Plating process of diamond bimetallic layer

-

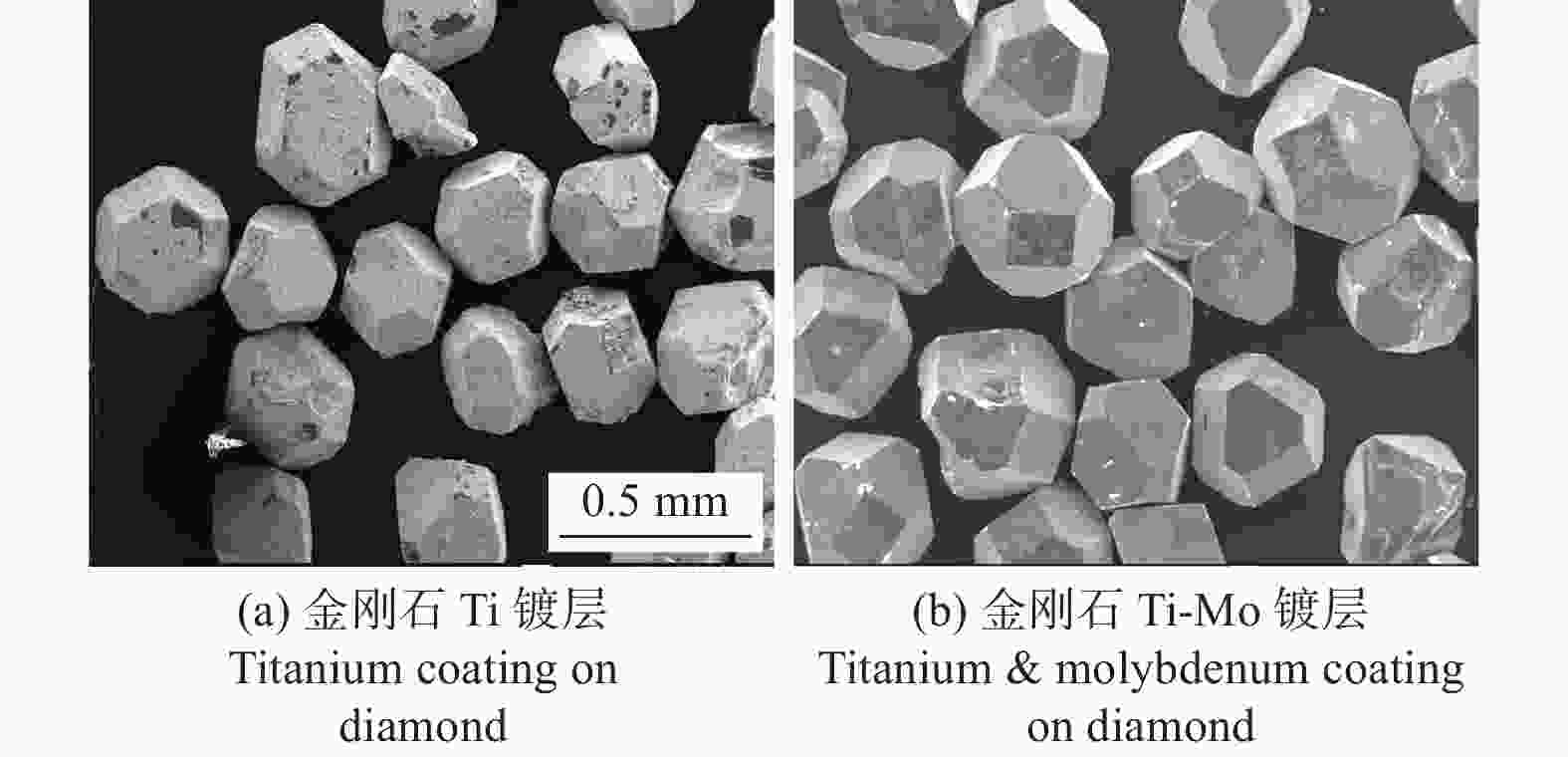

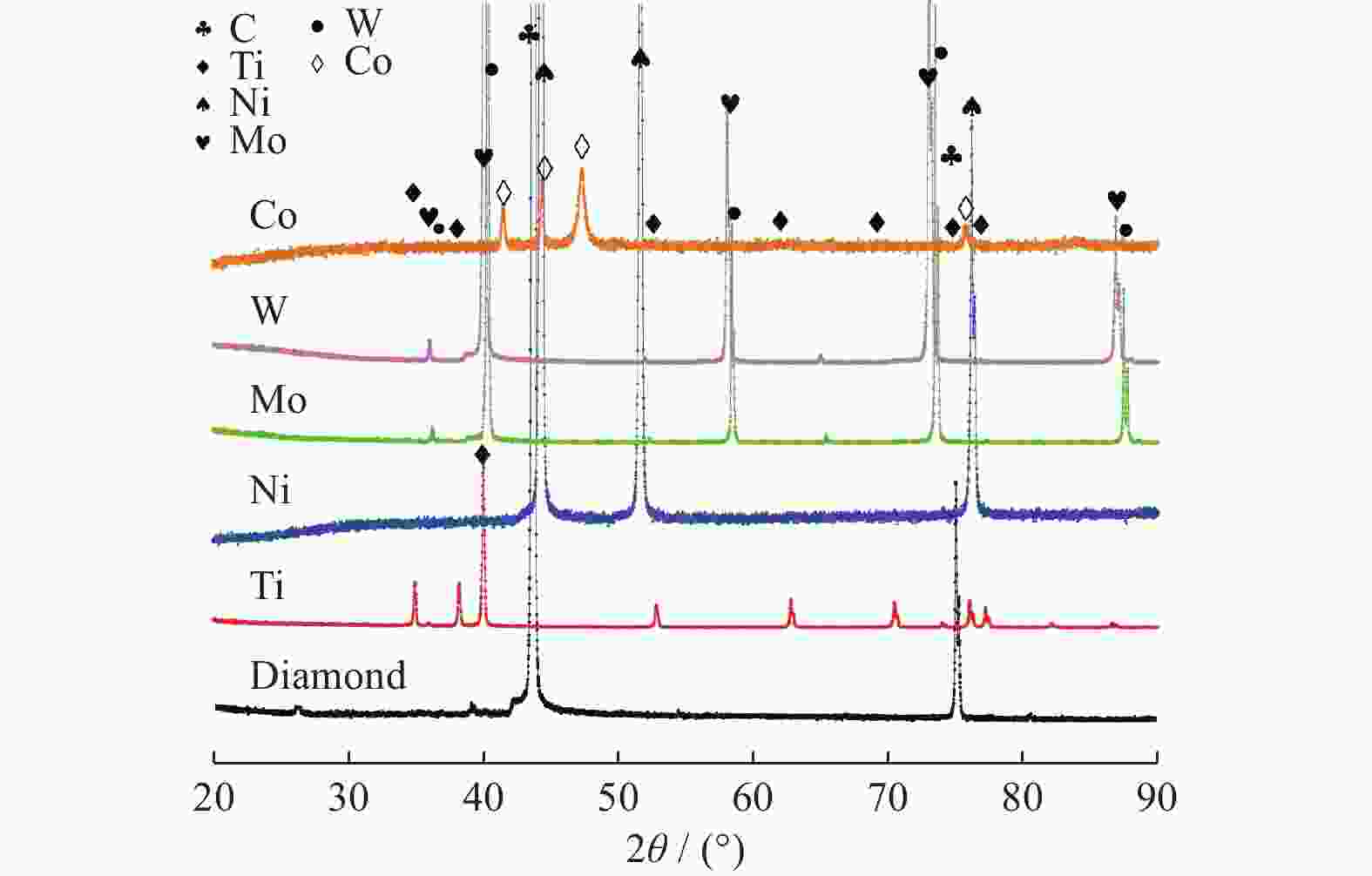

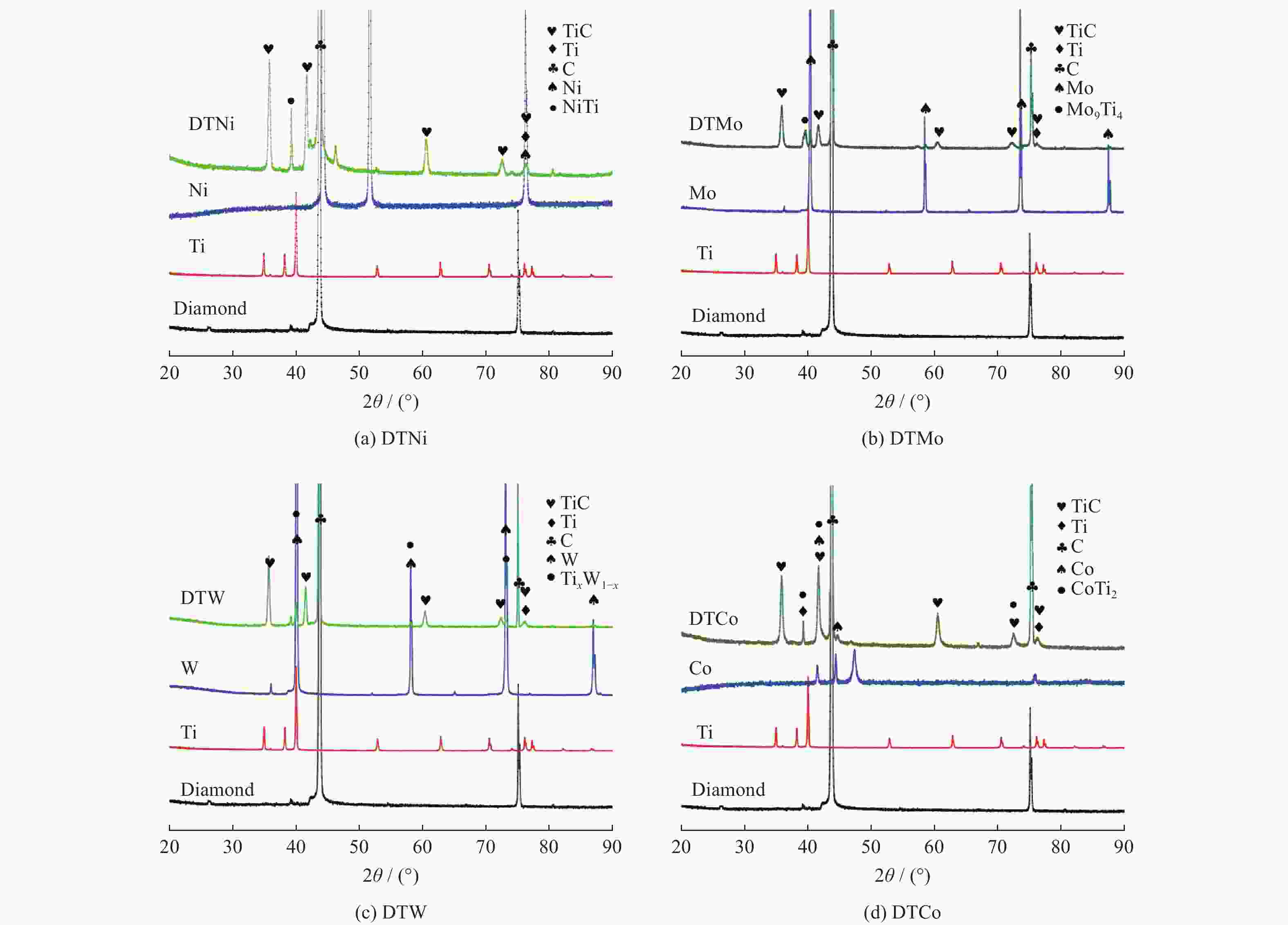

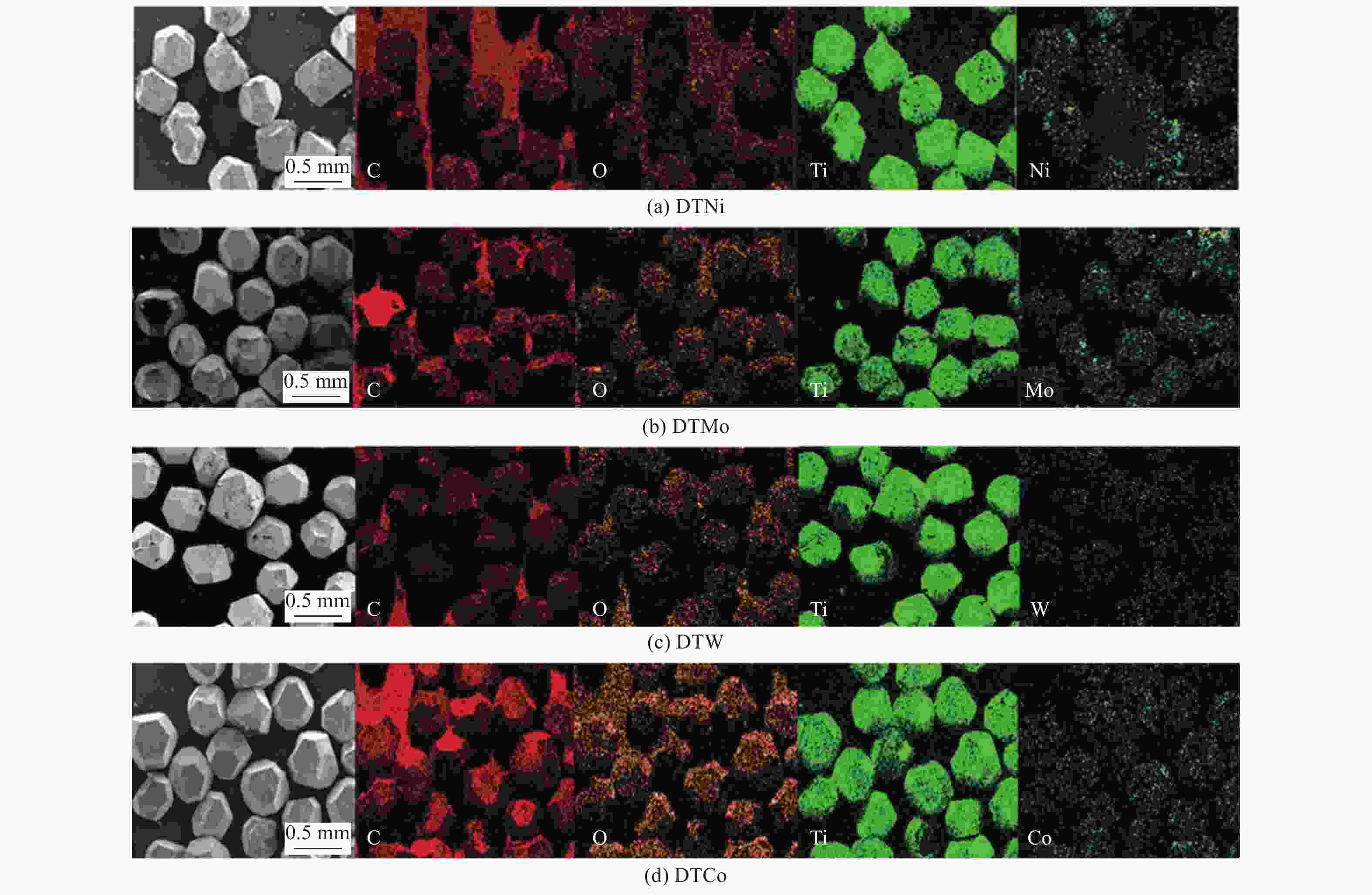

摘要: 采用盐浴镀覆法对金刚石表面进行双金属层改性处理,以实现金刚石/金属界面结合力的提升。通过对Ti-Ni、Ti-Mo、Ti-W、Ti-Co 4种双金属层改性金刚石的物相组成、微观形貌、镀层厚度、表面粗糙度等进行测试及分析,探究金属组合差异对金刚石镀层性能的影响。结果表明:金属化合物的热力学稳定性、界面相容性以及金属间晶格失配度影响镀层质量;Ti-W改性的金刚石表面因TixW1−x化合物的高稳定性、W的低扩散速率及Ti-W的高效还原性,其镀层厚度最大为3.4 μm,较界面亲和度较弱且晶格失配度较大的Ti-Co样品的镀层厚度提高了161.54%;Ti-Mo与Ti-W改性的金刚石表面因晶格失配度低,在金刚石(111)晶面表现出优异的表面平整性,其表面粗糙度Ra较Ti-Ni样品的分别降低了12.41%、21.05%,较Ti-Co样品的分别降低了57.16%、61.39%。Abstract:

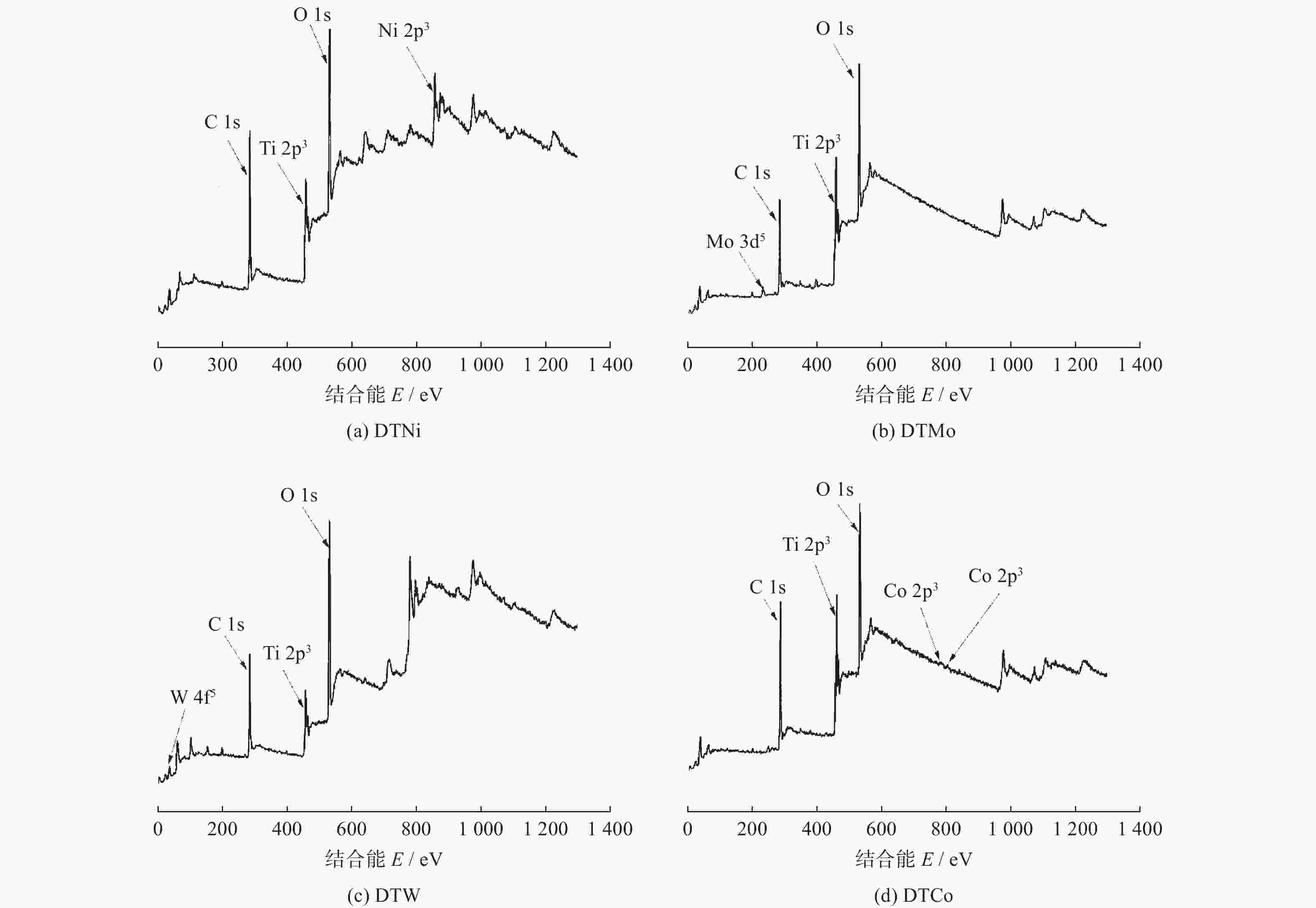

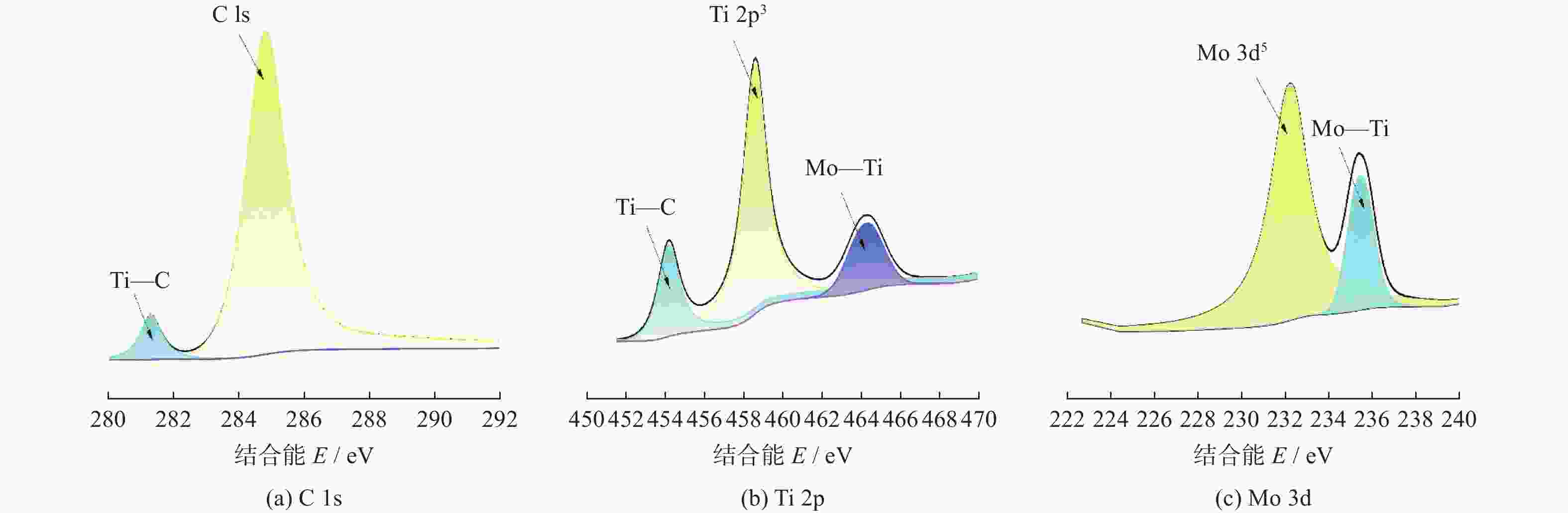

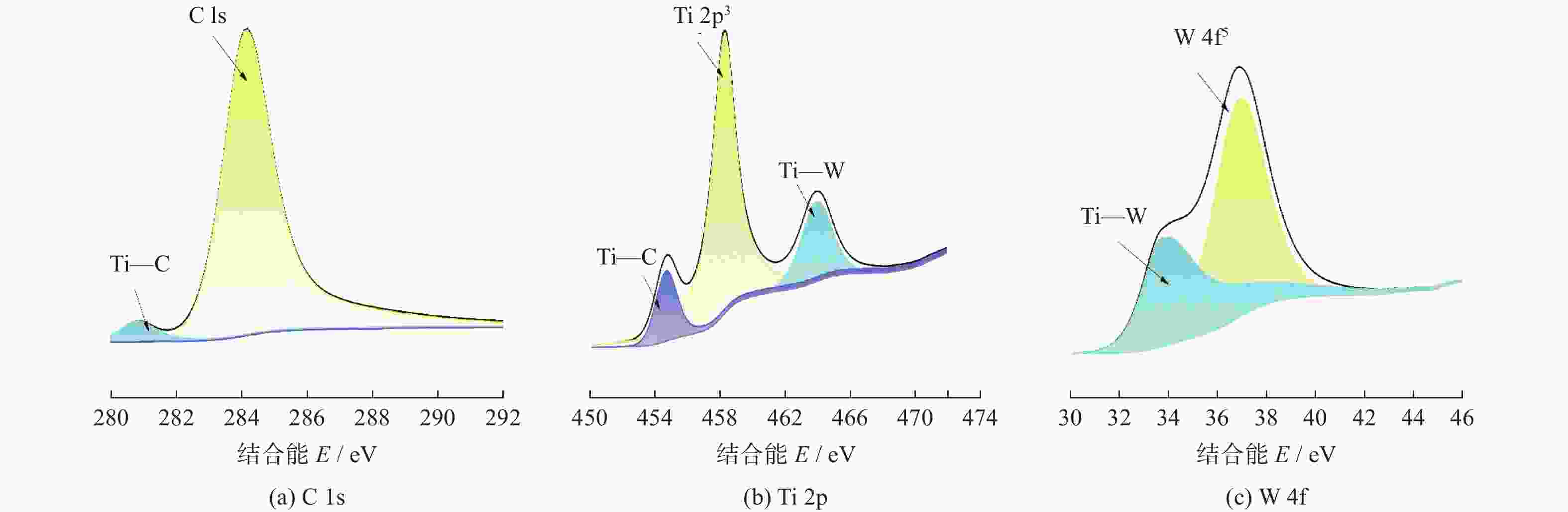

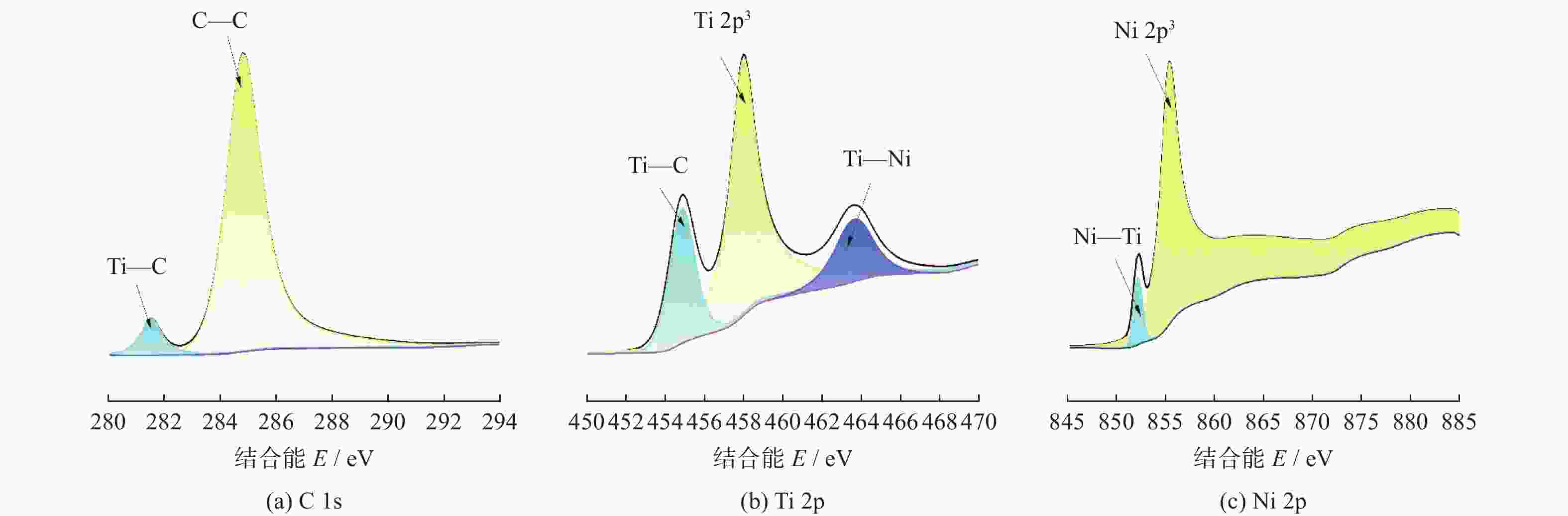

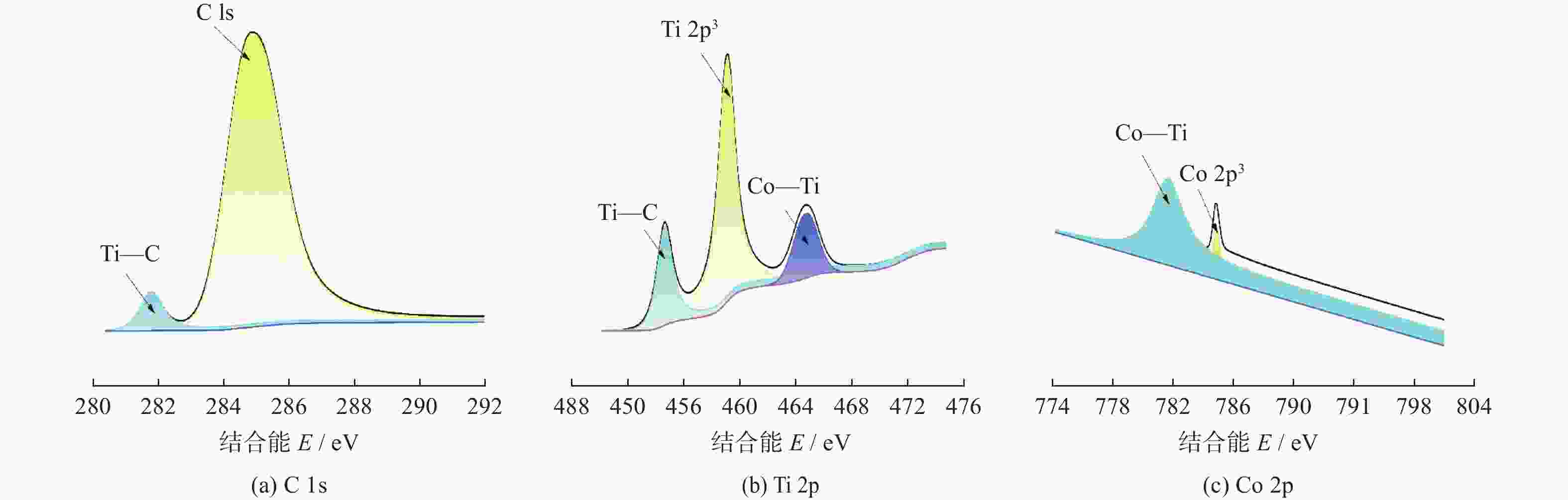

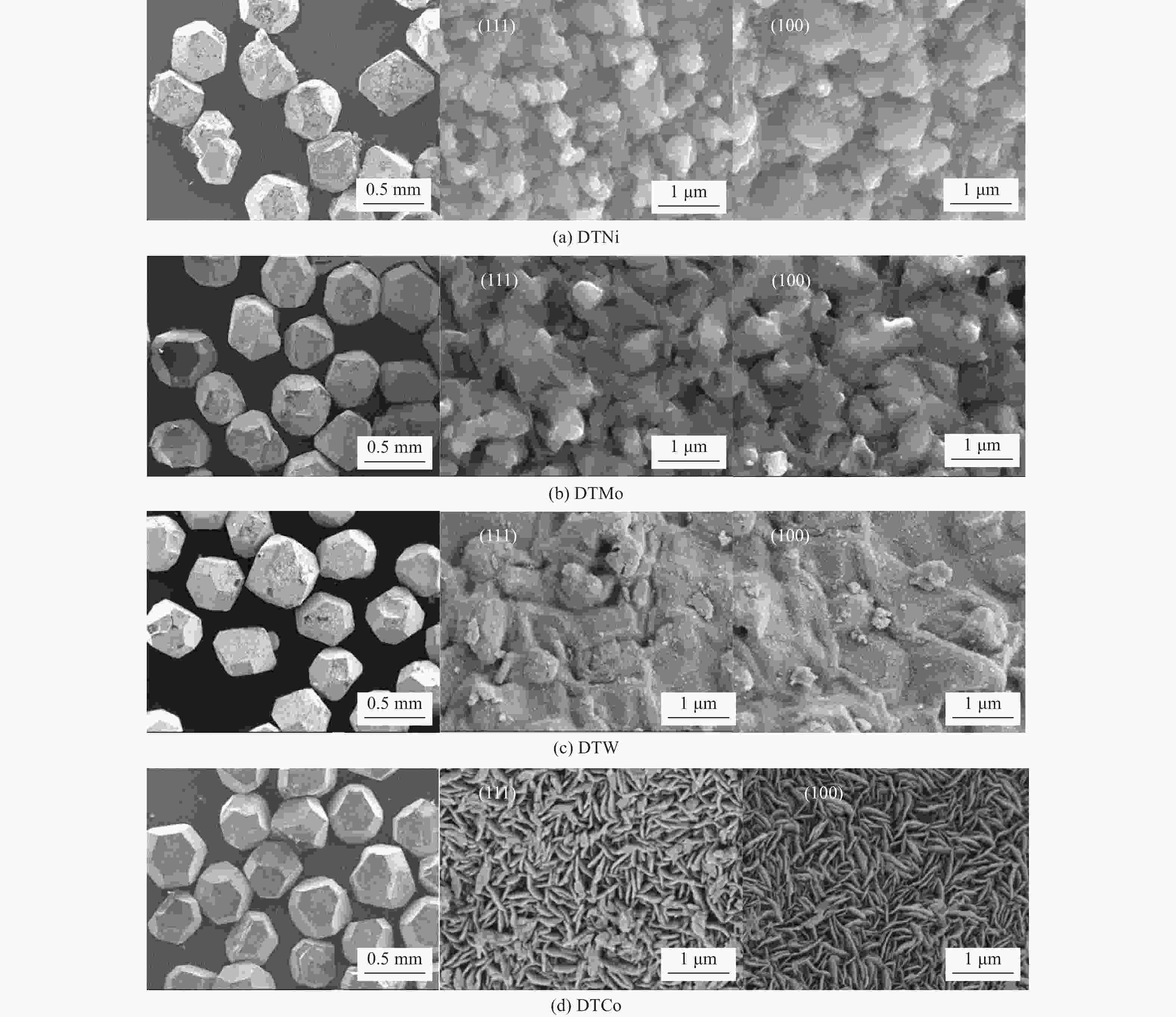

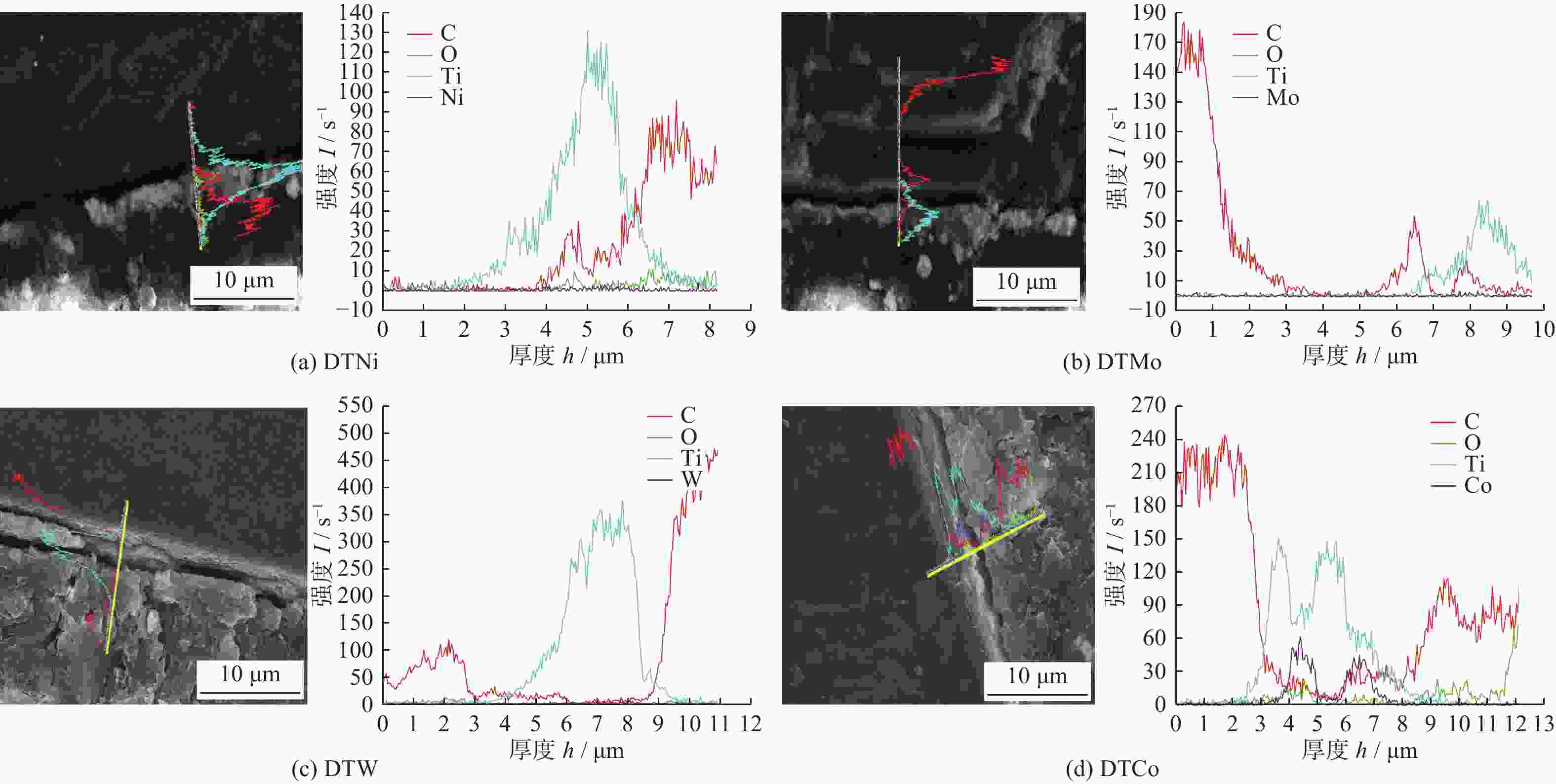

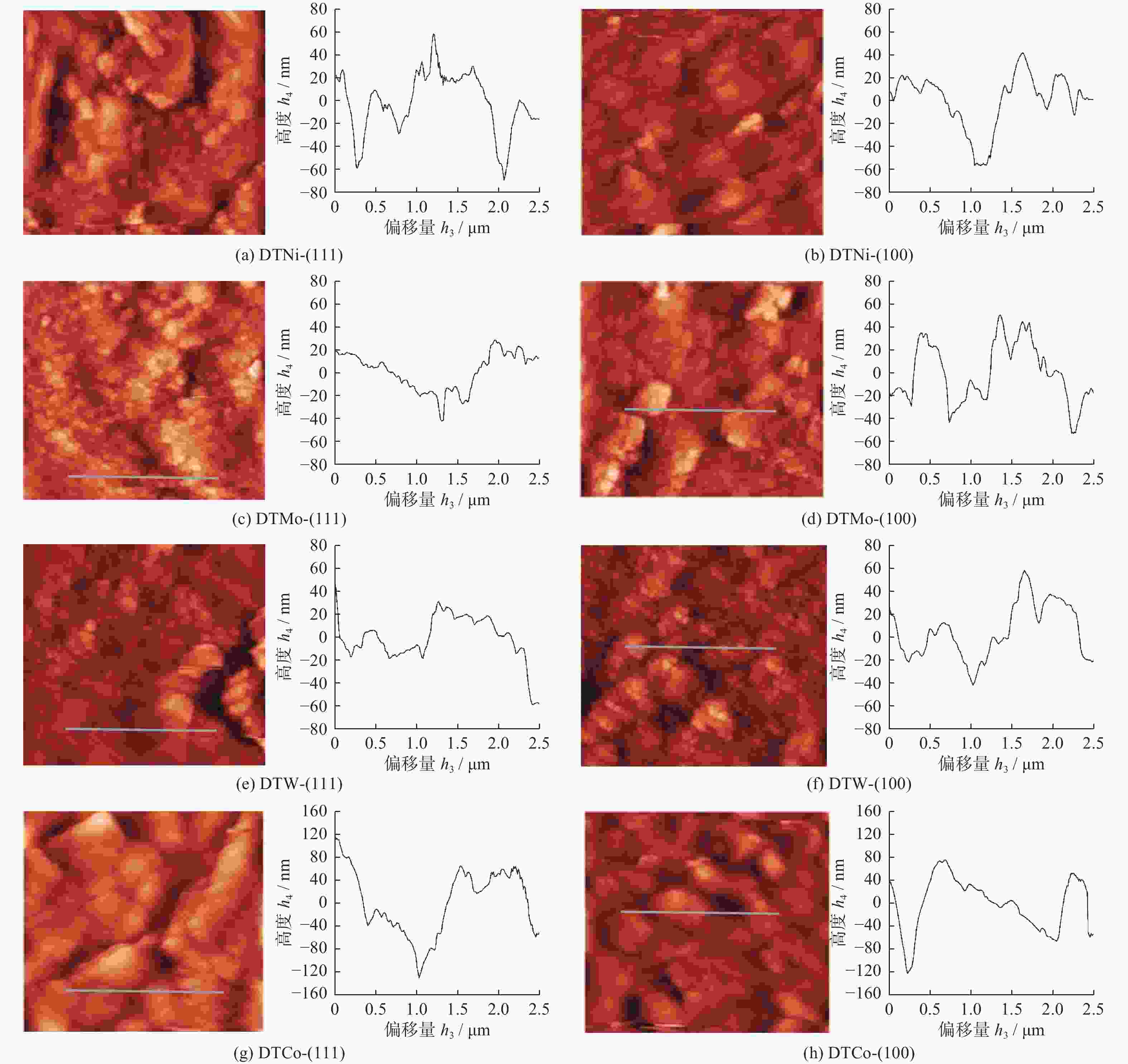

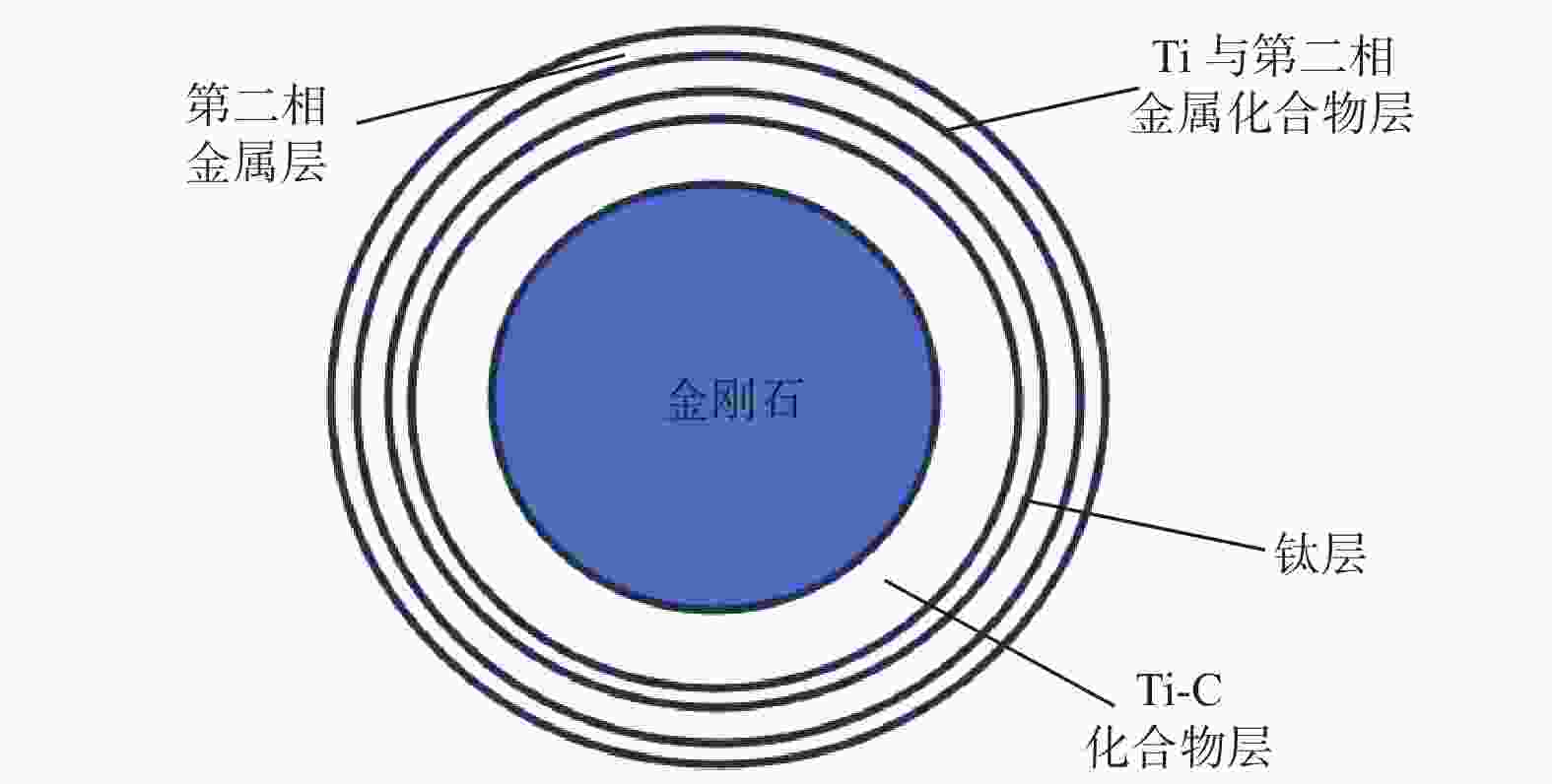

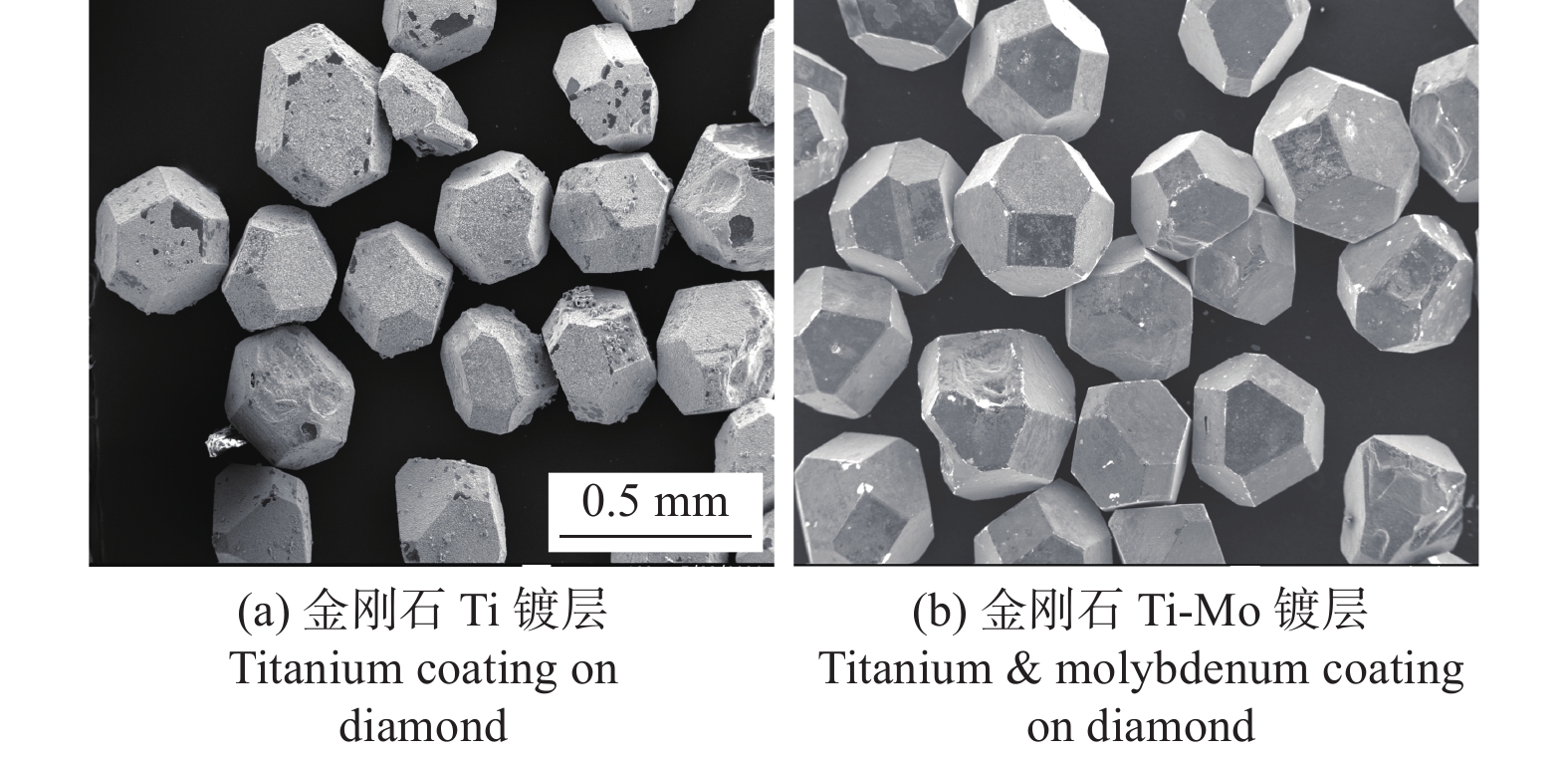

Objectives With the increasing demand for superhard tool performance in precision machining, the problems of weak bonding between diamond and metal interface, and high cost of controlling coating thickness urgently need to be solved. In this study, the molten salt plating process is adopted. The diamond surface is subjected to bimetallic synergistic modification treatment through the combination of four different metals, namely Ti-Ni, Ti-Mo, Ti-W and Ti-Co, in order to enhance the bonding force at the diamond/metal interface. Meanwhile, the influences of the differences in metal combinations on the coating are explored. Methods Four kinds of bimetallic modified diamond samples are prepared by the same molten salt plating process. The phase composition, the microscopic morphology, coating thickness and roughness of the samples are tested and analyzed to explore the influences of metal composition differences on the performance of diamond coatings. Taking the Ti-Ni plated sample as an example, its preparation process is as follows: (1) Under the conditions of NaCl mass fraction of 20.31%, KCl mass fraction of 25.84%, diamond mass fraction of 23.08%, titanium mass fraction of 7.69%, and nickel mass fraction of 23.08%, the masses of each raw material are weighed, and the mixture with a total mass of 3 g is placed in a burning boat. (2) The mixture is subjected to metallization plating treatment in a tubular furnace fully protected by argon gas. The plating temperature is 1 000 ℃, the holding time is 60 min, and the argon gas flow rate is 0.2 L/min. (3) After plating, the product is ultrasonically cleaned at 40 kHz for 30 minutes to remove the residual salt and the metal particles on its surface. Then, it is dried under vacuum at 60 ℃, ground and sieved to obtain the coated sample. Results (1) The thermodynamic stability and the interfacial compatibility of metal compounds affect the coating thickness. For the Ti-W modified diamond sample, due to the high stability of the TixW1−x compound, the low diffusion rate of W and the efficient reducing property of Ti-W, the maximum coating thickness is 3.4 μm. Due to the weak affinity of Ti-Co, the thinnest coating of the Ti-Co modified sample is 1.3 μm. Therefore, the coating thickness of the Ti-W sample is increased by 161.54% compared with that of the Ti-Co sample. Moreover, in the same sample, the thickness of the Ti-C layer formed by chemical bonding and the intermetallic compound layer varies greatly. The thickness difference between the Ti-C layer formed by chemical bonding and the intermetallic compound layer in the same sample is significant, with the former accounting for more than 79% of the thickness, while the physically deposited elemental metal layer is thinner. Therefore, the synergistic effect of the Ti-C covalent bond dominated by chemical bonding and the intermetallic compound interface structure with the metal layer assisted by physical deposition can effectively coordinate the interfacial stress and improve the bonding stability of the coating. (2) The lattice mismatch between metals affects the surface roughness Ra of bimetallic modified diamond. Low mismatch Ti-Mo (with mismatch degree of 0.064 6) and Ti-W (with mismatch degree of 0.070 7) bimetallic modified diamonds exhibit better surface quality on the (111) crystal plane, with Ra values of 17.021 and 15.341 nm, respectively, which are 12.41% and 21.05% lower than those of Ti-Ni (with mismatch degree of 0.193 8) bimetallic modified diamond, and 57.16% and 61.39% lower than those of Ti-Co (with mismatch degree of 0.151 8) bimetallic modified diamond, respectively. This is due to the regulatory effect of lattice compatibility on the interfacial bonding strength, which in turn affects the surface morphology of the coating. The mismatch degree between Ti-Co is lower than that between Ti-Ni, but its roughness is actually higher, which is related to the surface protrusions on the coating surface caused by the accumulation of cobalt elements during the deposition process. Conclusions The use of the molten salt method for bimetallic modification of diamond successfully triggers the interfacial chemical reaction between diamond and metal, transforming the bonding mode from single physical coating to a comprehensive combination of chemical bonding and physical coating. This significantly enhances the interfacial bonding strength of diamond/metal, providing a reference for the experimental optimization of high-performance diamond tools. -

Key words:

- salt bath plating /

- diamond /

- carbide /

- bimetallic coating

-

表 1 实验原料

Table 1. Experimental raw materials

原料 纯度 φ / % NaCl > 99.50 KCl > 99.50 Ti 99.50 Ni 99.99 Mo 99.90 W 99.90 Co 99.50 表 2 样品配方

Table 2. Sample formula

样品

名称NaCl质量

分数 ω1 / %KCl质量

分数 ω2 / %金刚石质量

分数 ω3 / %Ti粉质量

分数 ω4 / %第二相金属质

量分数 ω4 / %DTNi 20.31 25.84 23.08 7.69 23.08 DTMo 20.31 25.84 23.08 7.69 23.08 DTW 20.31 25.84 23.08 7.69 23.08 DTCo 20.31 25.84 23.08 7.69 23.08 表 3 主要实验仪器

Table 3. Main experimental apparatus

仪器名称 型号 生产厂家 管式炉 XD-1200NT 郑州兄弟窑炉有限公司 X射线衍射仪 SmartLab3 日本理学株式会社 X射线光电子能谱 Thermo Scientific

K-Alpha美国赛默飞世尔科技公司 扫描电子显微镜 JSM-7001F 日本电子株式会社 X射线能谱仪 EDS INCA X-act 牛津仪器科技有限公司 金相镶嵌机 XQ-2B 莱州市蔚仪试验器械

制造有限公司原子力显微镜 Solver Next NT-MDT 表 4 金属晶格参数统计表

Table 4. Statistical table of metal lattice parameters

金属 晶格常数 d / m 晶型 与金刚石的

失配度 Lm与Ti的

失配度 LTiα-Ti 2.956 × 10−10 HCP 0.169 7 β-Ti 3.307 × 10−10 BCC 0.169 7 Ni 3.529 × 10−10 FCC 0.008 7 0.193 8 Mo 3.147 × 10−10 BCC 0.116 0 0.064 6 W 3.165 × 10−10 BCC 0.111 0 0.070 7 Co 2.507 × 10−10 HCP 0.295 8 0.151 8 表 5 金刚石双金属镀层厚度统计表

Table 5. Diamond bimetal coating thickness statistics table

厚度 DTNi DTMo DTW DTCo Ti-C Ti Ti-Ni Ni Ti-C Ti Ti-Mo Mo Ti-C Ti Ti-W W Ti-C Ti Ti-Co Co 分厚度 h1 / μm 1.1 0.2 0.8 0.3 1.7 0.1 1.0 0.2 2.0 0.1 1.1 0.1 0.8 0.1 0.3 0.1 总厚度 h2 / μm 2.4 3.0 3.4 1.3 表 6 金刚石双金属镀层的表面粗糙度统计表

Table 6. Diamond bimetallic coating surface roughness statistics table

双镀层 (111)面 Ra / nm (111)面 Rq / nm (100)面 Ra / nm (100)面 Rq / nm DTNi 19.432 25.424 23.801 28.025 DTMo 17.021 20.998 24.396 29.947 DTW 15.341 17.794 18.625 22.068 DTCo 39.731 48.084 48.700 56.200 -

[1] 窦志强, 肖长江, 栗正新. 金刚石微粉表面镀覆技术研究进展 [J]. 电镀与精饰, 2017, 39(10): 23-27. doi: 10.3969/j.issn.1001-3849.2017.10.005DOU Zhiqiang, XIAO Changjiang, LI Zhengxin. Research progress of plating technology on ultrafine diamond surface [J]. Plating and Finishing, 2017, 39(10): 23-27. doi: 10.3969/j.issn.1001-3849.2017.10.005 [2] 杨彪, 杨军, 袁光生. 金刚石表面镀覆前处理工艺研究 [J]. 航天标准化, 2020(1): 34-35. doi: 10.3969/j.issn.1009-234X.2020.01.011YANG Biao, YANG Jun, YUAN Guangsheng. Study on pretreatment technology of diamond surface plating [J]. Aerospace Standardization, 2020(1): 34-35. doi: 10.3969/j.issn.1009-234X.2020.01.011 [3] 方莉俐, 刘韩, 姜羽飞, 等. 线锯用金刚石微粉表面化学镀镍工艺及性能研究 [J]. 工具技术, 2024, 58(4): 54-58. doi: 10.3969/j.issn.1000-7008.2024.04.009FANG Lili, LIU Han, JIANG Yufei, et al. Research on electroless nickel plating process and performance of diamond powder surface for wire saws [J]. Journal of Tool Technology, 2024, 58(4): 54-58. doi: 10.3969/j.issn.1000-7008.2024.04.009 [4] 马芝存. 辐照损伤合金化制备Mo/Ag系列层状金属基复合材料的研究 [D]. 天津: 天津大学, 2014.MA Zhicun. Research on preparation of Mo/Ag series laminar metal matrix composites using irradiation damage alloying method [D]. Tianjin: Tianjin University, 2014. [5] KANG Q, HE X, REN S, et al. Preparation of copper–diamond composites with chromium carbide coatings on diamond particles for heat sink applications [J]. Applied Thermal Engineering, 2013, 60(1/2): 423-429. doi: 10.1016/j.applthermaleng.2013.05.038 [6] 项东, 李木森, 刘科高, 等. 金刚石表面盐浴镀Ti层研究 [J]. 热加工工艺, 2009, 38(4): 74-77. doi: 10.3969/j.issn.1001-3814.2009.04.023XIANG Dong, LI Musen, LIU Kegao, et al. Study on salt-bath plating Ti layers on diamond surface [J]. Hot Working Technology, 2009, 38(4): 74-77. doi: 10.3969/j.issn.1001-3814.2009.04.023 [7] 杜全斌, 张志康, 崔冰, 等. 金刚石表面改性技术研究进展与应用 [J]. 金属加工(热加工), 2023(12): 5-7. doi: 10.3969/j.issn.1674-165X.2023.12.001DU Quanbin, ZHANG Zhikang CUI Bing, et al. Research progress and application of diamond surface modification technology [J]. MW Metal Forming, 2023(12): 5-7. doi: 10.3969/j.issn.1674-165X.2023.12.001 [8] 崔露露, 张磊. Ⅳ族及Ⅵ族过渡金属改性金刚石表面的热力学分析及应用 [J]. 有色金属(中英文), 2025, 15(2): 209-216. doi: 10.20242/j.issn.2097-5384.2025.02.004CUI Lulu, ZHANG Lei. Thermodynamic analysis and application of Ⅳ and Ⅵ transition metals modify diamond surface [J]. Nonferrous Metals, 2025, 15(2): 209-216. doi: 10.20242/j.issn.2097-5384.2025.02.004 [9] 温国栋. 金刚石表面改性单金属镀层的研究进展 [J]. 热加工工艺, 2019, 48(16): 18-21. doi: 10.14158/j.cnki.1001-3814.2019.16.004WEN Guodong. Research progress of diamond surface modified single metal coating [J]. Hot Working Technology, 2019, 48(16): 18-21. doi: 10.14158/j.cnki.1001-3814.2019.16.004 [10] CUI L L, ZHANG L, YANG Y F, et al. Enhancing the thermal conductivity of laser powder bed fusion AlSi20 by introducing a novel TiC-Ti coated diamond powder [J]. Metallurgical and Materials Transactions A, 2024, 55(8): 2869-2880. doi: 10.1007/s11661-024-07441-5 [11] WEI C L, XU X, WEI B Z, et al. Titanium coating on the surface of diamond particles by a novel rapid low-temperature salt bath plating method [J]. Chemical Physics Letters, 2020, 761: 138091. doi: 10.1016/j.cplett.2020.138091 [12] 祝平, 夏一骁, 张强, 等. 金刚石/金属复合材料界面改性研究进展 [J]. 中国材料进展, 2023, 42(12): 974-984. doi: 10.7502/j.issn.1674-3962.202305021ZHU Ping, XIA Yixiao, ZHANG Qiang, et al. Research progress in interfacial modification of diamond / metal composites [J]. Materials China, 2023, 42(12): 974-984. doi: 10.7502/j.issn.1674-3962.202305021 [13] 王长瑞, 李宏钊, 田威, 等. 金刚石(100)-(111)面微沉积钨/铜复合材料制备与性能 [J]. 复合材料学报, 2022, 39(12): 6004-6016. doi: 10.13801/j.cnki.fhclxb.20211228.002WANG Changrui, LI Hongzhao, TIAN Wei, et al. Preparation and properties of tungsten micro-deposited on diamond (100)-(111) facets/Cu composites [J]. Acta Materiae Compositae Sinica, 2022, 39(12): 6004-6016. doi: 10.13801/j.cnki.fhclxb.20211228.002 [14] ANG L, LAN S, WEI Z, et al. A simple way to fabricate Ti6Al4V matrix composites reinforced by graphene with exceptional mechanical properties [J]. Material Letters, 2019, 257: 126750. doi: 10.1016/j.matlet.2019.126750 [15] 张利琪. TiC镀层改性金刚石及其铜基复合材料的热性能研究 [D]. 西安: 长安大学, 2022.ZHANG Liqi. Study of modified diamond by TiC-coated and the thermal properties of its copper matrix composites [D]. Xi′an: Chang′an University, 2022. [16] 武玺旺, 皇甫战彪, 刘雪坤, 等. 熔盐法合成Ti和TiC镀覆层对金刚石热稳定性的影响 [J]. 金刚石与磨料磨具工程, 2023, 43(2): 196-201. doi: 10.13394/j.cnki.jgszz.2022.0054WU Xiwang, HUANGFU Zhanbiao, LIU Xuekun, et al. Effect of Ti and TiC coating on the thermal stability of diamond [J]. Diamond & Abrasives Engineering, 2023, 43(2): 196-201. doi: 10.13394/j.cnki.jgszz.2022.0054 [17] ZHANG H C, YUE W, SHA X H, et al. Vacuum tribological properties and impact toughness of polycrystalline diamond based on titanium-coated diamond particle [J]. Diamont Related Materials, 2020, 103: 107712. doi: 10.1016/j.diamond.2020.107712 [18] 汤英童, 杨长城. 金刚石粉表面化学镀镍工艺改进及镀层显微分析 [J]. 光学与光电技术, 2021, 19(5): 75-81. doi: 10.19519/j.cnki.1672-3392.2021.05.012TANG Yingtong, YANG Changcheng. Improvement of the electroless nickel plating technology and surface microstructure analyses of the coating on diamond powder [J]. Optics & Optoelectronic Technology, 2021, 19(5): 75-81. doi: 10.19519/j.cnki.1672-3392.2021.05.012 [19] 贾攀, 卢灿华, 郑大方, 等. 金刚石镀钛层的结构讨论 [J]. 超硬材料工程, 2008(5): 5-8. doi: 10.3969/j.issn.1673-1433.2008.05.002JIA Pan, LU Canhua, ZHENG Dafang, et al. Discussion on the structure of Ti-plated coat of diamond [J]. Superhard Material Engineering, 2008(5): 5-8. doi: 10.3969/j.issn.1673-1433.2008.05.002 [20] DONG Y H, ZHANG R Q, ZHOU L, et al. Formation mechanism and properties of thickness-controllable tungsten coating on diamond surface by salt bath plating [J]. Materials Science Forum, 2018, 933: 264-273. doi: 10.4028/www.scientific.net/MSF.933.264 [21] 潘彦鹏. 双镀层法制备金刚石/铜复合材料及其性能研究 [D]. 北京: 北京科技大学, 2019.PAN Yanpeng. Preparation and properties of diamond/Cu composites fabricated with double-layer coated diamond particles [D]. Beijing: University of Science and Technology Beijing, 2019. [22] 谢月扬. 低温熔盐法制备碳化铬镀层改性金刚石及其铜基复合材料的热性能 [D]. 西安: 长安大学, 2023: 32-47.XIE Yueyang. Thermal properties of copper matrix composites reinforced with chromium carbide-coated diamond prepared via low-temperature molten salts [D]. Xi′an: Chang’an University, 2023: 32-47. [23] 李东鹏, 王卫泽, 黄继波, 等. W, Re过渡层对碳基体表面Al2O3涂层高温热匹配性和层间扩散的影响 [J]. 稀有金属, 2022, 46(9): 1181-1189. doi: 10.13373/j.cnki.cjrm.XY21070032LI Dongpeng, WANG Weize, HUANG Jibo, et al. Alleviating high temperature thermal mismatch and element diffusion of Al2O3 coating on carbon substrate by introducing W/Re interlayer [J]. Chinese Journal of Rare Metals, 2022, 46(9): 1181-1189. doi: 10.13373/j.cnki.cjrm.XY21070032 [24] 胡玲. 熔盐电脱氧法制备钛钨合金时物质间的相互影响 [D]. 重庆: 重庆大学, 2016.HU Ling. Research in mutual influences between substances during preparation of Ti-W alloy via molten salt electro-deoxidation [D]. Chongqing: Chongqing University, 2016. [25] 刘双双. 热扩散过程对Cu/Ni/Ti界面结构及耐蚀性能的影响 [D]. 西安: 长安大学, 2018: 16-55.LIU Shuangshuang. The influence of thermal diffusion on the interface structure and corrosion resistance of Cu/Ni/Ti [D]. Xi′an: Chang′an University, 2018: 16-55. [26] WALID M D, HEE S P, SOON H H. Fabrication of TiN/cBN and TiC/diamond coated particles by titanium deposition process [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3562-3570. doi: 10.1016/S1003-6326(14)63502-0 [27] 徐俊. 金刚石盐浴镀钛对金刚石/铝复合材料组织及性能的影响 [D]. 南京: 东南大学, 2019.XU Jun. Effect of salt bath plating Ti on diamond particles on the microstructure and properties of diamond/Al composites [D]. Nanjing: Southeast University, 2019. [28] SHA X H, YUE W, ZHANG H C, et al. Enhanced oxidation and graphitization resistance of polycrystalline diamond sintered with Ti-coated diamond powders [J]. Journal of Materials Science & Technology, 2020, 43(8): 64-73. doi: 10.1016/j.jmst.2020.01.031 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS