Study on performance of brazed micronized diamond grinding head

-

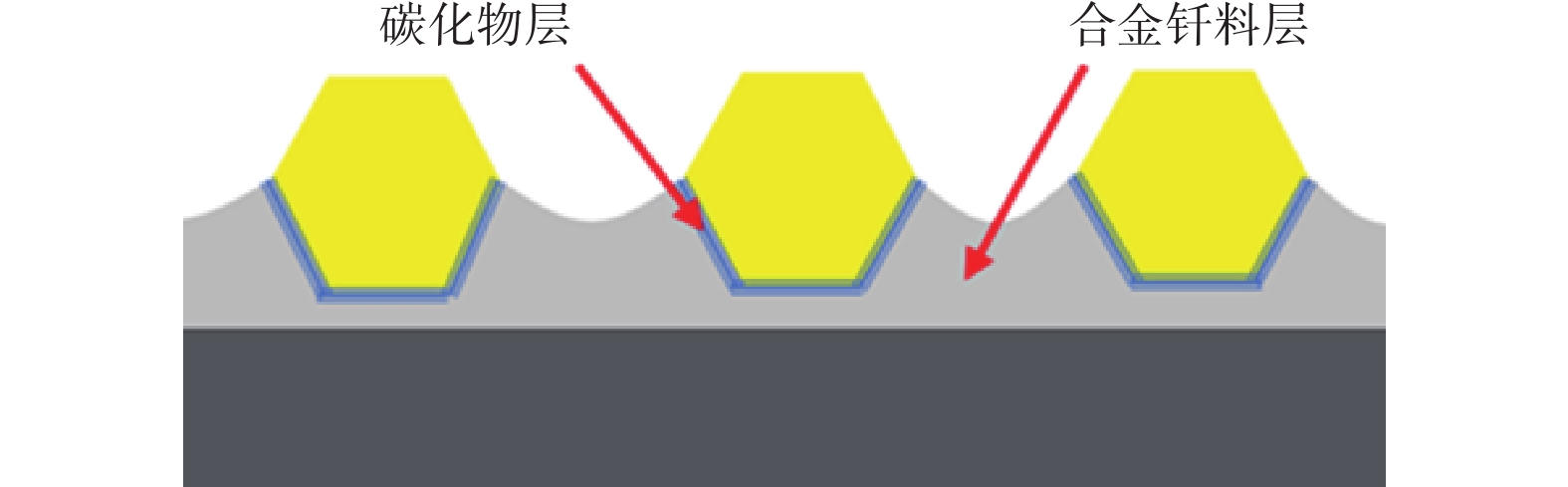

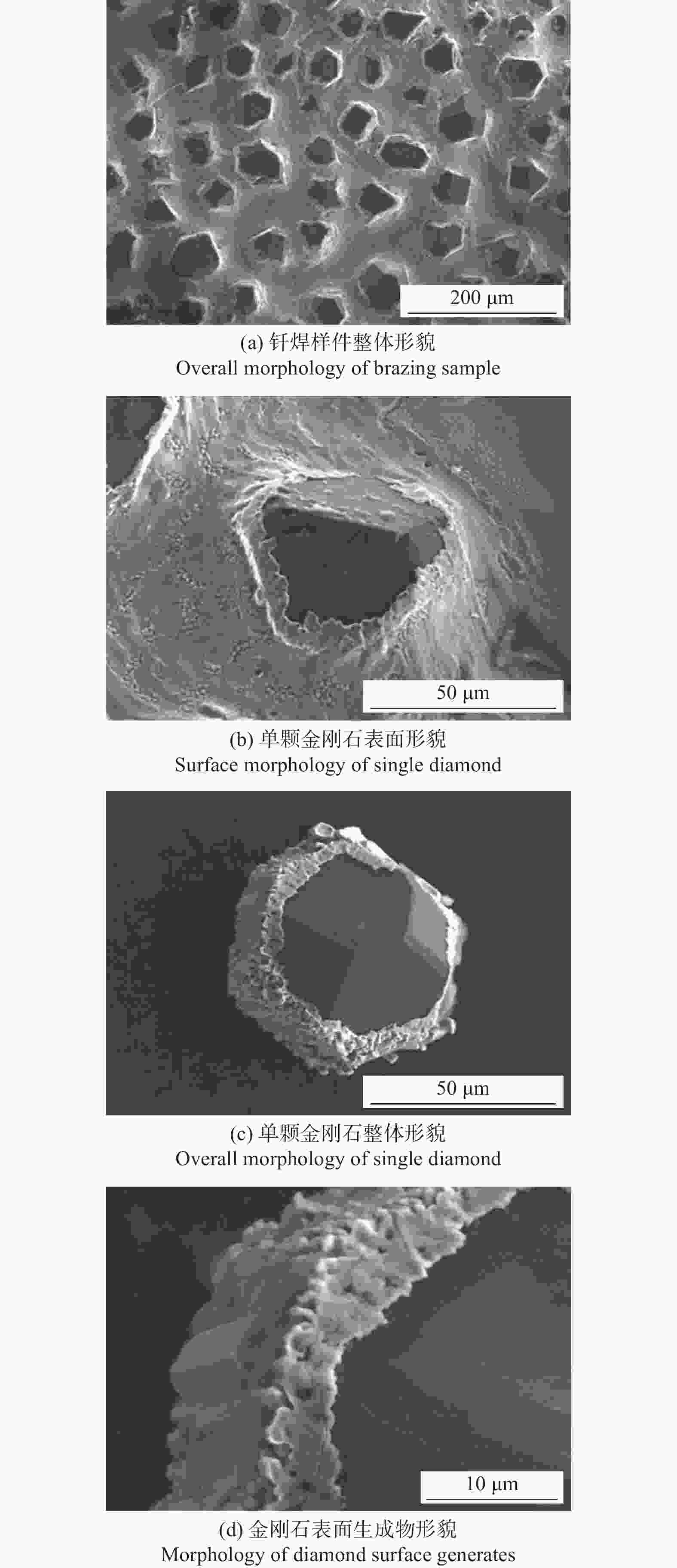

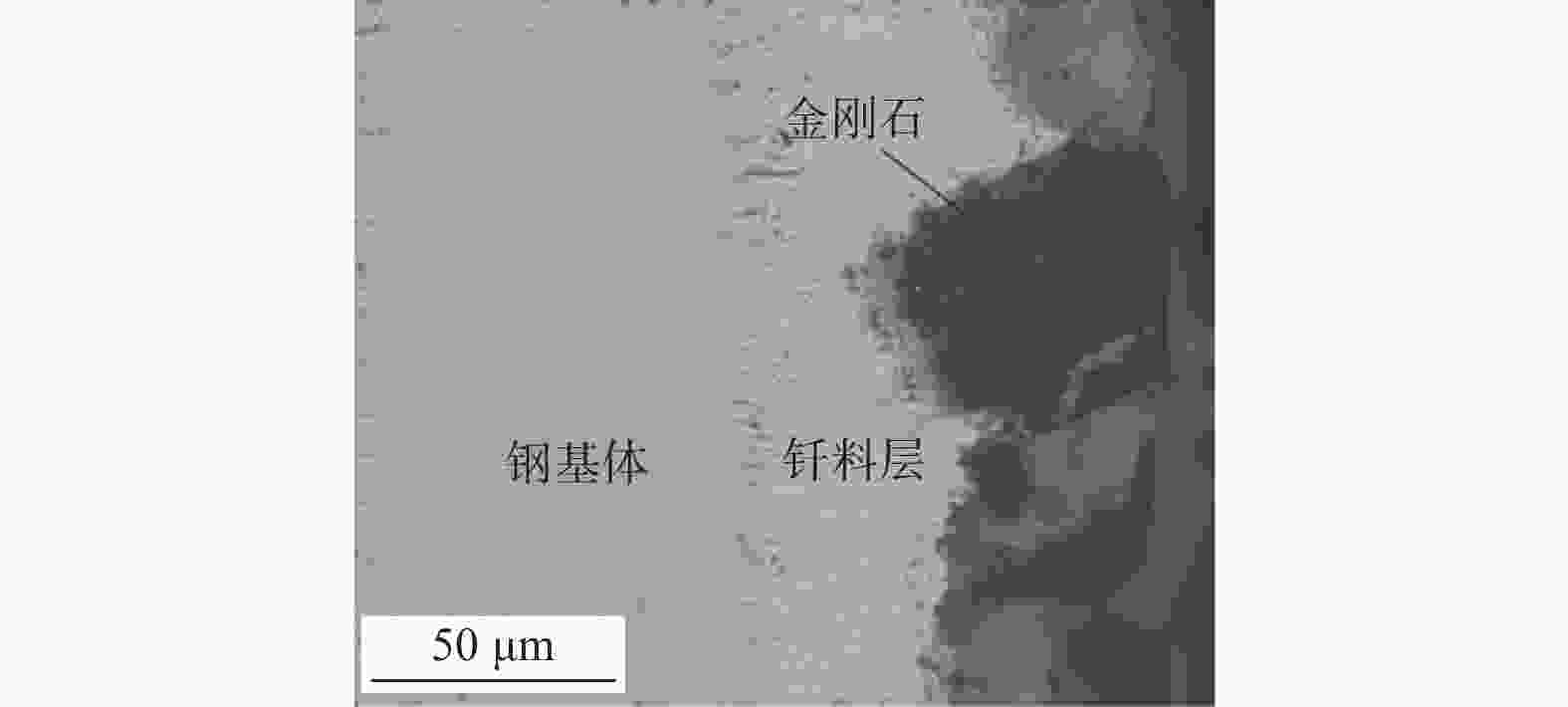

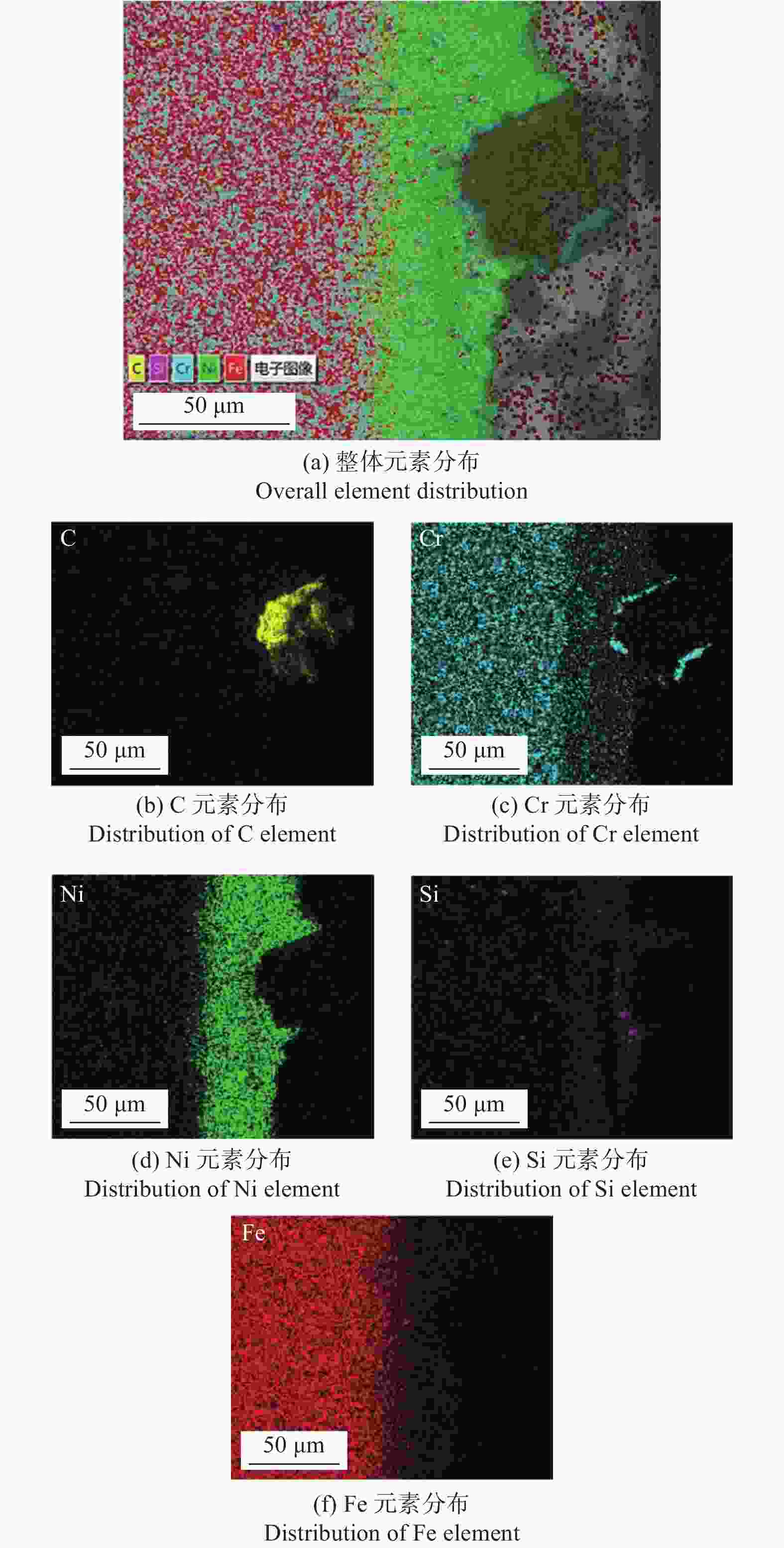

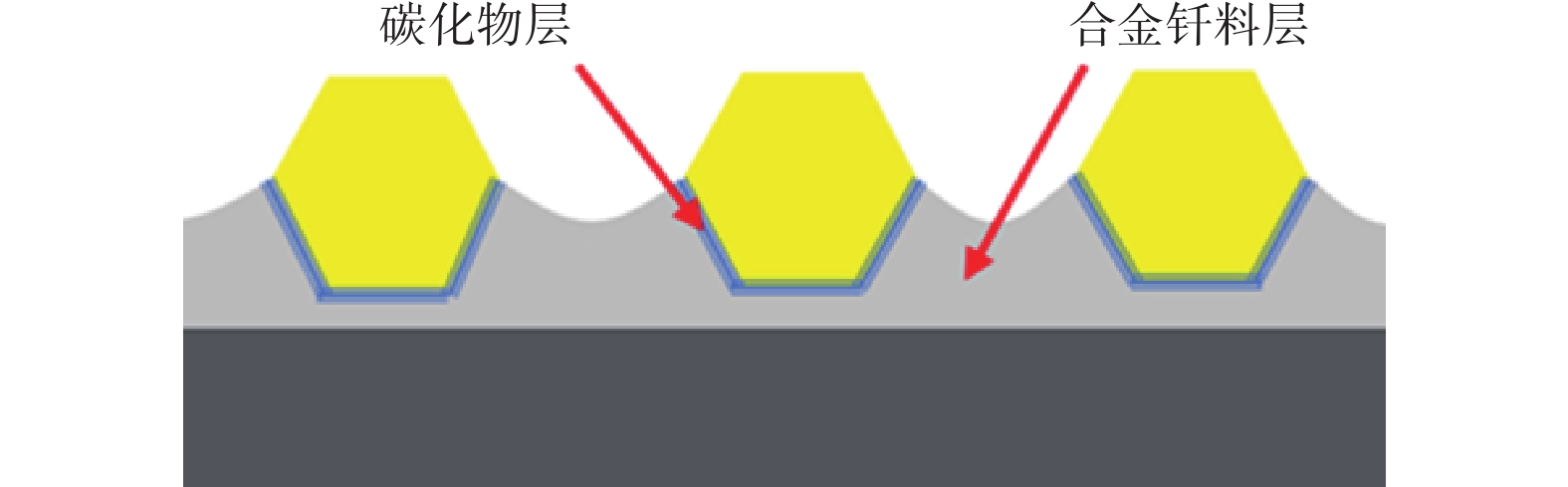

摘要: 为解决钎焊过程中微粉金刚石磨粒损伤严重、钎料与基体结合不牢的问题,采用合适的钎焊工艺在钢基体上钎焊微粉金刚石(325/400#),分析钎焊样件结合界面并制备磨头对氧化铝陶瓷板进行加工。研究发现:微粉金刚石磨粒损伤较小;钢基体与钎料结合界面生成物为Fe、Cr形成的γ相固溶体及Fe、Ni形成的Ni-Fe置换固溶体,固溶体的存在可保证钎料与基体之间的牢固结合;制备的钎焊微粉金刚石磨头在加工陶瓷板时拥有较长的使用寿命。Abstract:

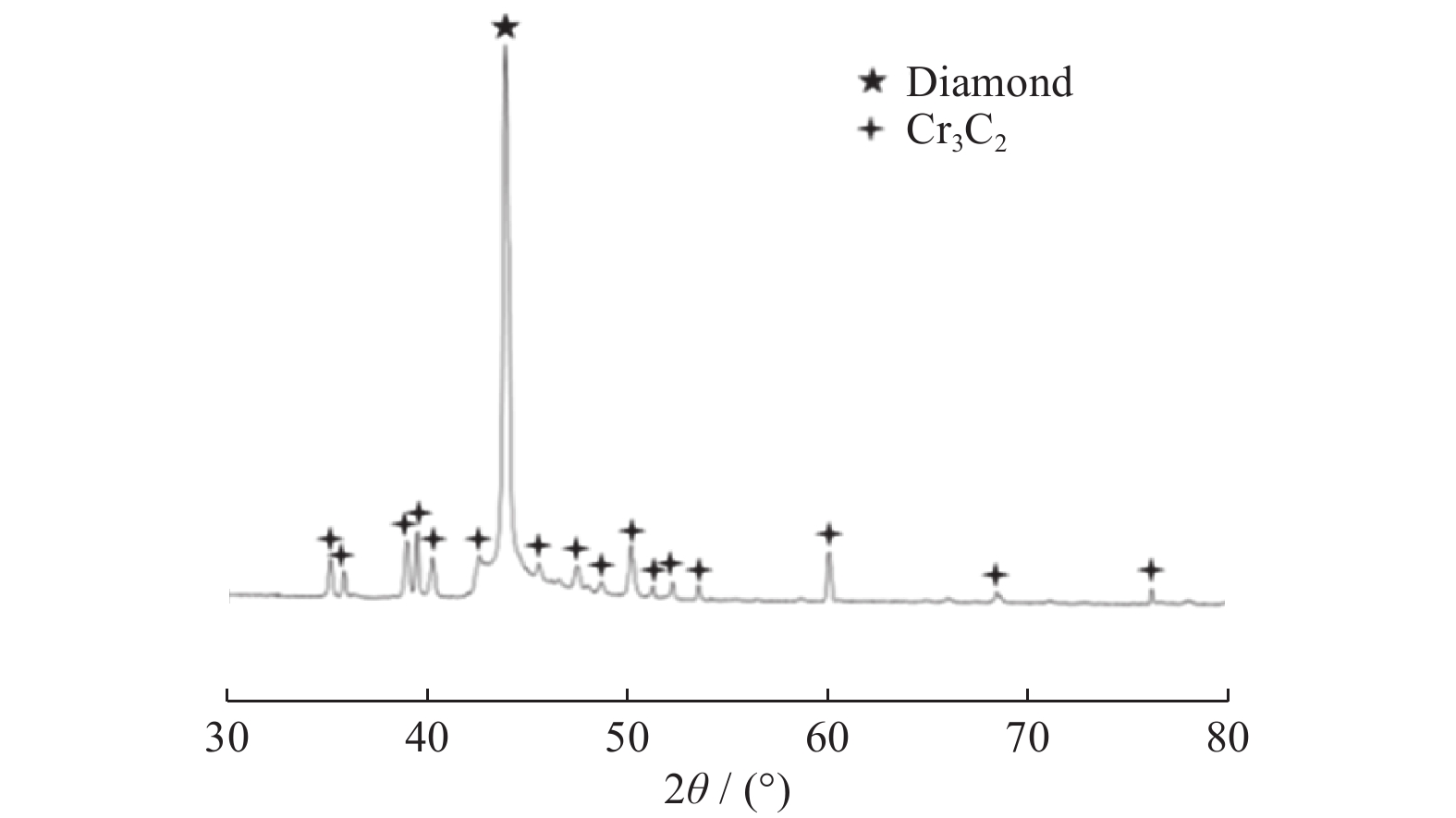

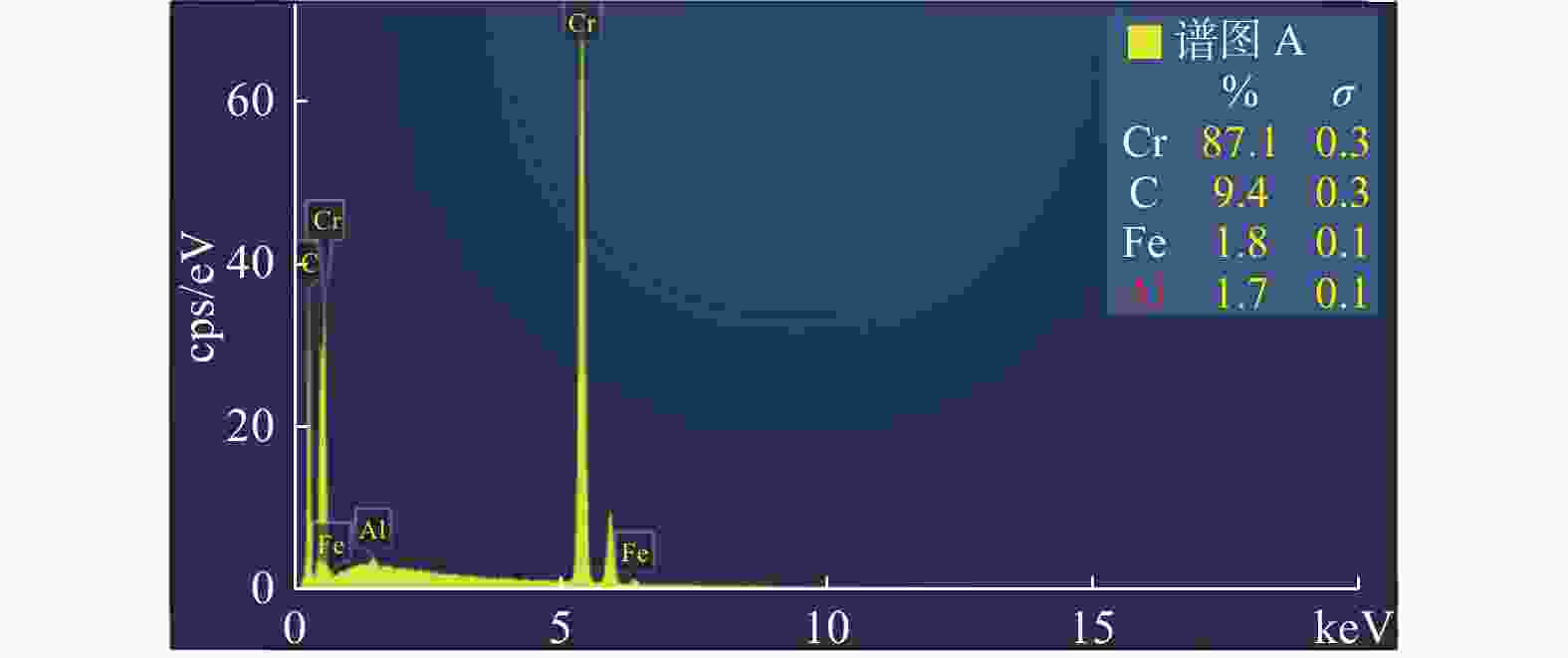

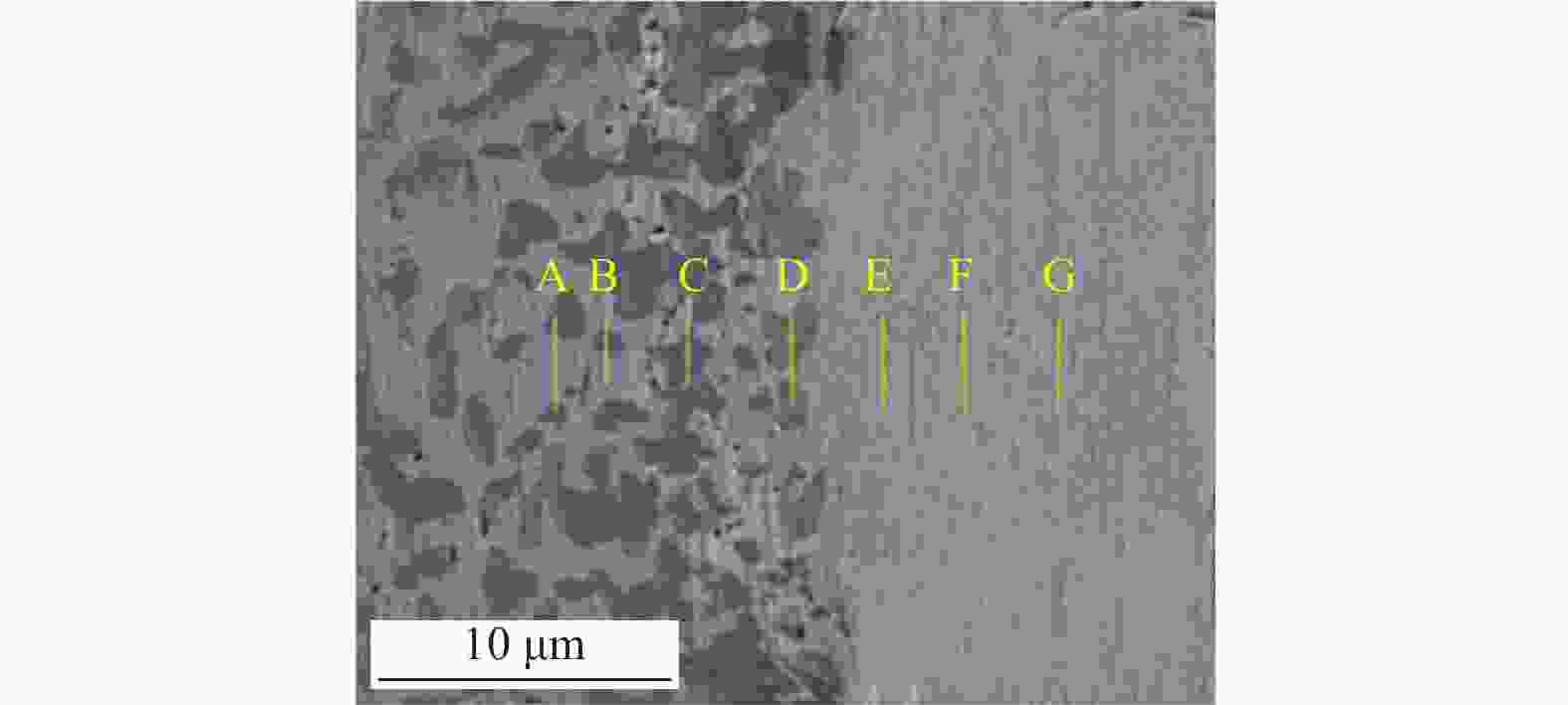

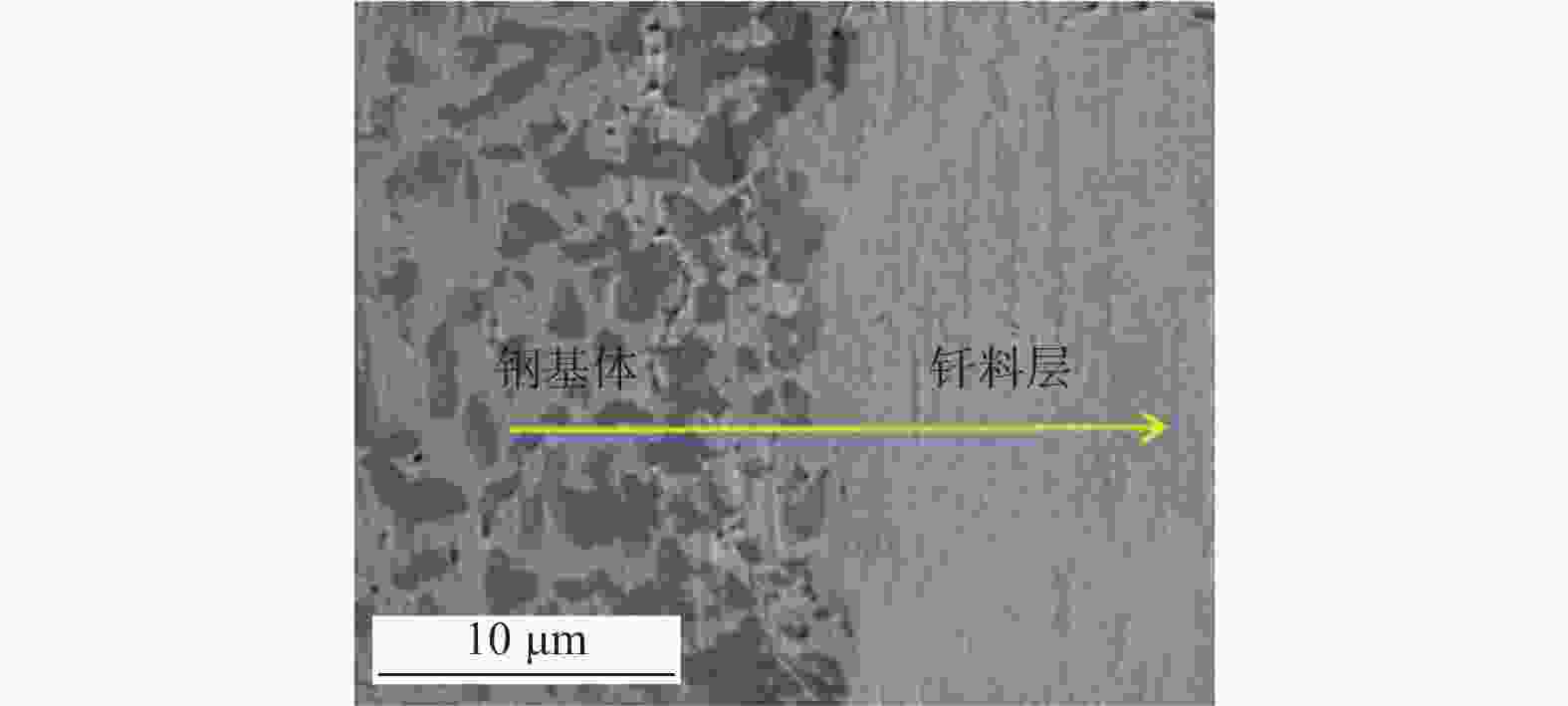

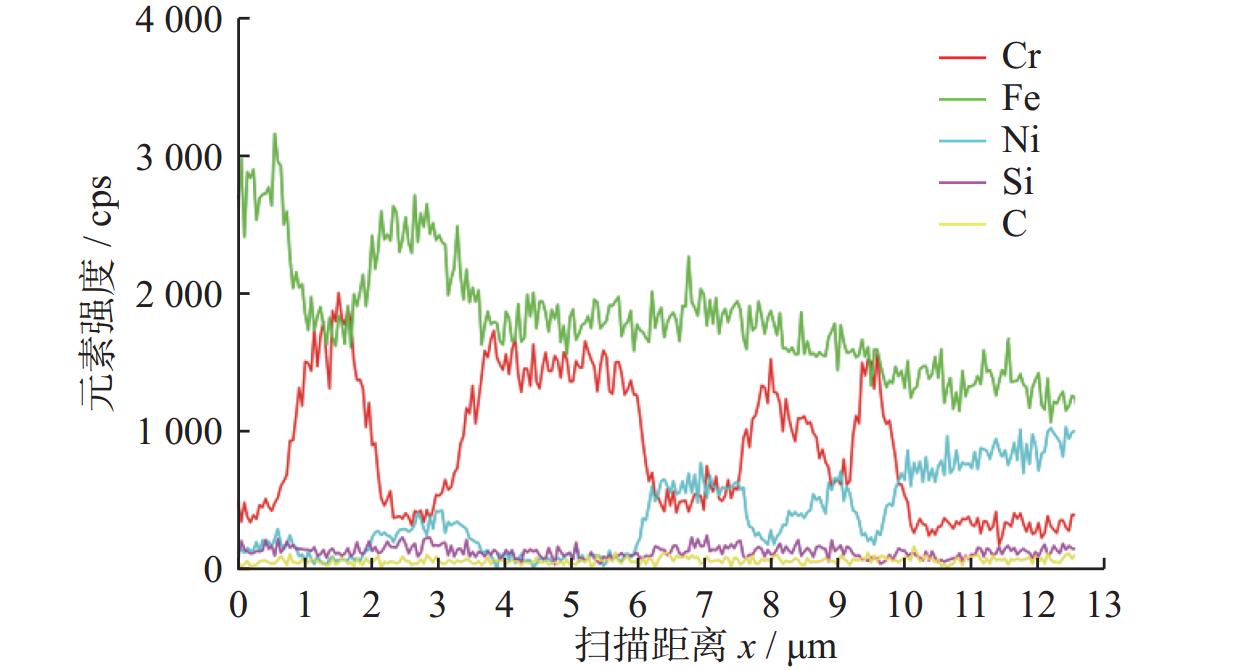

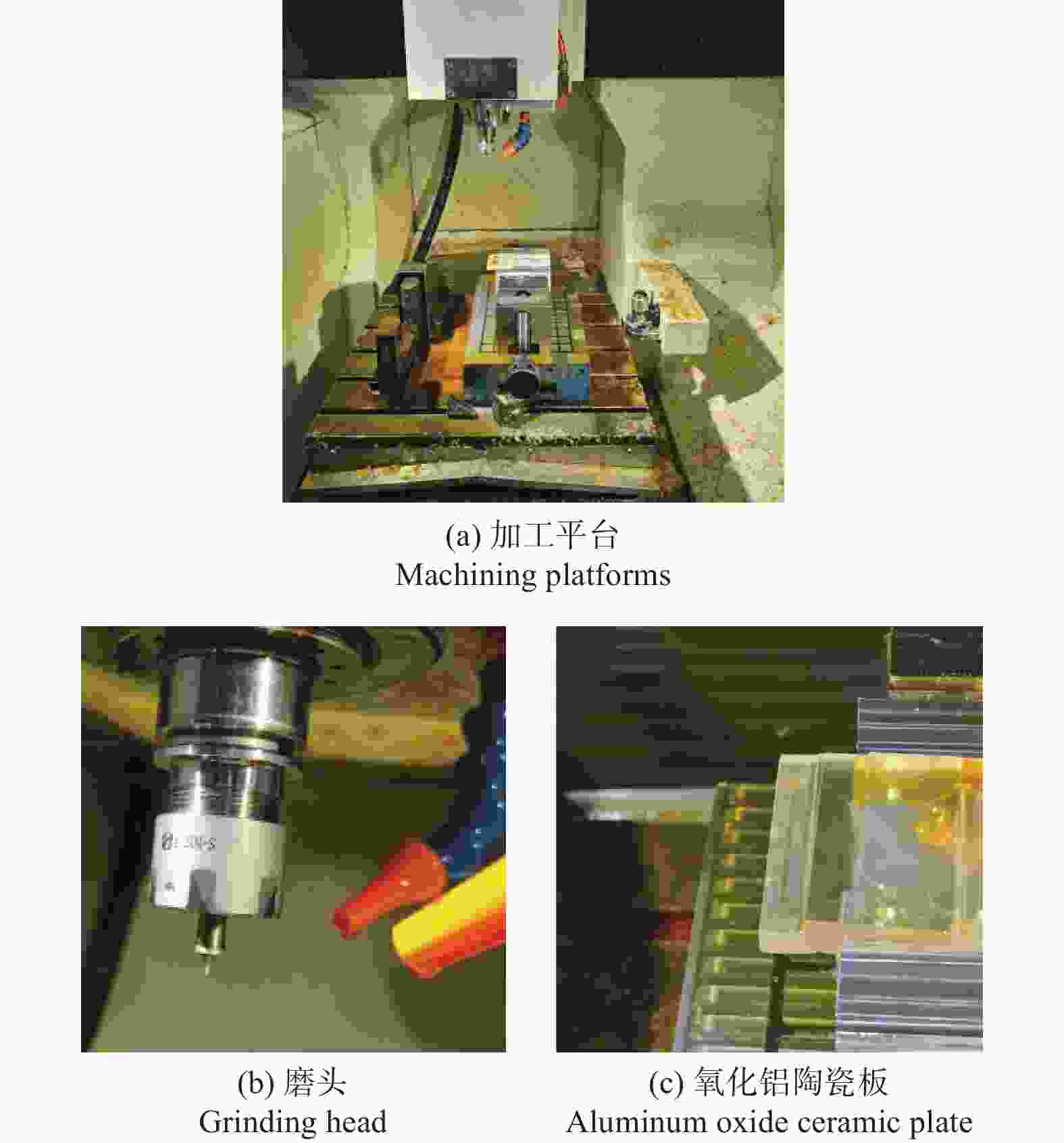

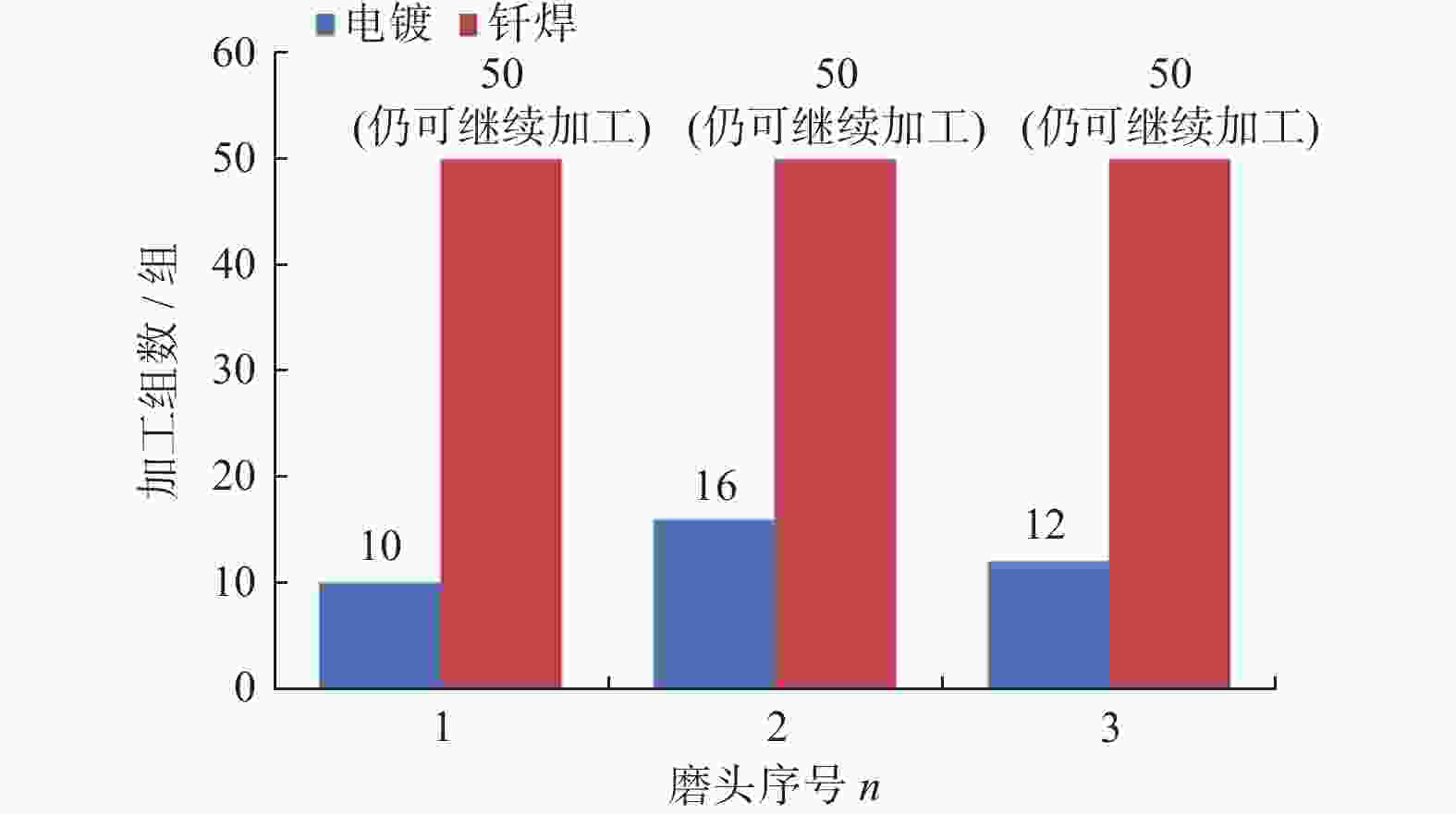

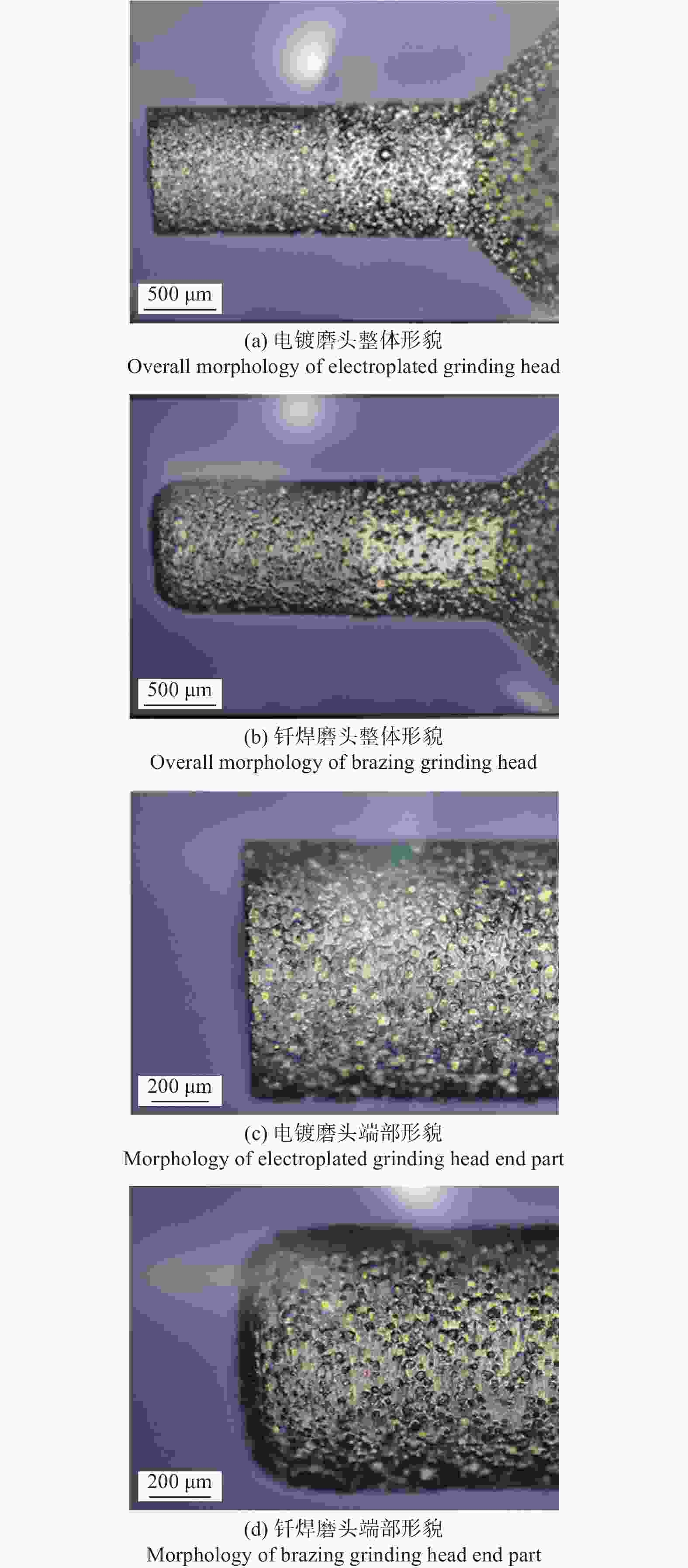

Objectives The use of brazing micro-powder diamond tools can achieve high-precision and efficient processing of ceramic materials. However, there are currently problems such as thin brazing layers, large abrasive damage during brazing, and poor bonding between the brazing material and the base metal. Current research has not been able to analyze the brazing effect from the micro-interface. Methods Brazing samples are prepared, and the surface morphology and the morphology of diamond abrasive particles and surface products are observed with a scanning electron microscope (SEM). The phases of the compounds on diamond are analyzed with an X-ray diffractometer. The cross-sectional structure of the brazing samples are observed with the backscattered electron imaging mode of SEM. The elemental composition of the bonding interface of the brazing samples is analyzed with an energy dispersive spectrometer (EDS). A grinding head is prepared to machine an alumina ceramic plate on a JDHGT type engraving machine, and it is compared with an electroplated grinding head. Results The exposure height of the micro-diamond abrasive is reasonable with no accumulation. The diamond is not over-consumed, and a plate-like Cr3C2 is generated on the diamond surface. There is sufficient elemental diffusion between the brazing alloy and the base metal. Products at the interface between the steel substrate and the brazing alloy are a γ-phase solid solution formed by Cr and Fe, and a Ni-Fe substitutional solid solution by Fe and Ni, which ensures a firm combination between the brazing alloy and the base metal. Conclusions The life of the brazed micro-diamond head is three times longer than that of the electroplated grinding head. The situation of abrasive particle breakage and shedding in the brazed grinding head is less, and there is no phenomenon of brazing alloy layer peeling. This proves that the brazing effect of micro-diamond is better, and the method of processing ceramics with brazed micro-diamond tools is feasible. -

Key words:

- brazing /

- micronized diamond /

- abrasive grain damage /

- interfacial analysis

-

表 1 BNi-2合金钎料组分

Table 1. Components of Ni-based BNi-2 alloy filler

成分 质量分数 ω / % 镍 (Ni) 83 铬 (Cr) 7 铁 (Fe) 4 硅 (Si) 3 硼 (B) 3 表 2 钎焊样件点扫描结果

Table 2. Point-scanning results of brazing sample

% 位置 Fe Ni Cr Si C A 67.50 2.86 29.02 0.28 0.34 B 75.84 15.91 7.28 0.65 0.32 C 66.75 3.26 29.36 0.27 0.36 D 61.27 5.78 32.34 0.27 0.34 E 40.93 52.36 5.31 1.05 0.35 F 30.60 62.53 5.33 1.16 0.38 G 22.89 69.35 5.50 1.92 0.34 化合物类型 元素置换方式 化合物晶型 (CrFe)3C2 Fe少量置换 斜方晶 (CrFe)23C6 Fe置换量≤35% 面心立方晶 (CrFe)7C3 Fe置换量≤50% 三方晶 (CrFe)3C7 Cr置换量≤35% 斜方晶 表 4 设备加工参数

Table 4. Equipment processing parameters

参数 取值 设备转速 v / (r ·min−1) 28 000 实际进给量 f / (mm·min−1) 600 工作行程 s / mm 65 切削深度 ap / mm 1.2 -

[1] LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials [J]. Progress in Materials Science, 2021, 116: 100736. doi: 10.1016/j.pmatsci.2020.100736 [2] 王海龙, 张国军. 新型高熵陶瓷材料 [J]. 硅酸盐学报, 2022, 50(6): 1455. doi: 10.7521/j.issn.2095-7645.2022.6.gsyxb202206001WANG Hailong, ZHANG Guojun. Advanced high entropy ceramics [J]. Journal of the Chinese Ceramic Society, 2022, 50(6): 1455. doi: 10.7521/j.issn.2095-7645.2022.6.gsyxb202206001 [3] WANG G C, LYU J, FANG Y, et al. Preparation of zirconia-based dental restorative materials and exploration on their wear performances on enamel/dentine [J]. Science of Advanced Materials, 2020, 12(10): 1535-1547. doi: 10.1166/sam.2020.3851 [4] HUANG H. High speed grinding of advanced ceramics: A review [J]. Key Engineering Materials, 2009, 404: 11-22. doi: 10.4028/www.scientific.net/KEM.404.11 [5] 李文霞, 张子煜. 钎焊金刚石工具的发展现状及改进研究 [J]. 热加工工艺, 2021, 50(17): 12-17. doi: 10.14158/j.cnki.1001-3814.20201129LI Wenxia, ZHANG Ziyu. Development status and improvement research of brazed diamond tools [J]. Hot Working Technology, 2021, 50(17): 12-17. doi: 10.14158/j.cnki.1001-3814.20201129 [6] 李全城, 沈剑云, 黄国钦. 微粉金刚石钎焊砂轮磨削氧化铝陶瓷的磨削力和表面粗糙度特征 [J]. 金刚石与磨料磨具工程, 2021, 41(5): 59-64. doi: 10.13394/j.cnki.jgszz.2021.5.0010LI Quancheng, SHEN Jianyun, HUANG Guoqin. Grinding force and surface roughness of alumina ceramics ground by brazed micro powder diamond wheel [J]. Diamond & Abrasives Engineering, 2021, 41(5): 59-64. doi: 10.13394/j.cnki.jgszz.2021.5.0010 [7] 卢金斌, 徐九华. Ag-Cu-Ti钎料钎焊金刚石的界面微观组织分析 [J]. 焊接学报, 2007, 28(8): 29-32,114. doi: 10.3321/j.issn:0253-360x.2007.08.008LU Jinbin, XU Jiuhua. Microstructure of interface between Ag-Cu-Ti brazing filler metal and diamond [J]. Transactions of the China Welding Institution, 2007, 28(8): 29-32,114. doi: 10.3321/j.issn:0253-360x.2007.08.008 [8] 马伯江, 王镇, 王超. 非晶Ni基合金感应钎焊微粉金刚石的研究 [J]. 硬质合金, 2020, 37(6): 417-422. doi: 10.3969/j.issn.1003-7292.2020.06.002MA Bojiang, WANG Zhen, WANG Chao. Study on induction brazing of micro-powder diamond with an amorphous Ni-based alloy [J]. Cemented Carbide, 2020, 37(6): 417-422. doi: 10.3969/j.issn.1003-7292.2020.06.002 [9] 李全城, 陈锐. 钎焊微粉金刚石磨盘磨块排布研究 [J]. 超硬材料工程, 2018, 30(3): 25-32. doi: 10.3969/j.issn.1673-1433.2018.03.007LI Quancheng, CHEN Rui. Study on the grinding blocks arrangement of the brazing micro powder diamond disc [J]. Superhard Material Engineering, 2018, 30(3): 25-32. doi: 10.3969/j.issn.1673-1433.2018.03.007 [10] 沈剑云, 尹刚刚, 姜波, 等. 微粉金刚石表面镀钛对钎焊磨具性能的影响 [J]. 中国表面工程, 2017, 30(4): 127-133. doi: 10.11933/j.issn.1007-9289.20170108002SHEN Jianyun, YIN Ganggang, JIANG Bo, et al. Effects of titanium coating of micro-powder diamond on properties of brazed abrasive grit tools [J]. China Surface Engineering, 2017, 30(4): 127-133. doi: 10.11933/j.issn.1007-9289.20170108002 [11] CORRIGAN F R, BUNDY F P. Direct transitions among the allotropic forms of boron nitride at high pressures and temperatures [J]. The Journal of Chemical Physics, 1975, 63(9): 3812-3820. doi: 10.1063/1.431874 [12] 杨志波, 徐九华, 傅玉灿, 等. 钢基体上镍基钎料激光钎焊金刚石磨粒的界面结构 [J]. 机械工程材料, 2007, 31(5): 17-19,23. doi: 10.3969/j.issn.1000-3738.2007.05.005YANG Zhibo, XU Jiuhua, FU Yucan, et al. Microstructure of laser brazed diamond grits [J]. Materials for Mechanical Engineering, 2007, 31(5): 17-19,23. doi: 10.3969/j.issn.1000-3738.2007.05.005 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS