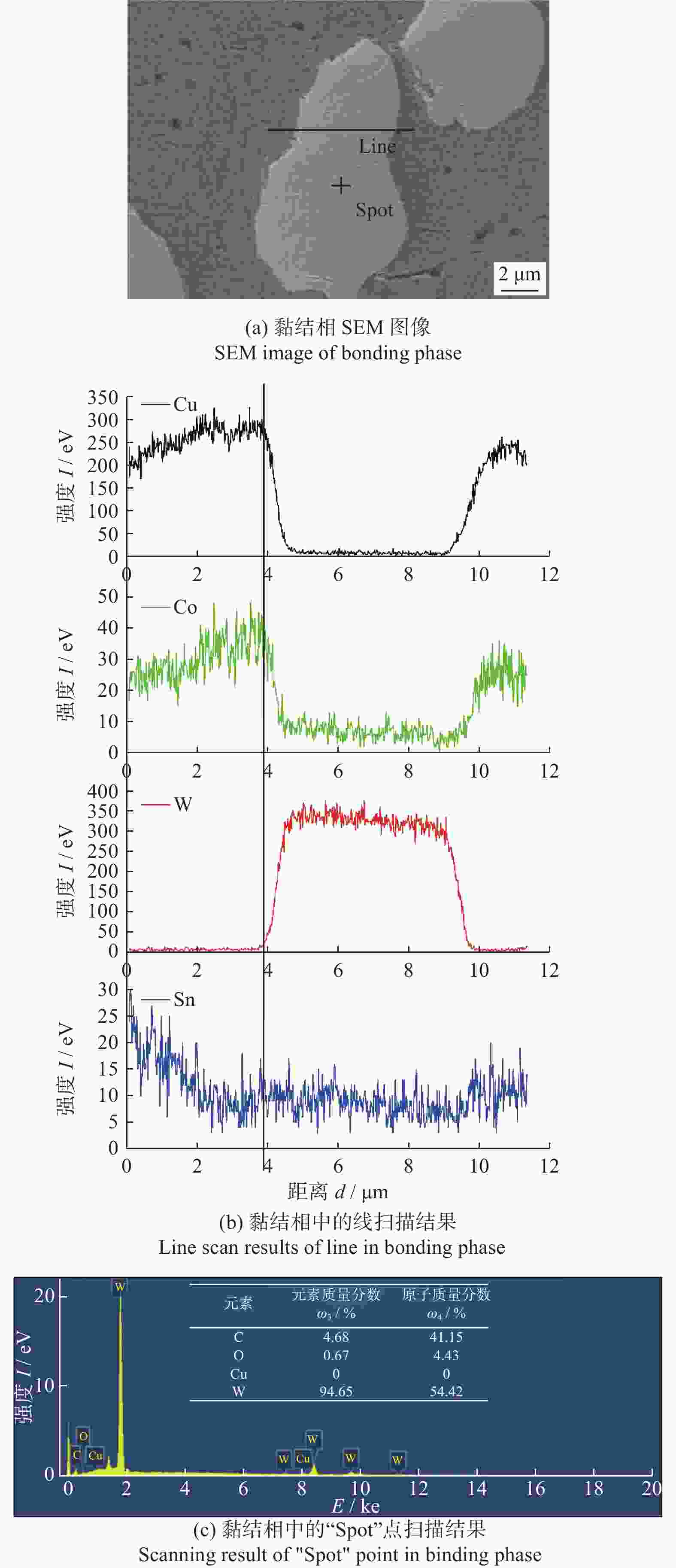

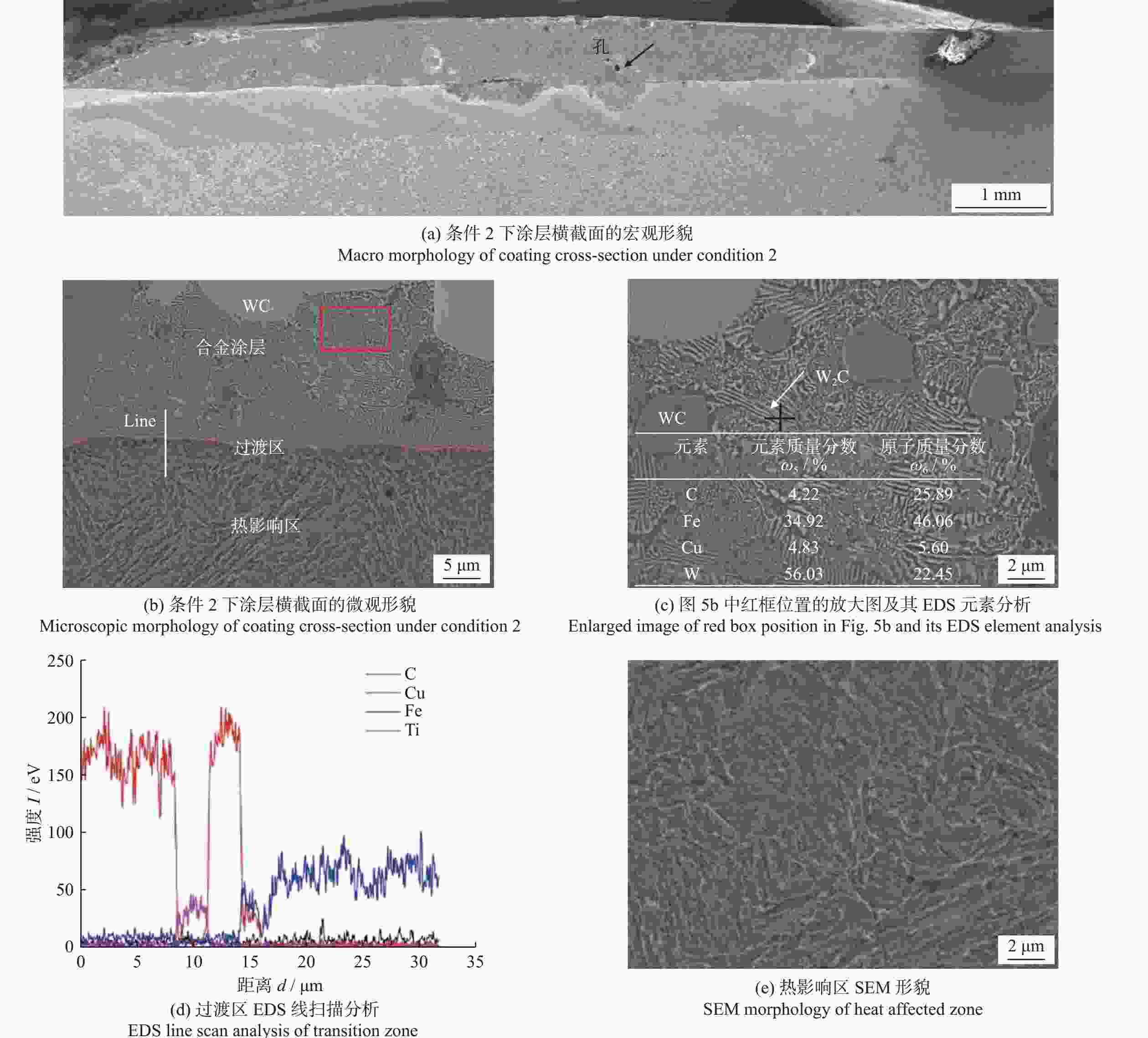

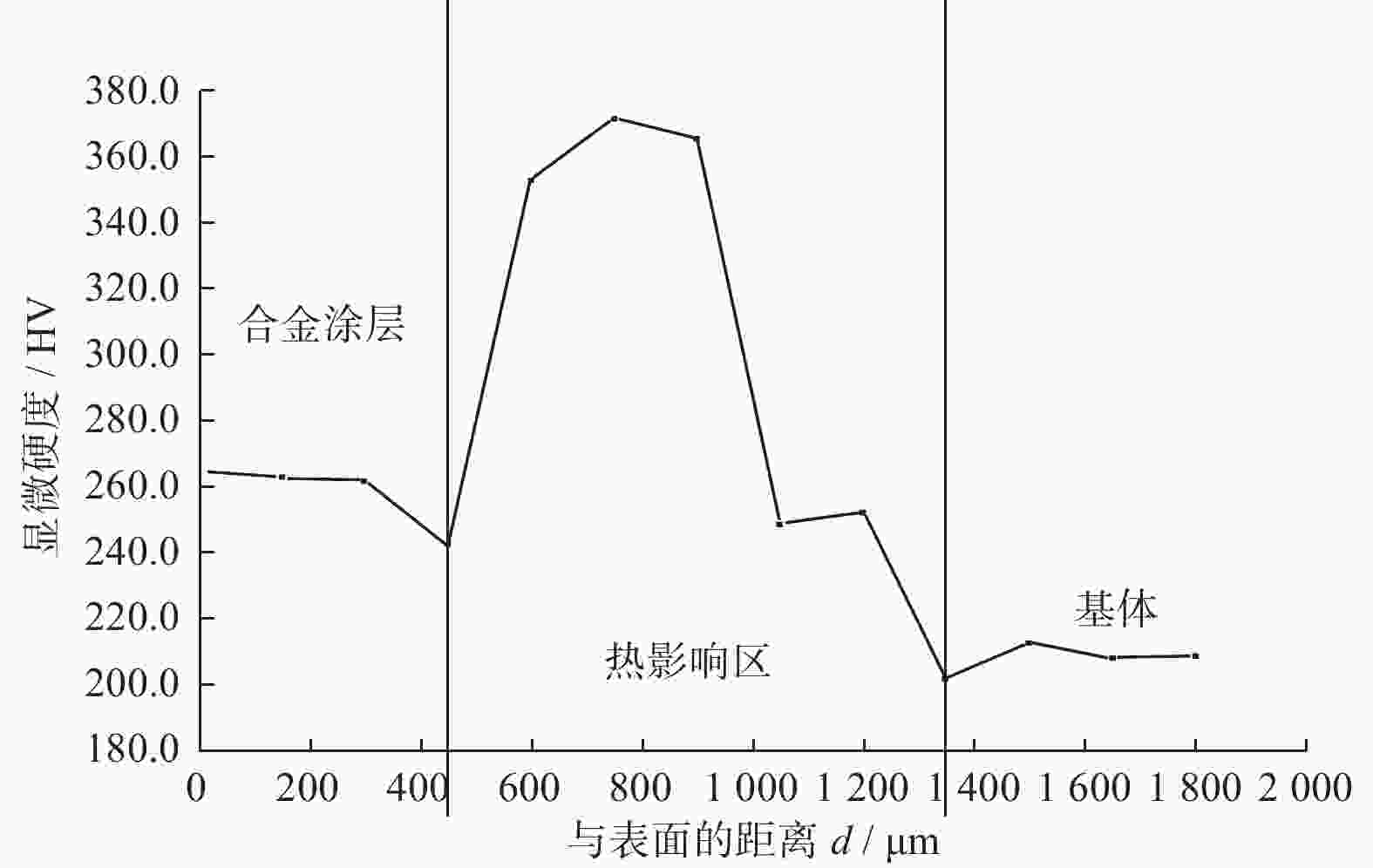

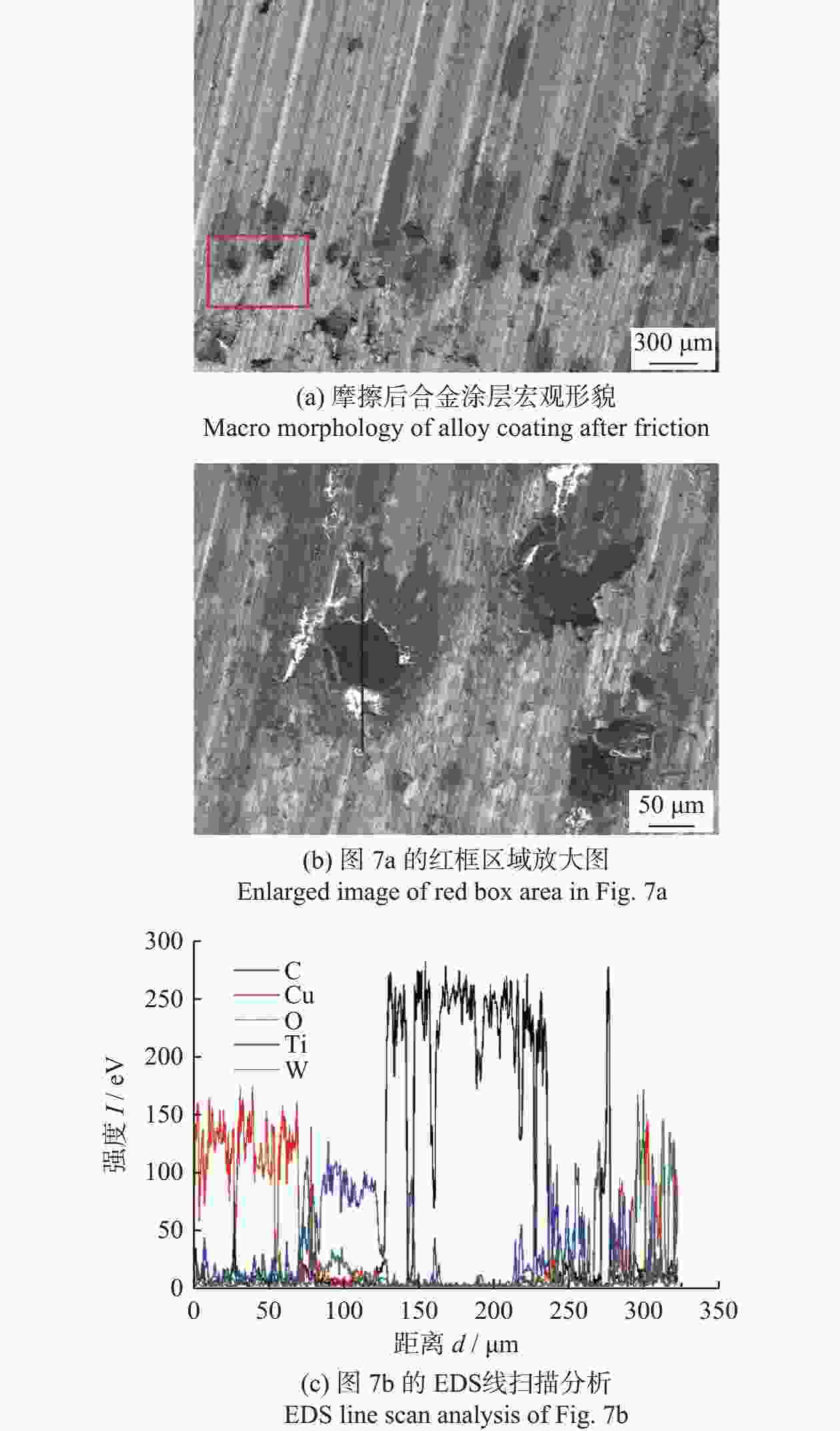

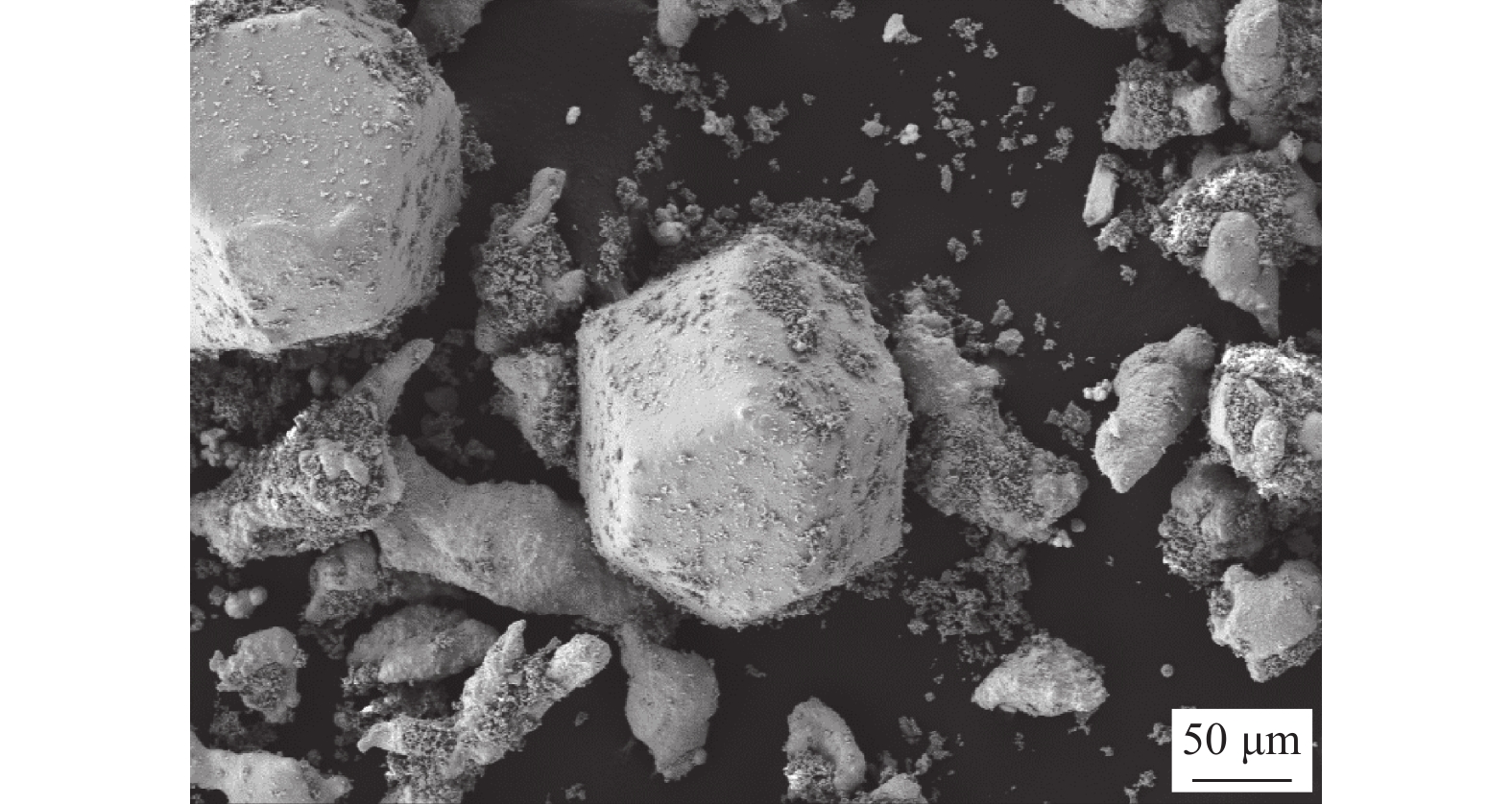

摘要: 为提高45钢的耐磨性,采用激光熔覆工艺在其表面制备以镀Ni金刚石为耐磨相、Ti与WC等材料为结构增强相的新型合金耐磨涂层,研究激光功率对金刚石石墨化及涂层冶金结合的影响,并通过金相显微镜、扫描电镜和维氏硬度计分析合金涂层的显微组织和显微硬度。结果表明:在45钢表面激光熔覆镀Ni金刚石合金涂层后,合金涂层中含有完整的金刚石颗粒且其与黏结相之间形成良好的冶金结合,合金涂层与基体间无明显分层现象;使用镀Ni金刚石以及添加WC、TiC粉末等可在高能激光束下保护金刚石,减少金刚石的烧蚀和石墨化现象;进一步添加Co、Ti等元素可改善合金涂层的流动性,增强其与金刚石的结合力,提高涂层硬度,使其平均显微硬度达到HV 257.85,为基材显微硬度HV 170.40的1.51倍。通过添加镀Ni金刚石和增强相,可有效提高合金涂层的硬度和耐磨性能,同时提高45钢表面耐磨性和使用寿命。Abstract:

Objectives To significantly enhance the surface wear resistance of 45 steel under high friction and high-load conditions, a new type of wear-resistant alloy coating with high hardness and strong adhesion is constructed on its surface using laser cladding technology. The coating is mainly composed of nickel-plated diamond as the wear-resistant phase, and high-melting-point ceramics such as WC and TiC as the reinforcing phases. Meanwhile, the microstructure and fluidity of the coating are improved by adding metal elements such as Ti and Co. The focus is on studying the influence of laser power on the graphitization of diamond and the metallurgical bonding quality with the substrate during the laser cladding process, thereby optimizing the process parameters and improving the comprehensive performances of the coating. Methods A multi-component alloy wear-resistant coating is prepared on the surface of 45 steel by the laser cladding process. The coating formula contains a certain proportion of nickel-plated diamond, WC, TiC, Ti and Co powders. The influence of adjusting the laser power on the structural stability of diamond particles, the interface bonding state and the overall microstructure morphology is investigated. After cladding, the microstructure of the coating is observed by metallographic microscope (OM) and scanning electron microscope (SEM) respectively, and the elemental distribution is analyzed by energy dispersive spectroscopy (EDS). Moreover, the microhardness of the coating is tested using a Vickers hardness tester, thereby comprehensively evaluating the performance of the coating. Results The laser power has a significant impact on the stability of the diamond structure during the coating formation process. Under appropriate laser power, the nickel-plated diamond particles do not exhibit significant graphitization during the melting process, and the particles remain intact and form a good metallurgical bond with the metal substrate. On the contrary, excessive laser power can cause some diamond particles to undergo graphitization, thereby affecting the performance of the coating. The introduction of WC and TiC reinforcing phases can effectively absorb some of the laser energy, reduce the thermal shock on the diamond surfaces, suppress their ablation and graphitization, while promoting the formation of fine-grained microstructures, improving the structural stability and wear resistance of the coating. In addition, the addition of Co and Ti elements significantly improves the wettability of the molten pool metal and the fluidity of the coating, enhances the bonding strength between the alloy coating and the ceramic particles, and effectively improves the uniformity and density of the coating. The internal structure of the alloy coating is uniform, without obvious cracks or delamination. The diamond particles are densely distributed and the interfaces are tightly bonded. The average hardness of the coating reaches HV 257.85, which is approximately 51% higher than HV 170.40 of the base 45 steel. Therefore, the hardness enhancement effect is remarkable. Conclusions By optimizing the laser cladding parameters and reasonably designing the alloy powder system, the nickel-plated diamond and the reinforcing phases such as WC and TiC can synergistically work under high-temperature laser cladding conditions, effectively improving the density of the coating structure, the stability of the diamond structure, and its adhesion with the substrate. The prepared alloy wear-resistant coating significantly improves the microhardness and the wear resistance of the 45 steel surface, and has good interfacial bonding and thermal stability, making it an ideal material for improving the wear resistance and service life of 45 steel. -

Key words:

- nickel-plated diamond /

- alloy coating /

- laser cladding /

- microstructure /

- microhardness

-

表 1 45钢化学成分

Table 1. Chemical compositions of 45 steel

元素 质量分数 ω1 / % C 0.420~0.500 Mn 0.500~0.800 Si 0.170~0.370 Cr ≤0.250 Mo 0.500~0.800 Ni ≤0.250 P ≤0.035 Fe 余量 表 2 激光熔覆合金粉末成分配比

Table 2. Composition ratio of laser cladding alloy powder

成分 质量分数 ω2 / % CuSn10 85 TiC 1 Co 2 WC 2 镀Ni金刚石 10 表 3 激光熔覆工艺参数

Table 3. Laser cladding parameters

条件 熔覆功率

P / W送粉速率

v / (r·min−1)氩气流量

qv / (L·min−1)搭接率

η / %1 700 2.0 6 30 2 850 2.0 6 30 3 850 2.5 6 30 -

[1] 马玉山, 何涛, 常占东, 等. 45钢阀杆失效机制分析 [J]. 有色矿冶, 2019, 35(3): 33-35,53. doi: 10.3969/j.issn.1007-967X.2019.03.009MA Yushan, HE Tao, CHANG Zhandong, et al. Analysis of failure mechanism of 45 steel value rod [J]. Non-Ferrous Mining and Metallurgy, 2019, 35(3): 33-35,53. doi: 10.3969/j.issn.1007-967X.2019.03.009 [2] 吕壮. 在45钢上电火花沉积立体结构自润滑涂层及其摩擦磨损性能的研究 [D]. 青岛: 青岛科技大学, 2023.LV Zhuang. Study on the friction and wear properties of self-lubricating coating with three-dimensional structure deposited on 45 steel by electric spark deposition [D]. Qingdao: Qingdao University of Science & Technology, 2023. [3] 刘晓玲. 机械设备金属材料的磨损失效及安全防范策略 [J]. 世界有色金属, 2021(17): 27-28. doi: 10.3969/j.issn.1002-5065.2021.17.014LIU Xiaoling. Wear failure and safety prevention strategy of metal materials of mechanical equipment [J]. World Nonferrous Metals, 2021(17): 27-28. doi: 10.3969/j.issn.1002-5065.2021.17.014 [4] 左俊文. 超音速火焰喷涂碳化钨陶瓷涂层相结构与性能研究 [D]. 青岛: 山东科技大学, 2013.ZUO Junwen. Study on the phase structures and properties of WC-cermet coatins sprayed via HCAF [D]. Qingdao: Shandong University of Science and Technology, 2013. [5] 李富梅. 机械设备金属材料的磨损失效及安全防范策略 [J]. 世界有色金属, 2023(12): 176-178. doi: 10.3969/j.issn.1002-5065.2023.12.057LI Fumei. Wear and failure of metal materials in mechanical equipment and safety prevention strategies [J]. World Nonferrous Metals, 2023(12): 176-178. doi: 10.3969/j.issn.1002-5065.2023.12.057 [6] DE G K, GEESINK R, KLEIN C P, et al. Plasma sprayed coatings of hydroxylapatite [J]. Journal of Biomedical Materials Research, 1987, 21(12): 1375-1381. doi: 10.1002/jbm.820211203 [7] ANG A S M, BERND C C. A review of testing methods for thermal spray coatings [J]. International Materials Reviews, 2014, 59(4): 179-223. doi: 10.1179/1743280414Y.0000000029 [8] 王龙虎, 郭宁, 陈得润, 等. 奥氏体不锈钢堆焊层焊接缺陷分析及改进措施 [J]. 铸造技术, 2023, 44(12): 1-5. doi: 10.16410/j.issn1000-8365.2023.2323WANG Longhu, GUO Ning, CHEN Derun, et al. Analysis of welding defects of austenitic stainless steel surfacing layers and improvement measures [J]. Foundry Technology, 2023, 44(12): 1-5. doi: 10.16410/j.issn1000-8365.2023.2323 [9] 崔成梅. 42CrMo钢离子氮化研究 [J]. 热加工工艺, 2014, 43(8): 145-149. doi: 10.14158/j.cnki.1001-3814.2014.08.043CUI Chengmei. Study on plasma nitriding of 42CrMo steel [J]. Hot Working Technology, 2014, 43(8): 145-149. doi: 10.14158/j.cnki.1001-3814.2014.08.043 [10] 刘颖波. 45钢表面激光熔覆Stellite 6/WC梯度复合涂层工艺、组织与性能研究 [D]. 兰州: 兰州理工大学, 2023.LIU Yingbo. Research on the technology and microstructure and properties of Stellite 6/WC gradient composite coatings by laser cladding on the surface of 45 steel [D]. Lanzhou: Lanzhou University of Technology, 2023. [11] 赵文雨. 2Cr12MoV表面激光熔覆Stellite 6涂层的组织及性能研究 [D]. 上海: 上海交通大学, 2015.ZHAO Wenyu. Research on microstructure and properties of Stellite 6 coatings by laser cladding on 2Cr12MoV [D]. Shanghai: Shanghai Jiao Tong University, 2015. [12] ARIF Z U, KHALID M Y, AI R A, et al. Laser deposition of high-entropy alloys: A comprehensive review [J]. Optics & Laser Technology, 2022, 145: 107447. doi: 10.1016/j.optlastec.2021.107447 [13] 韩文静, 宋进朝, 刘学功, 等. 煤矿机械应用激光熔覆技术的研究与实践 [J]. 电镀与精饰, 2016, 38(8): 18-22. doi: 10.3969/j.issn.1001-3849.2016.08.005HAN Wenjing, SONG Jinchao, LIU Xuegong, et al. Research and practice of laser cladding technology applied on coal mining machinery in China [J]. Plating and Finishing, 2016, 38(8): 18-22. doi: 10.3969/j.issn.1001-3849.2016.08.005 [14] 张剑华. 采煤设备维修应用表面工程技术的研究与实践 [J]. 煤炭学报, 2011, 36(S1): 172-176. doi: 10.13225/j.cnki.jccs.2011.s1.036ZHANG Jianhua. Research and practice of surface engineering technology applications on coal mining equipment maintenance [J]. Journal of China Coal Society, 2011, 36(S1): 172-176. doi: 10.13225/j.cnki.jccs.2011.s1.036 [15] 韩凯. 金刚石钎焊工具的制备及性能研究 [D]. 长沙: 湖南大学, 2022.HAN Kai. Preparation and properties of brazed diamond tools [D]. Changsha: Hunan University, 2022. [16] 马宇. H13钢表面激光熔覆改性组织性能研究 [D]. 沈阳: 东北大学, 2014.MA Yu. Surface modification of H13 steel by laser cladding [D]. Shenyang: Northeastern Unversity, 2014. [17] 谢子欣. 紫铜表面等离子熔覆WC增强Co基合金层制备及性能研究 [D]. 上海: 上海大学, 2021.XIE Zixin. Preparation and properties of plasma cladding WC strengthening Co-based alloy on copper surface [D]. Shanghai: Shanghai University, 2021. [18] 杜全斌, 王蕾, 赵伟伟, 等. 激光增材制造金刚石工具的研究现状与展望 [J]. 金属加工(热加工), 2025(3): 17-29. doi: 10.3969/j.issn.1674-165X.2025.03.003DU Quanbin, WANG Lei, ZHAO Weiwei, et al. Research status and prospect of laser additive manufacturing of diamond tools [J]. MW Metal Forming, 2025(3): 17-29. doi: 10.3969/j.issn.1674-165X.2025.03.003 [19] 刘敬明. 大面积化学气相沉积金刚石自支撑膜氧化性能的研究 [D]. 北京: 北京科技大学, 2002.LIU Jingming. Oxidation properties of large area CVD free-standing diamond films [D]. Beijing: University of Science and Technology Beijing, 2002. [20] MA Q, PENG Y B, CHEN Y Q, et al. Quantitative investigation of thermal evolution and graphitisation of diamond abrasives in powder bed fusion-laser beam of metal-matrix diamond composites [J]. Virtual and Physical Prototyping, 2023, 18(1): 1-16. doi: 10.1080/17452759.2022.2121224 [21] WU Q P, OU Y, Wang Y, et al. Precision grinding of engineering ceramic based on the electrolytic dressing of a multi-layer brazed diamond wheel [J]. Diamond and Related Materials, 2019, 100: 1-12. doi: 10.1016/j.diamond.2019.107552 [22] 朱晨颖, 孙志鹏, 王宇. 感应钎涂金刚石/镍基合金复合涂层的性能 [J]. 焊接学报, 2022, 43(2): 106-112,120. doi: 10.12073/j.hjxb.20210521003ZHU Chenying, SUN Zhipeng, WANG Yu. Properties of induction brazing diamong/Ni-based alloy composite coating [J]. Transactions of the China Welding Institution, 2022, 43(2): 106-112,120. doi: 10.12073/j.hjxb.20210521003 [23] ZHOU Z, LI S, GAO X. Numerical modeling of thermal behavior of melt pool in laser additive manufacturing of Ni-based diamond tools [J]. Ceramics International, 2022, 48(10): 14876-14890. doi: 10.1016/j.ceramint.2022.02.024 [24] 肖小军, 刘允中, 程文, 等. 激光选区熔化成形含钛6061铝合金的显微组织与力学性能 [J]. 材料工程, 2023, 51(5): 36-45. doi: 10.11868/j.issn.1001-4381.2021.001013XIAO Xiaojun, LIU Yunzhong, CHENG Wen, et al. Microstructure and mechanical property of titanium-containing 6061 aluminum alloy prepared by selective laser melting [J]. Journal of Material Engineering, 2023, 51(5): 36-45. doi: 10.11868/j.issn.1001-4381.2021.001013 [25] REYES M, NEVILLE A. Degradation mechanisms of Co-based alloy and WC metal–matrix composites for drilling tools offshore [J]. Wear, 2003, 255(7): 1143-1156. doi: 10.1016/S0043-1648(03)00151-0 [26] DILAWARY S A A, MOTALLEBZADEH A, PAKSOY A H, et al. Influence of laser surface melting on the characteristics of Stellite 12 plasma transferred arc hardfacing deposit [J]. Surface and Coatings Technology, 2017, 317: 110-116. doi: 10.1016/j.surfcoat.2017.03.051 [27] DILAWARY S A A, MOTALLEBZADEH A, AFZAL M, et al. Laser surface melting of 10 wt% Mo alloyed hardfacing Stellite 12 plasma transferred arc deposits: Structural evolution and high temperature wear performance [J]. Optics and Laser Technology, 2018, 101: 404-412. doi: 10.1016/j.optlastec.2017.11.038 [28] 邵延凡, 王泽华, 李潇, 等. 双相不锈钢表面激光熔覆钴基合金组织和性能研究 [J]. 表面技术, 2020, 49(4): 299-305. doi: 10.16490/j.cnki.issn.1001-3660.2020.04.035SHAO Yanfan, WANG Zehua, LI Xiao, et al. Microstructure and properties of laser cladding Co-based alloys on duplex stainless steel [J]. Surface Technology, 2020, 49(4): 299-305. doi: 10.16490/j.cnki.issn.1001-3660.2020.04.035 [29] 罗亮斌, 梁国星, 刘东刚, 等. 42CrMo钢表面激光熔覆钴基金刚石耐磨层组织及性能 [J]. 表面技术, 2024, 53(5): 96-107. doi: 10.16490/j.cnki.issn.1001-3660.2024.05.010LUO Liangbin, LIANG Guoxing, LIU Donggang, et al. Microstructure and properties of laser cladding Co-based diamond wear resistant layer on 42CrMo steel surface [J]. Surface Technology, 2024, 53(5): 96-107. doi: 10.16490/j.cnki.issn.1001-3660.2024.05.010 [30] 孙海东. 铁碳马氏体的孪晶结构和硬化机理研究 [D]. 秦皇岛: 燕山大学, 2023.SUN Haidong. Investigation on the twinned substructure and hardening mechanism of Fe-C martensite [D]. Qinghuangdao: Yanshan University, 2023. [31] 蔡志海, 秦航, 柳建, 等. 中锰铁基合金激光熔覆层组织性能研究 [J]. 应用激光, 2018, 38(5): 726-729. doi: 10.14128/j.cnki.al.20183805.726CAI Zhihai, QIN Hang, LIU Jian, et al. Research of microstructure and performance of laser cladding Fe-based medium manganses alloy [J]. Applied Laser, 2018, 38(5): 726-729. doi: 10.14128/j.cnki.al.20183805.726 [32] 庞爱红, 孙贵乾, 董俊言, 等. 激光熔覆金刚石-金属耐磨涂层的组织和性能 [J]. 金刚石与磨料磨具工程, 2023, 43(4): 514-522. doi: 10.13394/j.cnki.jgszz.2023.0127PANG Aihong, SUN Guiqian, DONG Junyan, et al. Microstructure and properties of laser cladding diamond-metal wear-resistant coating [J]. Diamond & Abrasives Engineering, 2023, 43(4): 514-522. doi: 10.13394/j.cnki.jgszz.2023.0127 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS