Research on preparation of adhesive magnetic polishing abrasives and polishing performance

-

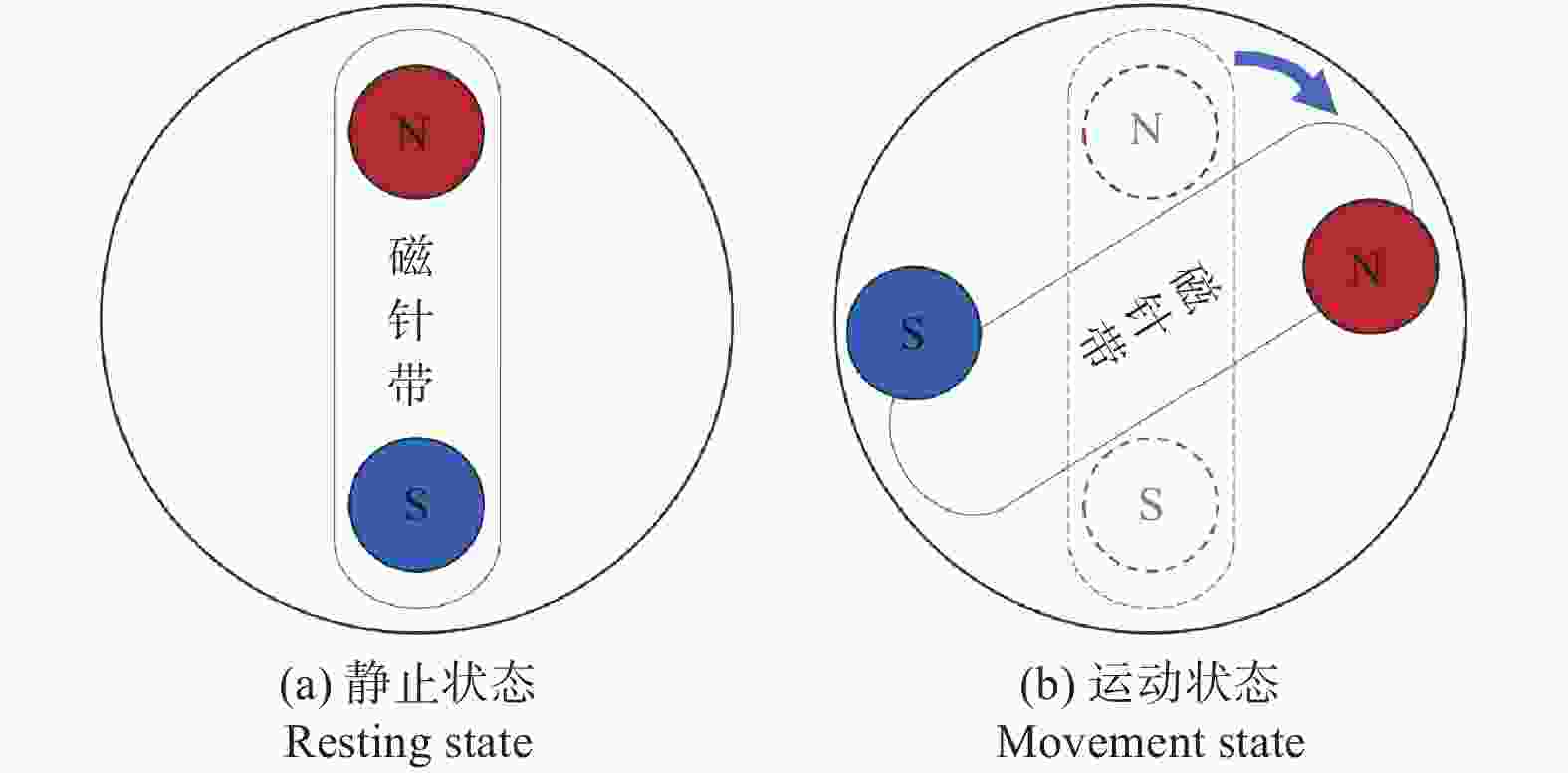

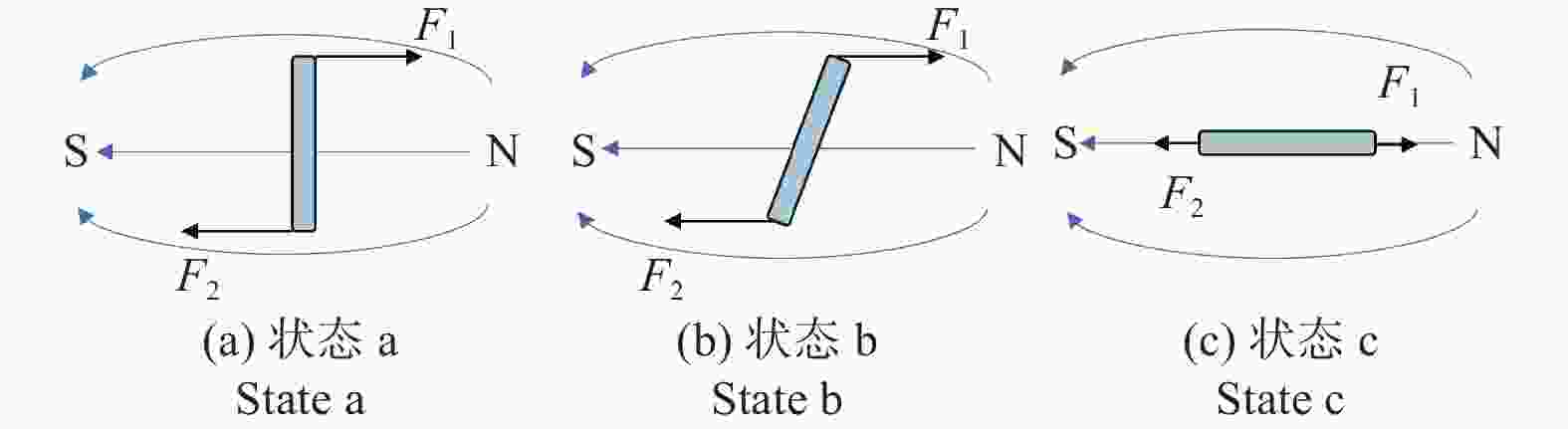

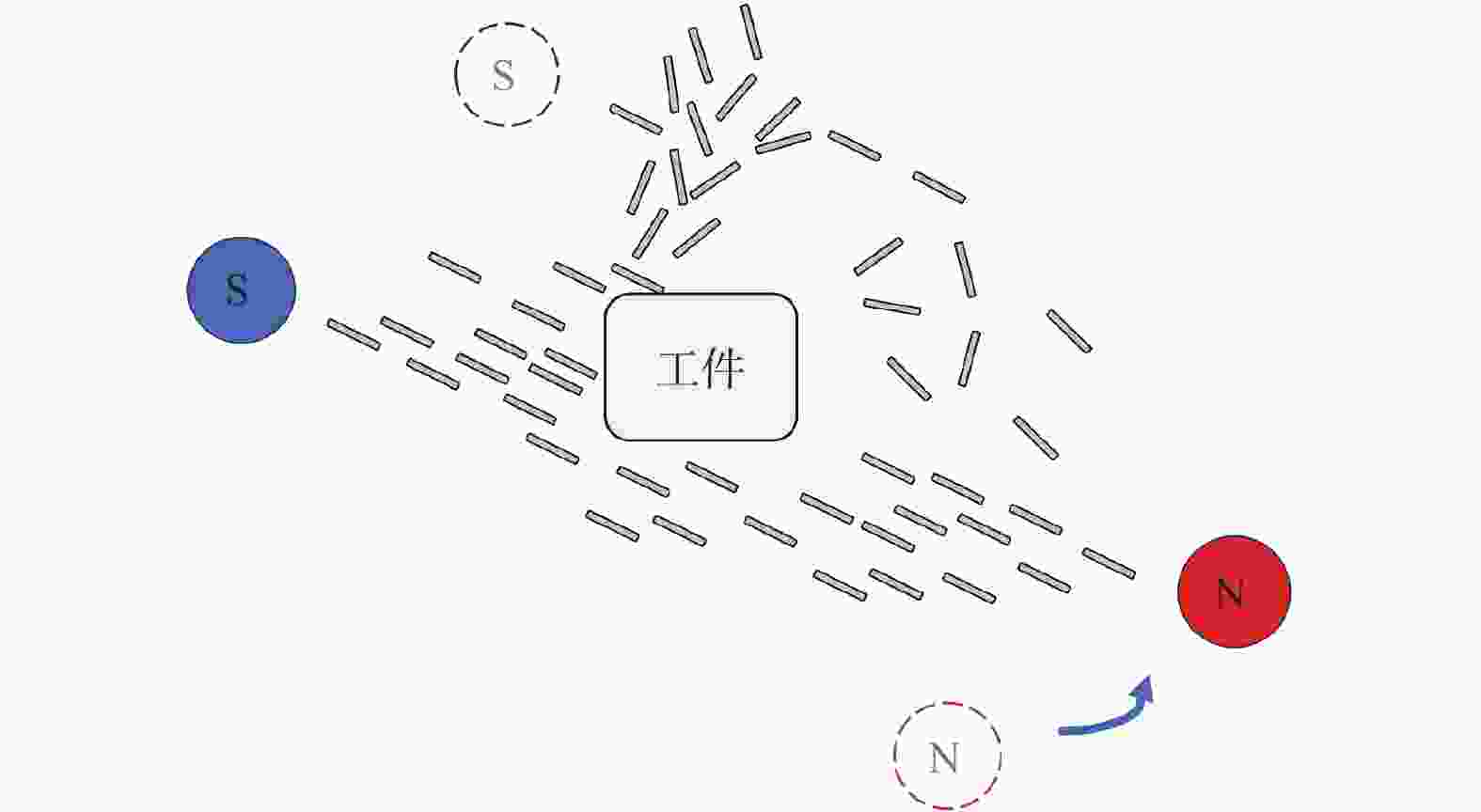

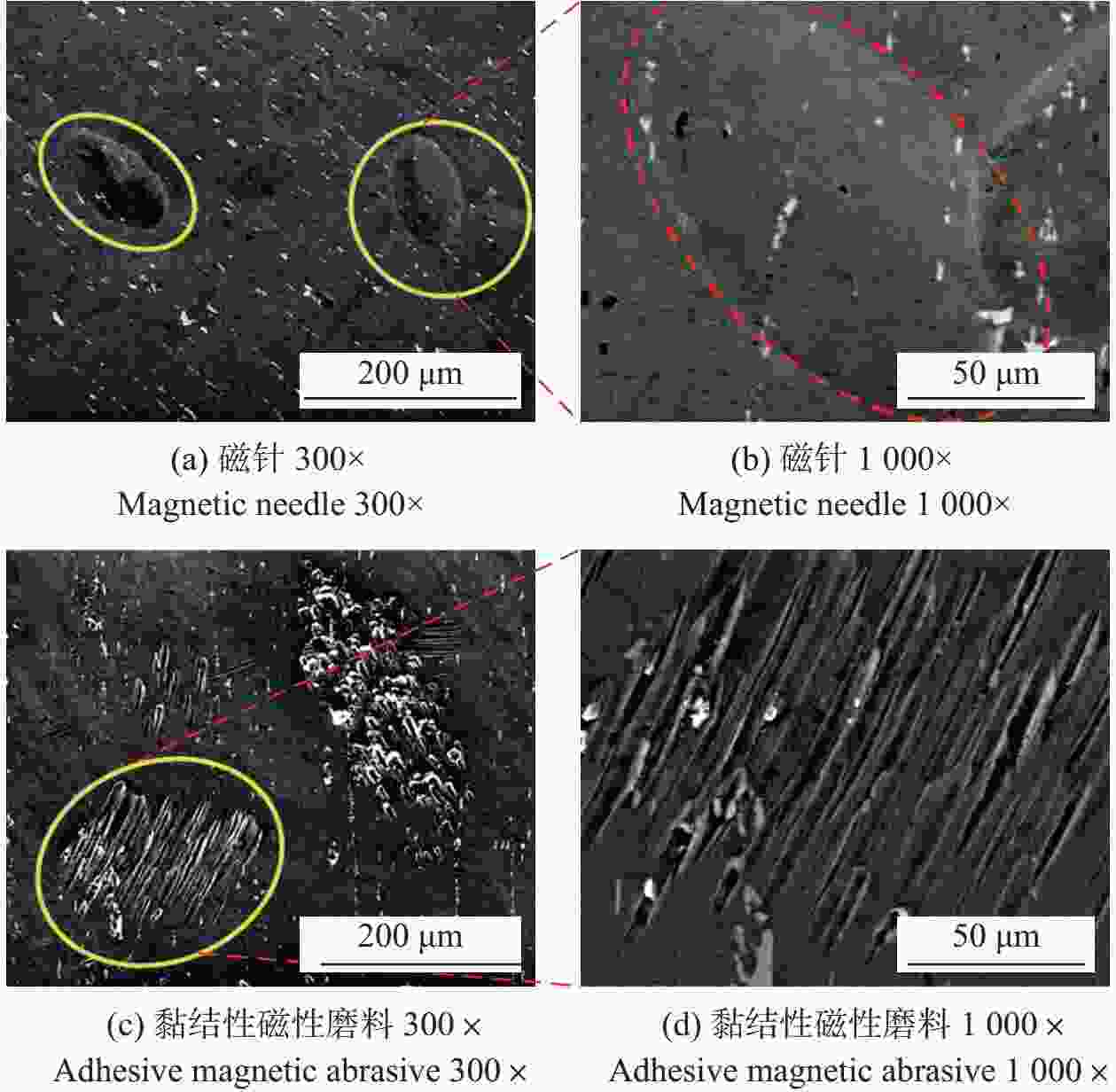

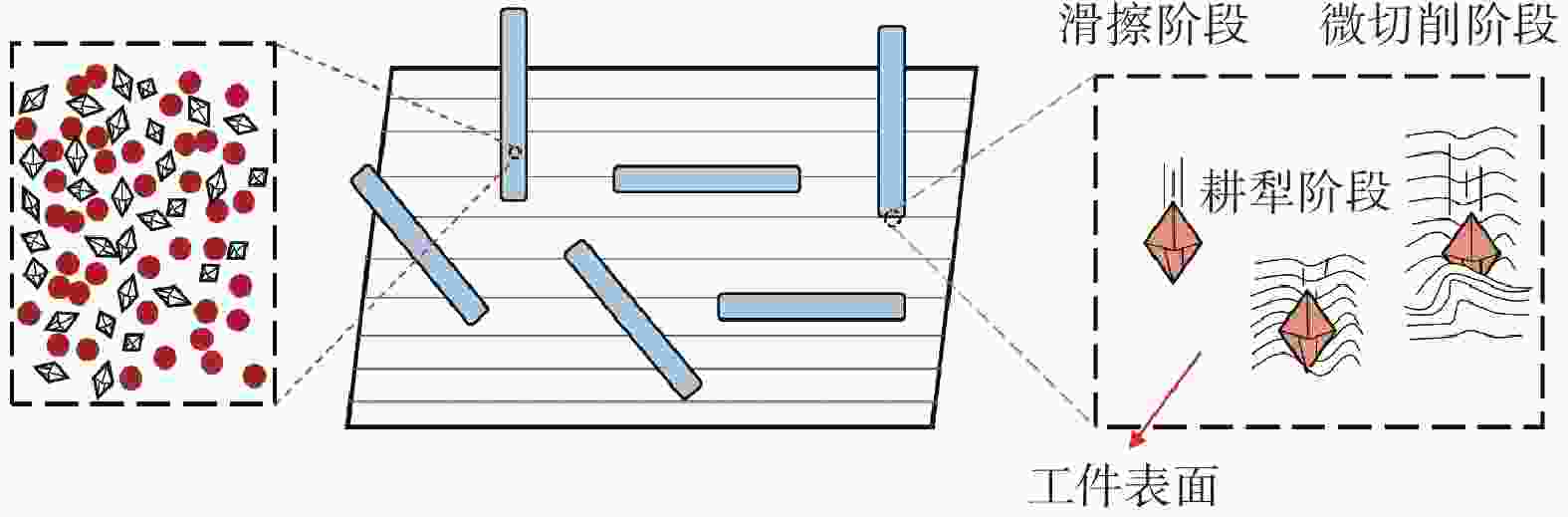

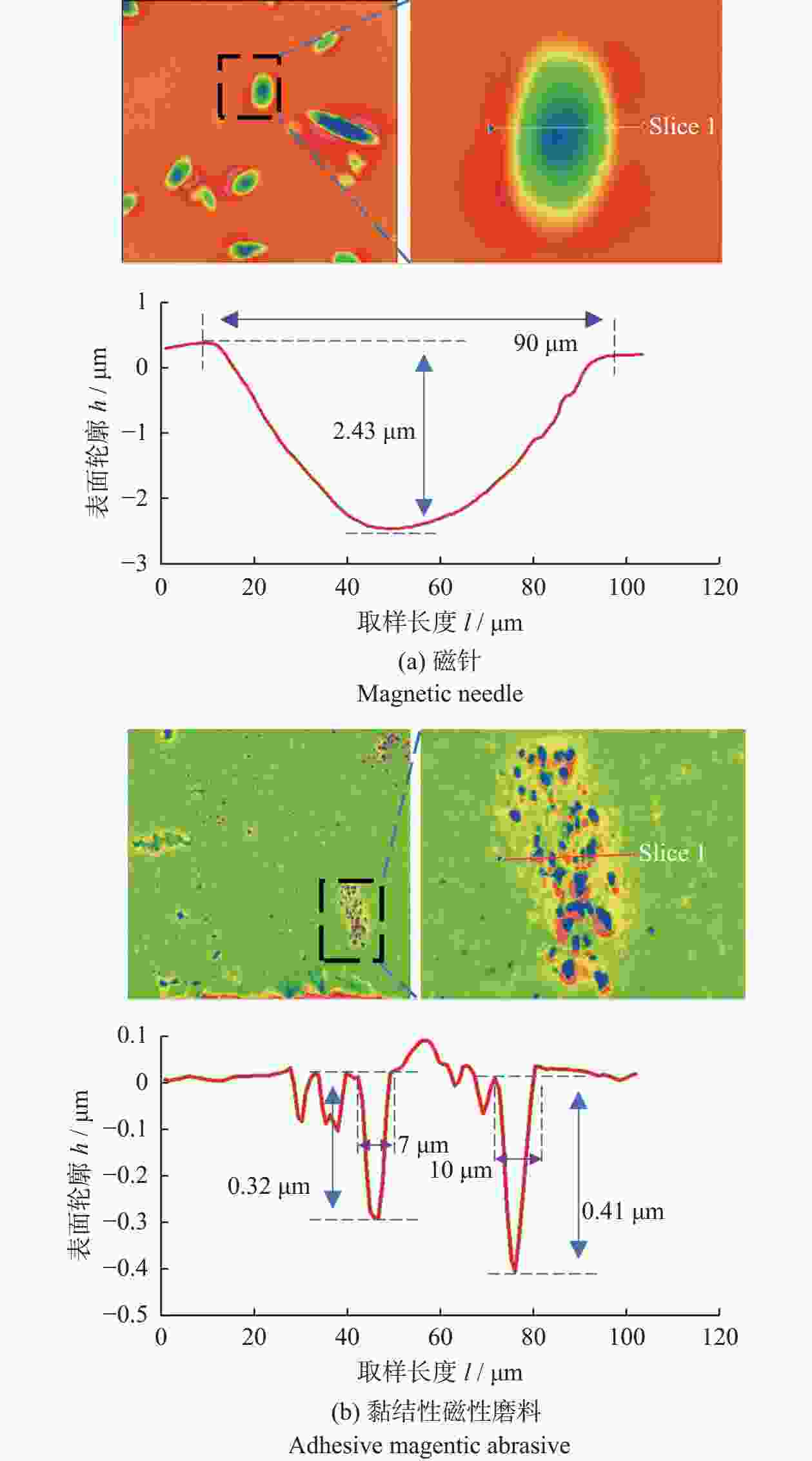

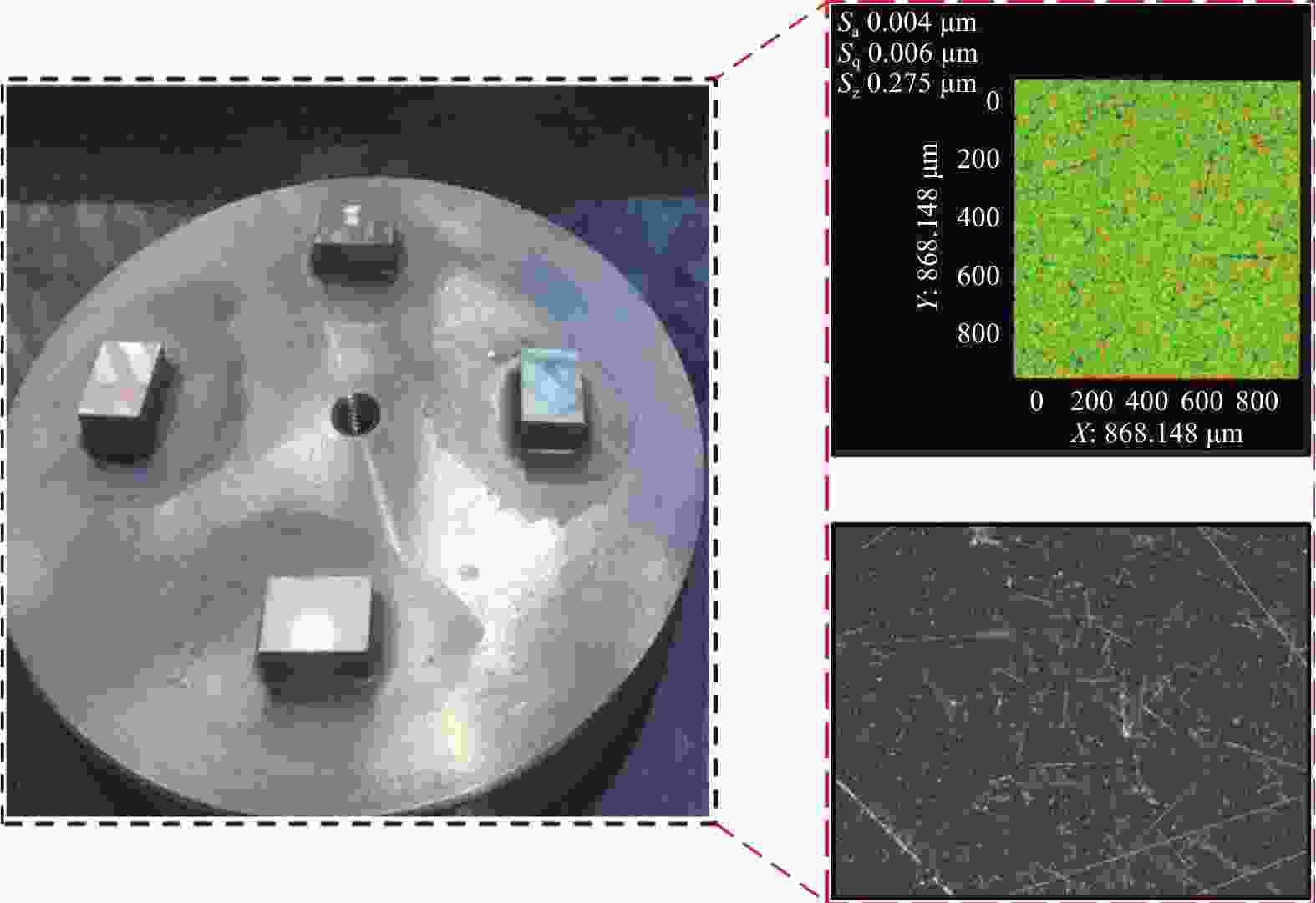

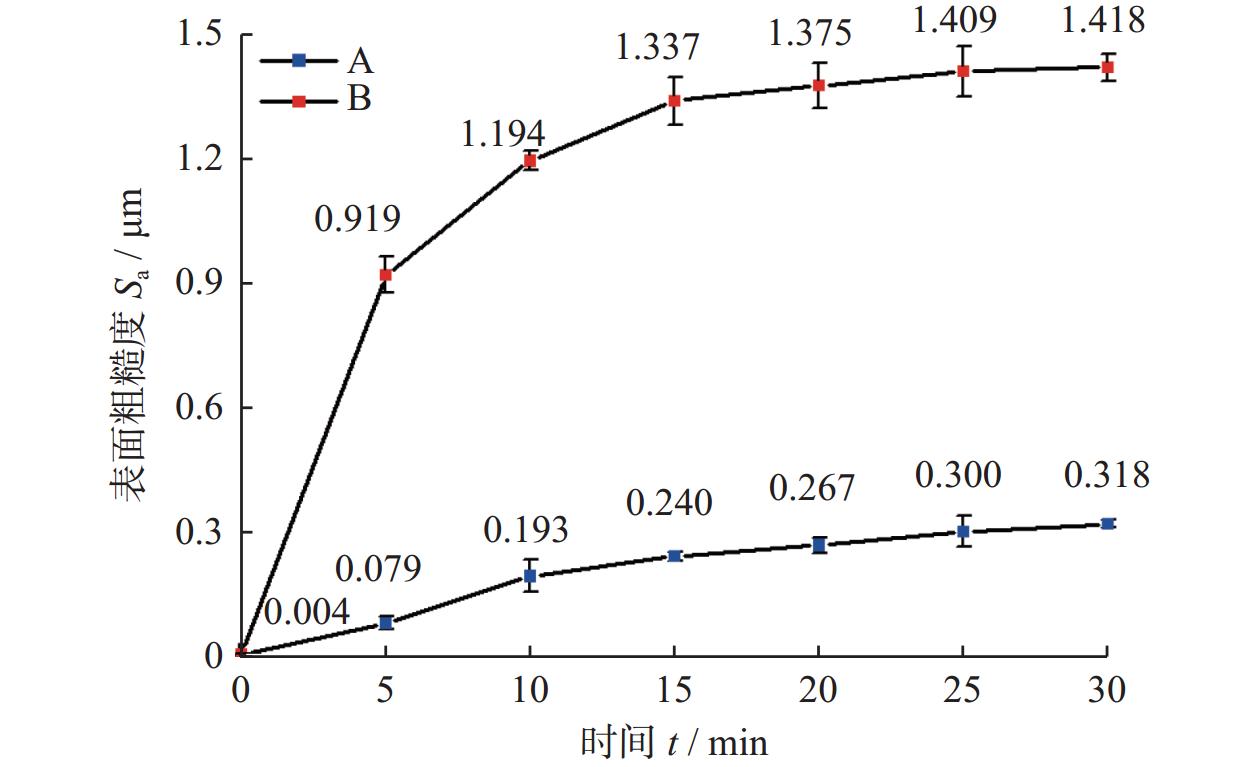

摘要: 针对铝合金等低硬度材料加工时传统磁力抛光磨料介质(不锈钢磁针)加工性能差的问题,提出一种细长型黏结性磁性磨料。该磨料以羰基铁粉作为磁力相,碳化硅作为磨粒相,采用树脂黏结法制备,并且通过偶联剂化学改性来提升结合强度。分析所制备黏结性磁性磨料的运动及机理,探索其与传统不锈钢磁针的区别,并且通过镜面铝合金样件验证2者在微观层面上作用划痕的不同,预测2者对表面质量的影响。采用镜面铝合金样件,以5 min为间隔观察不锈钢磁针和细长型黏结性磁性磨料抛光后工件的表面粗糙度以及表面形貌变化,得到2者的抛光极限表面粗糙度Sa分别为1.418和0.318 μm。结果表明,制备的黏结性磁性磨料可以代替不锈钢磁针作为磨料介质,能够有效提高磁力抛光的抛光性能。Abstract:

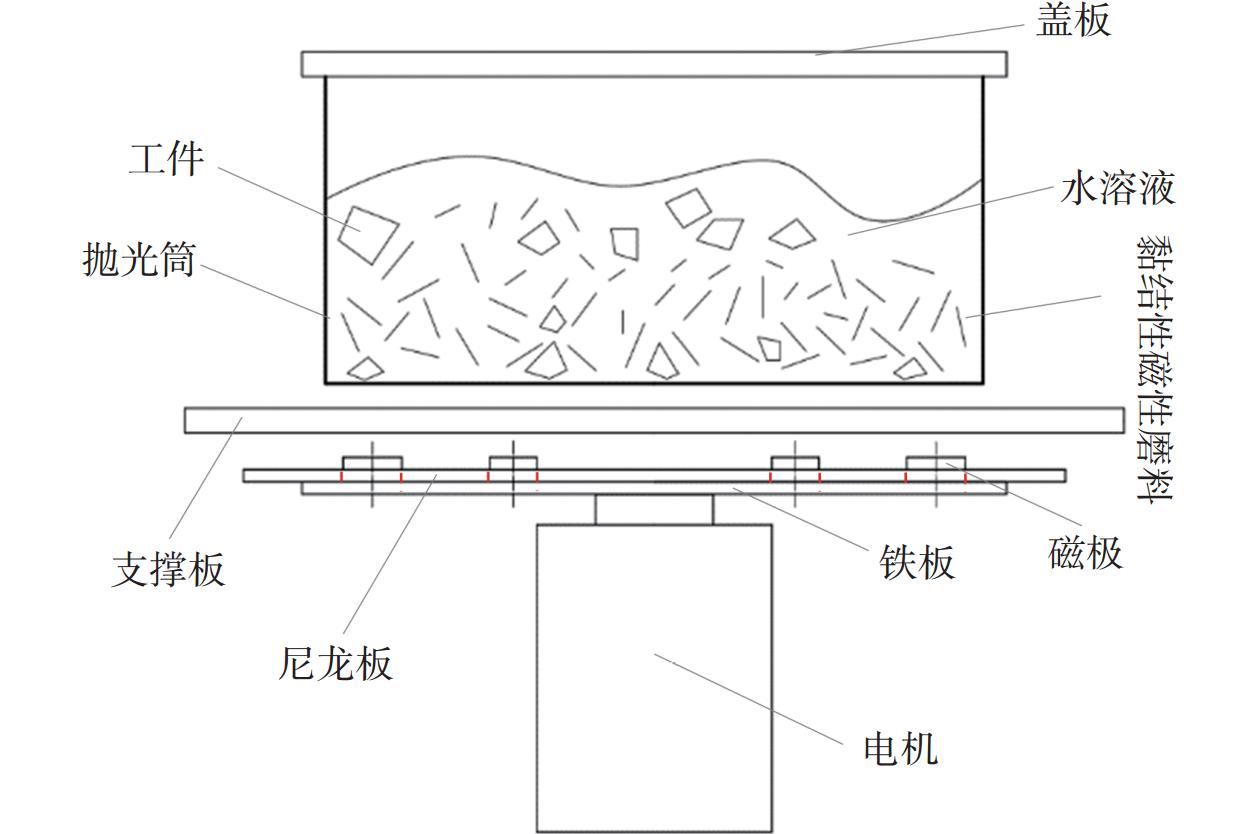

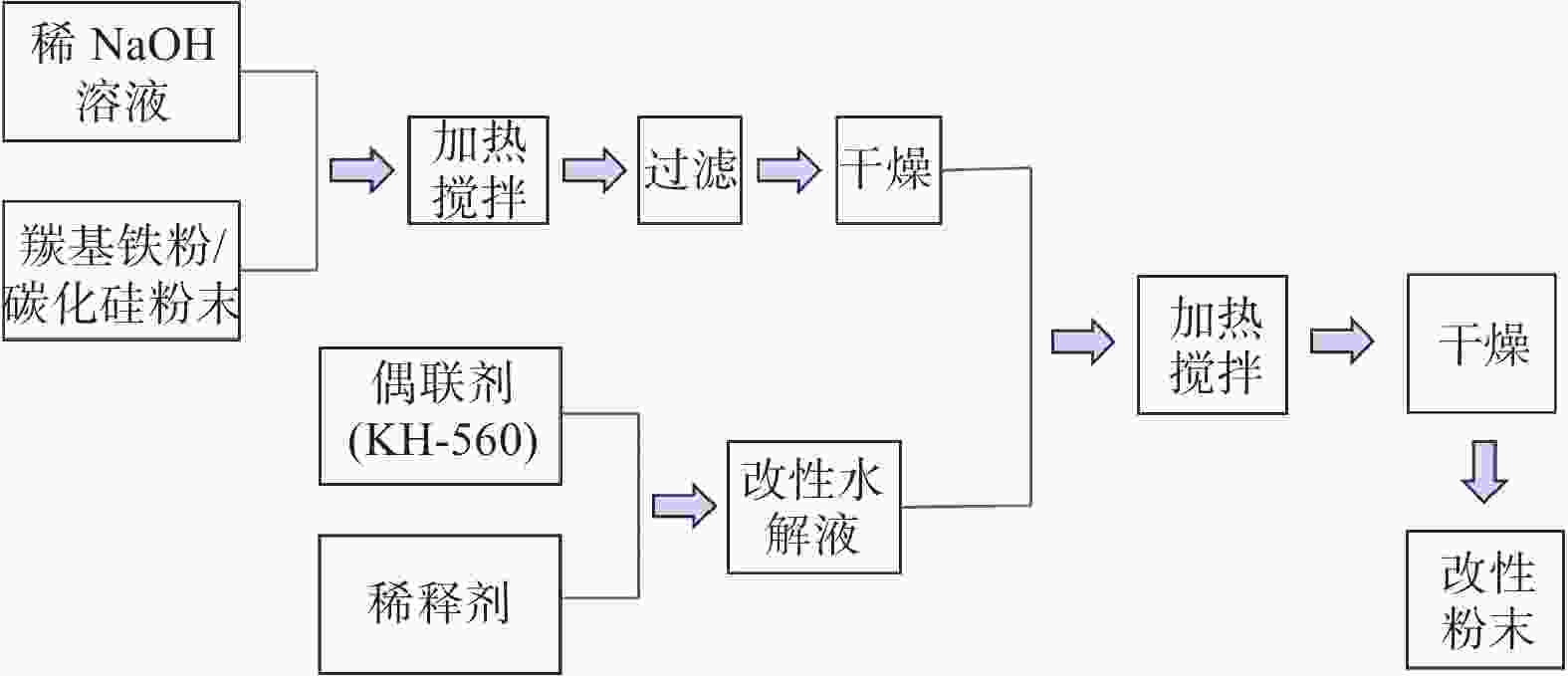

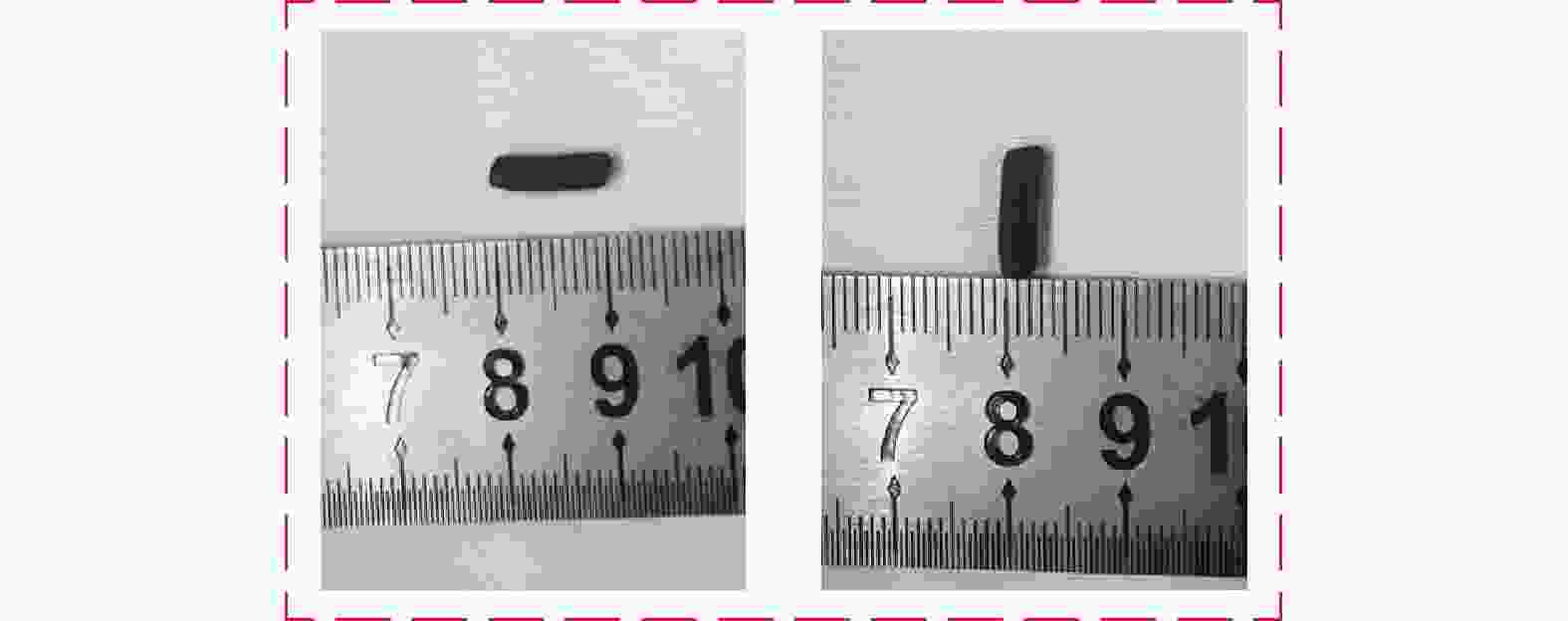

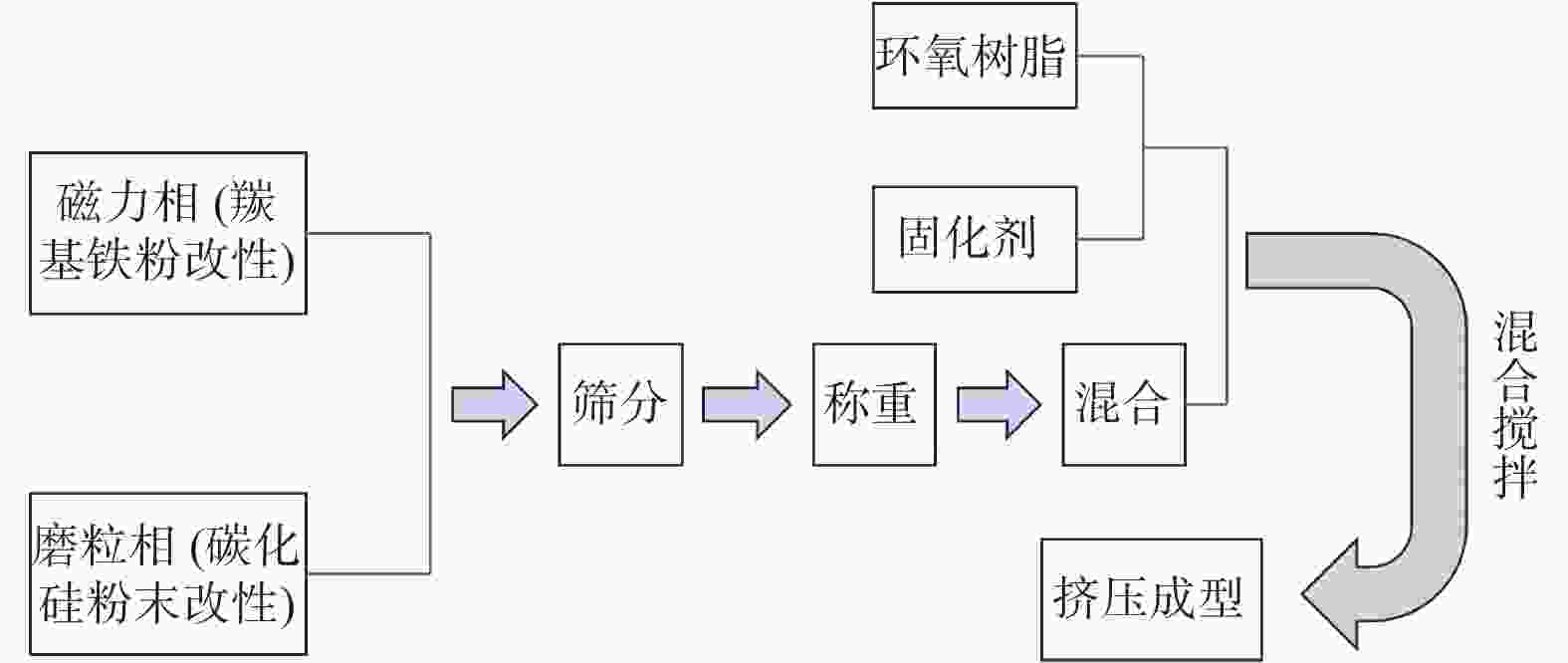

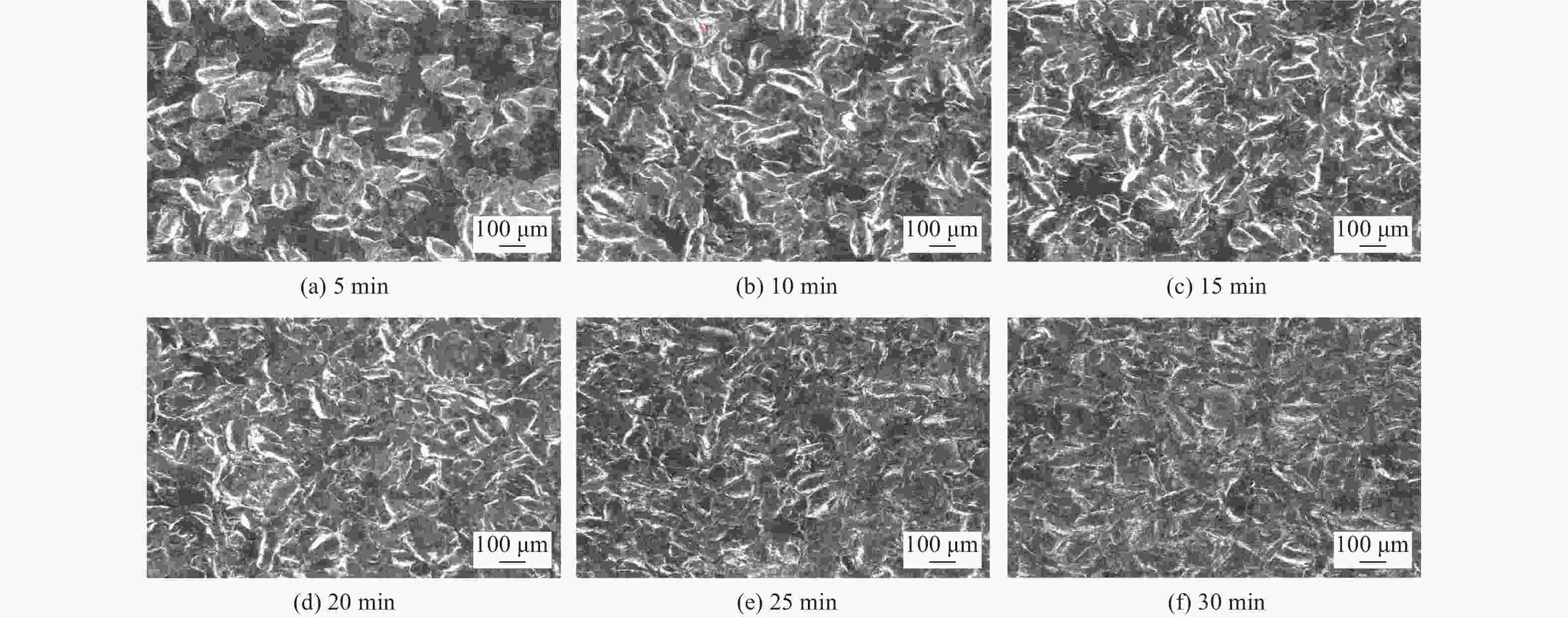

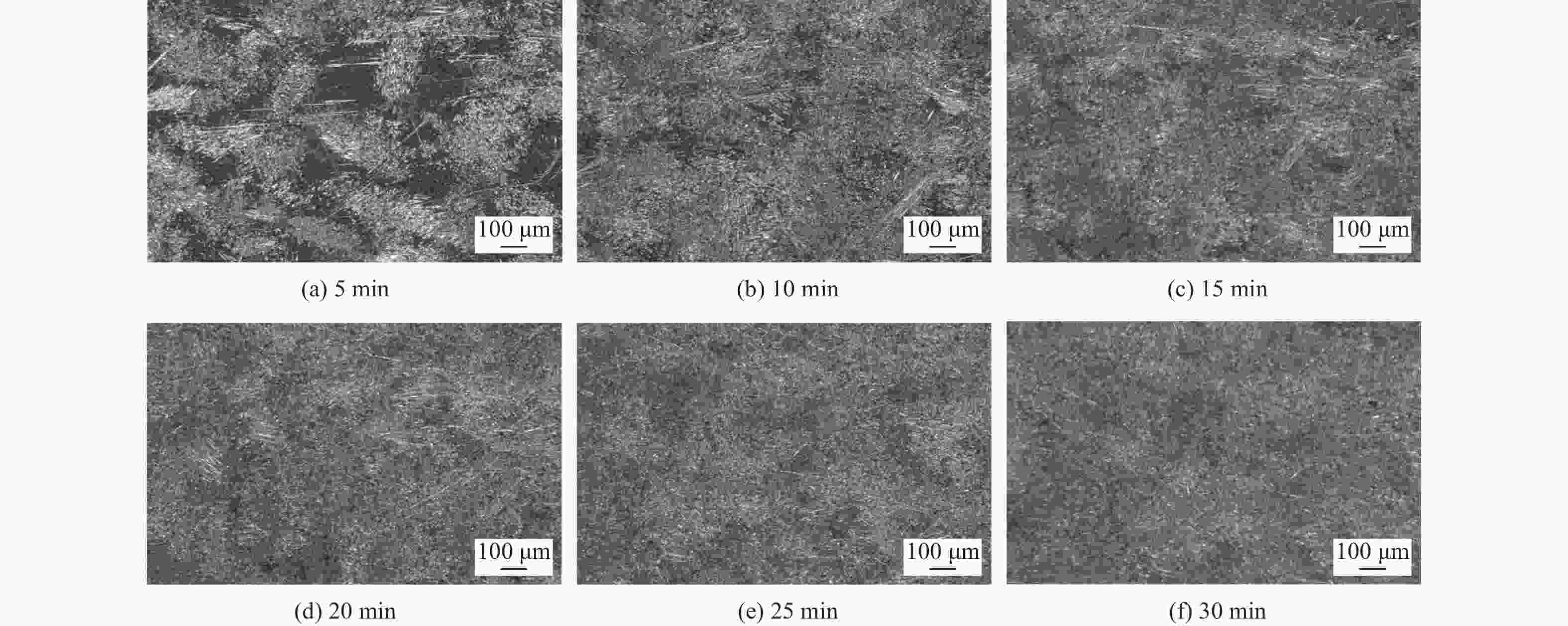

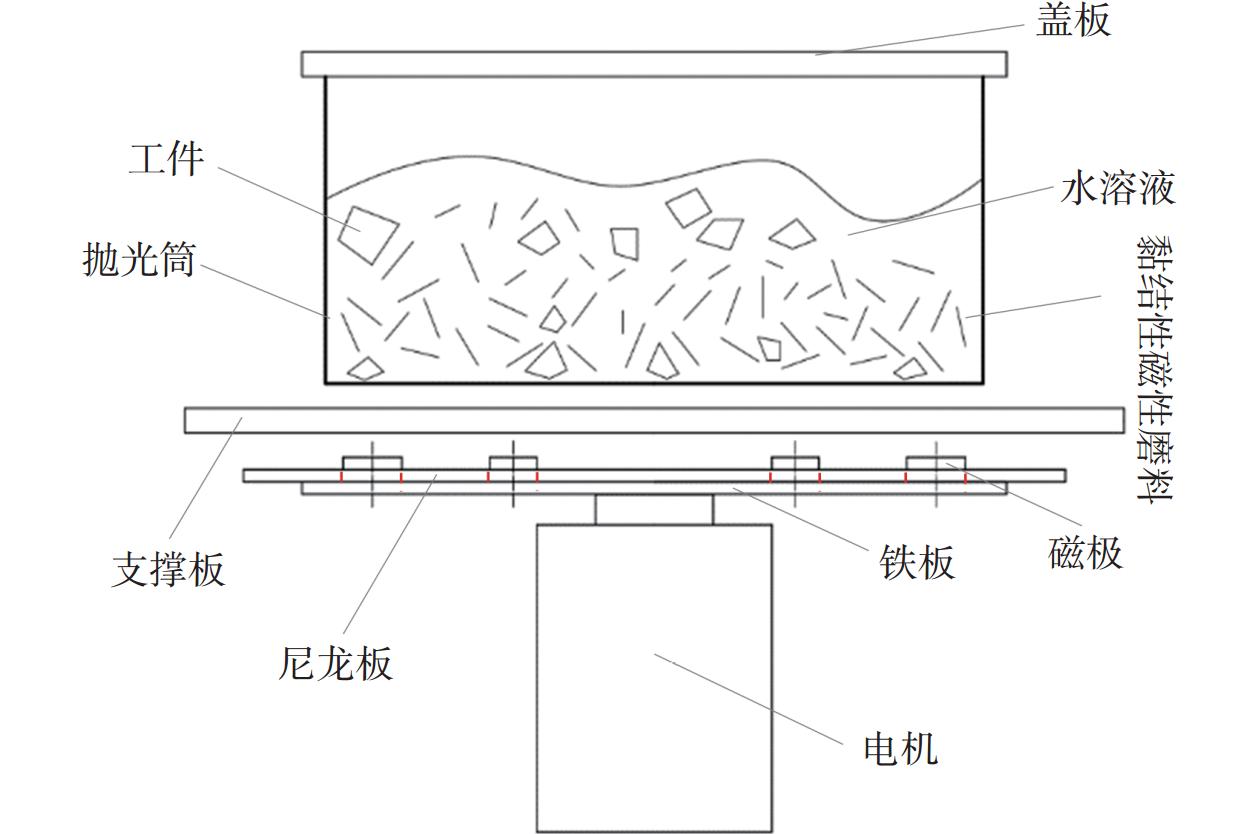

Objectives With the increasing demand for parts with complex shapes and fine structures in high-end equipment, the requirements for finishing precision and surface quality are becoming more stringent. Magnetic polishing technology relies on magnetic fields to drive magnetic abrasives to move relative to the parts, allowing for simultaneous polishing of multiple complex parts. It is an effective method for achieving high-quality and efficient finishing of parts with complex shapes and fine structures. Magnetic abrasives serve as the "cutting tools" in magnetic polishing, and their preparation is a key technology in this process. Magnetic abrasives prepared by sintering, bonding, and atomization methods possess good polishing effects, however, they need be crushed into powdery particles for use, which causes inconvenience in magnetic polishing. Research on the preparation of magnetic abrasives is therefore indispensable to meet the demands of high-performance polishing. Methods To enhance the performance of magnetic polishing, a slender bonded magnetic abrasive is designed, where carbonyl iron powders are adopted as the magnetic phase and silicon carbide are adopted as the abrasive phase. The two-phase materials are bonded with resin chemicals, and bonding strength is enhanced through chemical modification using a coupling agent. The movement patterns and material removal mechanisms of the prepared magnetic abrasives are analyzed to explore their differences from conventional stainless-steel magnetic needles. The differences in scratch behavior at the micro level are experimentally studied using aluminum alloy samples, and the impact on polishing quality is studied. Preparation of magnetic polishing abrasives: First, carbonyl or silicon carbide powders are separately added into a 0.1 g/mL dilute NaOH solution in a beaker, fully submerged, and stirred at constant temperature, then washed with anhydrous ethanol until neutral and dried. Second, the treated carbonyl iron powders or silicon carbide powders are placed in a beaker, a silane coupling agent KH-560 is added, and the mixture is processed in a water bath to obtain dried powders. Third, the above-modified carbonyl iron powders and silicon carbide powders are weighed and mixed in a predetermined mass ratio, and stirred for 6 hours to solve the problem of uneven powder agglomeration. Finally, a predetermined ratio of epoxy resin is added to the mixed inorganic powders, and slender magnetic abrasives with a diameter of 2-3 mm and a length of 6-8 mm are obtained through extrusion molding, followed by a 24 h curing treatment at room temperature. Results A study is conducted on the material removal effect of magnetic abrasives. The polishing effects of workpiece surfaces using magnetic needles and magnetic abrasives are compared. The elasticity of the bonded magnetic abrasives is significantly higher than that of magnetic needles, resulting in a weaker impact on workpieces, with polishing mainly achieved by the embedded silicon carbide abrasives. To facilitate observation of scratches in magnetic polishing, 6061 aluminum alloy workpieces with an initial surface roughness of Sa 4 nm are adopted for magnetic polishing experiments, for exploration of differences in polishing between magnetic needles and elastic magnetic abrasives. With magnetic needles, the surface texture caused by the superposition of pits formed by needle impact tends to stablilize after 30 min of polishing, achieving a surface roughness of Sa 1.418 μm. With magnetic abrasives, the surface texture caused by abrasive scratches tends to stabilize after 20 min of polishing, achieving a surface roughness of Sa 0.318 μm.Conclusions A preparation method is proposed for the fabrication of slender, elastic magnetic abrasives. Material removal mechanisms and surface morphology formation are analyzed, and experiments on 6061 aluminum alloy workpieces are carried out to compare conventional magnetic needles with the slender magnetic abrasives. The results show that elastic magnetic abrasives possess higher polishing efficiency and achieve better polishing effects than magnetic needles for metal materials such as 6061 aluminum alloy. -

Key words:

- magnetic abrasive /

- bonding method /

- coupling agent /

- magnetic polishing

-

表 1 黏结性磁性磨料制备规格表

Table 1. Preparation specification table for adhesive magnetic abrasive

标号 羰基铁粉粒径

d1 / μm碳化硅粉末粒径

d2 / μm羰基铁粉与碳化硅

粉末质量比 nA 6.5 14 (W14) 4∶1 表 2 实验加工参数表

Table 2. Experimental processing parameter table

标号 磨料规格 电机频率 f / Hz 抛光时间 t / s A W14 20 30 B ϕ 1.2 mm × 8 mm 20 30 表 3 时间单因素实验加工参数

Table 3. Time single factor experimental processing parameter

标号 磨料规格 电机频率 f / Hz 抛光时间 t / min A W14 20 0, 5, 10, 15, 20, 25, 30 B ϕ 1.2 mm × 8 mm 20 0, 5, 10, 15, 20, 25, 30 -

[1] KISHORE D S C, BASHA S M J. Optimization of process parameters in surface finishing of Al6061 by using magnetic abrasive finishing process [J]. Materials Today: Proceedings, 2019, 18: 3365-3370. doi: 10.1016/j.matpr.2019.07.259 [2] 刘文浩, 陈燕, 李文龙, 等. 磁粒研磨加工技术的研究进展 [J]. 表面技术, 2021, 50(1): 47-61. doi: 10.16490/j.cnki.issn.1001-3660.2021.01.004LIU Wenhao, CHEN Yan, LI Wenlong, et al. Research progress of magnetic abrasive finishing technology [J]. Surface Technology, 2021, 50(1): 47-61. doi: 10.16490/j.cnki.issn.1001-3660.2021.01.004 [3] 孟庆涛. 磁力研磨加工实验研究 [D]. 大连: 大连理工大学, 2006.MENG Qingtao. Experimental study on magnetic abrasive machining [D]. Dalian: Dalian University of Technology, 2006. [4] 刘静远. 磁力抛光磁极阵列方案优化设计及实验研究 [D]. 太原: 太原理工大学, 2019.LIU Jingyuan. Optimization design of magnetic pole array scheme and experimental research based on magnetic polishing [D]. Taiyuan: Taiyuan University of Technology, 2019. [5] 杨艳, 李唯东, 杨胜强, 等. 钢珠对磁力抛光工艺影响规律的实验研究 [J]. 现代制造工程, 2020(3): 98-104. doi: 10.16731/j.cnki.1671-3133.2020.03.017YANG Yan, LI Weidong, YANG Shengqiang, et al. Experimental study of influence of steel ball on magnetic polishing process [J]. Modern Manufacturing Engineering, 2020(3): 98-104. doi: 10.16731/j.cnki.1671-3133.2020.03.017 [6] 郭源帆, 尹韶辉, 黄帅. Halbach阵列与不同励磁方式的磁流变抛光特性及机理研究 [J]. 机械工程学报, 2023, 59(15): 341-353. doi: 10.3901/JME.2023.15.341GUO Yuanfan, YIN Shaohui, HUANG Shuai. Study on machining characteristic and its mechanism of magnetorheological polishing with Halbach array and other excitation modes [J]. Journal of Mechanical Engineering, 2023, 59(15): 341-353. doi: 10.3901/JME.2023.15.341 [7] 潘晶, 刘新材, 徐志锋, 等. 粘结Fe + SiC磁性磨料的研究 [J]. 机械工程材料, 2001, 25(5): 26-28. doi: 10.3969/j.issn.1000-3738.2001.05.008PAN Jing, LIU Xincai, XU Zhifeng, et al. Fe + SiC bonded magnetic abrasives used in magnetic polishing [J]. Materials for Mechanical Engineering, 2001, 25(5): 26-28. doi: 10.3969/j.issn.1000-3738.2001.05.008 [8] 贺美云, 白增树, 孟丽霞. 磁性磨料的制备技术 [J]. 表面技术, 2005, 34(4): 76-77. doi: 10.3969/j.issn.1001-3660.2005.04.029HE Meiyun, BAI Zengshu, MENG Lixia. Preparation technique of magnetic abrasive [J]. Surface Technology, 2005, 34(4): 76-77. doi: 10.3969/j.issn.1001-3660.2005.04.029 [9] 赵文渊. 基于固—液搅拌混合与直接成粒粘结法制备工艺与试验研究 [D]. 太原: 太原理工大学, 2018.ZHAO Wenyuan. Preparation process and experimental study of bonded magnetic abrasives based on solid-liquid mixing and direct molding [D]. Taiyuan: Taiyuan University of Technology, 2018. [10] 任晓静. 表面化学改性法制备非固结磁性磨料工艺与实验研究 [D]. 太原: 太原理工大学, 2017.REN Xiaojing. Study on surface chemical modification preparation process and experiment of unconsolidated magnetic abrasive [D]. Taiyuan: Taiyuan University of Technology, 2017. [11] 金哲生. 17-4PH不锈钢粉末表面改性及注射成型喂料 [D]. 合肥: 合肥工业大学, 2019.JIN Zhesheng. Surface modification of 17-4PH stainless steel powders and injection molding feed [D]. Heifei: Hefei University of Technology, 2019. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS