Design and performance of compliant grinding tools for blade root smooth grinding

-

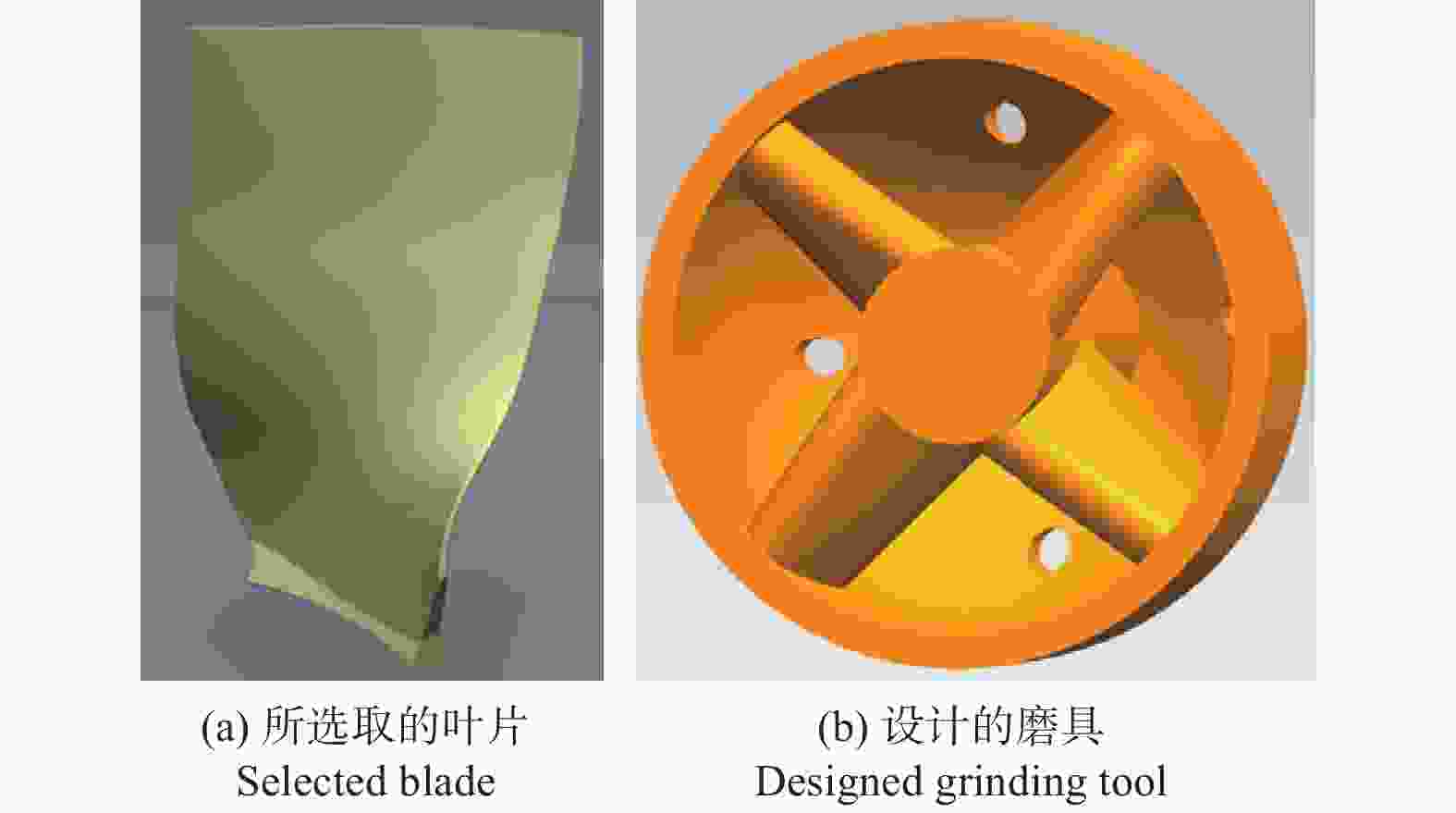

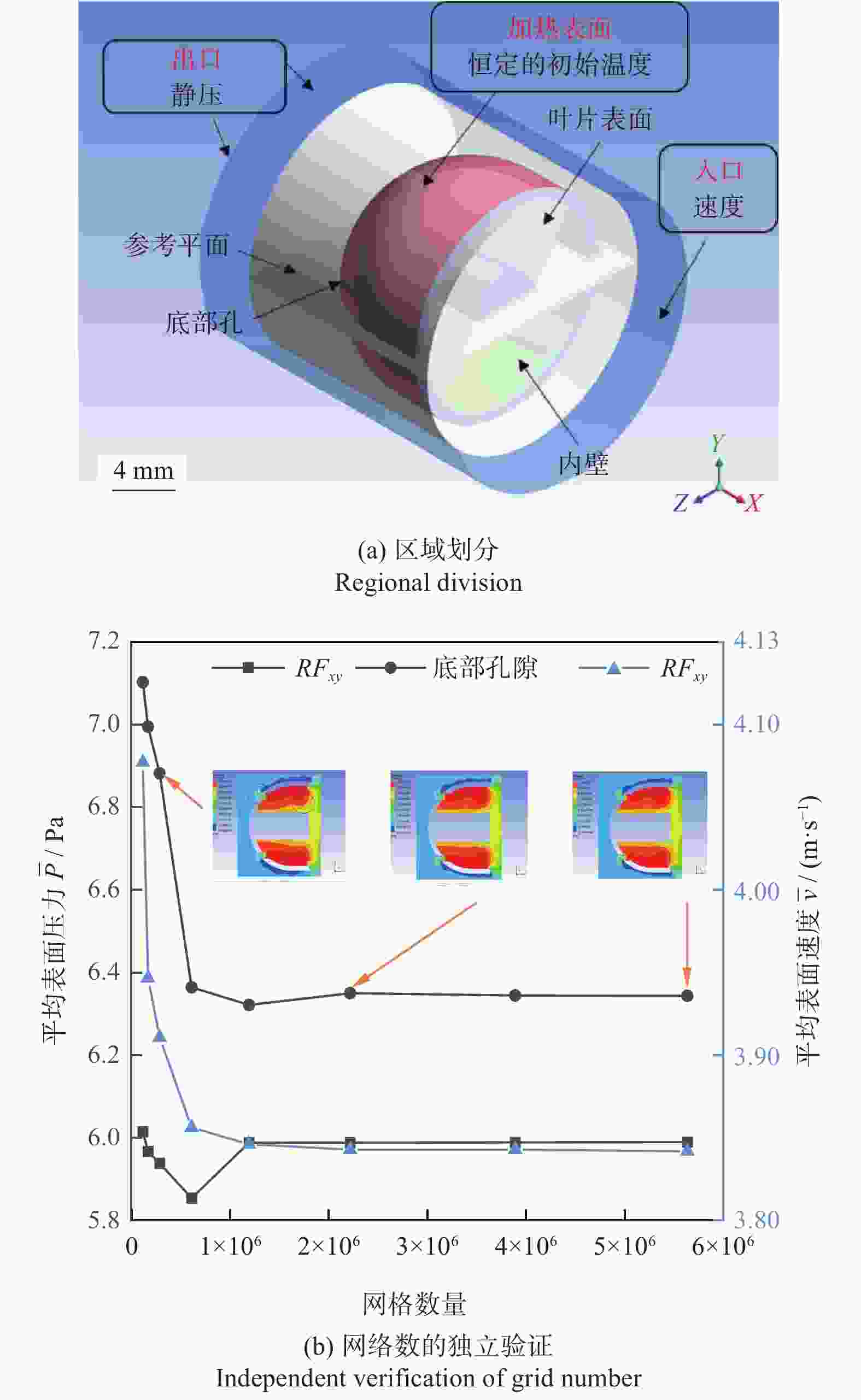

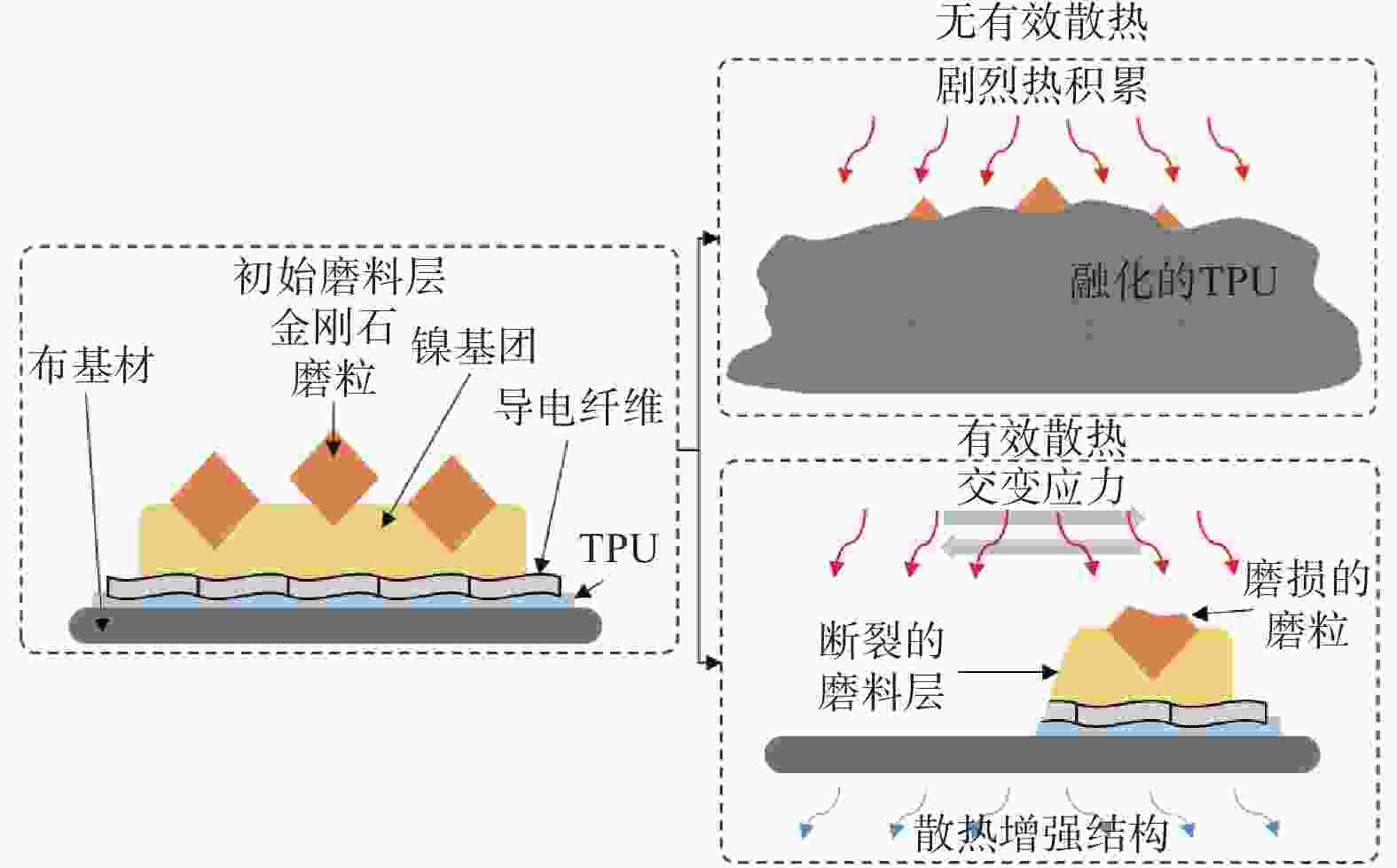

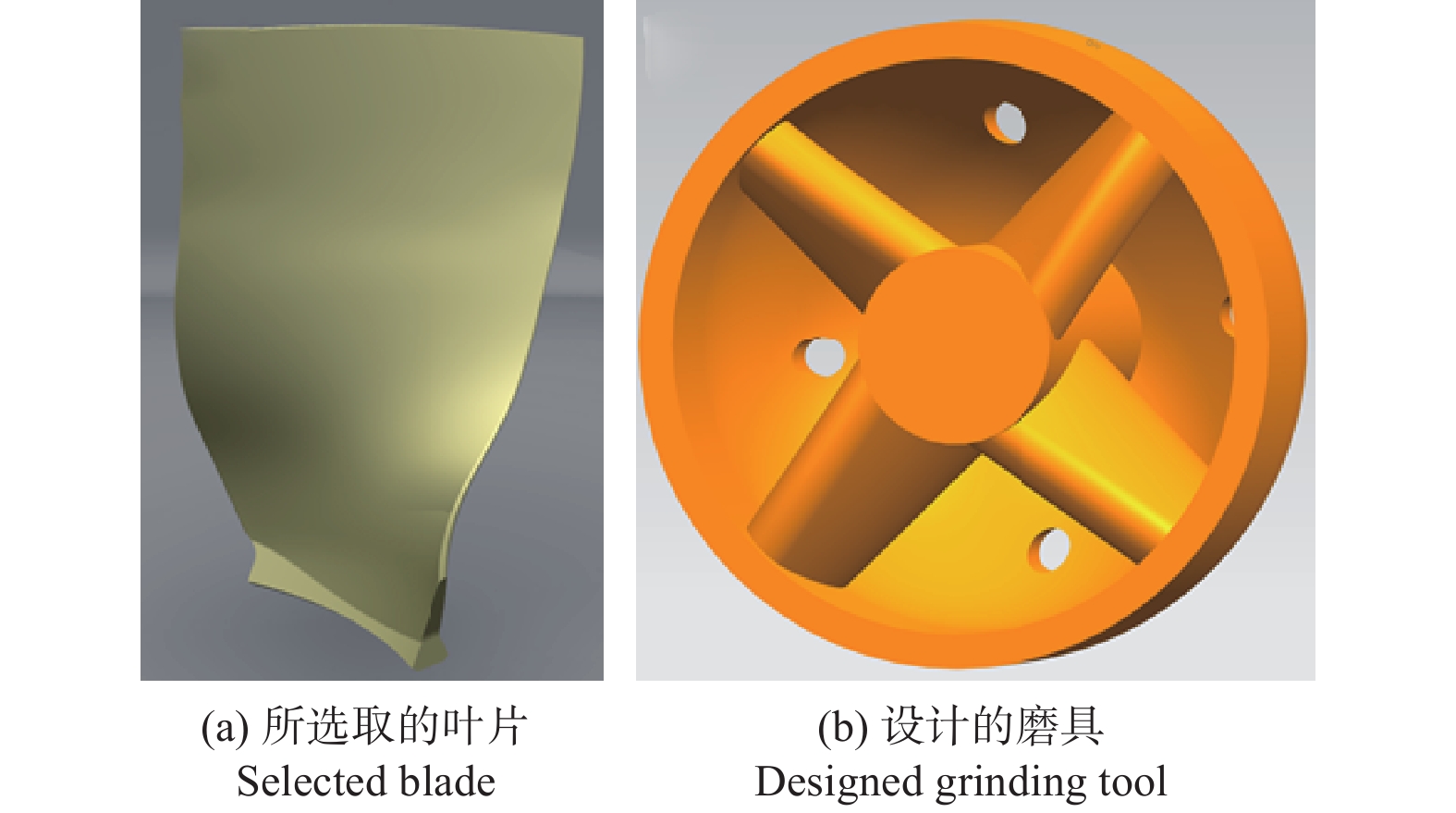

摘要: 小尺寸柔性磨具有助于解决以航空发动机叶片根部为代表的复杂结构件难加工部位的精密磨抛难题,但工件的弱导热性与柔性材料自身的弱热稳定性特质,使磨削热积累,从而制约磨具寿命与磨削性能。为此,提出在球头磨具中引入基于风扇叶片的增强换热结构以改善其传热性能,并基于多射流熔融3D打印方法制造磨具。通过数值模拟研究旋转方向、转速和强制冷空气速度对磨具传热机理的影响,且通过钛合金板材磨削实验对比所设计磨具与传统结构磨具的磨削性能。结果表明:内叶片结构有效地向磨具内腔引入高动量流体,增大磨具内腔压力并提高传热效率,最大降温幅度可达18.29%;在持续的磨削实验中,内叶片结构磨具具有更好的磨削性能一致性,可有效减轻连续磨削过程中热量积聚导致的柔性材料黏附,使磨具寿命延长40%。Abstract:

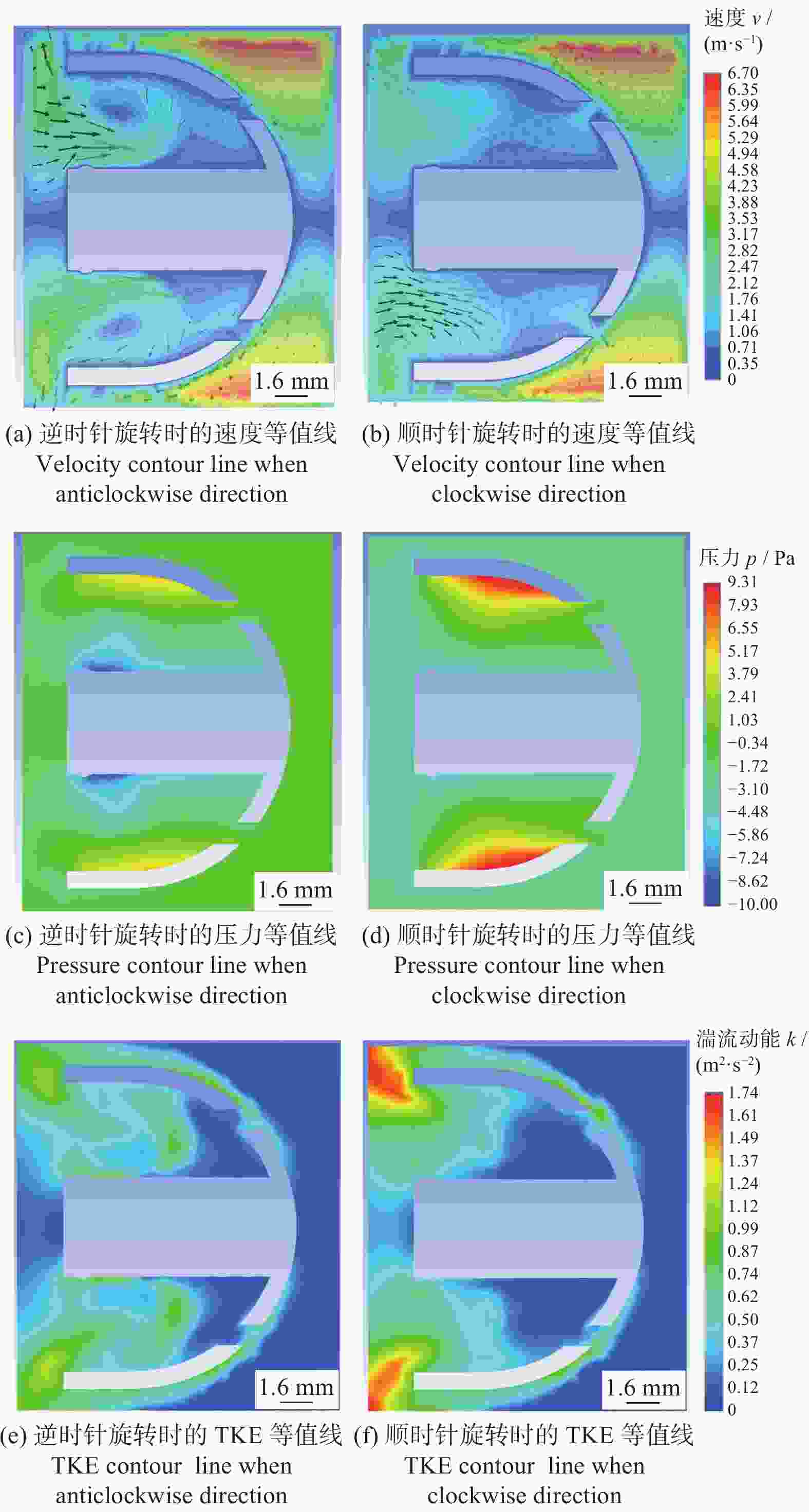

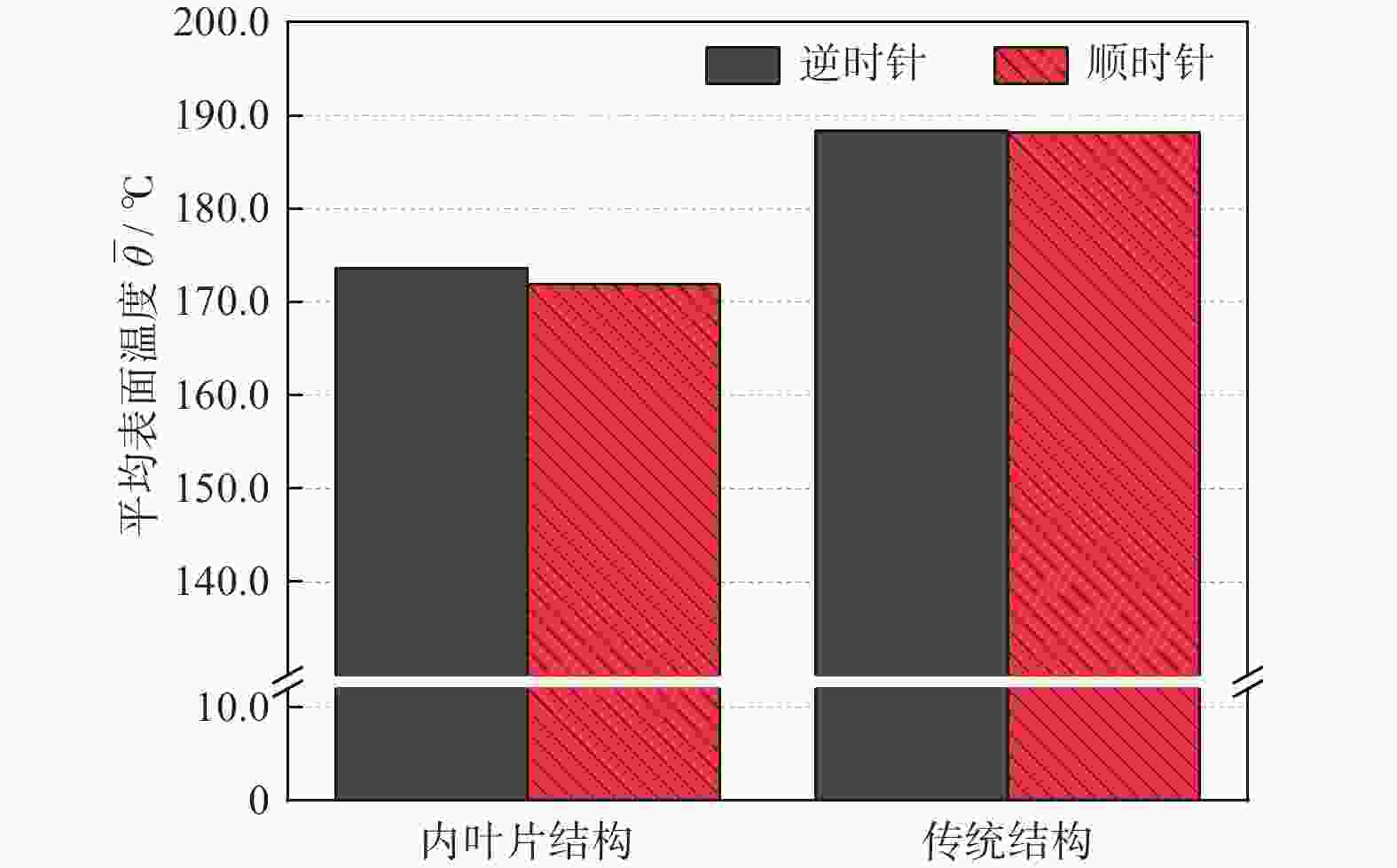

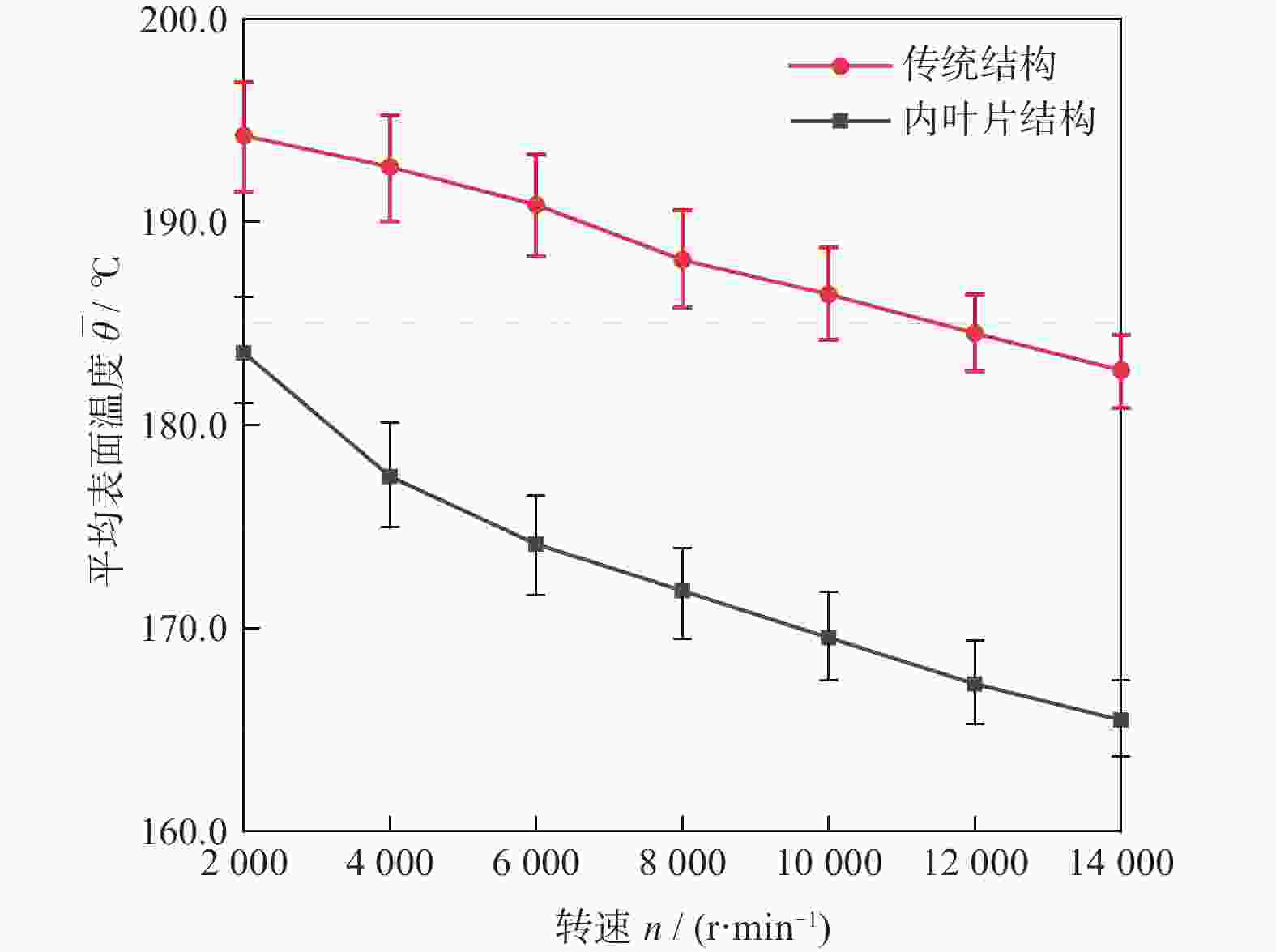

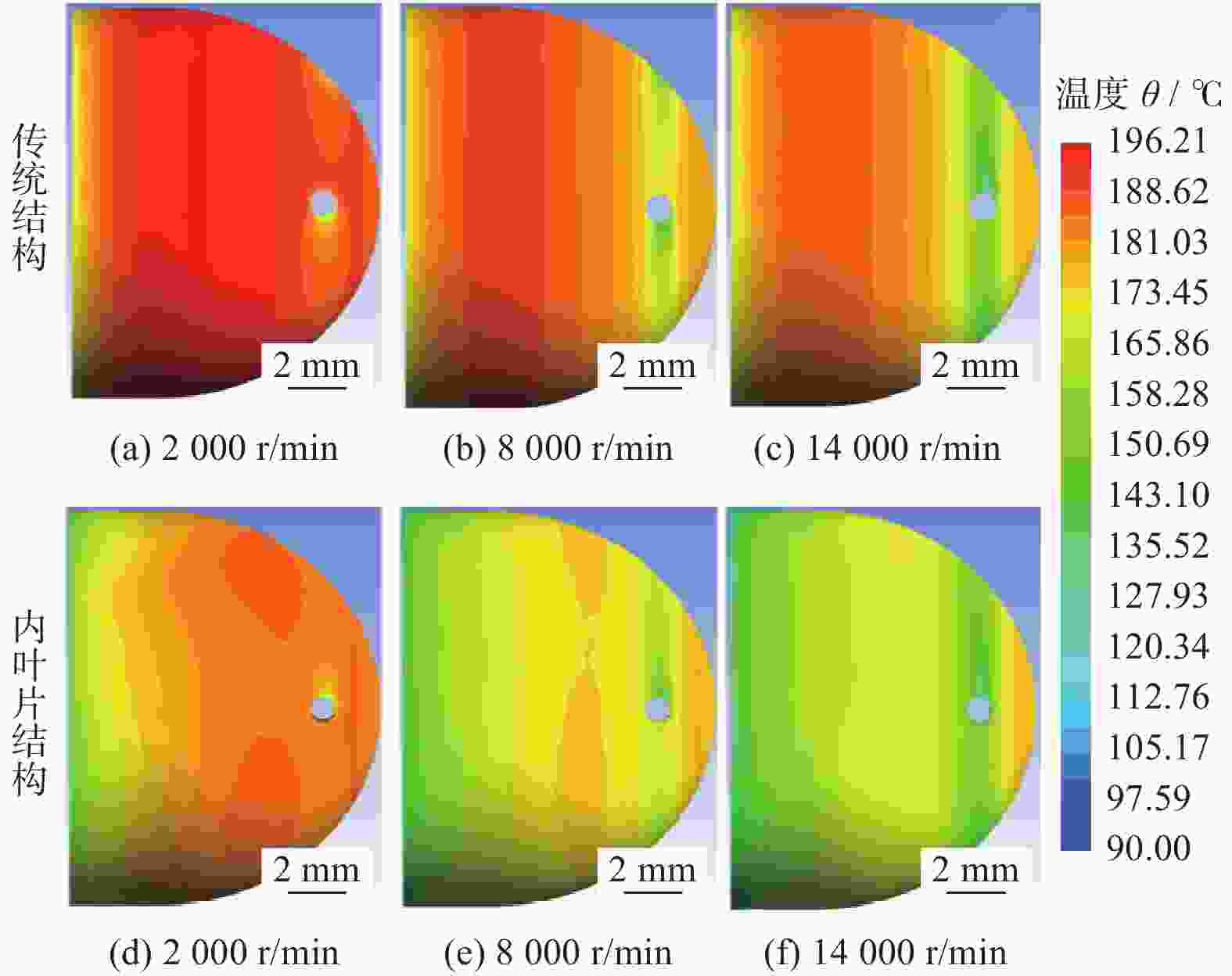

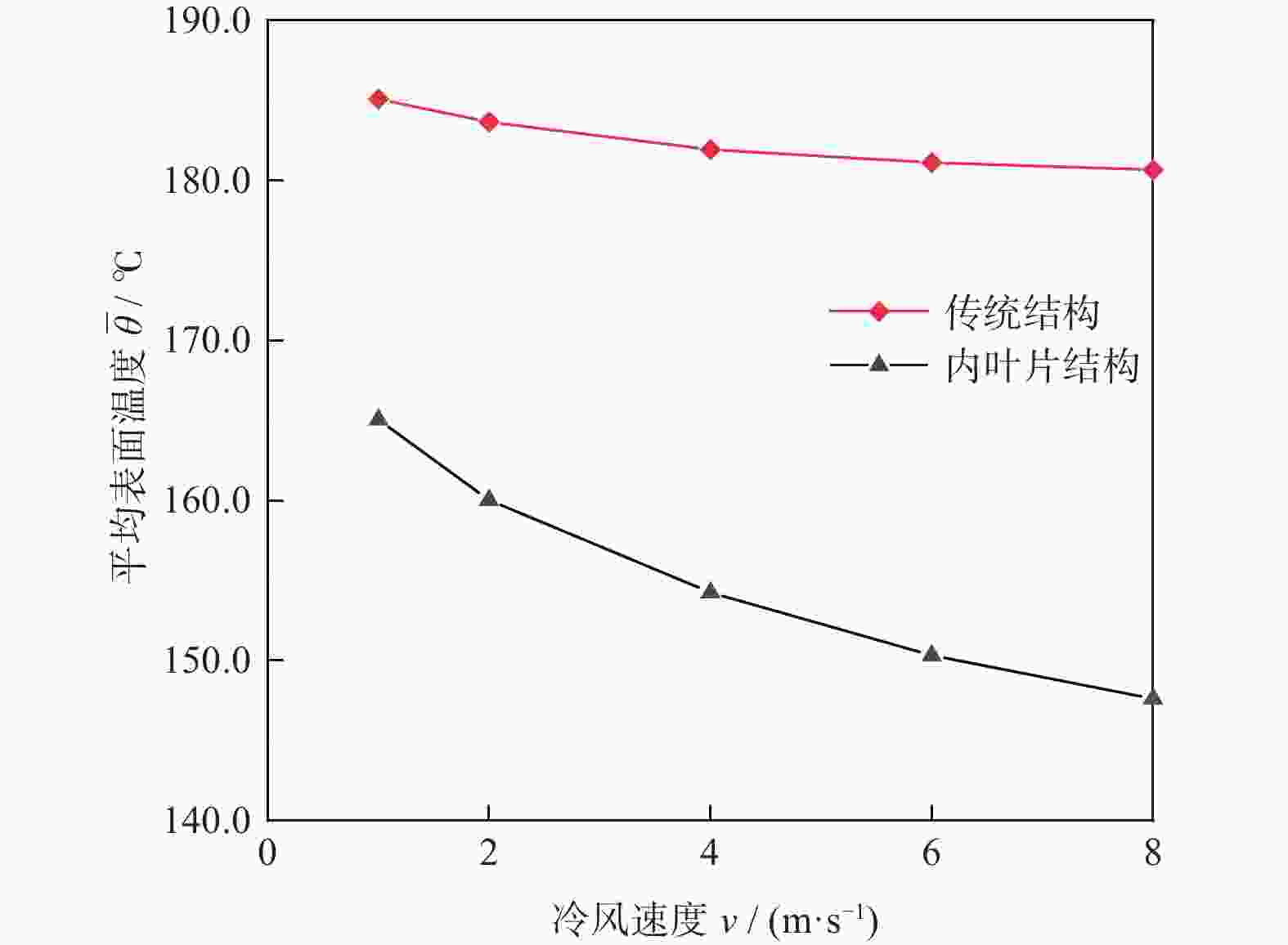

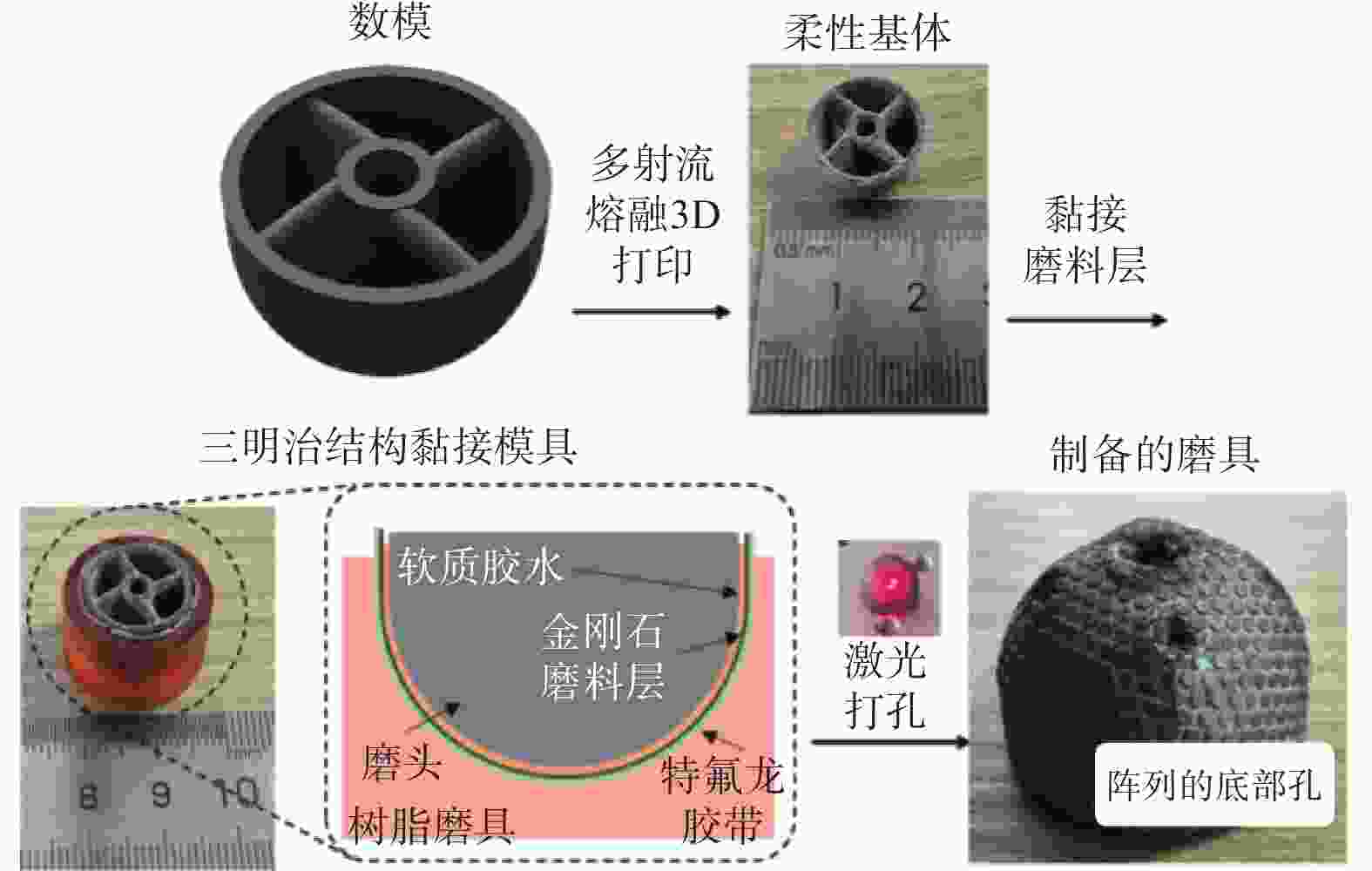

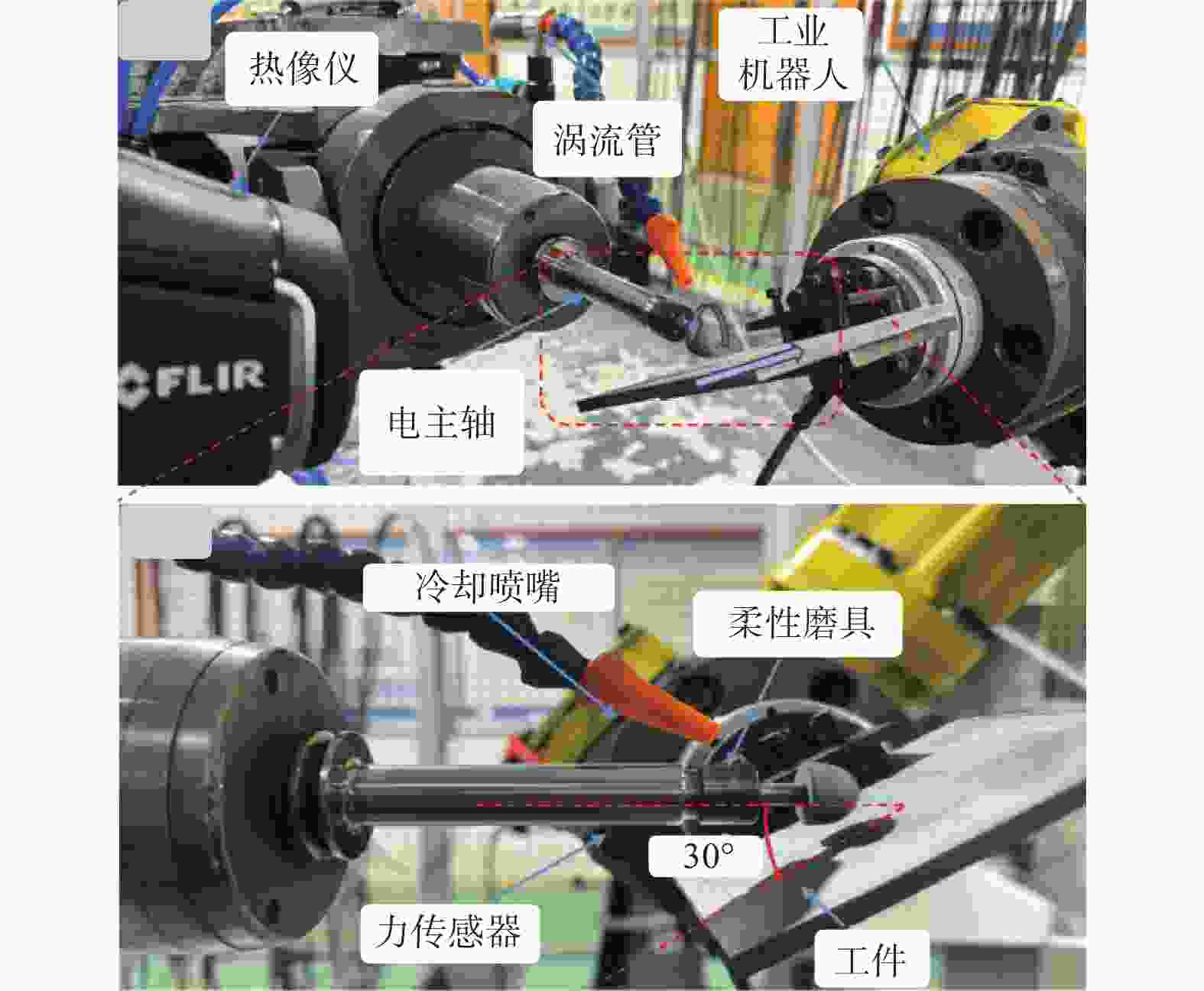

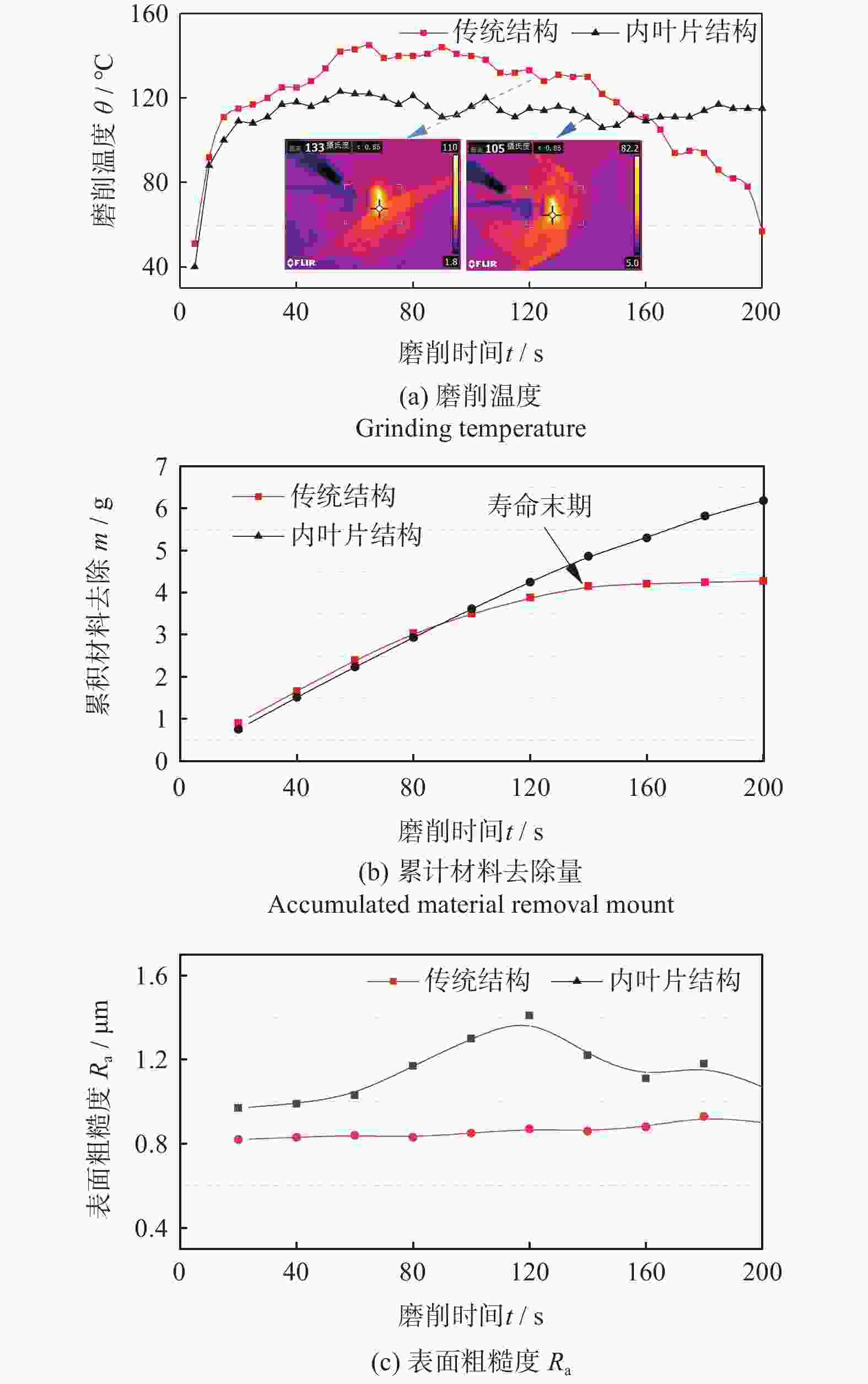

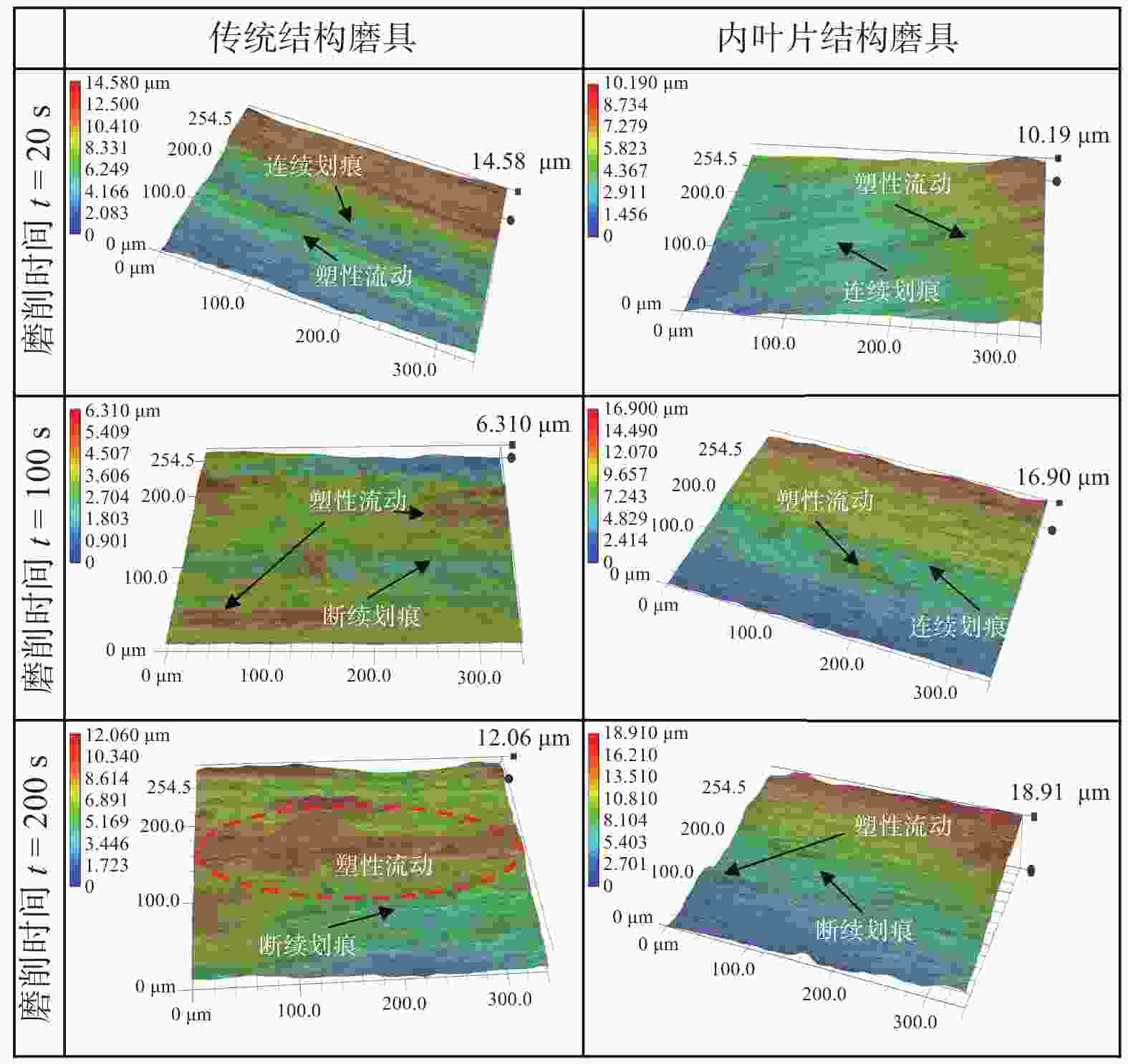

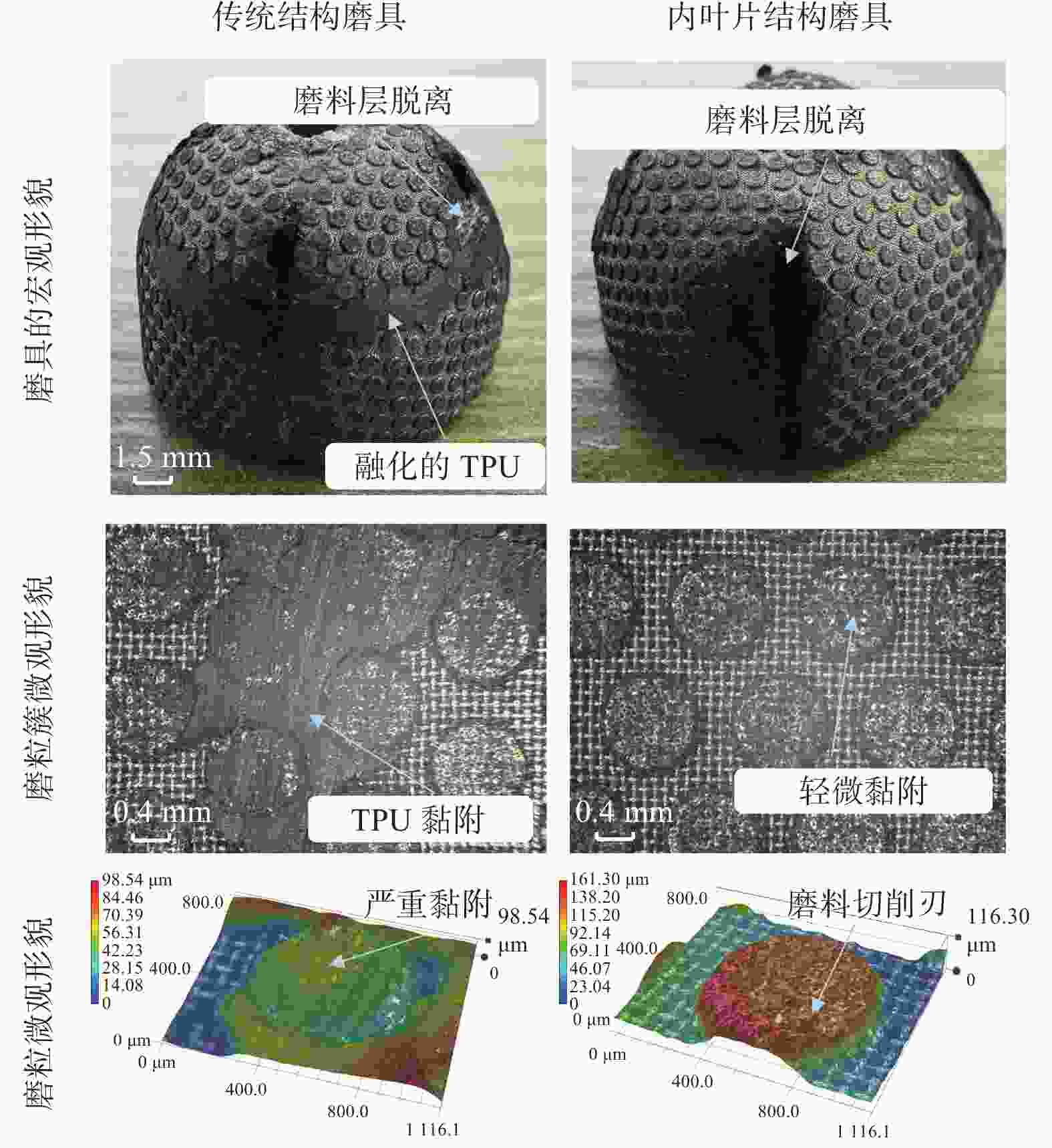

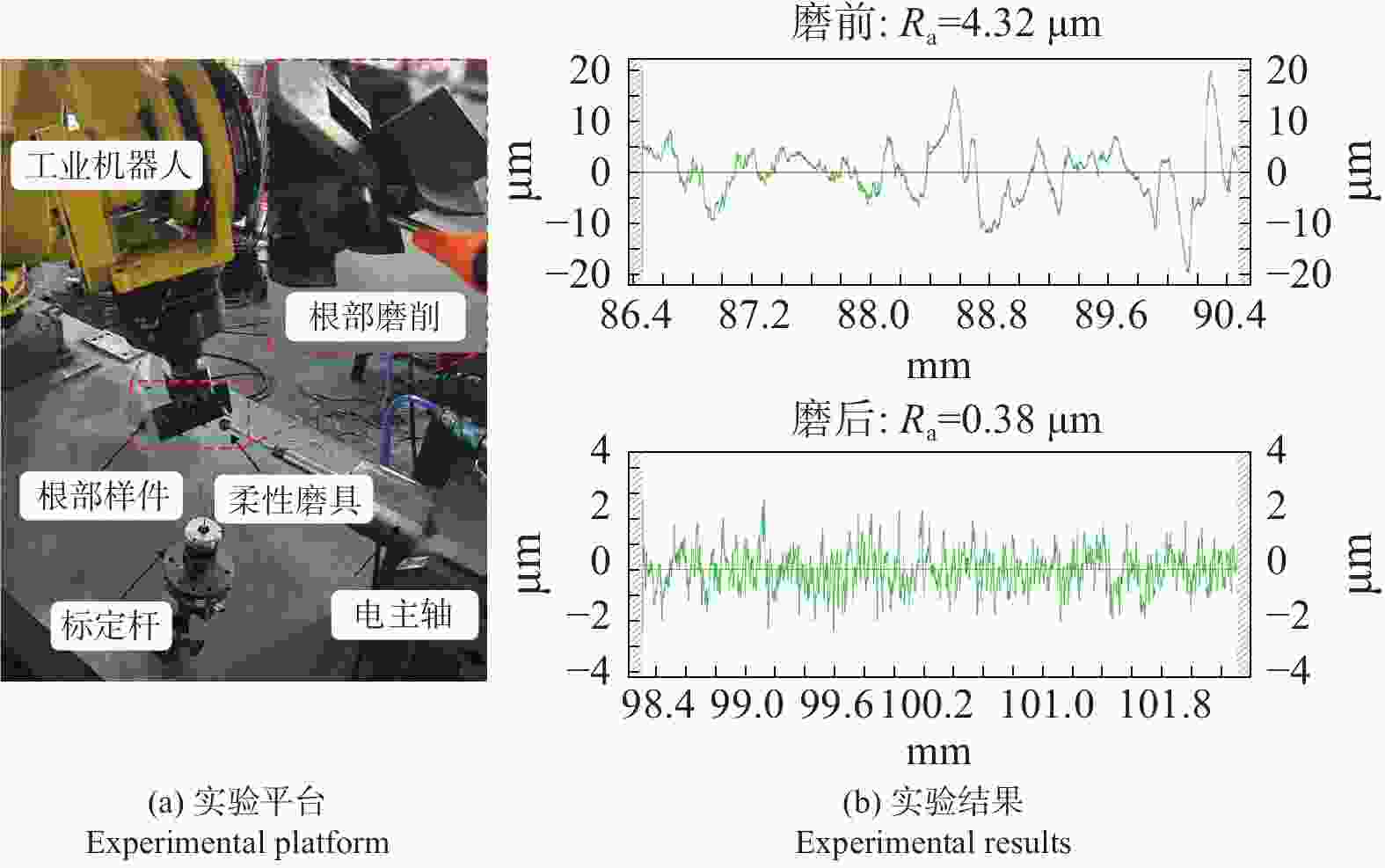

Objectives The difficulty in machining complex structural components such as aircraft engine blade roots is a common problem in the precision machining industry, and the stability of grinding tool performance is crucial for achieving automated machining. In a narrow processing space, due to the poor thermal stability of flexible materials themselves, the accumulation of grinding heat can reduce the service life and grinding performance of the grinding tool, becoming a key factor in the decrease of precision in automated processing of complex structural components. Therefore, an enhanced blade heat conduction structure is introduced into the ball-end grinding tool to improve the heat conduction performance of the grinding tool and increase its service life and application performance. Methods Through fluid dynamics simulation, the influences of the rotation direction, the rotation speed of the grinding tool, and the flow rate of external cold air on the flow field, temperature field, pressure field of the grinding tool are studied. A flexible grinding tool substrate with a complex internal structure is prepared using multi-layer melt spraying technology, and an adhesive grinding tool with a sandwich structure is designed to ensure precise and tight adhesion between the abrasive layer and the ball-head grinding tool substrate. The processing trajectory programmed by industrial robots is adopted to conduct an automated processing of titanium alloy plates for 200 s. The grinding performance differences between the designed grinding tools and the traditional structural grinding tools are compared through indicators such as grinding temperature, surface roughness, and cumulative material removal depth. Meanwhile, through the analysis of the microscopic morphology of the grinding surface of titanium alloy and the wear of the grinding tool, the internal mechanism of the designed grinding tool in improving the continuous grinding performance is clarified. Results When the grinding tool with an enhanced heat transfer mechanism rotates counterclockwise, the external fluid is introduced into the inner cavity of the grinding tool, forming a significant vortex. Meanwhile, the blade structure helps enhance the convection of gas in the inner cavity to achieve heat exchange. Moreover, the external fluid is blown at high speed towards the cavity near the outer side of the inner wall, forming a high-pressure area, which further promotes heat transfer. The grinding tools with an internal blade structure have a stronger cooling capacity at higher rotational speeds, and the surface temperature is lower than 170 ℃ when the rotational speed is 14000 r/min. However, the cooling effect of the grinding tools with traditional structures is relatively weak as the rotational speed increases. When the rotational speed is14000 r/min, the surface temperature is still higher than 180 ℃. As the flow of external cold air increases, more cold air is drawn into the interior of the grinding tool blade structure, bringing a stronger heat transfer effect, improving the cooling utilization rate and reducing the temperature of the grinding tool. The grinding temperature of traditional solid-structured grinding tools is the highest, exceeding 140 ℃ between 55 and 100 s. The strong accumulation of local grinding heat causes the flexible material to melt and adhere to the surface of the grinding tool, hindering its material removal. Therefore, the material removal capacity of traditional solid-structured grinding tools drops sharply after 140 s. In addition, there are significant fluctuations in the surface roughness of the workpiece grinding. The annular adhesion phenomena are observed on the surface of traditional structural grinding tools. The main failure mode of the internal blade structure grinding tool is the stripping of the abrasive layer. Its enhanced heat conduction structure can effectively achieve heat exchange between cold air and local high temperature in the grinding area, thereby alleviating the adhesion of the flexible substrate.Conclusions The formation, propagation and dissipation of vortices inside the grinding tool promote the improvement of heat conduction efficiency, thereby enabling the designed flexible grinding tool to achieve higher heat conduction performance and grinding effect. In addition, as the grinding speed increases, the temperature uniformity on the surface and inside the grinding tool is improved. The grinding tools with an internal blade structure maintain a relatively stable grinding temperature and material removal capacity during continuous grinding, as well as good surface quality of the workpiece. -

表 1 磨削过程参数

Table 1. Parameters of experiment process

参数 类型或取值 金刚石磨料粒度代号 M36/54 转速 n / (r·min−1) 9000 进给速度 Vw / (mm·s−1) 0.3 法向力 Fn / N 5 工件材料 TC4, HRC 30 -

[1] 段继豪, 安佳乐, 吴卓繁, 等. 航发叶片砂碟磨削接触特性及材料去除机理 [J]. 机械工程学报, 2023, 59(17): 349-360. doi: 10.3901/JME.2023.17.349DUAN Jihao, AN Jiale, WU Zhuofan, et al. Contact characteristics and material removal mechanism of abrasive disc grinding of aero-engine blade [J]. Journal of Mechanical Engineering, 2023, 59(17): 349-360. doi: 10.3901/JME.2023.17.349 [2] LIU M, LI C, YANG M, et al. Mechanism and enhanced grindability of cryogenic air combined with biolubricant grinding titanium alloy[J]. Tribology International, 2023, 187: 108704. [3] LI M, HUANG Y, WANG W, et al. A novel 3D printed compliant ball-end grinding tool with crystal structure: Feasibility and performance analysis [J]. Materials & Design, 2024, 237: 112591. doi: 10.1016/j.matdes.2023.112591 [4] PUŠAVEC F, GRGURAŠ D, KOCH M, et al. Cooling capability of liquid nitrogen and carbon dioxide in cryogenic milling [J]. CIRP Annals, 2019, 68(1): 73-76. doi: 10.1016/j.cirp.2019.03.016 [5] 钱宁, 徐九华, 傅玉灿, 等. 面向绿色高效磨削的振荡热管砂轮磨削温度与强化传热分析 [J]. 机械工程学报, 2022, 58(15): 105-120. doi: 10.3901/JME.2022.15.105QIAN Ning, XU Jiuhua, FU Yucan, et al. Investigation on grinding temperature and heat transfer performance of oscillating grinding wheel for high-efficient green grinding [J]. Journal of Mechanical Engineering, 2022, 58(15): 105-120. doi: 10.3901/JME.2022.15.105 [6] XIANG X, YU J, MEI C, et al. An internal cooling grinding wheel: From design to application [J]. Chinese Journal of Aeronautics, 2023, 36(11): 465-482. doi: 10.1016/j.cja.2023.02.024 [7] GHEYNANI A R, AKBARI O A, ZARRINGHALAM M, et al. Investigating the effect of nanoparticles diameter on turbulent flow and heat transfer properties of non-Newtonian carboxymethyl cellulose/CuO fluid in a microtube [J]. International Journal of Numerical Methods for Heat & Fluid Flow, 2018, 29(5): 1699-1723. doi: 10.1108/hff-07-2018-0368 [8] GHETAN S, RAO P V. Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy [J]. Journal of Cleaner Production, 2019, 231: 1036-1049. doi: 10.1016/j.jclepro.2019.05.196 [9] REDDY P P, GHOSH A. Some critical issues in cryo-grinding by a vitrified bonded alumina wheel using liquid nitrogen jet [J]. Journal of Materials Processing Technology, 2016, 229: 329-337. doi: 10.1016/j.jmatprotec.2015.09.040 [10] QIAN N, JIANG F, MARENGO M, et al. Thermal performance of a radial-rotating oscillating heat pipe and its application in grinding processes with enhanced heat transfer [J]. Applied Thermal Engineering, 2023, 233: 121213. doi: 10.1016/j.applthermaleng.2023.121213 [11] TONG J, PENG R, SONG Q. A Cu-based ceramic porous abrasive ring with phyllotactic pattern in internal cooling grinding of Inconel 718 [J]. Journal of Materials Processing Technology, 2023, 315: 117890. doi: 10.1016/j.jmatprotec.2023.117890 [12] PENG R, TONG J, TANG X, et al. Application of a pressurized internal cooling method in grinding inconel 718: Modeling-simulation and testing-validation [J]. International Journal of Mechanical Sciences, 2021, 189: 105985. doi: 10.1016/j.ijmecsci.2020.105985 [13] MIZUTANI T, SATAKE U, ENOMOTO T. A study on a cooling method for bone grinding using diamond bur for minimally invasive surgeries [J]. Precision Engineering, 2021, 70: 155-163. doi: 10.1016/j.precisioneng.2021.01.010 [14] LAN J, ZHANG Z, LIANG X, et al. Experimental and numerical investigation on thermal performance of data center via fan-wall free cooling technology [J]. Applied Thermal Engineering, 2023, 228: 120467. doi: 10.1016/j.applthermaleng.2023.120467 [15] PENG C C, CHEN T Y. A recursive low-pass filtering method for a commercial cooling fan tray parameter online estimation with measurement noise [J]. Measurement, 2022, 205: 112193. doi: 10.1016/j.measurement.2022.112193 [16] GALLONI E, PARISI P, MARIGNETTI F, et al. CFD analyses of a radial fan for electric motor cooling [J]. Thermal Science and Engineering Progress, 2018, 8: 470-476. doi: 10.1016/j.tsep.2018.10.003 [17] ZHONG X L, CHAN K C, FU S C, et al. Enhancement of piezoelectric fan cooling by geometrical arrangements [J]. International Journal of Heat and Mass Transfer, 2022, 199: 123479. doi: 10.1016/j.ijheatmasstransfer.2022.123479 [18] AMER M. A novel bionic impeller for laptop cooling fan system [J]. Results in Engineering, 2023, 20: 101558. doi: 10.1016/j.rineng.2023.101558 [19] CHOUDHARY M, MUKHERJEE S, KUMAR P. Analysis and optimization of geometry of 3D printer part cooling fan duct [J]. Materials Today: Proceedings, 2022, 50: 2482-2487. doi: 10.1016/j.matpr.2021.10.444 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS