Advance on molecular dynamics simulations of precision polishing of SiC

-

摘要: 化学机械抛光(chemical mechanical polishing,CMP)是SiC衬底平坦化的关键技术,目前针对CMP工艺已有大量研究,但磨粒、溶液介质与SiC表面协同作用的机理并不明确。分子动力学(molecular dynamics,MD)模拟是基于牛顿运动定律和量子力学原理,用于揭示物质微观结构和性质之间相互作用的模拟方法,目前被广泛应用于SiC表面去除机理研究。首先分析SiC精密抛光MD模拟常用的势函数,并总结其应用领域,然后对现有的SiC化学机械抛光MD模拟研究进行整合分析。结果表明: Tersoff势函数在机械行为方面的研究中应用较多,而研究SiC表面化学反应和吸附行为使用ReaxFF较多。SiC衬底精密抛光的MD模拟主要分为3类:SiC材料性能、磨粒磨削、SiC表面化学反应。目前大部分研究集中于磨粒与SiC表面的机械行为作用,而对化学反应机理的研究相对较少。未来研究的重点在于利用ReaxFF通过MD模拟研究SiC在各种条件下的反应机理,构建更多势函数以适应不同抛光条件,建立综合模型考虑多种因素对表面相互作用的影响。Abstract:

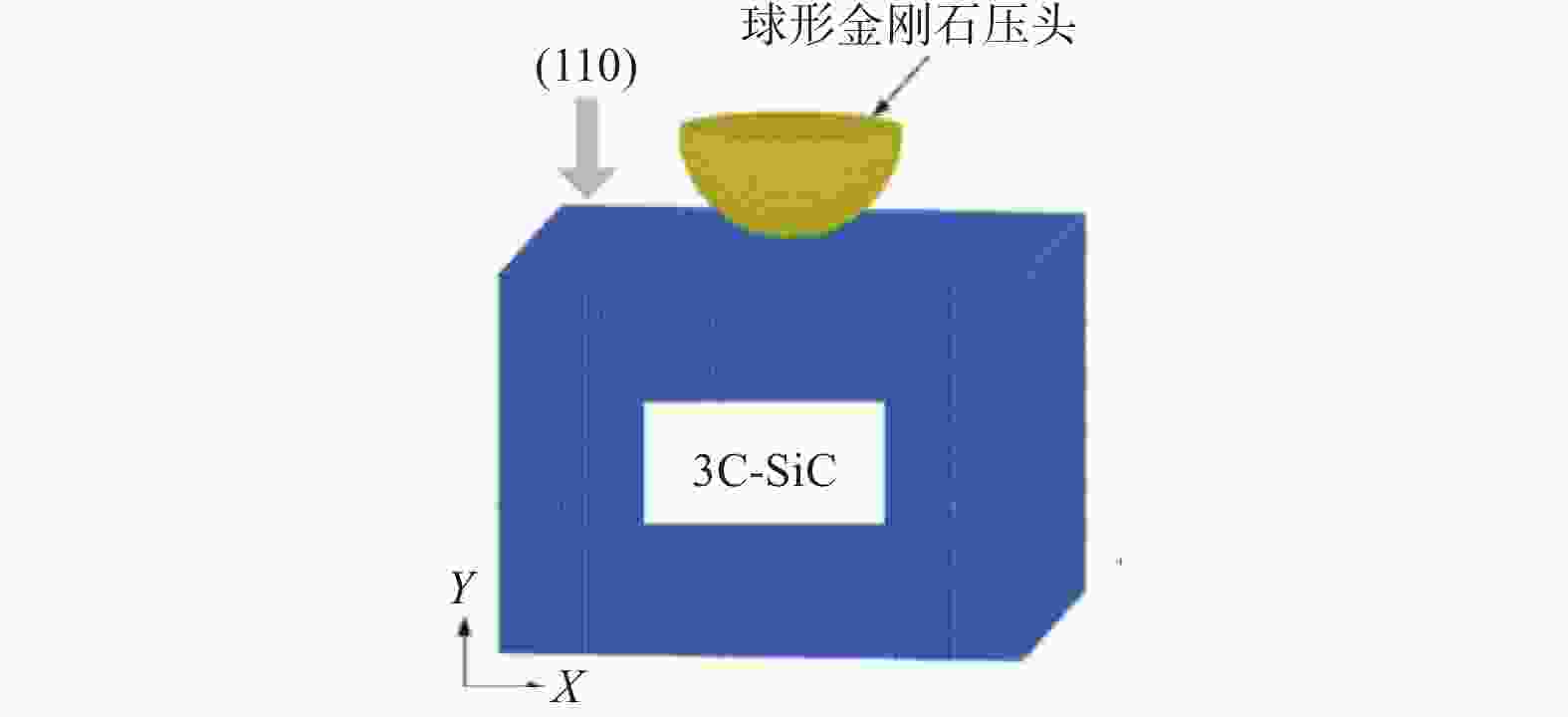

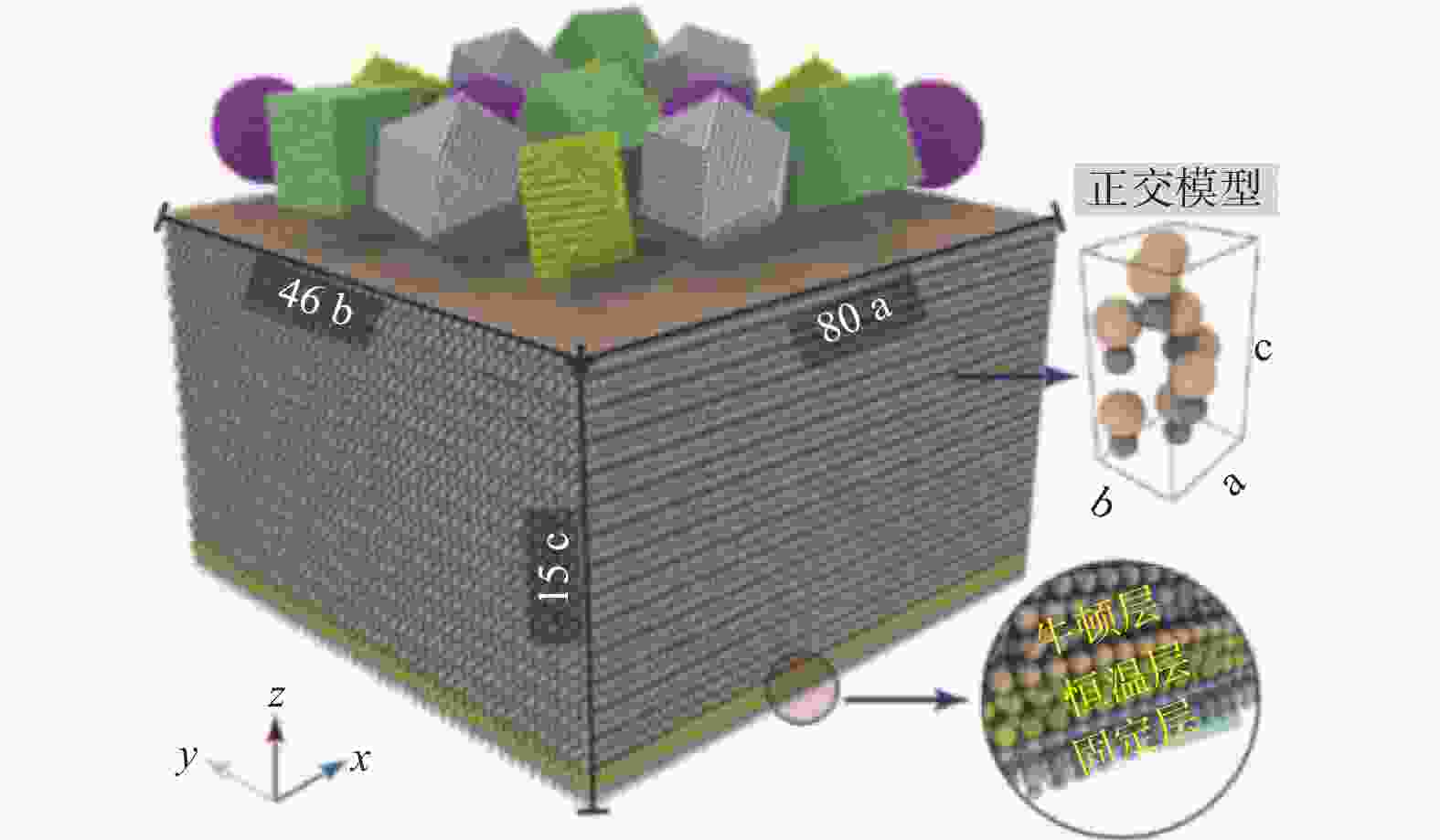

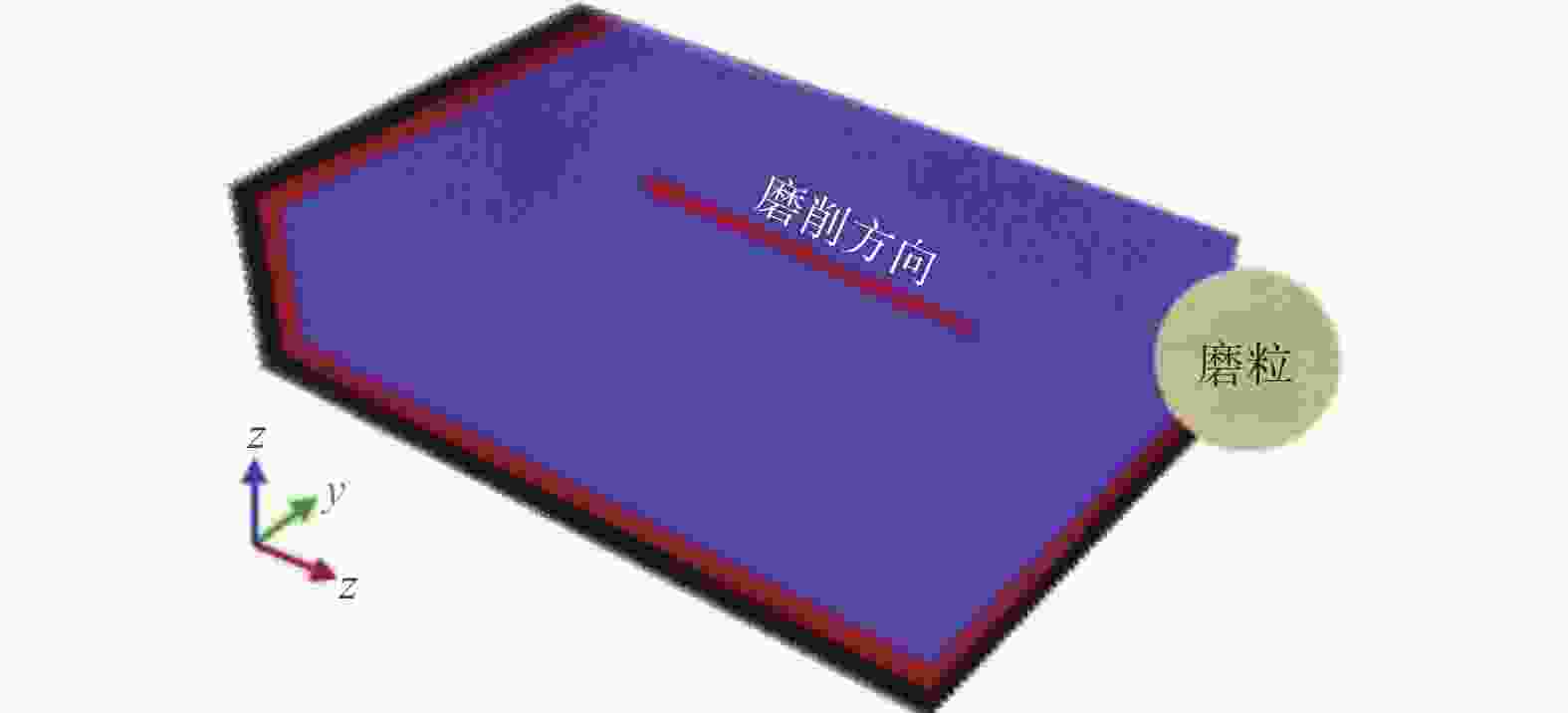

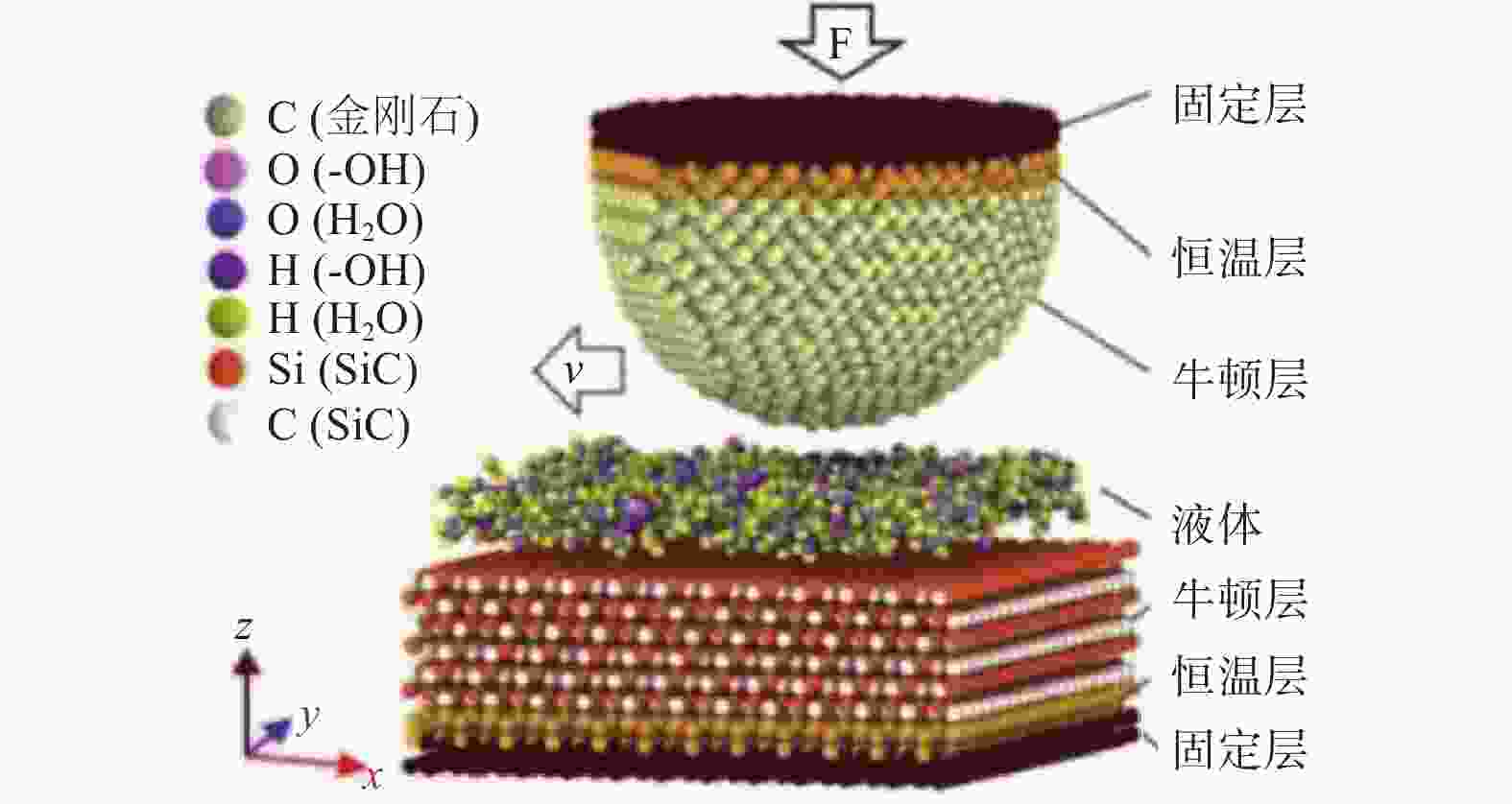

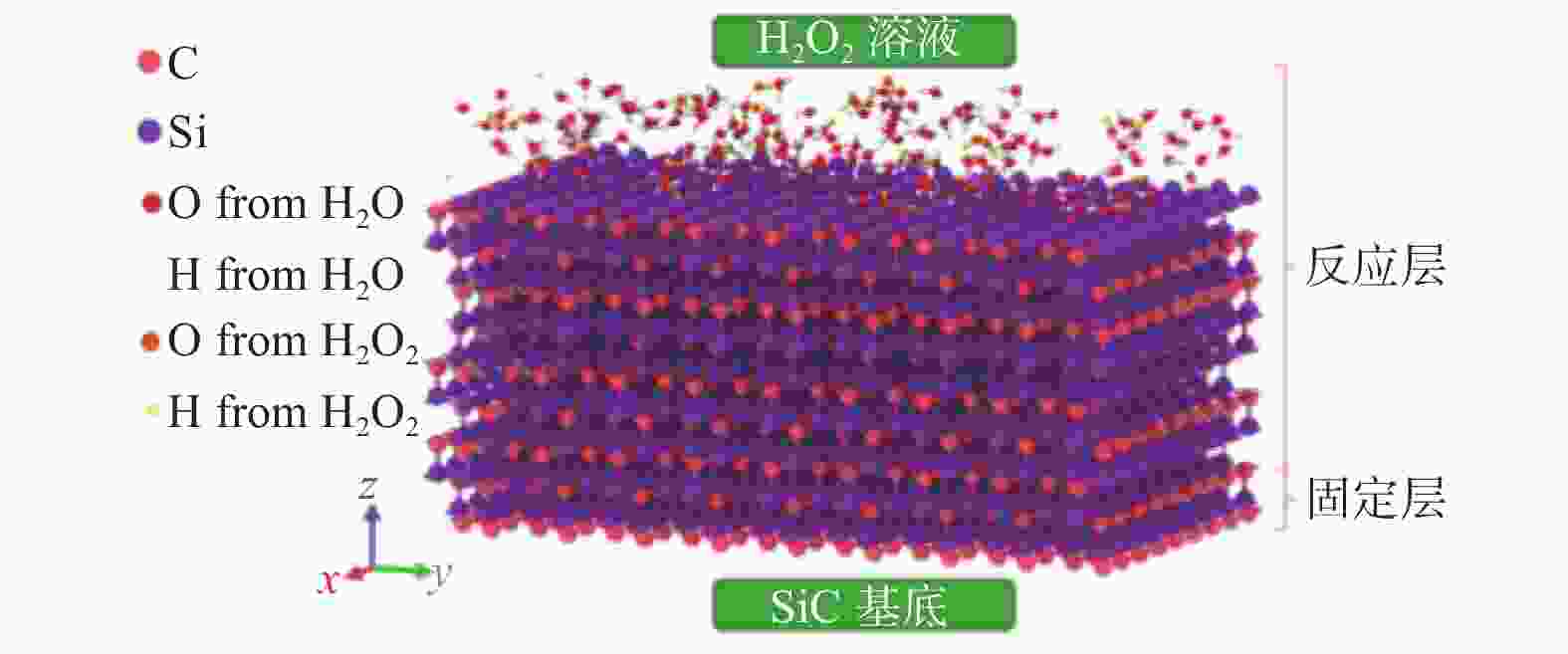

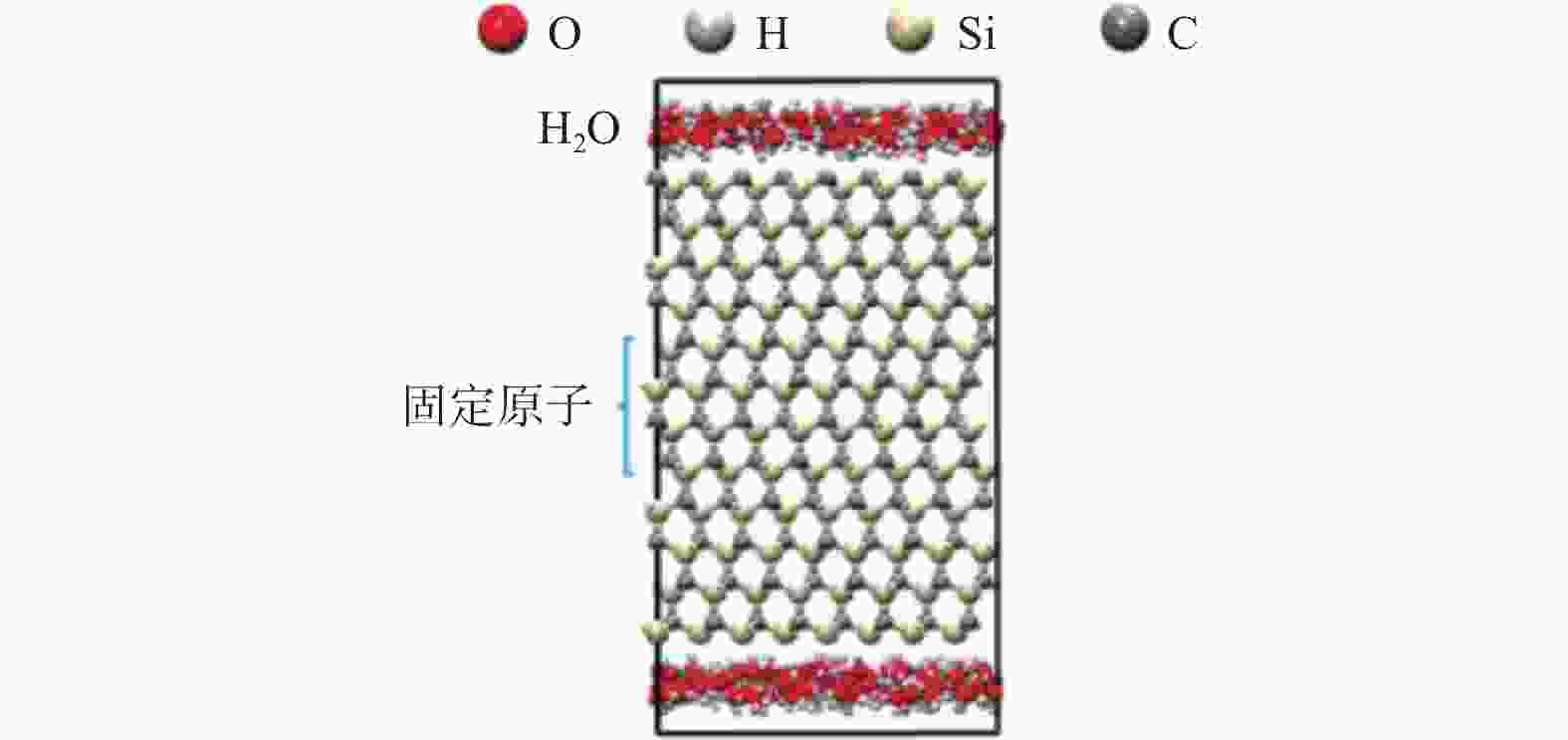

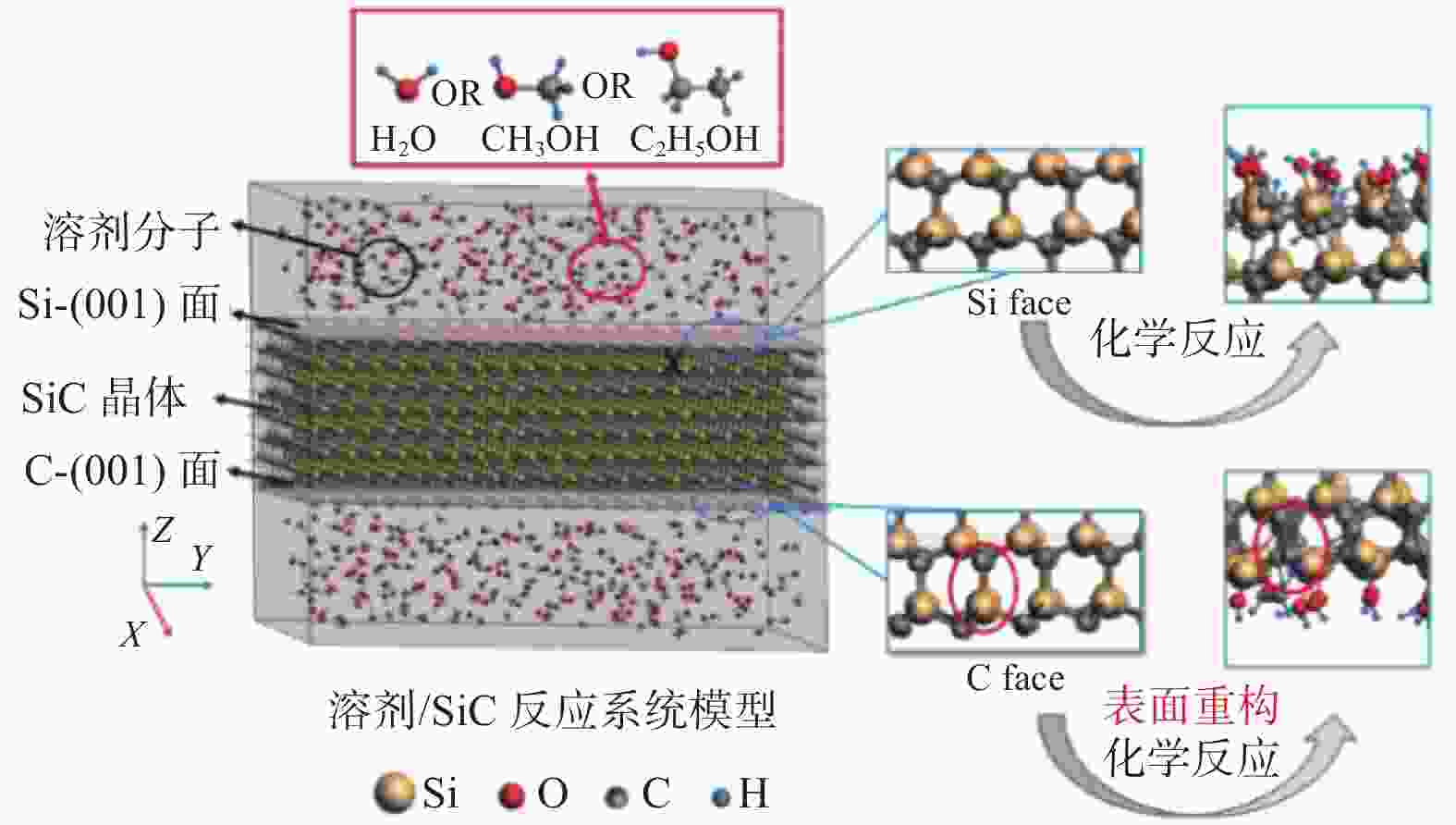

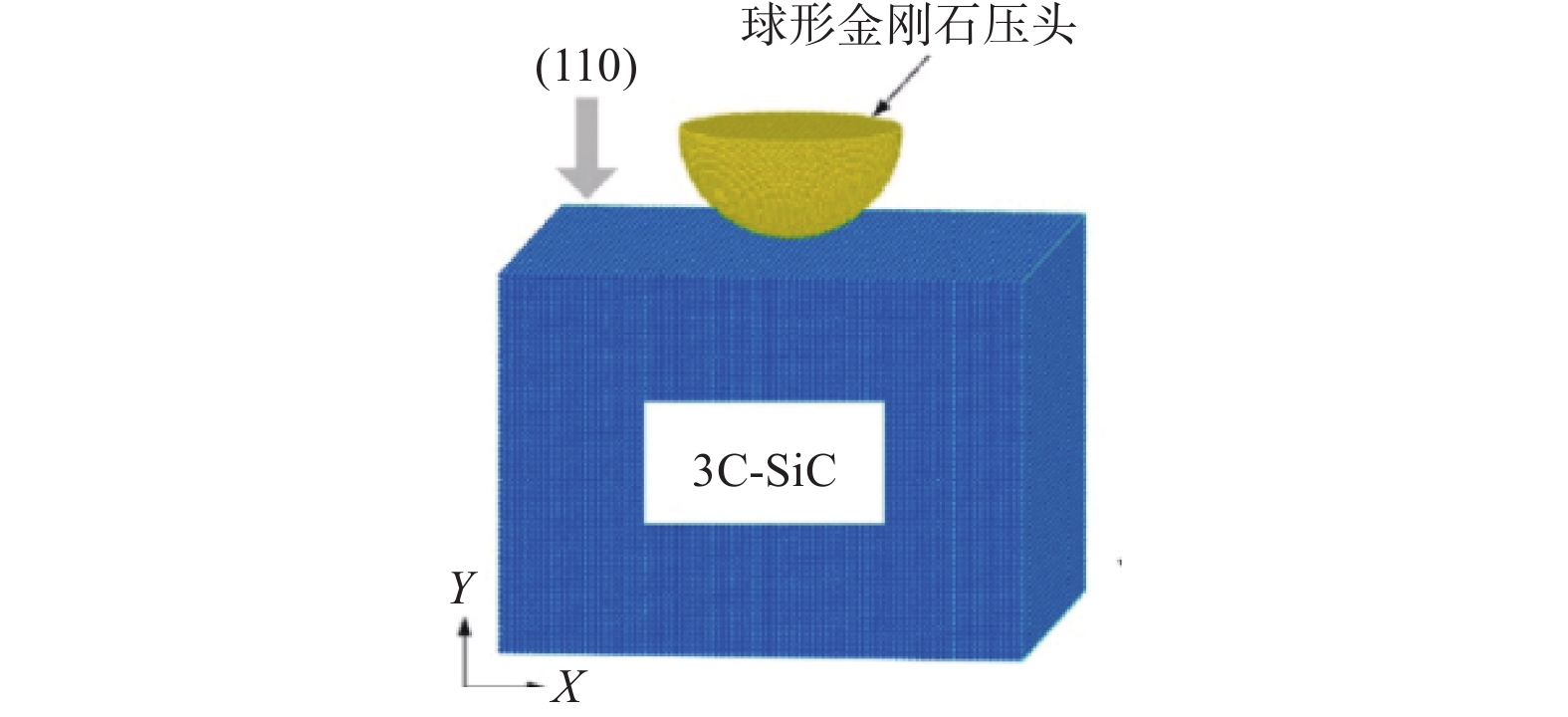

Significance Silicon carbide (SiC), as a representative material of third-generation semiconductors, holds vast potential for applications in microelectronics, optoelectronics, aerospace, and energy. However, its high hardness and chemical stability pose significant challenges for processing. Chemical mechanical polishing (CMP) is a crucial technology for planarizing SiC substrates. It can effectively remove the damaged layer and impurities on the wafer surface, achieve a high degree of planarization, thereby enhance the performance and reliability of SiC devices. Extensive research has been conducted on CMP processes, yet the mechanisms of interaction and synergy among abrasives, solution media, and SiC surfaces remain unclear. Molecular dynamics (MD) simulation, based on Newton's laws of motion and the principles of quantum mechanics, is a simulation method used to reveal the interactions between the microscopic structure and properties of matter. It is currently widely applied in the study of SiC surface removal mechanisms. By simulating the scratching behavior of abrasives on SiC surfaces, changes in material morphology, crystal structure, temperature, cutting force, and potential energy can be observed, thereby providing deeper insights into polishing mechanisms. This in-depth understanding of polishing mechanisms aids in optimizing polishing process parameters, improving polishing efficiency, and surface quality. Meanwhile, during the SiC CMP process, certain components in the polishing solution interact with the SiC surface, potentially involving a series of chemical reactions. MD simulation can reveal the detailed mechanisms of these chemical reactions, including the reaction pathways, reaction rates, and reaction products, thereby facilitating a deeper understanding of the material removal mechanism during the polishing process and providing a theoretical basis for optimizing polishing processes. Progress The article first analyzes the potential functions commonly used in MD simulations for SiC precision polishing and summarizes their application fields. It then integrates and analyzes existing MD simulation studies on SiC CMP. MD simulations for SiC substrate precision polishing are mainly classified into three categories: SiC material properties, abrasive grinding, and SiC surface chemical reactions. The Tersoff potential function has been widely applied in the preparation and properties of SiC materials, demonstrating excellent simulation results. It has become the most popular potential function for MD simulations of SiC materials. The Tersoff / ZBL potential function enhances the Tersoff potential function by incorporating the ZBL potential, thus adding short-range interactions and providing a more accurate description of short-range atomic collisions. The ABOP potential function, based on the Tersoff potential function, allows for the breaking of chemical bonds, making it more suitable for simulating wear behavior. The Vashishta potential function is well-suited for accurately simulating the deformation of ionic and covalent bonds in 3C-SiC, including bending and stretching. It is widely used in simulations involving impact behavior and nanoindentation of SiC. The advantage of the ReaxFF lies in its ability to simulate the formation and breaking of bonds during chemical reactions, making it suitable for simulating chemical reactions, adsorption, and other phenomena on SiC surfaces. Conclusions and Prospects Currently, many aspects of the CMP mechanism of SiC materials remain unclear. MD simulations can be utilized to study the interaction mechanisms between liquids, oxides, and surfaces during CMP, such as charge transfer and surface adsorption. Most research has focused on the mechanical interactions between abrasives and SiC surfaces, with relatively little attention paid to chemical reaction mechanisms. Future research will emphasize using the ReaxFF through MD simulations to study the reaction mechanism of SiC under various conditions, developing more potential functions to accommodate different polishing conditions, and establishing comprehensive models to consider the impact of multiple factors on surface interactions. During MD simulations of SiC oxidation mechanisms, different potential functions have distinct application fields. Although the ReaxFF reactive force field can effectively simulate SiC surface oxidation reactions, using the Tersoff potential function to simulate the interaction between SiC and abrasives is more reasonable. Due to the high modeling proficiency required to establish mixed potential function models combining the ReaxFF reactive force field with other potential functions, researchers often adopt the ReaxFF single intermolecular potential for calculations. If oxidation reactions and abrasive grinding occur simultaneously during the calculation process, it may not accurately describe the SiC surface interaction mechanisms. Therefore, combining the ReaxFF with other potential functions to achieve MD simulation of chemical mechanical polishing under the combined action of multiple factors will be a direction for future research. -

表 1 CMP协同增效方式对比

Table 1. Comparison of synergistic enhancement modes in CMP

参考文献 协同方式 抛光液成分 抛光效果 备注 材料去除率

RMRR / (μm·h−1)表面粗糙

度 / nm文献[19] Fenton反应,MRF,

半固结磨料抛光Fe3O4,H2O2,3 μm

金刚石0.796 Rt = 9.12 将Fe3O4同时作为磁性颗粒和固相催化剂嵌入弹性抛光垫,在同等条件下相较于其他工艺,材料去除率提高了33% 文献[20] 复合磨粒,ECMP,PCMP PS / CeO2,核壳磨料,CeO2-TiO2,光催化剂 1.109 Ra = 0.74 PS是一种新型异质结构聚苯乙烯,光催化剂被固定于钛网上 文献[21] 湿法氧化,高温

退火碱性SiO2胶体 Rq = 0.15 1 100 ℃下湿法氧化1 h,生成SiO2薄膜后抛光去除速度很快,抛光后在1 300 ℃的高温感应加热石墨炉中退火3 h 文献[22] 超声振动辅助

氧化,PAPCeO2磨粒,电解液为1%的NaCl溶液 11.250 Ra = 0.46 超声波振动辅助可以加快SiC表面的氧化速度,提高整体抛光速度 文献[23] PCMP,ECMP P25型TiO2,H2O2,SiO2 1.18 Ra = 0.22 通过外电路施加一个阳极偏压,使光生电子经由外电路迁移至阴极表面,抑制电子e−和空穴h + 的复合 文献[24] 混合磨粒,PCMP 自改性金刚石磨粒,TiO2-石墨烯浆料 4.9 Sa = 0.72 金刚石磨料具有多孔结构,石墨烯和TiO2的结合与使用传统CMP工艺相比,去除效率提高了3倍 文献[25] 混合磨粒,PCMP Al2O3 / ZrO2混合磨粒,H2O2 0.694 Ra = 0.489 采用高机械球磨法制备混合磨粒,ZrO2表面的电子在紫外线照射下产生跃迁,促进·OH的产生 表 2 SiC抛光常用势函数对比

Table 2. Comparison of potential functions for SiC polishing

势函数 特点 主要模拟领域 模拟研究现状 Tersoff 势函数 描述半导体、金属和碳等材料共价键结合的键级势,已经针对SiC材料开发了一系列Tersoff势函数版本 热学[37]、力学[38]、加工制备[39]、疲劳 / 冲击损

伤[40-42]等广泛应用于各种场景下SiC物理性能研究的MD模拟中且计算准确度较高 Tersoff / ZBL

势函数描述了Tersoff电位的短程相互作用,从而可以更准确地描述SiC的平衡特性和短程原子碰撞 辐照损伤[43-44]、离子注入[45]等 用于模拟小体系不同条件下的SiC物理性能、结构变化,常被应用于SiC辐照损伤和离子注入模拟领域 ABOP 势函数 可准确反映SiC原子间离子键和共价键的相互作用,允许考虑化学键的形成和断裂 力学[46]、离子注入[47]、加工制备[48]等 广泛应用于3C-SiC的相关MD模拟,尤其是对物理化学性能方面的模拟研究有着较高的精确度 Vashishta 势函数 库仑、空间排斥和其他相互作用包含在其双体势位部分;其三体势部分来自Stillinger-Weber势,可以准确描述SiC共价键和离子键的弯曲和拉伸 热学[49]、电学[50]、力学[51]、加工制备[52]、疲劳 / 冲击损伤[53]等 可以用于精确模拟计算SiC材料的结构能、结构转变和层错能等多种物理性能,首先用于模拟结晶和非晶行为,后来也被应用于机械性能、加工制备等模拟领域 ReaxFF 基于第一性原理,模拟化学反应过程中键的形成和断裂,从而更好地捕捉分子间的相互作用 化学反应[54-55]、吸附反应[56-57]等 广泛应用于SiC与不同物种间存在化学反应的模拟计算中,其对辅助抛光、催化氧化反应、表面吸附、摩擦化学等方面的模拟研究有着巨大的贡献 表 3 SiC抛光机理研究总结

Table 3. Summary of research on polishing mechanism of SiC

方法 侧重点 反应势函数 SiC类型 结论 纳米压痕 位错非晶态转变机理[58-61] Vashishta,

Tersoff3C-SiC

4H-SiC

6H-SiC非晶态转变和位错是材料变形的主要机制,位错环会演变为棱柱位错环 游离磨粒磨削 磨粒压入深度对SiC变形的

影响[54-56,65,71,74]ABOP, Tersoff, Tersoff /

ZBL, Vashishta3C-SiC

4H-SiC深度越大、温度越高,材料去除越多,但会提高表面粗糙度、增加裂纹 磨粒运动方式对SiC变形的影响[54-55,70-71] ABOP, Tersoff, Tersoff /

ZBL3C-SiC

4H-SiC顺时针滚动组合振动有利于材料去除,磨料自转能消除应力降低表面与磨粒损伤 SiC表面环境对其变形的

影响[54,57,73]ABOP, Tersoff 3C-SiC

4H-SiCSiC表面粗糙度不同会造成不同的运动模式,水环境下压力增大能降低摩擦系数 固结磨料磨削 多磨粒干涉作用[78-80] ABOP

Tersoff3C-SiC

6H-SiC多磨粒之间的干涉作用主要受横向间距与切削深度的影响 表面反应 氧化反应[84-85] ReaxFF 4H-SiC 磨料磨削能促进自由基与SiC的氧化反应 溶剂吸附反应[93-95, 97-98] ReaxFF 4H-SiC

6H-SiC

3C-SiCH2O可以吸附在SiC表面并发生解离,金刚石磨粒也可能与SiC直接键合 -

[1] CHEN X F, YANG X L, XIE X J, et al. Research progress of large size SiC single crystal materials and devices [J]. Light, Science & Applications, 2023, 12(1): 28. doi: 10.1038/s41377-022-01037-7 [2] WANG J L. Recent research progress in preparation and application of silicon carbide [J]. Open Journal of Natural Science, 2022, 10: 220-226. doi: 10.12677/OJNS.2022.103028 [3] WANG W T, LU X S, WU X K, et al. Chemical-mechanical polishing of 4H silicon carbide wafers [J]. Advanced Materials Interfaces, 2023, 10(13): 2202369. doi: 10.1002/admi.202202369 [4] TSAI M Y, WANG S M, TSAI C C, et al. Investigation of increased removal rate during polishing of single-crystal silicon carbide [J]. The International Journal of Advanced Manufacturing Technology, 2015, 80(9): 1511-1520. doi: 10.1007/s00170-015-7023-4 [5] HSIEH C H, CHANG C Y, HSIAO Y K, et al. Recent advances in silicon carbide chemical mechanical polishing technologies: Micromachines [J]. Micromachines, 2022, 13(10): 1752. doi: 10.3390/mi13101752 [6] ZHANG Q X, PAN J S, ZHANG X W, et al. Tribological behavior of 6H–SiC wafers in different chemical mechanical polishing slurries [J]. Wear, 2021, 472 / 473: 203649. doi: 10.1016/j.wear.2021.203649 [7] 路家斌, 曹纪阳, 邓家云, 等. Fe3O4特性对单晶SiC固相芬顿反应研磨丸片性能的影响 [J]. 金刚石与磨料磨具工程, 2022, 42(2): 223-232. doi: 10.13394/j.cnki.jgszz.2022.0008LU Jiabin, CAO Jiyang, DENG Jiayun, et al. Effect of Fe3O4 characteristics on properties of solid-phase Fenton reaction lapping pellets for single-crystal SiC [J]. Diamond & Abrasives Engineering, 2022, 42(2): 223-232. doi: 10.13394/j.cnki.jgszz.2022.0008 [8] GAO B, GUO D, ZHANG X, et al. Picosecond laser-assisted chemical mechanical polishing (CMP): Aiming at the Si-face of single-crystal 6H-SiC wafer [J]. ECS Journal of Solid State Science and Technology, 2021, 10(4): 044008. doi: 10.1149/2162-8777/abf726 [9] XIE X Z, PENG Q F, CHEN G P, et al. Femtosecond laser modification of silicon carbide substrates and its influence on CMP process [J]. Ceramics International, 2021, 47(10, Part A): 13322-13330. doi: 10.1016/j.ceramint.2021.01.188 [10] 路家斌, 熊强, 阎秋生, 等. 6H-SiC单晶紫外光催化抛光中光照方式和磨料的影响 [J]. 金刚石与磨料磨具工程, 2019, 39(3): 29-37. doi: 10.13394/j.cnki.jgszz.2019.3.0006LU Jiabin, XIONG Qiang, YAN Qiusheng, et al. Effects of lights modes and abrasives on UV-photocatalysis assisted polishing of 6H-SiC single crystal [J]. Diamond & Abrasives Engineering, 2019, 39(3): 29-37. doi: 10.13394/j.cnki.jgszz.2019.3.0006 [11] GAO B, ZHAI W J, ZHAI Q, et al. Electro-chemical mechanical polishing of 4H-SiC for scratch-free surfaces with less oxide layer at high efficiency [J]. ECS Journal of Solid State Science and Technology, 2019, 8(11): 677-684. doi: 10.1149/2.0031911jss [12] LUO Y R, XIONG Q, LU J B, et al. Chemical mechanical polishing exploiting metal electrochemical corrosion of single-crystal SiC [J]. Materials Science in Semiconductor Processing, 2022, 152: 107067. doi: 10.1016/j.mssp.2022.107067 [13] 王磊, 吴润泽, 牛林, 等. 碳化硅晶体电化学机械抛光工艺研究 [J]. 金刚石与磨料磨具工程, 2022, 42(4): 504-510. doi: 10.13394/j.cnki.jgszz.2022.0029WANG Lei, WU Runze, NIU Lin, et al. Study on electrochemical mechanical polishing process of silicon carbide crystal [J]. Diamond & Abrasives Engineering, 2022, 42(4): 504-510. doi: 10.13394/j.cnki.jgszz.2022.0029 [14] YANG X Z, YANG X, GU H Y, et al. Efficient and slurryless ultrasonic vibration assisted electrochemical mechanical polishing for 4H–SiC wafers [J]. Ceramics International, 2022, 48(6): 7570-7583. doi: 10.1016/j.ceramint.2021.11.301 [15] YANG X Z, YANG X, KAWAI K, et al. Ultrasonic-assisted anodic oxidation of 4H-SiC (0001) surface [J]. Electrochemistry Communi-cations, 2019, 100: 1-5. doi: 10.1016/j.elecom.2019.01.012 [16] WU Y S, PAN J S, WANG H, et al. Study of corrosion rate control mechanism based on magnetorheological electro-Fenton composite polishing of single-crystal GaN wafers [J]. Journal of Solid State Electrochemistry, 2023, 27(8): 2163-2176. doi: 10.1007/s10008-023-05468-z [17] DENG J Y, LU J B, YAN Q S, et al. Preparation and polishing properties of water-based magnetorheological chemical finishing fluid with high catalytic activity for single-crystal SiC [J]. Journal of Intelligent Material Systems and Structures, 2020, 32(13): 1441-1451. doi: 10.1177/1045389X20975503 [18] 梁华卓, 付有志, 何俊峰, 等. 单晶SiC基片的磁流变化学复合抛光 [J]. 金刚石与磨料磨具工程, 2022, 42(1): 129-135. doi: 10.13394/j.cnki.jgszz.2021.0108LIANG Huazhuo, FU Youzhi, HE Junfeng, et al. Magnetorheological chemical compound polishing of single crystal SiC substrate [J]. Diamond & Abrasives Engineering, 2022, 42(1): 129-135. doi: 10.13394/j.cnki.jgszz.2021.0108 [19] HU D, LI H L, LU J B, et al. Study on heterogeneous Fenton reaction parameters for polishing single-crystal SiC using magnetorheological elastomers polishing pads [J]. Smart Materials and Structures, 2023, 32(2): 025003. doi: 10.1088/1361-665X/acacd8 [20] GAO B, ZHAI W J, ZHAI Q, et al. Novel photoelectrochemically combined mechanical polishing technology for scratch-free 4H-SiC surface by using CeO2-TiO2 composite photocatalysts and PS / CeO2 core / shell abrasives [J]. Applied Surface Science, 2021, 570: 151141. doi: 10.1016/j.apsusc.2021.151141 [21] SHI X D, LU Y Q, CHAUSSENDE D, et al. Wet-oxidation-assisted chemical mechanical polishing and high-temperature thermal annealing for low-loss 4H-SiC integrated photonic devices [J]. Materials, 2023, 16(6): 2324. doi: 10.3390/ma16062324 [22] 张晨. SiC单晶超声辅助电解液等离子体抛光仿真及实验研究 [D]. 西安: 西安理工大学, 2023.ZHANG Chen. Simulation and experimental study on ultrasonic-assisted electrolyte plasma polishing of SiC single crystal [D]. Xi'an: Xi'an University of Technology, 2023. [23] 何艳, 苑泽伟, 段振云, 等. 单晶SiC的电助光催化抛光及去除机理 [J]. 中国机械工程, 2020, 31(4): 403-409. doi: 10.3969/j.issn.1004-132X.2020.04.005HE Yan, YUAN Zewei, DUAN Zhenyun, et al. Electrical enhanced photocatalysis polishing and removal mechanism for single crystal SiC [J]. China Mechanical Engineering, 2020, 31(4): 403-409. doi: 10.3969/j.issn.1004-132X.2020.04.005 [24] TSAI M Y, HOO Z T. Polishing single-crystal silicon carbide with porous structure diamond and graphene-TiO2 slurries [J]. The International Journal of Advanced Manufacturing Technology, 2019, 105: 1519-1530. doi: 10.1007/s00170-019-04223-x [25] WANG W T, ZHANG B G, SHI Y H, et al. Improved chemical mechanical polishing performance in 4H-SiC substrate by combining novel mixed abrasive slurry and photocatalytic effect [J]. Applied Surface Science, 2022, 575: 151676. doi: 10.1016/j.apsusc.2021.151676 [26] TERSOFF J. Modeling solid-state chemistry: Interatomic potentials for multicomponent systems [J]. Physical Review B, 1989, 39(8): 5566-5568. doi: 10.1103/PhysRevB.39.5566 [27] WANG J, LU C, WANG Q, et al. Understanding large plastic deformation of SiC nanowires at room temperature [J]. EPL(Europhysics Letters), 2011, 95(6): 63003-1-63003-5. doi: 10.1209/0295-5075/95/63003 [28] JIN E Z, DU S Y, LI M, et al. Influence of helium atoms on the shear behavior of the fiber / matrix interphase of SiC / SiC composite [J]. Journal of Nuclear Materials, 2016, 479: 504-514. doi: 10.1016/j.jnucmat.2016.07.041 [29] LIN K X, ZENG M, CHEN H M, et al. Dynamic strength, reinforcing mechanism and damage of ceramic metal composites [J]. International Journal of Mechanical Sciences, 2022, 231: 107580. doi: 10.1016/j.ijmecsci.2022.107580 [30] DEVANATHAN R, RUBIA T D D L, WEBER W J. Displacement threshold energies in β-SiC [J]. Journal of Nuclear Materials, 1998, 253(1/2/3): 47-52. doi: 10.1016/S0022-3115(97)00304-8 [31] BRENNER D W. Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films [J]. Physical Review B, 1990, 42(15): 9458-9471. doi: 10.1103/PhysRevB.42.9458 [32] LI W H, YAO X H. The spallation of single crystal SiC: The effects of shock pulse duration [J]. Computational Materials Science, 2016, 124: 151-159. doi: 10.1016/j.commatsci.2016.07.028 [33] VASHISHTA P, KALIA R K, RINO J P, et al. Interaction potential for SiO2: A molecular-dynamics study of structural correlations [J]. Physical Review B, 1990, 41(17): 12197-12209. doi: 10.1103/PhysRevB.41.12197 [34] VASHISHTA P, KALIA R K, NAKANO A, et al. Interaction potential for silicon carbide: A molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide [J]. Journal of Applied Physics, 2007, 101(10): 103515. doi: 10.1063/1.2724570 [35] SENFTLE T P, HONG S, ISLAM M M, et al. The ReaxFF reactive force-field: Development, applications and future directions [J]. NPJ Computational Materials, 2016, 2(1): 15011. doi: 10.1038/npjcompumats.2015.11 [36] NEWSOME D A, SENGUPTA D, FOROUTAN H, et al. Oxidation of silicon carbide by O2 and H2O: A ReaxFF reactive molecular dynamics study, Part I [J]. The Journal of Physical Chemistry C, 2012, 116(30): 16111-16121. doi: 10.1021/jp306391p [37] DONG X Y, SHIN Y C. Predictions of thermal conductivity and degradation of irradiated SiC / SiC composites by materials-genome-based multiscale modeling [J]. Journal of Nuclear Materials, 2018, 512: 268-275. doi: 10.1016/j.jnucmat.2018.10.021 [38] NIU X M, BIAN J, CHEN X H, et al. Molecular dynamics simulation on PyC interfacial failure mechanism and shear strength of SiC / SiC composites [J]. Modelling and Simulation in Materials Science and Engineering, 2021, 29(8): 85008. doi: 10.1088/1361-651X/ac2478 [39] WANG H X, GAO S, KANG R K, et al. Mechanical load-induced atomic-scale deformation evolution and mechanism of SiC polytypes using molecular dynamics simulation [J]. Nanomaterials, 2022, 12(14): 2489. doi: 10.3390/nano12142489 [40] WANG R Q, HAN J B, MAO J X, et al. A molecular dynamics based cohesive zone model for interface failure under monotonic tension of 3D four direction SiCf / SiC composites [J]. Composite Structures, 2021, 274: 114397. doi: 10.1016/j.compstruct.2021.114397 [41] AI T C, LIU J, QIU H J, et al. Removal behavior and performance analysis of defective silicon carbide in nano-grinding [J]. Precision Engineering, 2021, 72: 858-869. doi: 10.1016/j.precisioneng.2021.07.011 [42] 涂睿, 李盈盈, 孔淑妍, 等. 分子动力学模拟辐照对碳化硅裂纹扩展过程的影响 [J]. 材料科学与工程学报, 2023, 41(5): 710-717. doi: 10.14136/j.cnki.issn1673-2812.2023.05.003TU Rui, LI Yingying, KONG Shuyan, et al. Molecular dynamics simulation of lrradiation effects on the crackpropagation in 3C-SiC [J]. Journal of Materials Science and Engineering, 2023, 41(5): 710-717. doi: 10.14136/j.cnki.issn1673-2812.2023.05.003 [43] WALLACE J, CHEN D, WANG J, et al. Molecular dynamics simulation of damage cascade creation in SiC composites containing SiC / graphite interface [J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2013, 307: 81-85. doi: 10.1016/j.nimb.2013.02.036 [44] LI Y Y, XIAO W, LI H L. Molecular dynamics simulation of C / Si ratio effect on the irradiation swelling of β-SiC [J]. Journal of Nuclear Materials, 2016, 480: 75-79. doi: 10.1016/j.jnucmat.2016.08.004 [45] KANG Q, FANG X D, WU C, et al. Mechanical properties and indentation-induced phase transformation in 4H–SiC implanted by hydrogen ions [J]. Ceramics International, 2022, 48(11): 15334-15347. doi: 10.1016/j.ceramint.2022.02.067 [46] LI Y Y, LI Y, XIAO W. Point defects and grain boundary effects on tensile strength of 3C-SiC studied by molecular dynamics simulations [J]. Nuclear Engineering and Technology, 2019, 51(3): 769-775. doi: 10.1016/j.net.2018.12.010 [47] WU W L, HU Y, MENG X S, et al. Molecular dynamics simulation of ion-implanted single-crystal 3C-SiC nano-indentation [J]. Journal of Manufacturing Processes, 2022, 79: 356-368. doi: 10.1016/j.jmapro.2022.04.071 [48] LIU B, LI X L, KONG R J, et al. A numerical analysis of ductile deformation during nanocutting of silicon carbide via molecular dynamics simulation [J]. Materials, 2022, 15(6): 2325. doi: 10.3390/ma15062325 [49] KHAN T A, BURR P A, PAYNE D, et al. Molecular dynamic simulation on temperature evolution of SiC under directional microwave radiation [J]. Journal of Physics: Condensed Matter, 2022, 34(19): 195701. doi: 10.1088/1361-648X/ac553c [50] CHEN W, LI L S. The study of the optical phonon frequency of 3C-SiC by molecular dynamics simulations with deep neural network potential [J]. Journal of Applied Physics, 2021, 129(24): 244104. doi: 10.1063/5.0049464 [51] UTKIN A V, FOMIN V M. Molecular dynamics study of silicon carbide properties under external dynamic loading [J]. AIP Conference Proceedings, 2017, 1983(1): 30018. doi: 10.1063/1.5007476 [52] TRANH D T N, HOANG V V, HANH T T T. Modeling glassy SiC nanoribbon by rapidly cooling from the liquid: An affirmation of appropriate potentials [J]. Physica B: Condensed Matter, 2021, 608: 412746. doi: 10.1016/j.physb.2020.412746 [53] FENG L X, LI W H, HAHN E N, et al. Structural phase transition and amorphization in hexagonal SiC subjected to dynamic loading [J]. Mechanics of Materials, 2022, 164: 104139. doi: 10.1016/j.mechmat.2021.104139 [54] DO T T, FANG T H. Deep insights into interaction behaviour and material removal of β-SiC wafer in nanoscale polishing [J]. Tribology International, 2023, 186: 108639. doi: 10.1016/j.triboint.2023.108639 [55] BIAN Z T, GAO T H, GAO Y, et al. Effects of three-body diamond abrasive polishing on silicon carbide surface based on molecular dynamics simulations [J]. Diamond and Related Materials, 2022, 129: 109368. doi: 10.1016/j.diamond.2022.109368 [56] GAO S, WANG H X, HUANG H, et al. Molecular simulation of the plastic deformation and crack formation in single grit grinding of 4H-SiC single crystal [J]. International Journal of Mechanical Sciences, 2023, 247: 108147. doi: 10.1016/j.ijmecsci.2023.108147 [57] MENG B B, YUAN D D, XU S L. Study on strain rate and heat effect on the removal mechanism of SiC during nano-scratching process by molecular dynamics simulation [J]. International Journal of Mechanical Sciences, 2019, 151: 724-732. doi: 10.1016/j.ijmecsci.2018.12.022 [58] ZHU B, ZHAO D, ZHANG Z J, et al. Atomic study on deformation behavior and anisotropy effect of 3C-SiC under nanoindentation [J]. Journal of Materials Research and Technology, 2024, 28: 2636-2647. doi: 10.1016/j.jmrt.2023.12.081 [59] SUN S, PENG X H, XIANG H G, et al. Molecular dynamics simulation in single crystal 3C-SiC under nanoindentation: Formation of prismatic loops [J]. Ceramics International, 2017, 43(18): 16313-16318. doi: 10.1016/j.ceramint.2017.09.003 [60] SZLUFARSKA I, KALIA R K, NAKANO A, et al. Atomistic processes during nanoindentation of amorphous silicon carbide [J]. Applied Physics Letters, 2005, 86(2): 21915. doi: 10.1063/1.1849843 [61] TIAN Z G, CHEN X, XU X P. Molecular dynamics simulation of the material removal in the scratching of 4H-SiC and 6H-SiC substrates [J]. International Journal of Extreme Manufacturing, 2020, 2(4): 045104. doi: 10.1088/2631-7990/abc26c [62] 王桂莲, 张广辉, 王治国, 等. 纳米抛光碳化硅压力对相变影响的分子动力学模拟 [J]. 机械设计与制造, 2021(2): 35-39. doi: 10.19356/j.cnki.1001-3997.2021.02.009WANG Guilian, ZHANG Guanghui, WANG Zhiguo, et al. Effect of pressure changes on the nano-polishing process of silicon carbide based on molecular dynamics [J]. Machinery Design & Manufacture, 2021(2): 35-39. doi: 10.19356/j.cnki.1001-3997.2021.02.009 [63] 梁杰. 单晶SiC纳米压入 / 刻划研究[D]. 长沙: 长沙理工大学, 2022.LIANG Jie. Research on nanoindentation / nanoscratch of single crystal SiC [D]. Changsha: Changsha University of Science & Technology, 2022. [64] SHI X L, PAN G S, ZHOU Y, et al. Extended study of the atomic step-terrace structure on hexagonal SiC (0001) by chemical-mechanical planarization [J]. Applied Surface Science, 2013, 284: 195-206. doi: 10.1016/j.apsusc.2013.07.080 [65] DENG H, ENDO K, YAMAMURA K. Competition between surface modification and abrasive polishing: A method of controlling the surface atomic structure of 4H-SiC (0001) [J]. Scientific Reports, 2015, 5(1): 8747. doi: 10.1038/srep08947 [66] HEYDEMANN V D, EVERSON W J, GAMBLE R D, et al. Chemi-mechanical polishing of on-axis semi-insulating SiC substrates [J]. Materials Science Forum, 2004, 457/458/459/460: 805-808. doi: 10.4028/www.scientific.net/MSF.457-460.805 [67] LEE H S, JEONG H D. Chemical and mechanical balance in polishing of electronic materials for defect-free surfaces [J]. CIRP Annals-Manufacturing Technology, 2009, 58(1): 485-490. doi: 10.1016/j.cirp.2009.03.115 [68] 唐爱玲, 苑泽伟, 唐美玲, 等. 磨粒振动对碳化硅CMP的微观结构演变和材料去除的影响 [J]. 金刚石与磨料磨具工程, 2024, 44(1): 109-122. doi: 10.13394/j.cnki.jgszz.2023.0053TANG Ailing, YUAN Zewei, TANG Meiling, et al. Effect of abrasive vibration on microstructure evolution and material removal of SiC CMP [J]. Diamond & Abrasives Engineering, 2024, 44(1): 109-122. doi: 10.13394/j.cnki.jgszz.2023.0053 [69] HUANG Y H, ZHOU Y Q, LI J M, et al. Understanding of the effect of wear particles removal from the surface on grinding silicon carbide by molecular dynamics simulations [J]. Diamond and Related Materials, 2023, 137: 110150. doi: 10.1016/j.diamond.2023.110150 [70] CHEN H, WANG C, CHEN J, et al. Changing torque-force synchronization condition for abrasive particle improves material removal during silicon carbide abrasive machining [J]. Tribology International, 2024, 192: 109247. doi: 10.1016/j.triboint.2023.109247 [71] ZHOU Y Q, HUANG Y H, LI J M, et al. The effects of abrasive moving speed and motion mode on the thinning mechanism of SiC in three-body contact [J]. Physica Scripta, 2023, 98(11): 115403. doi: 10.1088/1402-4896/acfc6d [72] ZHOU Y Q, HUANG Y H, LI J M, et al. The effect of contact types on SiC polishing process [J]. Materials Science in Semiconductor Processing, 2022, 147: 106709. doi: 10.1016/j.mssp.2022.106709 [73] ZHOU Y Q, HUANG Y H, LI J M, et al. Polishing process of 4H-SiC under different pressures in a water environment [J]. Diamond and Related Materials, 2023, 133: 109710. doi: 10.1016/j.diamond.2023.109710 [74] HUANG Y H, ZHOU Y Q, LI J M, et al. Understanding the role of surface mechanical properties in SiC surface machining [J]. Materials Science in Semiconductor Processing, 2023, 163: 107594. doi: 10.1016/j.mssp.2023.107594 [75] WANG H Q, NIU F L, CHEN J P, et al. High efficiency polishing of silicon carbide by applying reactive non-aqueous fluids to fixed abrasive pads [J]. Ceramics International, 2022, 48(5): 7273-7282. doi: 10.1016/j.ceramint.2021.11.288 [76] LUO Q F, LU J, XU X P. A comparative study on the material removal mechanisms of 6H-SiC polished by semi-fixed and fixed diamond abrasive tools [J]. Wear, 2016350/351: 99-106. doi: 10.1016/j.wear.2016.01.014 [77] MURATA J, HAYAMA K, TAKIZAWA M. Environment-friendly electrochemical mechanical polishing using solid polymer electrolyte / CeO2 composite pad for highly efficient finishing of 4H-SiC (0001) surface [J]. Applied Surface Science, 2023, 625: 157190. doi: 10.1016/j.apsusc.2023.157190 [78] WU Z H, ZHANG L C, YANG S Y, et al. Effects of grain size and protrusion height on the surface integrity generation in the nanogrinding of 6H-SiC [J]. Tribology International, 2022, 171: 107563. doi: 10.1016/j.triboint.2022.107563 [79] ZHOU P, SHI X D, LI J, et al. Molecular dynamics simulation of SiC removal mechanism in a fixed abrasive polishing process [J]. Ceramics International, 2019, 45(12): 14614-14624. doi: 10.1016/j.ceramint.2019.04.180 [80] ZHOU P, ZHU N N, XU C Y, et al. Mechanical removal of SiC by multi-abrasive particles in fixed abrasive polishing using molecular dynamics simulation [J]. Computational Materials Science, 2021, 191: 110311. doi: 10.1016/j.commatsci.2021.110311 [81] ISHIKAWA Y, MATSUMOTO Y, NISHIDA Y, et al. Surface treatment of silicon carbide using TiO2(IV) photocatalyst [J]. Journal of the American Chemical Society, 2003, 125(21): 6558-6562. doi: 10.1021/ja020359i [82] LIU W T, LU J B, XIONG Q, et al. Investigation on influence of polishing disc materials in UV-catalytic polishing of single crystal diamond [J]. Diamond and Related Materials, 2024, 141: 110678. doi: 10.1016/j.diamond.2023.110678 [83] ZHOU Y, PAN G S, ZOU C L, et al. Planarization of SiC wafer using photo-catalyst incorporated pad [C] / / International Conference on Planarization / CMP Technology, Leuven Belgium: ICPT 2017: 165-170. [84] YUAN Z W, TANG M L, WANG Y, et al. Atomistic removal mechanisms of nano polishing single-crystal SiC in hydroxyl free radical aqueous solution [J]. Physica Scripta, 2023, 98(8): 085404. doi: 10.1088/1402-4896/acdbf0 [85] HE Y, YUAN Z W, TANG M L, et al. Mechanism of chemical and mechanical mutual promotion in photocatalysis-assisted chemical mechanical polishing for single-crystal SiC [J]. Proceedings of The Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2022, 236(24): 11464-11478. doi: 10.1177/09544062221117953 [86] TOKUMURA M, MORITO R, HATAYAMA R, et al. Iron redox cycling in hydroxyl radical generation during the photo-Fenton oxidative degradation: Dynamic change of hydroxyl radical concentration [J]. Applied Catalysis B: Environmental, 2011, 106(3): 565-576. doi: 10.1016/j.apcatb.2011.06.017 [87] BOKARE A D, CHOI W. Review of iron-free Fenton-like systems for activating H2O2 in advanced oxidation processes [J]. Journal of Hazardous Materials, 2014, 275: 121-135. doi: 10.1016/j.jhazmat.2014.04.054 [88] LU J B, CHEN R, LIANG H Z, et al. The influence of concentration of hydroxyl radical on the chemical mechanical polishing of SiC wafer based on the Fenton reaction [J]. Precision Engineering, 2018, 52: 221-226. doi: 10.1016/j.precisioneng.2017.12.011 [89] LIANG H Z, LU J B, PAN J S, et al. Material removal process of single-crystal SiC in chemical-magnetorheological compound finishing [J]. The International Journal of Advanced Manufacturing Technology, 2018, 94(5/6/7/8): 2939-2948. doi: 10.1007/s00170-017-1098-z [90] LI X, WU X J, WU P F, et al. Effects of polishing media on the surface chemical and micromechanical properties of SiC [J]. Computational Materials Science, 2024, 233: 112753. doi: 10.1016/j.commatsci.2023.112753 [91] YANG S Y, LI X L, ZHAO Y T, et al. MD simulation of chemically enhanced polishing of 6H-SiC in aqueous H2O2 [J]. Journal of Manufacturing Processes, 2023, 107: 515-528. doi: 10.1016/j.jmapro.2023.10.056 [92] ZHOU Y Q, HUANG Y H, LI J M, et al. Investigation of the chemical action mechanism based on reactive force field in SiC chemical–mechanical polishing process [J]. Applied Surface Science, 2024, 646: 158927. doi: 10.1016/j.apsusc.2023.158927 [93] MORISHITA T, KAYANUMA M, NAKAMURA T, et al. Cooperative reaction of hydrogen-networked water molecules at the SiC–H2O2 solution interface: Microscopic insights from Ab initio molecular dynamics [J]. The Journal of Physical Chemistry C, 2022, 126(30): 12441-12449. doi: 10.1021/acs.jpcc.2c02464 [94] TIAN Z G, LU J, LUO Q F, et al. Chemical reaction on silicon carbide wafer (0 0 0 1 and 0 0 0 −1) with water molecules in nanoscale polishing [J]. Applied Surface Science, 2023, 607: 903-912. doi: 10.1016/j.apsusc.2022.155090 [95] LUO Q F, LU J, JIANG F, et al. Tribochemical mechanisms of abrasives for SiC and sapphire substrates in nanoscale polishing [J]. Nanoscale, 2023, 15(38): 15675-15685. doi: 10.1039/D3NR02353B [96] ZHANG P F, ZHANG Y L. Initial oxidation of 3C-SiC (111) in oxidizing atmosphere containing water vapor: H2O adsorption from first-principles calculations [J]. Materials Today Communications, 2021, 26: 102072. doi: 10.1016/j.mtcomm.2021.102072 [97] CHEN H B, CHEN J P, WU J X, et al. ReaxFF molecular dynamics simulation and experimental validation about chemical reactions of water and alcohols on SiC surface [J]. Ceramics International, 2024, 50(3): 4332-4349. doi: 10.1016/j.ceramint.2023.11.070 [98] SHEN J F, CHEN H B, CHEN J P, et al. Mechanistic difference between Si-face and C-face polishing of 4H-SiC substrates in aqueous and non-aqueous slurries [J]. Ceramics International, 2023, 49(5): 7274-7283. doi: 10.1016/j.ceramint.2022.10.193 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS