Effect of heat treated tungsten interlayer on microcrystalline diamond coatings

-

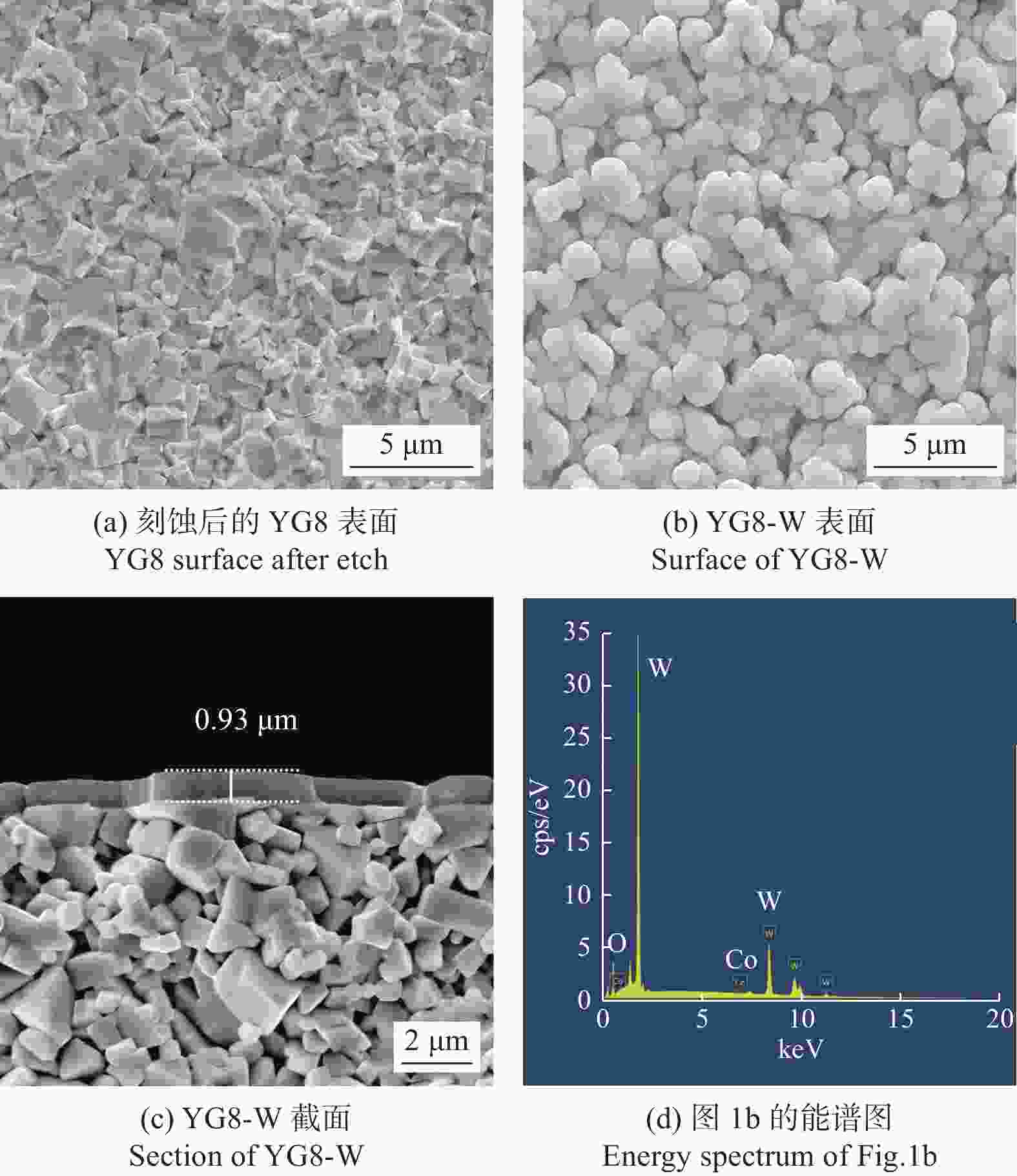

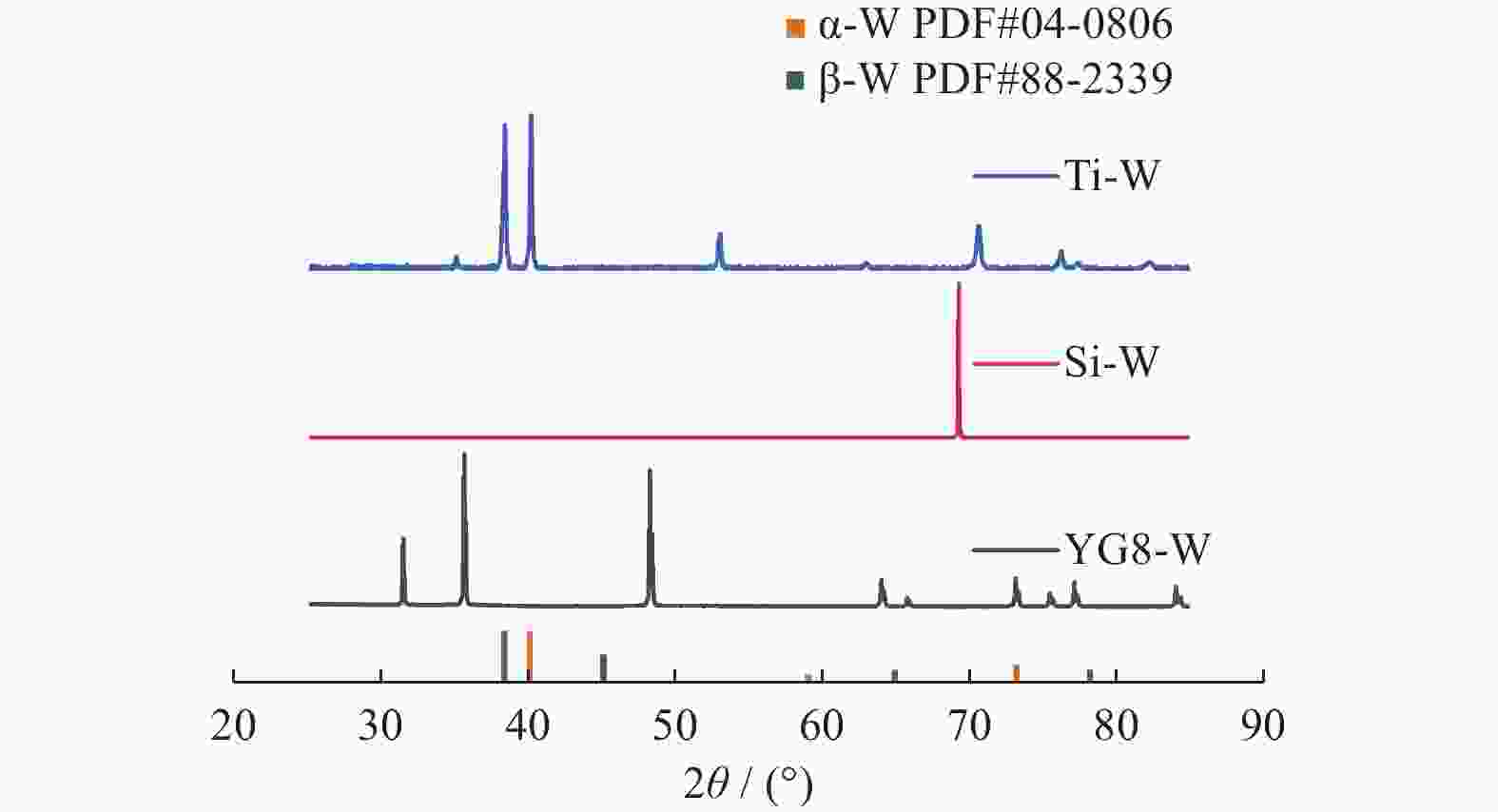

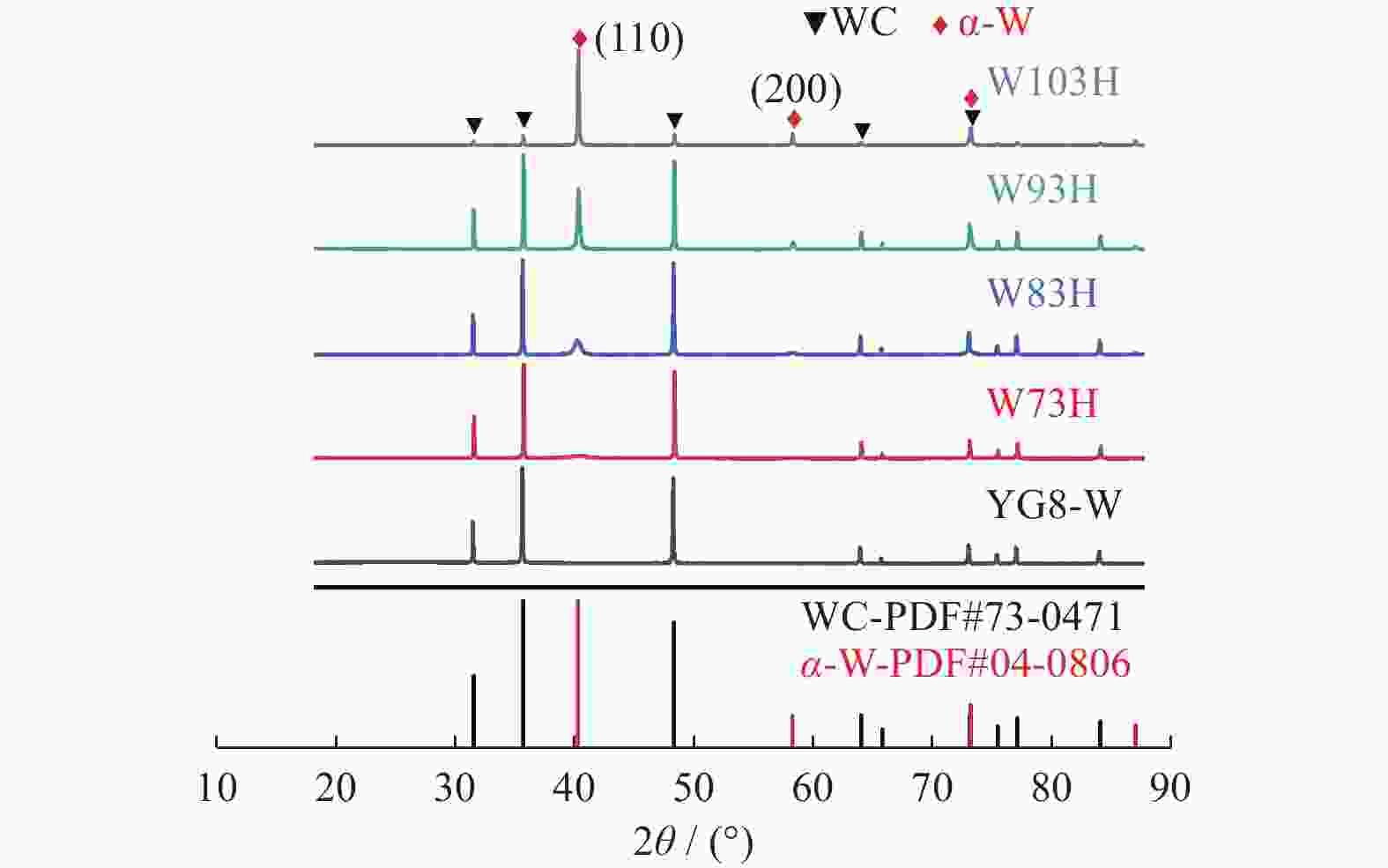

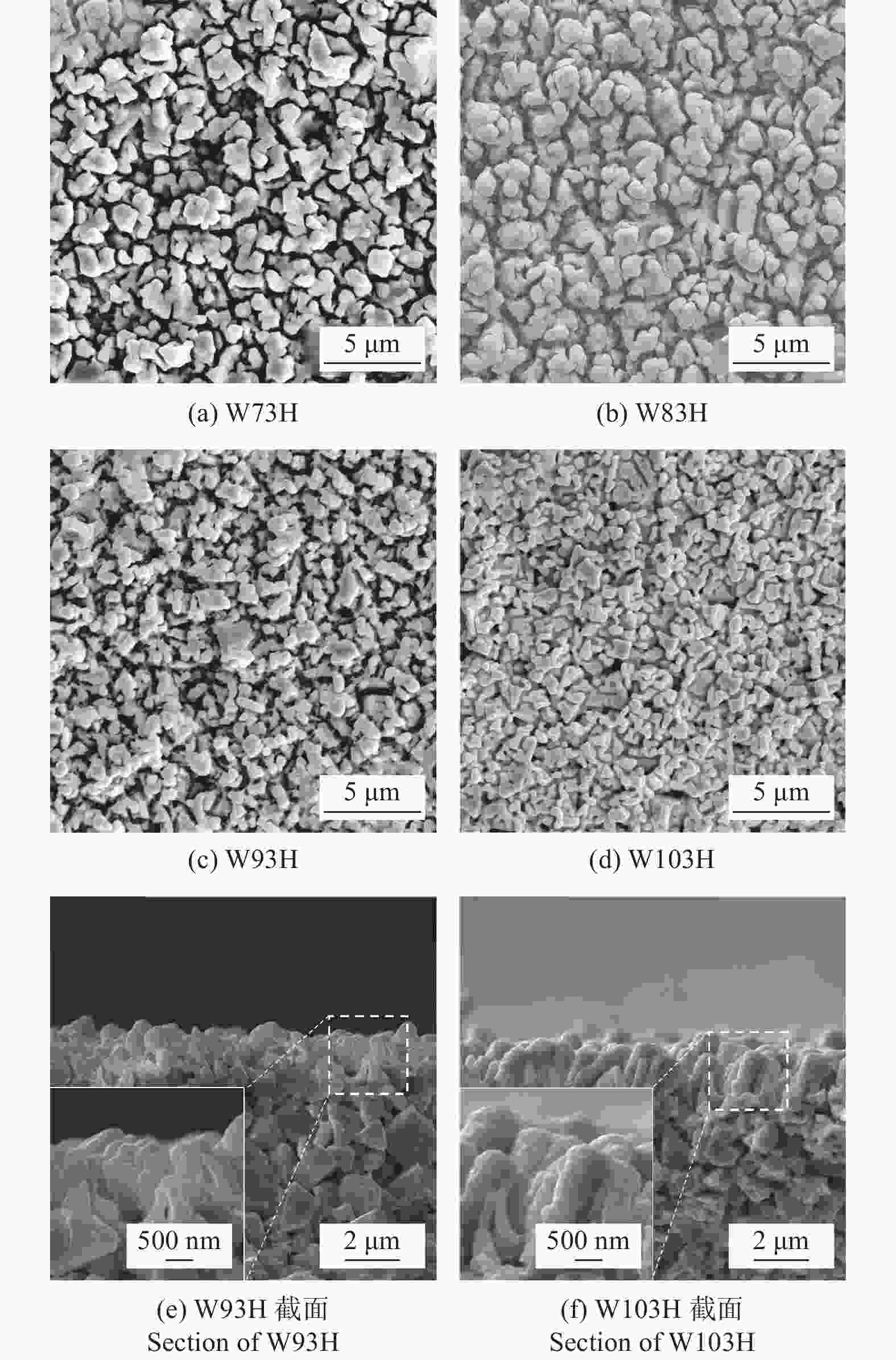

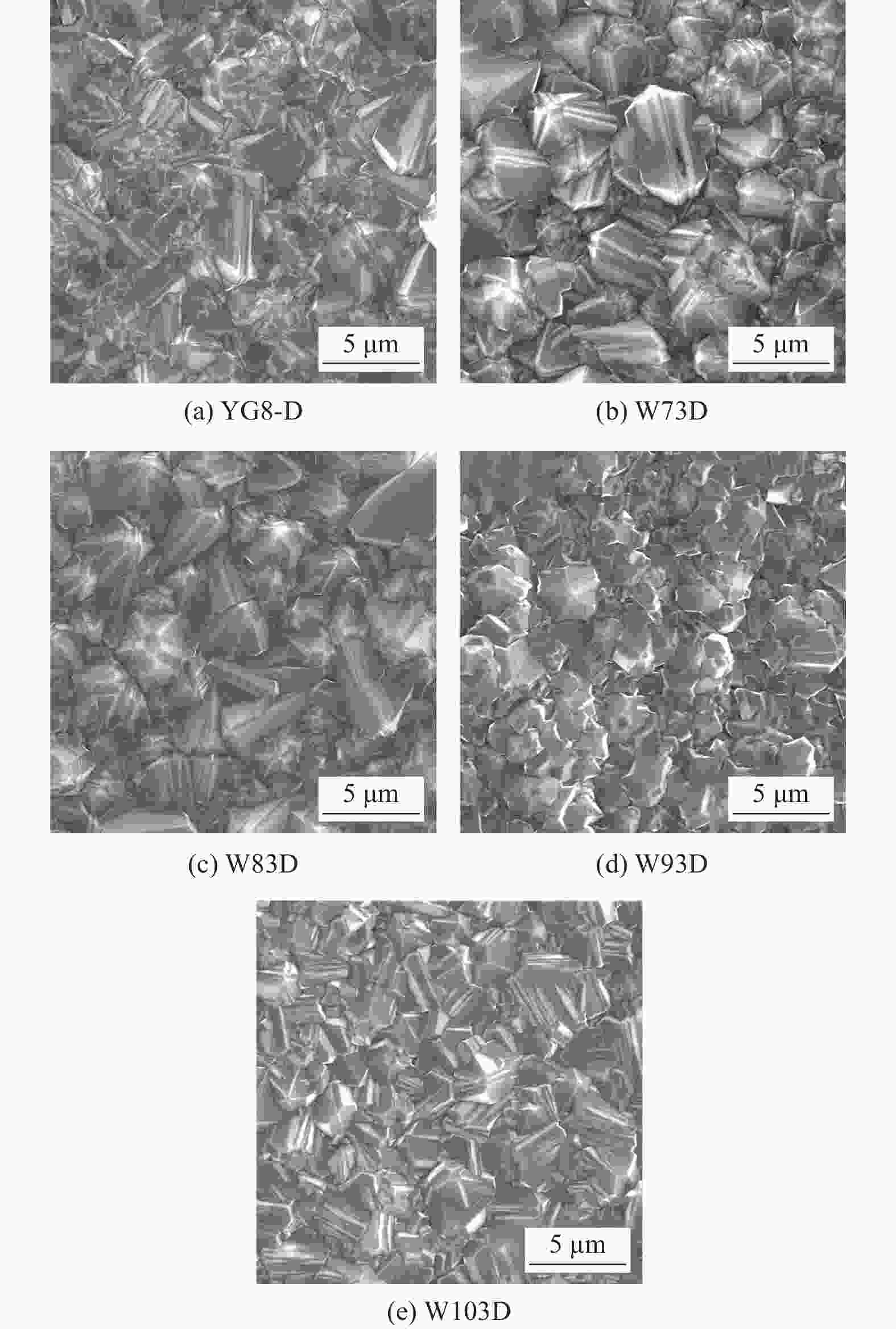

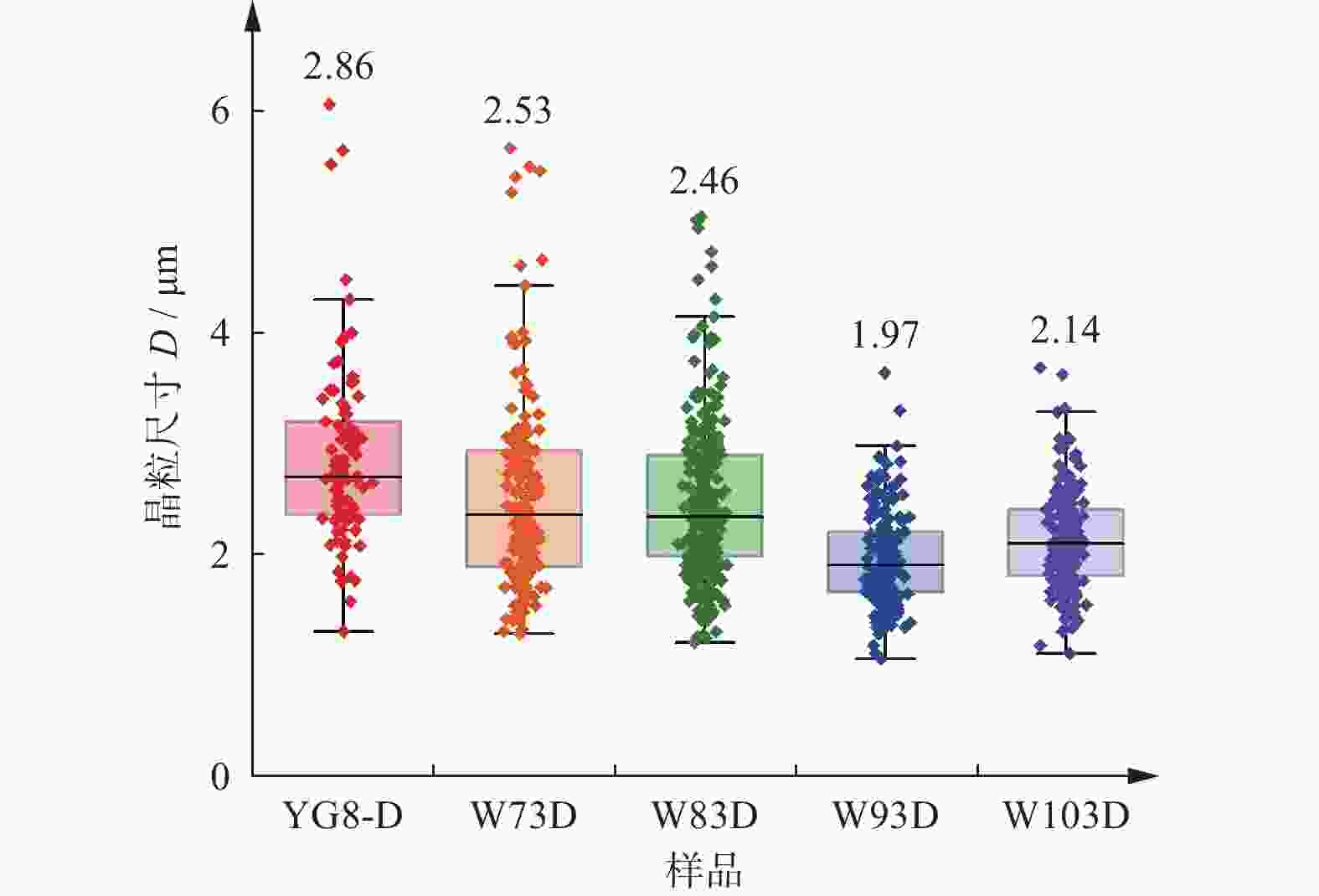

摘要: 硬质合金基微米晶金刚石涂层存在的晶粒粗大和结合性能不佳等情况,影响其在精密加工领域中的应用。为改善硬质合金基微米晶金刚石涂层的结合性能并细化金刚石晶粒,采用蒸发法在硬质合金表面沉积钨过渡层,经热处理后采用热丝化学气相沉积法在其上方沉积金刚石涂层,研究不同热处理温度对钨过渡层结构及金刚石涂层形貌、质量和性能的影响。结果表明:蒸镀的钨过渡层呈现非晶结构,随着热处理温度升高,钨过渡层的结晶度升高并形成不同尺寸的“孤岛−沟壑”结构。SEM图像、X射线衍射图谱和拉曼光谱显示,经热处理后钨过渡层上生长的金刚石涂层晶粒尺寸变小,结晶度更高。900 ℃热处理30 min的钨过渡层表面“孤岛−沟壑”结构尺寸适中,均匀性最好,其上生长的金刚石涂层平均晶粒尺寸约为1.97 μm,平均摩擦系数最低;对应的摩擦副表面最平整,磨损率也明显降低。900和1 000 ℃热处理钨过渡层上的金刚石涂层结合性能相比无过渡层样品有显著提高,在600 N载荷下分别达到HF2和HF1级别。Abstract:

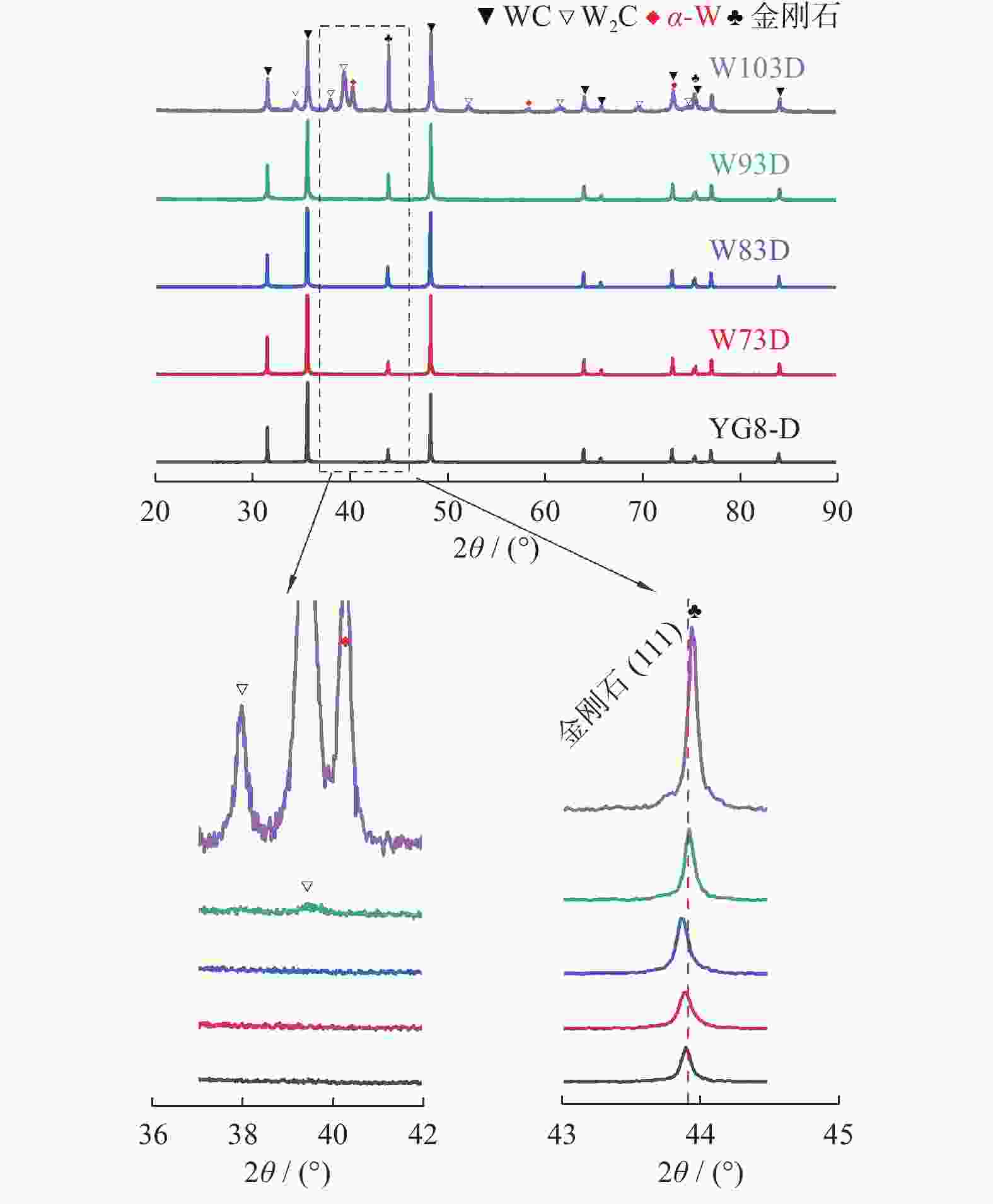

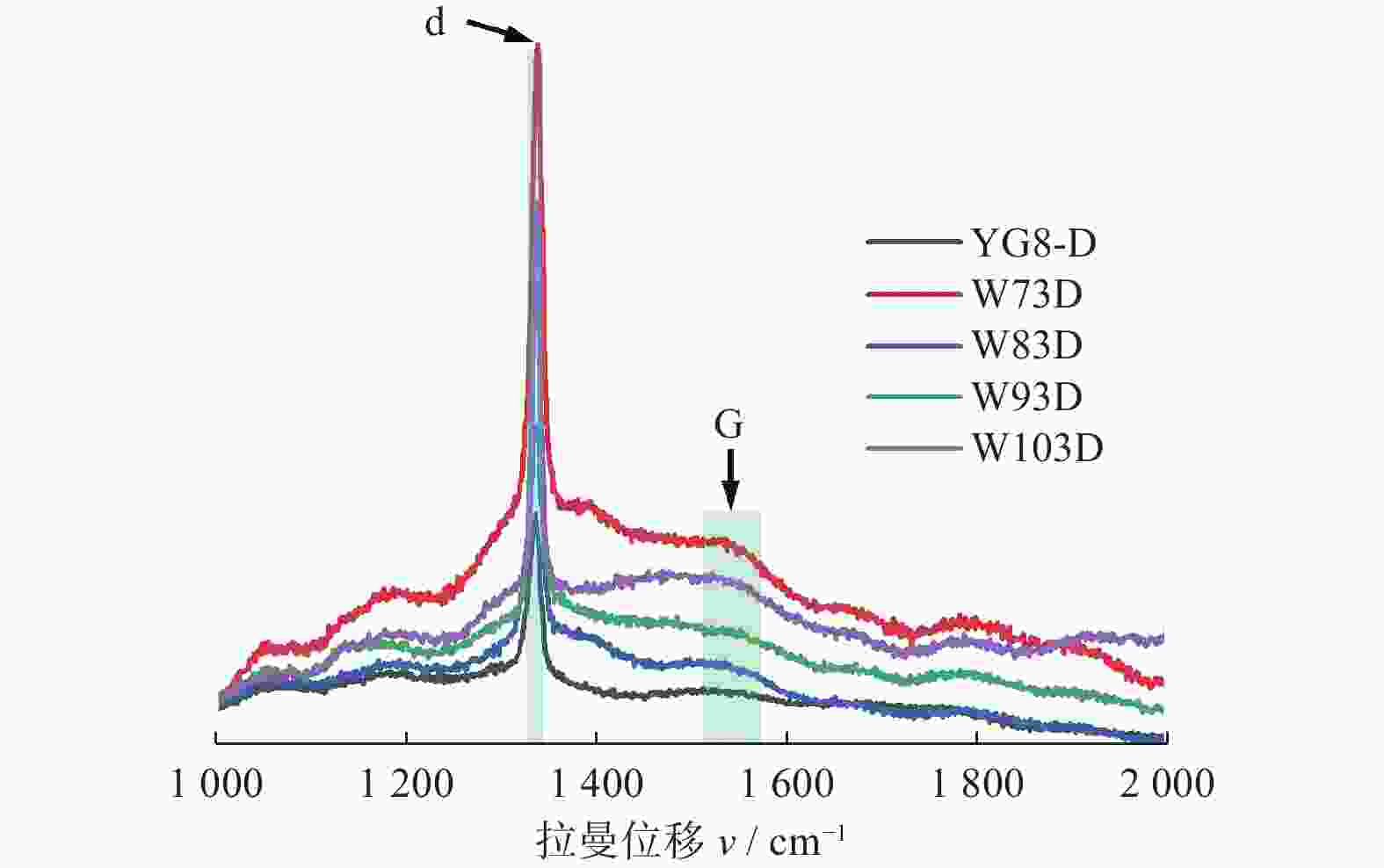

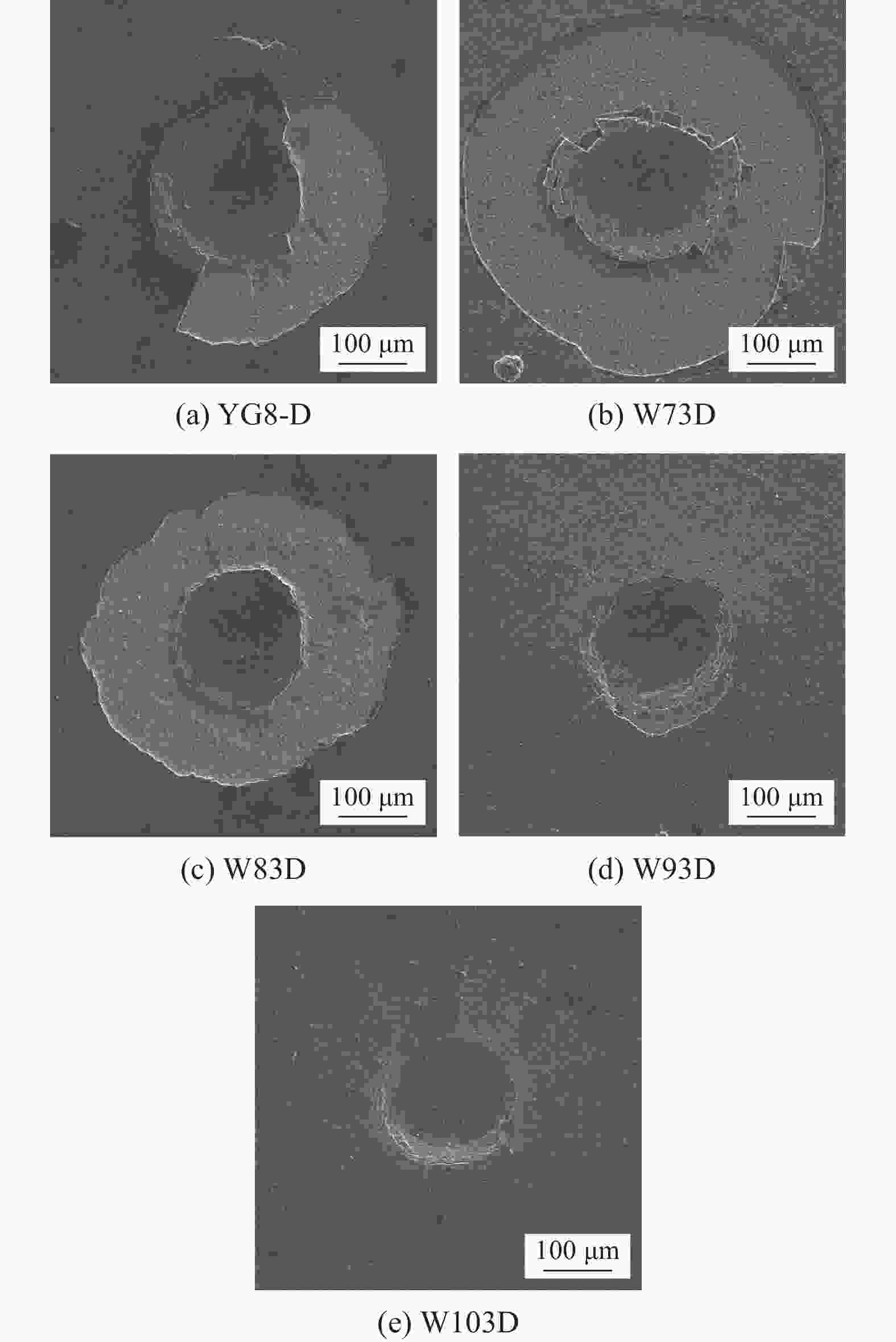

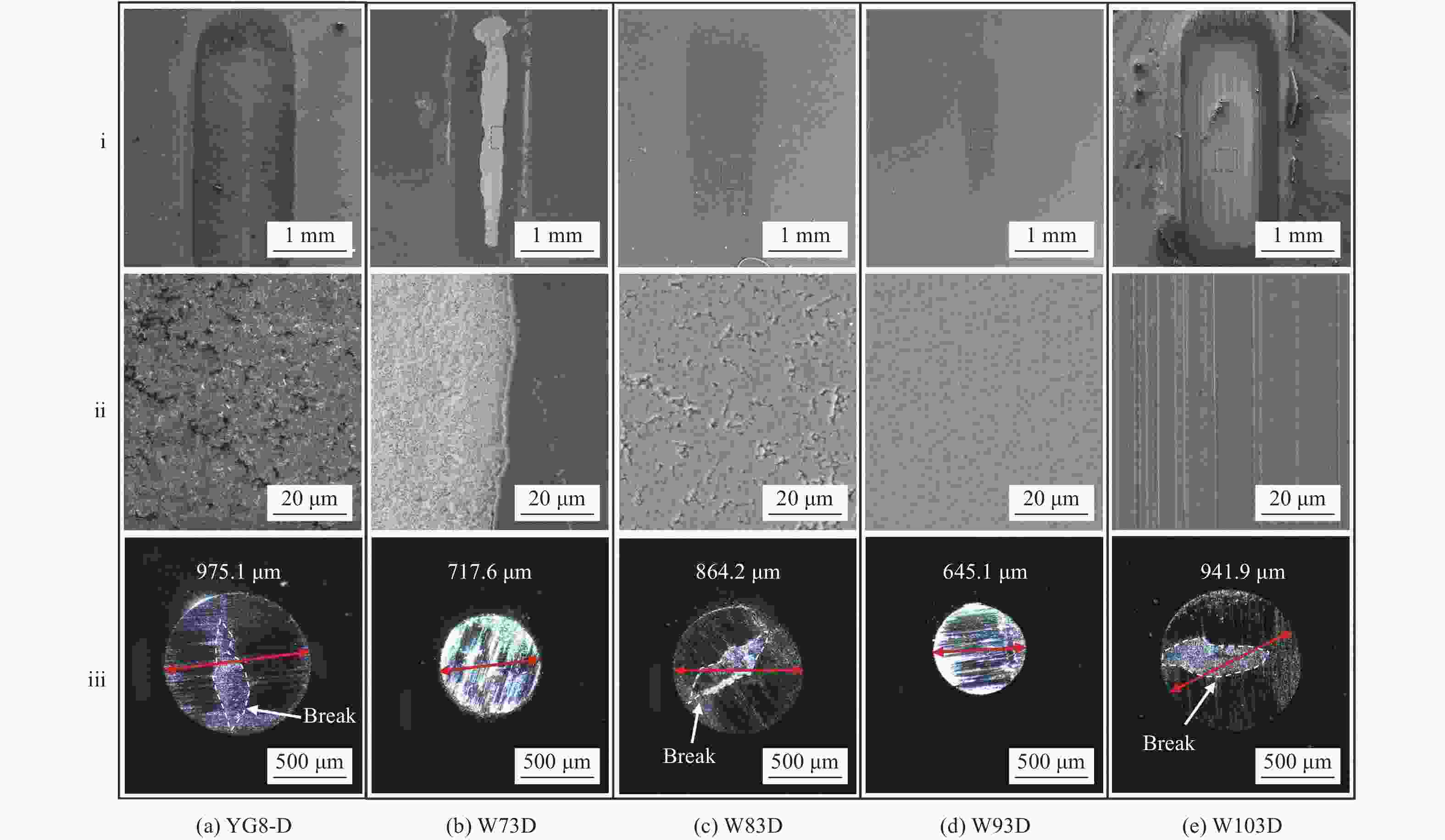

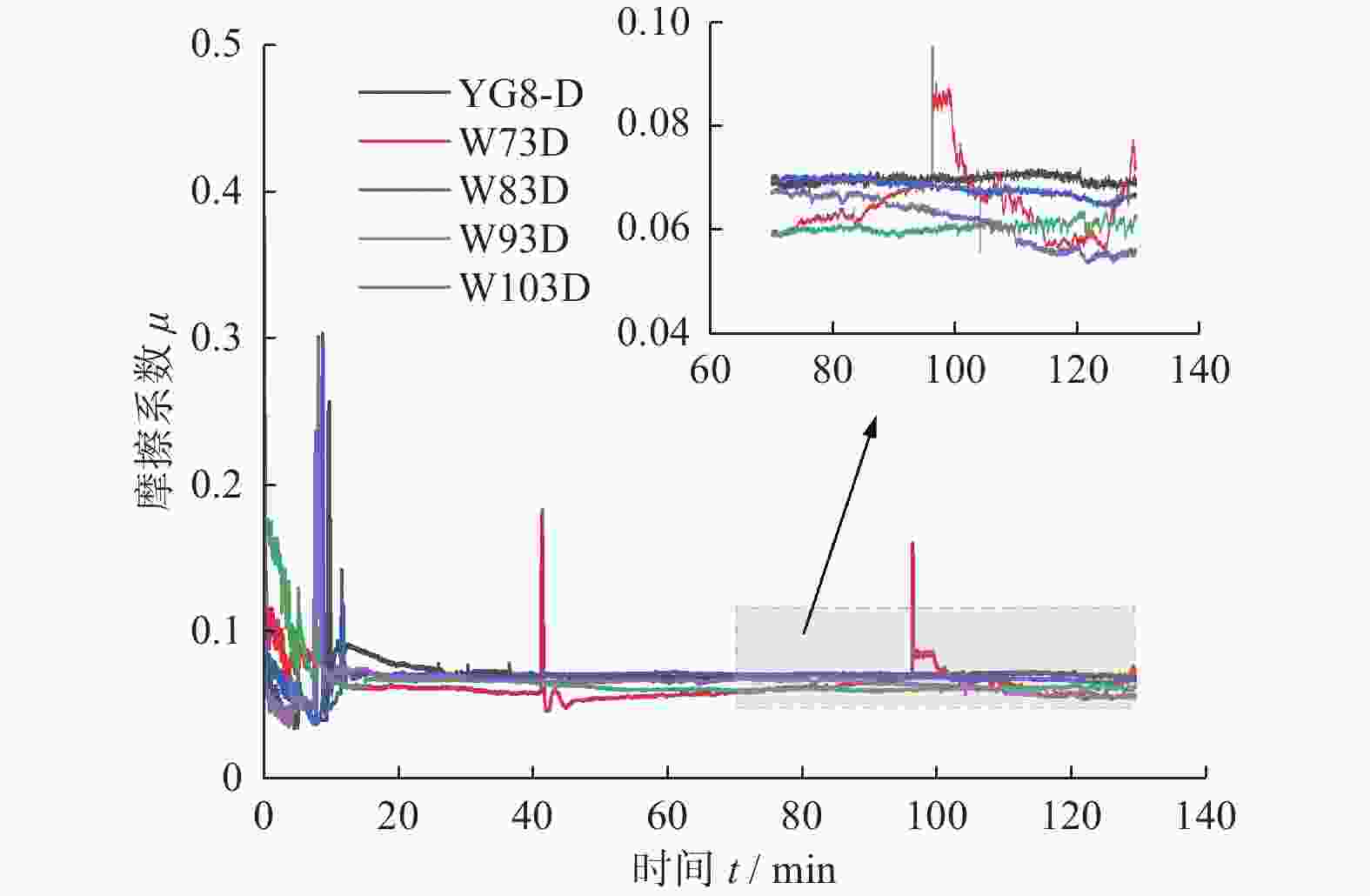

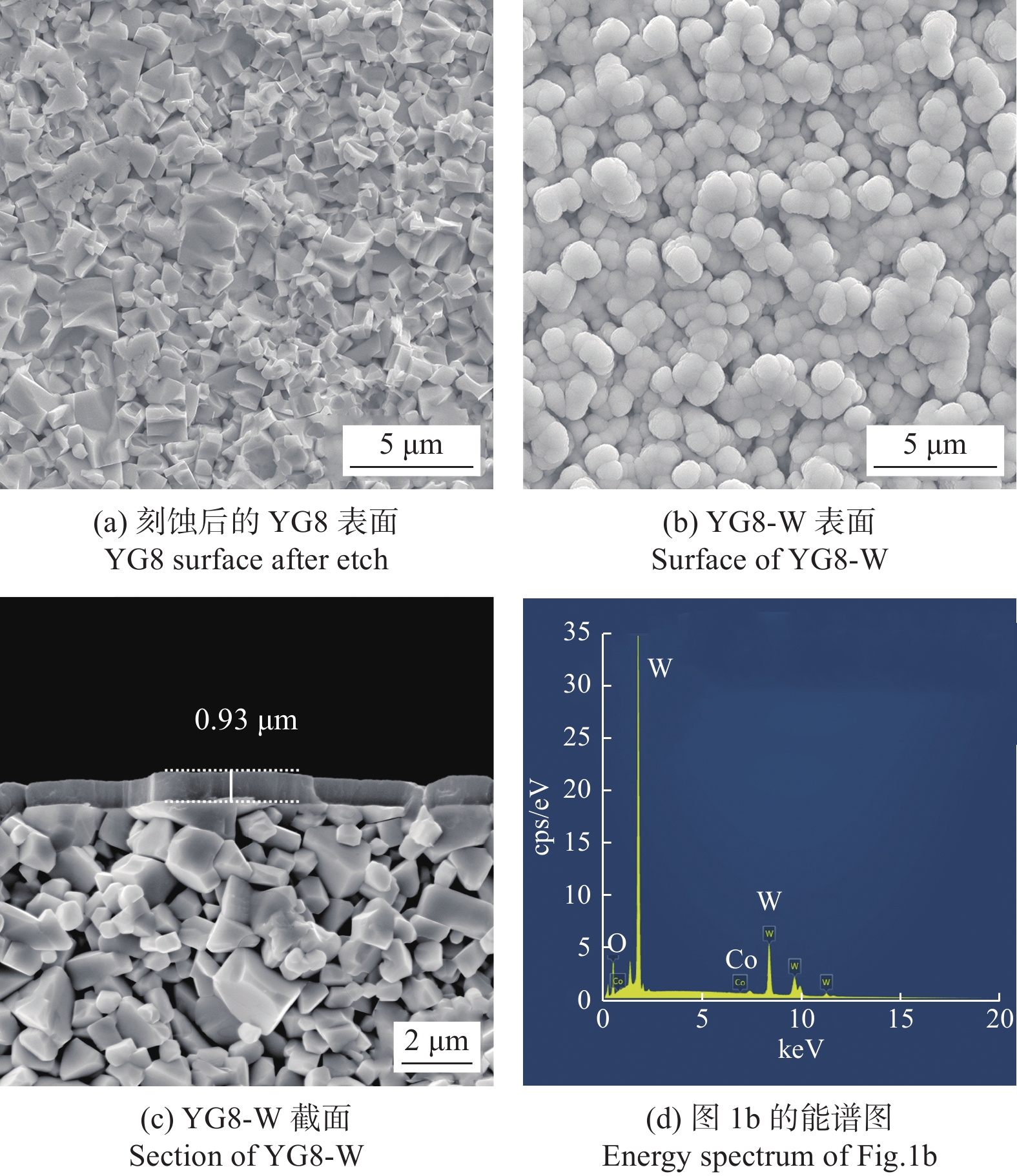

Objectives Microcrystalline diamond coatings have extremely high hardness and excellent wear resistance, but their application field is limited by poor tribological and binding properties. To improve the tribological properties of microcrystalline diamond coatings on cemented carbide substrates, tungsten metal is chosen as the interlayer material, and microscopic texture is constructed by heat treatment on the surface of the tungsten interlayer. Methods The evaporation method is used to deposit a tungsten interlayer on the surface of cemented carbide from which cobalt has been removed by an acid-base two-step method. The tungsten interlayer is then heat-treated in a reducing atmosphere with a certain proportion of argon and hydrogen gas mixture. After heat treatment for 30 minutes at various temperatures (700, 800, 900, 1 000 ℃), the effects of different heat treatment temperatures on the composition, morphology, and microstructure of the tungsten interlayer are studied using scanning electron microscopy (SEM) and X-ray diffraction (XRD). Diamond coatings are deposited using the hot filament chemical vapor deposition (HFCVD) method on substrates without any treatment and on tungsten interlayers heat-treated at different temperatures. The substrate temperature is controlled at (800 ± 50) ℃, and the growth time is 6 hours. The morphology and quality of the diamond coatings are analyzed using SEM, X-ray diffraction, and laser Raman spectroscopy. Reciprocating friction and wear tester are conducted using Si3N4 ceramic balls against the diamond coatings for 120 minutes to evaluate the friction performance of each coating sample. Results The tungsten interlayer deposited by vapor deposition exhibits an amorphous structure, and its crystallinity significantly increases after heat treatment. Cracks are generated on the surface of the interlayer, forming "island - gully" structures of different sizes. The crystallinity of the tungsten interlayer after heat treatment at 700−800 ℃ is poor, with larger "island" and narrower “gullies” on the surface. The structure of the tungsten interlayer after heat treatment at 900 ℃ was more moderate, while the interlayer after heat treatment at 1 000 ℃ has the best crystallinity and the smallest "islands". SEM surface morphology, XRD patterns, and Raman spectroscopy show that the diamond grown on the substrate surface without a tungsten interlayer has the largest average grain size and uneven grain size distribution. The crystallinity and content of diamond coatings grown on tungsten interlayers after heat treatment are better, as reflected in the higher diffraction intensity of the diamond peak in the XRD spectrum and the narrower full width at half maximum (FWHM) of the diamond peak in the Raman spectrum. The grain size of diamond shows a trend of first decreasing and then increasing with rising heat treatment temperature, but in all cases is smaller than that of the sample without a tungsten interlayer. Rockwell indentation tests are conducted on each diamond-coated sample under a load of 600 N, and the indentation morphology is analyzed using scanning electron microscopy. The indentation results indicates that tungsten interlayers heat-treated at 700 and 800 ℃ do not significantly improve the bonding properties of the diamond coating, with both exhibiting HF6-grade bonding strength. In contrast, heat treatment at 900 and 1 000 ℃ effectively enhances the bonding properties of the diamond coating, with bonding strength grades reaching HF2 and HF1, respectively. The enhancement of bonding strength relies on the crystallinity of the tungsten interlayer and the formation of a good mechanical meshing effect due to the “island-gully” structure. Friction and wear results indicate that the diamond coating grown on the tungsten interlayer after 700 ℃ heat treatment has large drop. The coating grown on tungsten interlayers heat-treated at 800−1 000 ℃ ensures good bonding performance while improving friction performance to varying degrees. Among them, the diamond coating grown on the tungsten interlayer heat-treated at 900 ℃ has the smoothest wear mark, with an average friction coefficient as low as 0.062, and the corresponding Si3N4 friction pair has the smallest wear mark diameter and wear rate. Conclusions The tungsten interlayer and its “island-gully” structure after heat treatment can significantly improve the growth and crystal state of diamond, resulting in grain refinement and improved bonding and friction properties. The surface of the tungsten interlayer treated at 900 ℃ for 30 minutes produces a moderately sized “island-gully” structure and the best uniformity. The average grain size of the diamond coating grown on it is about 1.97 μm, with the lowest average friction coefficient, and the corresponding friction pair wear rate is only 19.2% of the sample without a tungsten interlayer. The bonding properties of diamond coating on tungsten interlayer after 1 000 ℃ heat-treated is significantly enhanced. -

Key words:

- diamond coating /

- heat treatment /

- tungsten interlayer /

- grain size /

- bonding properties /

- friction and wear

-

表 1 蒸镀钨过渡层的热处理参数

Table 1. Heat treatment parameters of tungsten interlayer by evaporation

样品 热处理 温度 θ / ℃ 气氛 YG8-W W73H 700 Ar / H2 = 30/20 sccm,

(10 ± 0.2)kPaW83H 800 W93H 900 W103H 1 000 表 2 金刚石涂层样品的高斯拟合拉曼峰信息

Table 2. Gaussian fitting Raman peaks information of diamond coatings samples

样品 金刚石峰 λ / cm−1 残余应力 σ / GPa Id / IG FWHM / cm−1 YG8-D 1 334.06 −0.88 4.43 14.67 W73D 1 336.65 −2.35 3.37 15.20 W83D 1 334.78 −1.34 3.99 13.72 W93D 1 335.32 −1.80 3.82 11.87 W103D 1 336.85 −2.43 3.78 10.01 表 3 金刚石涂层样品的摩擦磨损信息

Table 3. Friction and wear test information of diamond coatings

样品 最大摩擦系数 μmax 平均摩擦系数 μavg 摩擦副磨损面情况 摩擦副磨损率 K / (mm3·N−1·m−1) YG8-D 0.349 0.071 破损 27.54 × 10−8 W73D 0.382 — — — W83D 0.373 0.069 破损 16.99 × 10−8 W93D 0.217 0.062 平整 5.28 × 10−8 W103D 0.453 0.065 破损 23.98 × 10−8 -

[1] CHEN T, XIANG J, GAO F, et al. Study on cutting performance of diamond-coated rhombic milling cutter in machining carbon fiber composites [J]. The International Journal of Advanced Manufacturing Technology, 2019, 103(9/10/11/12): 4731-4737. doi: 10.1007/s00170-019-03902-z [2] LIN Q, CHEN S, JI Z, et al. High-temperature wear behavior of micro- and ultrananocrystalline diamond films against titanium alloy [J]. Surface and Coatings Technology, 2021, 422: 127537. doi: 10.1016/j.surfcoat.2021.127537 [3] WANG H, YANG J, SUN F. Cutting performances of MCD, SMCD, NCD and MCD/NCD coated tools in high-speed milling of hot bending graphite molds [J]. Journal of Materials Processing Technology, 2020, 276: 116401. doi: 10.1016/j.jmatprotec.2019.116401 [4] SONG X, WANG H, WANG X, et al. Coupling effects of methane concentration and nitrogen addition level on morphologies and properties of MPCVD diamond films on WC-Co substrates [J]. Diamond and Related Materials, 2021, 117: 108487. doi: 10.1016/j.diamond.2021.108487 [5] WANG H, WEBB T, BITLER J W. Study of thermal expansion and thermal conductivity of cemented WC–Co composite [J]. International Journal of Refractory Metals and Hard Materials, 2015, 49: 170-177. doi: 10.1016/j.ijrmhm.2014.06.009 [6] 郭晓光, 刘涛, 翟昌恒, 等. 过渡金属作用下的金刚石石墨化机理研究 [J]. 机械工程学报, 2016, 52(20): 23-29. doi: 10.3901/JME.2016.20.023GUO Xiaoguang, LIU Tao, ZHAI Changheng, et al. Study on the mechanism of diamond graphite with the action of transition metals [J]. Journal of Mechanical Engineering, 2016, 52(20): 23-29. doi: 10.3901/JME.2016.20.023 [7] 谷继腾, 杨扬, 唐永炳. 热处理工艺对硬质合金表面金刚石薄膜附着性能的影响 [J]. 集成技术, 2017, 6(4): 80-88. doi: 10.3969/j.issn.2095-3135.2017.04.009GU Jiteng, YANG Yang, TANG Yongbing. Effects of heat-treatment on the adhesive strength of diamond films coated on the cemented carbide substrates [J]. Journal of Intergration Technology, 2017, 6(4): 80-88. doi: 10.3969/j.issn.2095-3135.2017.04.009 [8] WANG X, WANG C, HE W, et al. Co evolutions for WC–Co with different Co contents during pretreatment and HFCVD diamond film growth processes [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(3): 469-486. doi: 10.1016/S1003-6326(18)64680-1 [9] 潘秋丽, 张荣良. 以 Cr/CrSiN膜为过渡层在高钴硬质合金表面沉积金刚石薄膜 [J]. 金刚石与磨料磨具工程, 2023, 43(6): 698-703. doi: 10.13394/j.cnki.jgszz.2023.0004PAN Qiuli, ZHANG Rongliang. Depositing diamond film on high Co content cemented carbide using Cr/CrSiN film as an interlayer [J]. Diamond & Abrasives Engineering, 2023, 43(6): 698-703. doi: 10.13394/j.cnki.jgszz.2023.0004 [10] ZHANG J, WANG X, SHEN B, et al. Effect of boron and silicon doping on improving the cutting performance of CVD diamond coated cutting tools in machining CFRP [J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 285-292. doi: 10.1016/j.ijrmhm.2013.04.017 [11] SHARIF U M, SEAH K H W, LI X P, et al. Effect of crystallographic orientation on wear of diamond tools for nano-scale ductile cutting of silicon [J]. Wear, 2004, 257(7/8): 751-759. doi: 10.1016/j.wear.2004.03.012 [12] AJIKUMAR P K, GANESAN K, KUMAR N, et al. Role of microstructure and structural disorder on tribological properties of polycrystalline diamond films [J]. Applied Surface Science, 2019, 469: 10-17. doi: 10.1016/j.apsusc.2018.10.265 [13] 余寒, 夏鑫, 朱俊奎, 等. 籽晶种植及掺硼形核对硬质合金表面金刚石涂层的影响 [J]. 粉末冶金材料科学与工程, 2023, 28(4): 404-412. doi: 10.19976/j.cnki.43-1448/TF.2023035YU Han, XIA Xin, ZHU Junkui, et al. Effects of seeding and boron-doped nucleation on diamond coating of cemented carbide surface [J]. Materials Science and Engineering of Powder Metallurgy, 2023, 28(4): 404-412. doi: 10.19976/j.cnki.43-1448/TF.2023035 [14] ALI M, ÜRGEN M. Surface morphology, growth rate and quality of diamond films synthesized in hot filament CVD system under various methane concentrations [J]. Applied Surface Science, 2011, 257(20): 8420-8426. doi: 10.1016/j.apsusc.2011.04.097 [15] POULON-QUINTIN A, FAURE C, TEULÉ-GAY L, et al. A multilayer innovative solution to improve the adhesion of nanocrystalline diamond coatings [J]. Applied Surface Science, 2015, 331: 27-34. doi: 10.1016/j.apsusc.2015.01.050 [16] XU Y, WANG T, CHEN B, et al. Interface design to tune stress distribution for high performance diamond/silicon carbide coated cemented carbide tools [J]. Surface and Coatings Technology, 2020, 397: 125975. doi: 10.1016/j.surfcoat.2020.125975 [17] CHANDRAN M, HOFFMAN A. Diamond film deposition on WC–Co and steel substrates with a CrN interlayer for tribological applications [J]. Journal of Physics D: Applied Physics, 2016, 49: 213002. doi: 10.1088/0022-3727/49/21/213002 [18] XU F, XU J H, YUEN M F, et al. Adhesion improvement of diamond coatings on cemented carbide with high cobalt content using PVD interlayer [J]. Diamond and Related Materials, 2013, 34: 70-75. doi: 10.1016/j.diamond.2013.01.012 [19] YANG T, WEI Q, QI Y, et al. The diffusion behavior of carbon in sputtered tungsten film and sintered tungsten block and its effect on diamond nucleation and growth [J]. Diamond and Related Materials, 2015, 52: 49-58. doi: 10.1016/j.diamond.2014.12.009 [20] GUO Z, DENG F, ZHANG L, et al. Fabrication and tribological properties of textured diamond coatings on WC-Co cemented carbide surfaces [J]. Ceramics International, 2021, 47(4): 5423-5431. doi: 10.1016/j.ceramint.2020.10.124 [21] MA D, HEI H, ZHENG K, et al. Effects of TiMoTa nano-crystalline interlayer on nucleation, adhesion and tribological behaviors of diamond coating [J]. Ceramics International, 2023, 49(6): 9512-9522. doi: 10.1016/j.ceramint.2022.11.118 [22] HSIEH C T, TING J M. Effect of growth conditions on the structure and properties of tungsten films prepared using a thermal evaporation process [J]. Journal of Vacuum Science & Technology A, 2007, 25(6): 1552-1556. [23] SHEN Y G, MAI Y W, MCBRIDE W E, et al. Oxygen-induced amorphous structure of tungsten thin films [J]. Applied Physics Letters, 1999, 75(15): 2211-2213. doi: 10.1063/1.124967 [24] 郑子樵. 材料科学基础 [M]. 长沙: 中南大学出版社, 2013.ZHENG Ziqiao. Fundamentals of materials science [M]. Changsha: Central South University Press, 2013. [25] BOWDEN F P, SINGER K E. Surface self-diffusion of tungsten [J]. Nature, 1969, 222: 977-979. doi: 10.1038/222977b0 [26] WEI Q P, YU Z M, MA L, et al. The effects of temperature on nanocrystalline diamond films deposited on WC–13wt.% Co substrate with W–C gradient layer [J]. Applied Surface Science, 2009, 256(5): 1322-1328. doi: 10.1016/j.apsusc.2009.06.091 [27] RALCHENKO V G, SMOLIN A A, PEREVERZEV V G, et al. Diamond deposition on steel with CVD tungsten intermediate layer [J]. Diamond and Related Materials, 1995, 4: 754-758. doi: 10.1016/0925-9635(94)05299-9 [28] GUILLEMET T, XIE Z Q, ZHOU Y S, et al. Stress and phase purity analyses of diamond films deposited through laser-assisted combustion synthesis [J]. ACS Applied Materials & Interfaces, 2011, 3(10): 4120-4125. doi: 10.1021/am201010h [29] VIDAKIS N, ANTONIADIS A, BILALIS N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds [J]. Journal of Materials Processing Technology, 2003, (143/144): 481-485. doi: 10.1016/S0924-0136(03)00300-5 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS