Preliminary investigation of dry tribochemical mechanical polishing of single crystal SiC substrates

-

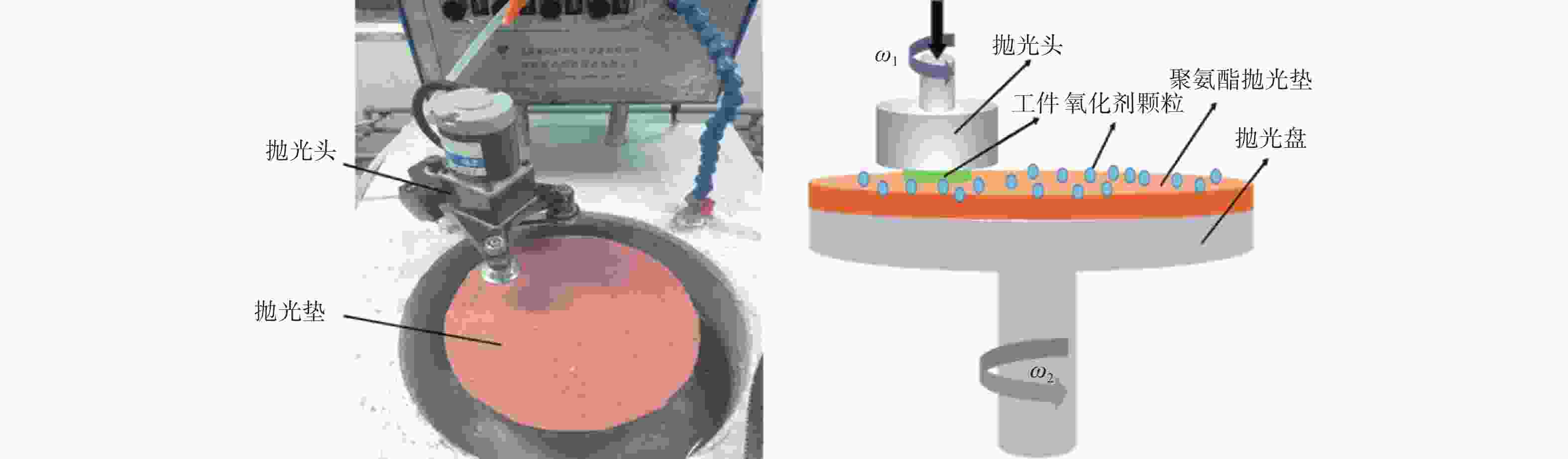

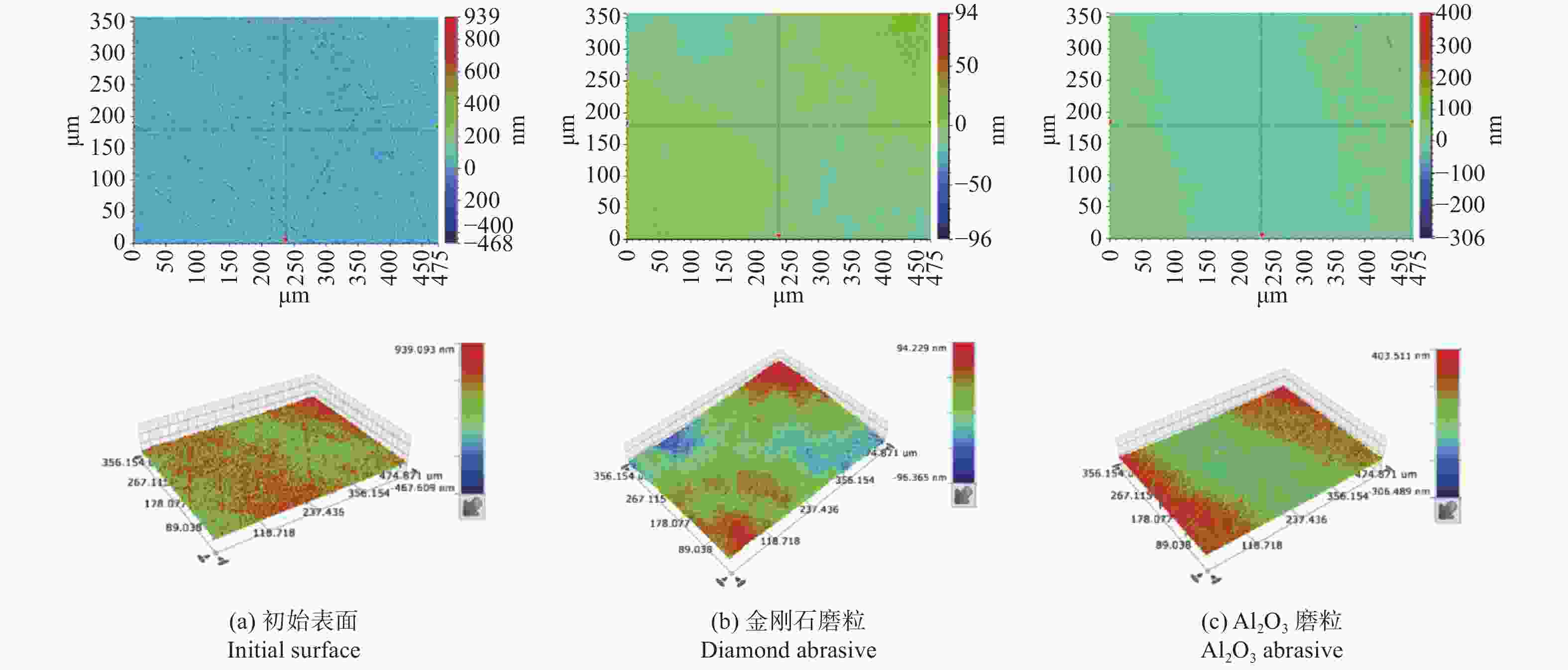

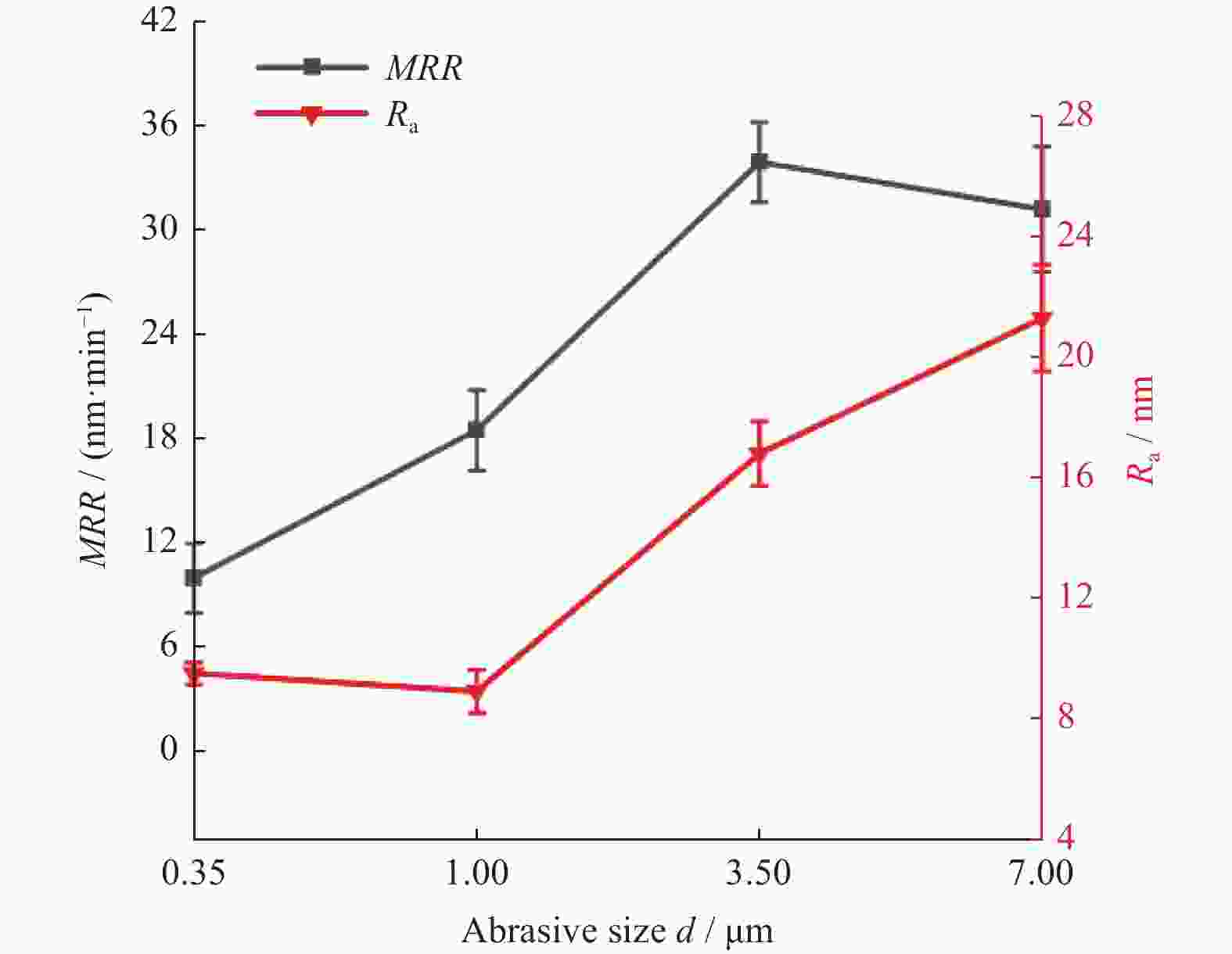

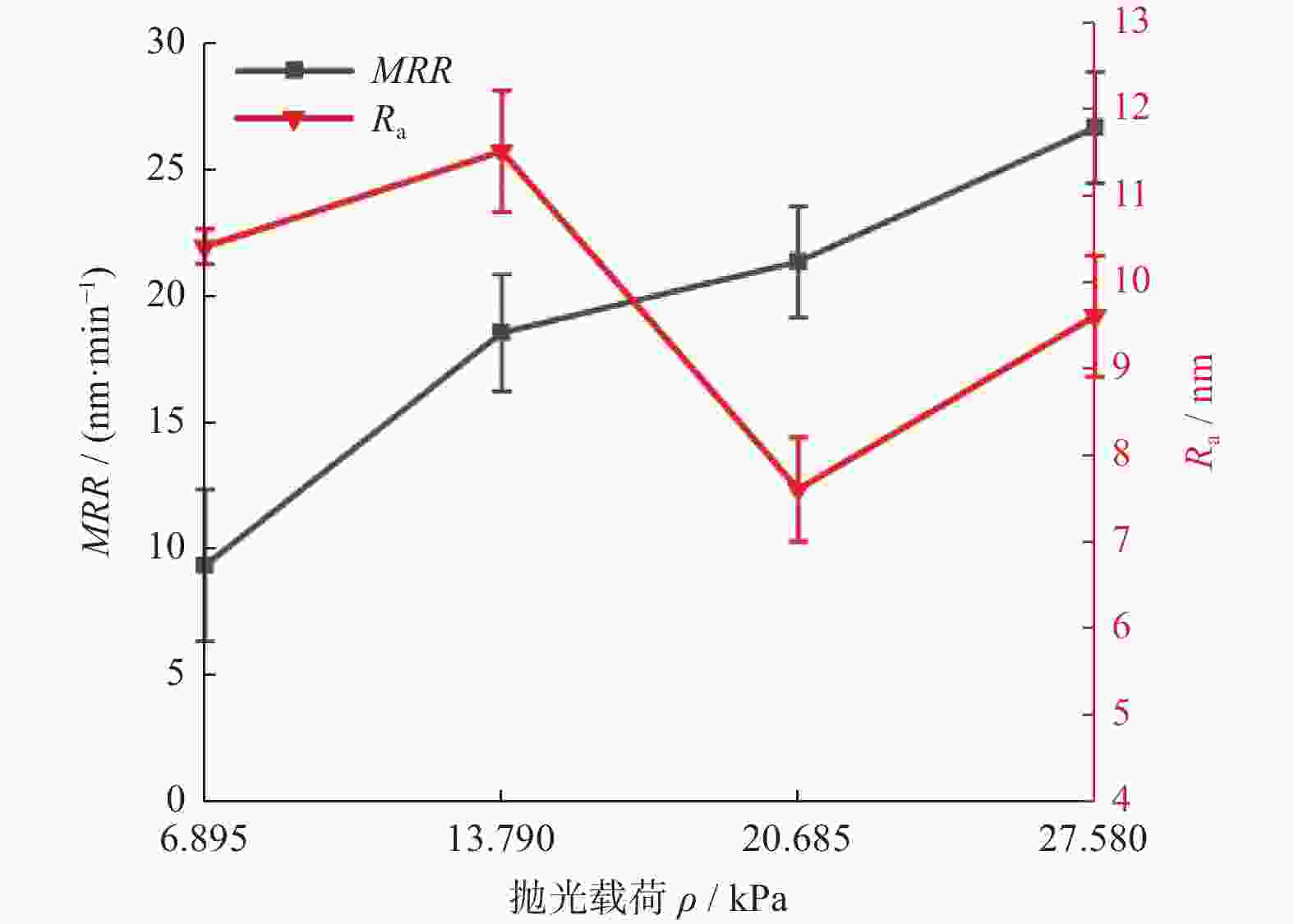

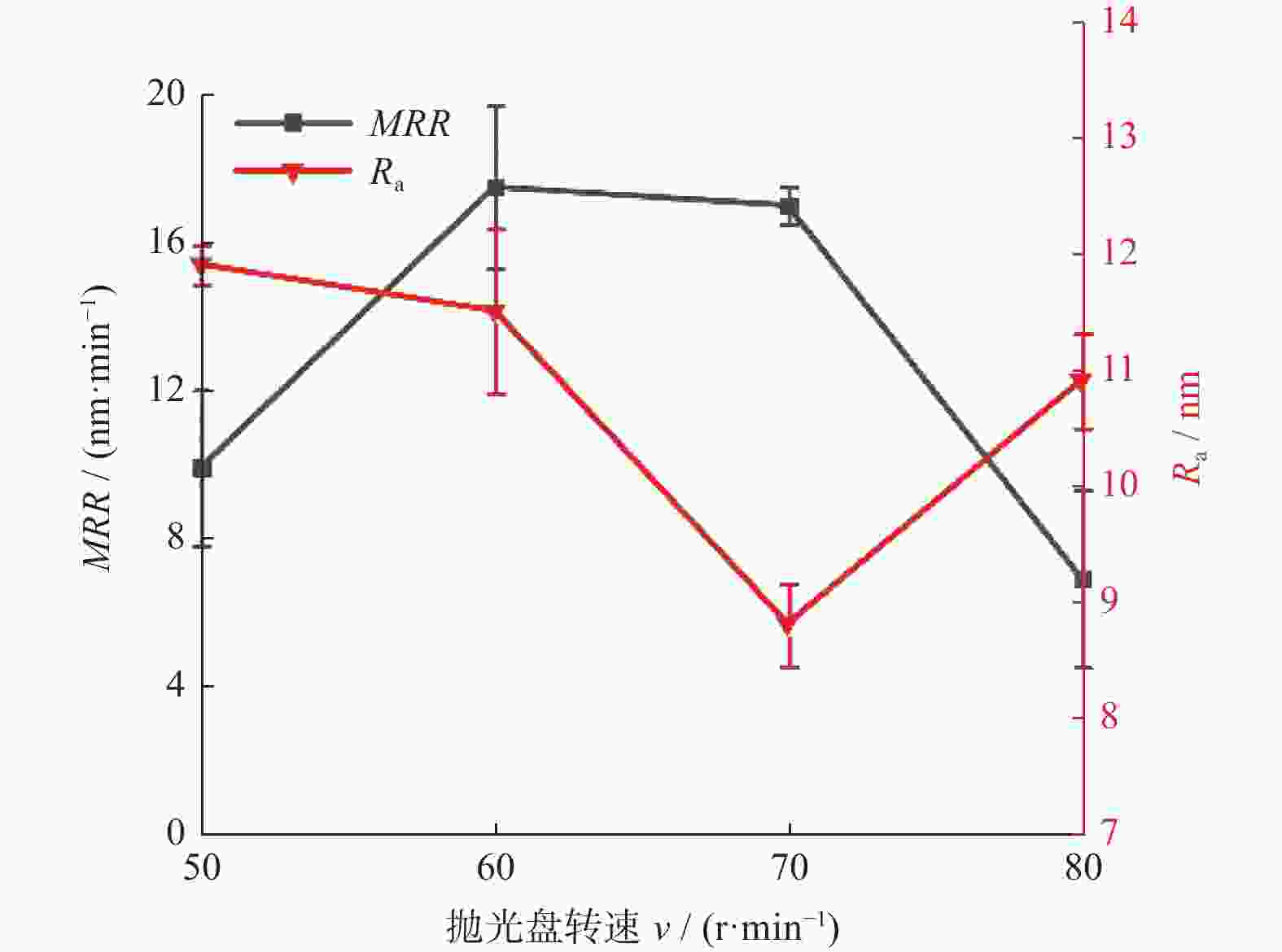

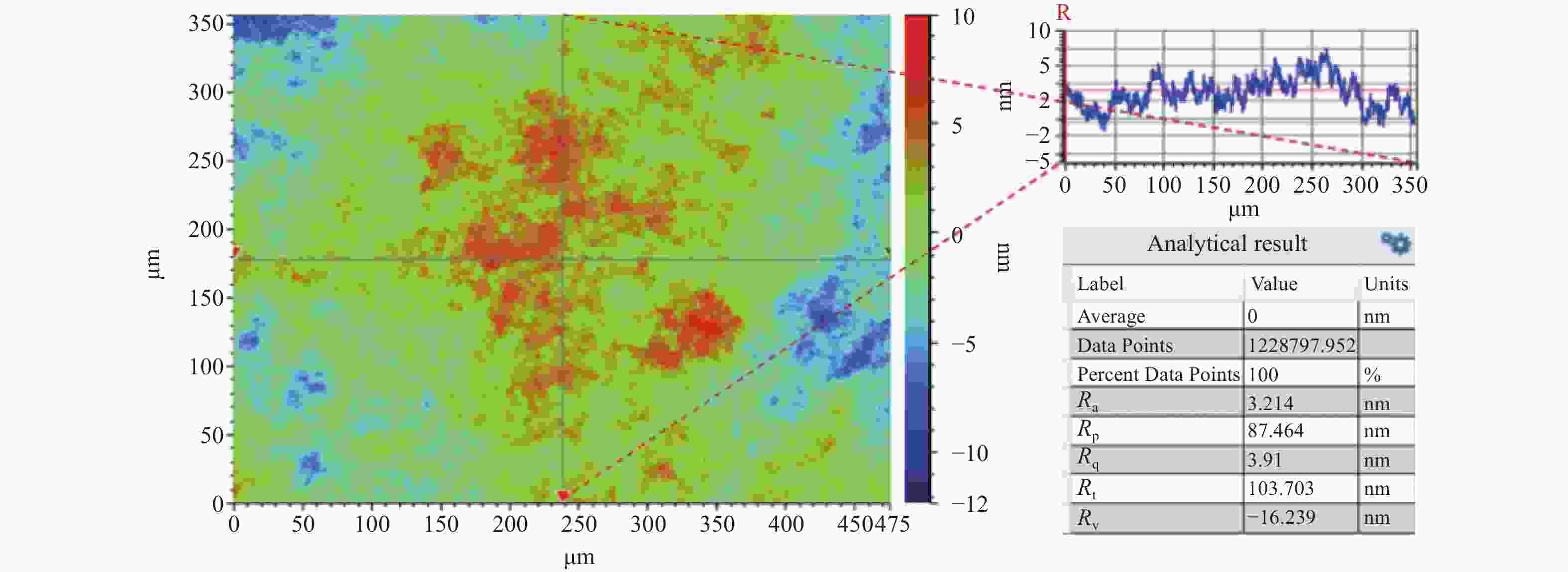

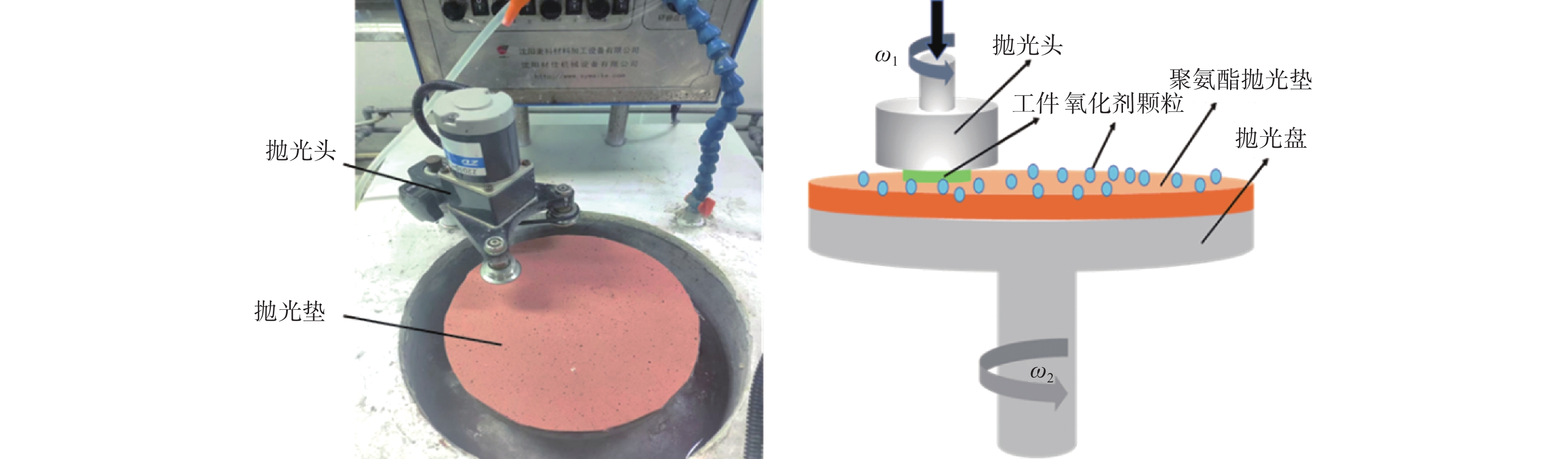

摘要: 针对碳化硅(SiC)基片在抛光过程中效率低、费用高、环境污染大等问题,提出了一种在干式状态下对SiC基片进行摩擦化学机械抛光的方法(dry tribochemical mechanical polishing, DTCMP)。探究不同工艺参数(磨料种类、磨粒粒径、磨粒含量、抛光盘转速、抛光载荷、固相氧化剂含量)对单晶SiC基片抛光效率和表面质量的影响规律。研究结果表明:金刚石磨粒更适合SiC的摩擦化学机械抛光;当磨粒粒径为W1,磨粒质量为4 g,抛光盘转速为70 r/min,抛光载荷为20.685 kPa,固相氧化剂过碳酸钠添加量为10 g时,其为最优工艺参数。采用最优工艺参数对表面粗糙度约为20 nm的单晶6H-SiC基片进行干式抛光加工,最终获得表面粗糙度Ra为3.214 nm。DTCMP方法抛光SiC基片比水基抛光法热量损失少,所产生的界面温度更高,反应所需的活化能更低,可以实现SiC基片的绿色、高效和高质量抛光。

-

关键词:

- SiC基片 /

- 干式摩擦化学机械抛光 /

- 材料去除率 /

- 表面粗糙度

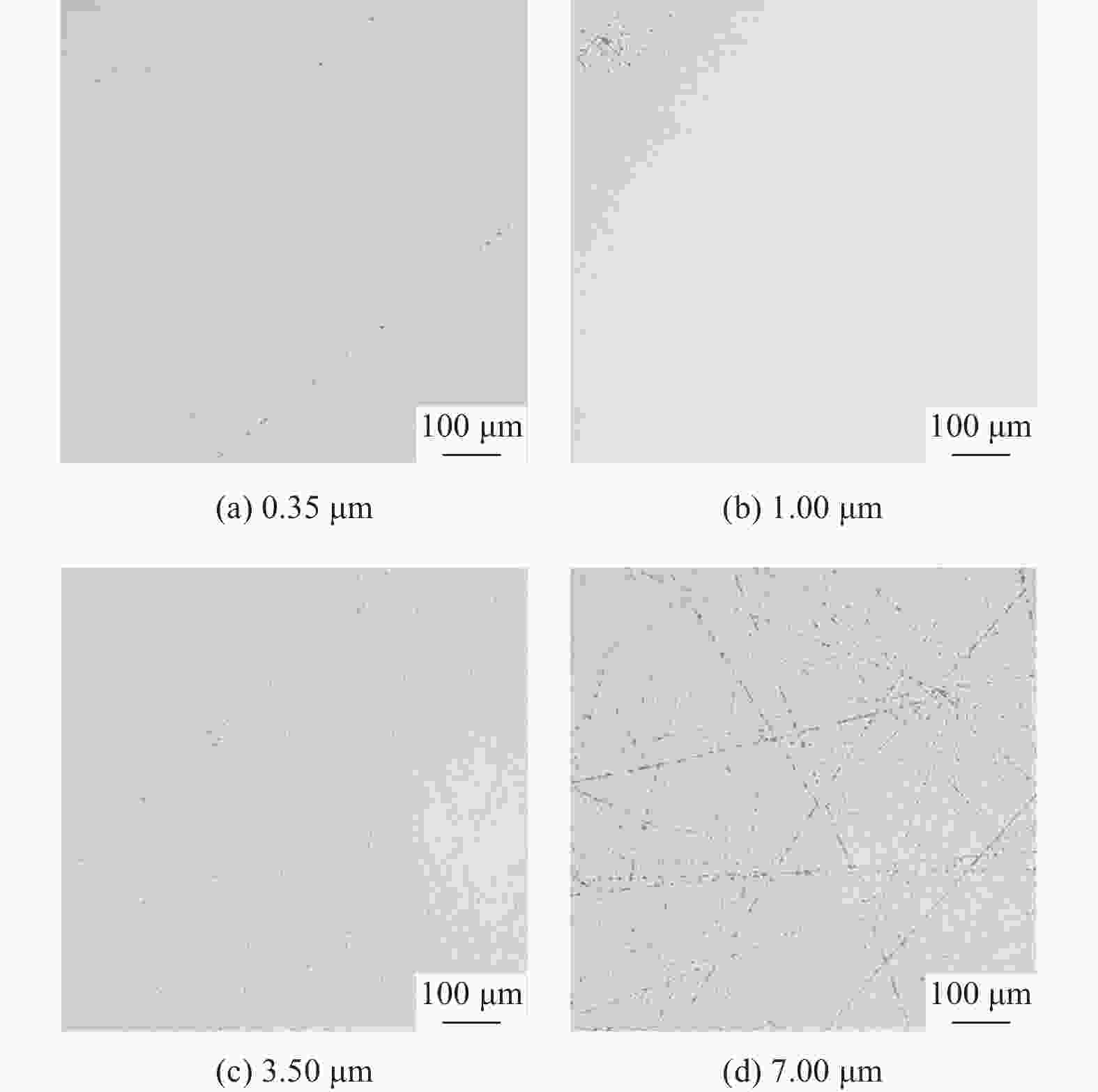

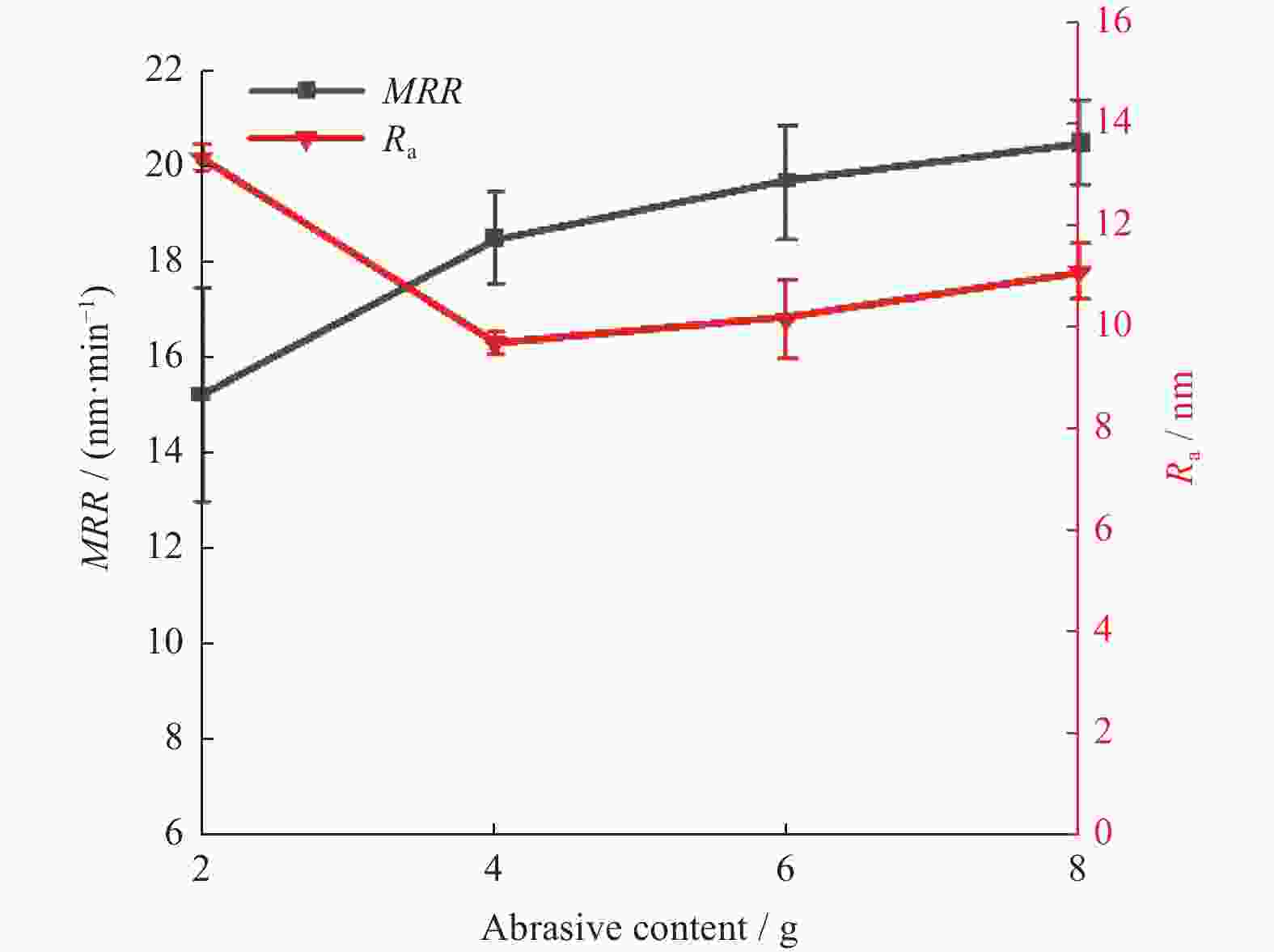

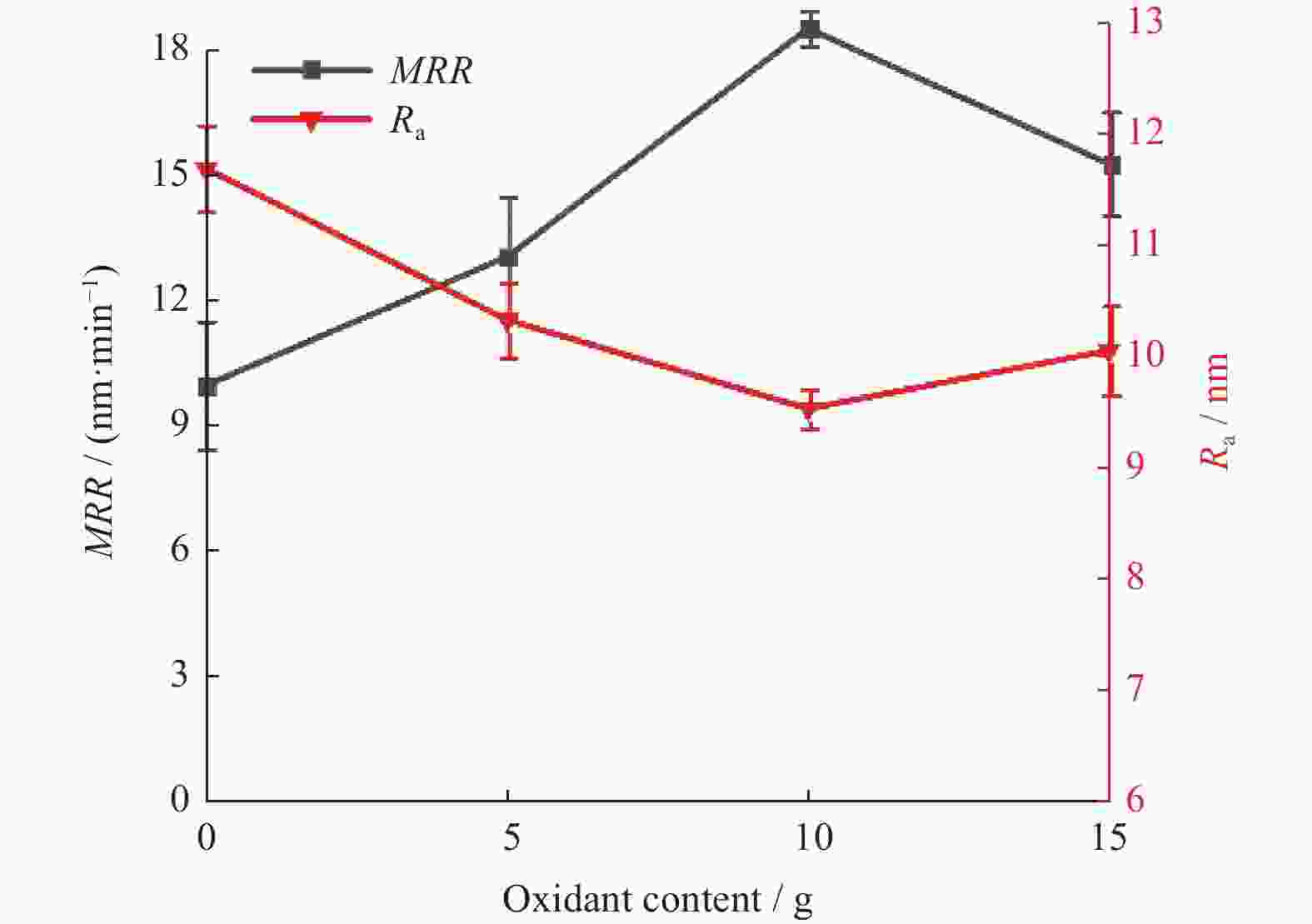

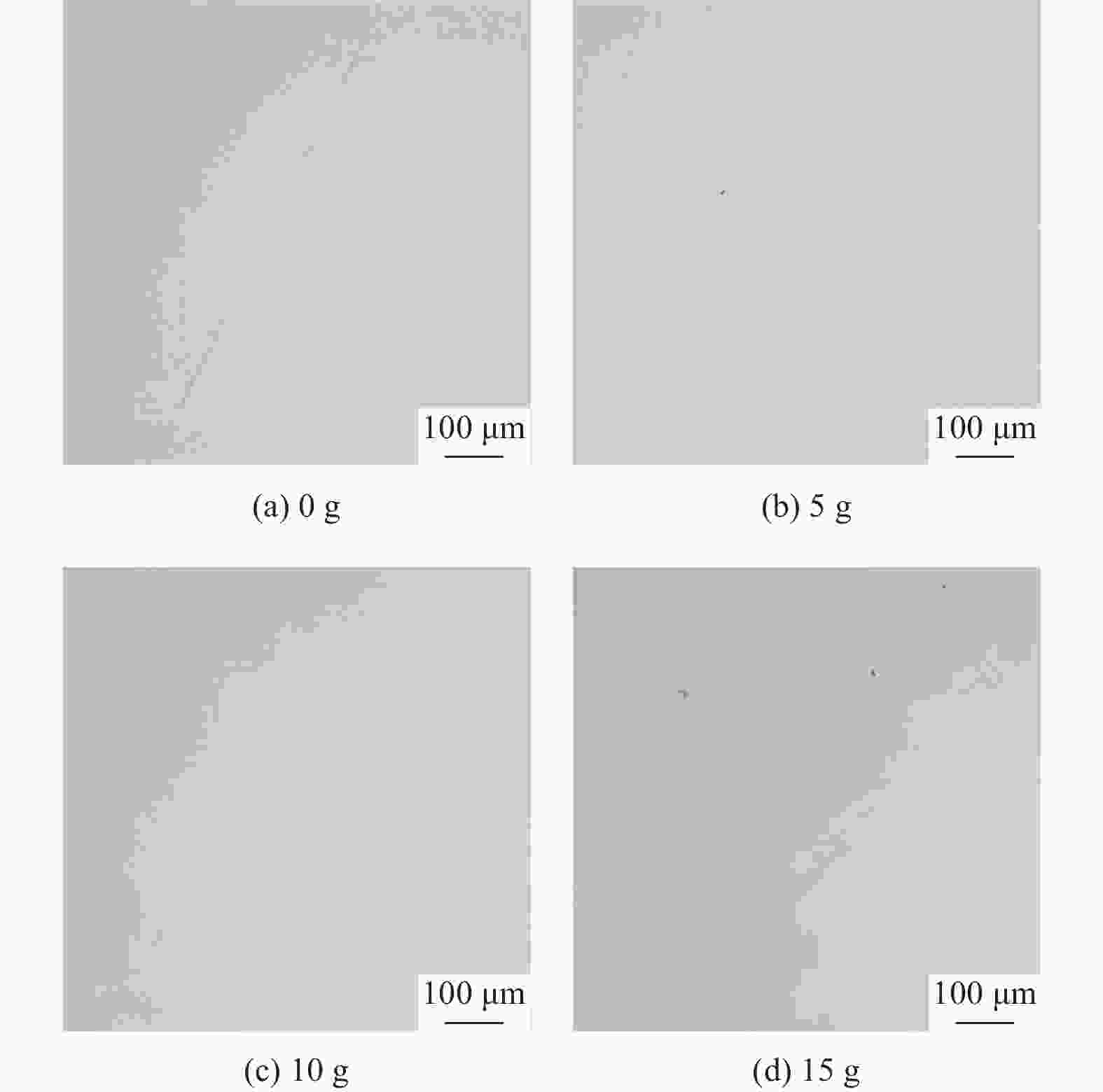

Abstract: Aiming at the issues of low efficiency, high cost, and environmental pollution associated with silicon carbide (SiC) substrates in the polishing process, a method of tribochemical mechanical polishing of SiC substrates in the dry state (Dry Tribochemical Mechanical Polishing, DTCMP) is proposed. The effect of different process parameters (abrasive type, abrasive size, abrasive content, polishing plate speed, polishing load, solid phase oxidant content) on the polishing efficiency and surface quality of single-crystal silicon carbide substrates was investigated. The results show that diamond abrasive is more suitable for the tribochemical mechanical polishing of silicon carbide. Optimal test parameters are achieved when the abrasive size is W1, the abrasive content is 4 g, the polishing plate speed is 70 r/min, the polishing load is 20.685 kPa, and the solid phase oxidant sodium percarbonate is added at 10 g. Single-crystal 6H-SiC substrates with a surface roughness of approximately 20 nm were polished using the optimal process parameters, finanlly resulting in a surface roughness of Ra of 3.214 nm. The DTCMP method for polishing SiC substrate has less heat loss than water-based polishing method, enabling higher interface temperature and lower activation energy required for reactions. This method can realize green, efficient and high-quality polishing of SiC substrates. -

表 1 加工工艺参数

Table 1. Processing parameters

参数 类型和取值 抛光机 ZYP230 抛光垫 聚氨酯抛光垫 磨料类型 金刚石、氧化铝 磨粒粒径 d / μm 0.35,1.00,3.50,7.00 磨粒质量m1 / g 2,4,6,8 氧化剂 Na2CO3-1.5H2O2 固相氧化剂质量m2 / g 0,5,10,15,20 抛光载荷P/ kPa 6.895,13.790,20.685,27.580 抛光盘转速v/ (r·min−1) 50,60,70,80 抛光时间t/ min 30 -

[1] GOEL S. The current understanding on the diamond machining of silicon carbide [J]. Journal of Physics D:Applied Physics,2014,47(24):243001. doi: 10.1088/0022-3727/47/24/243001 [2] 何艳. 光催化辅助抛光碳化硅晶片工艺及机理研究 [D]. 沈阳: 沈阳工业大学, 2019.HE Yan. Study on the technique and mechanism of photocatalysis assisted polishing silicon carbide wafer [D]. Shenyang: Shenyang University of Technology, 2019. [3] 李洁静. SiC单晶基片固结磨粒摩擦化学机械研磨研究 [D]. 新乡: 河南科技学院, 2019.LI Jiejing. Study on friction chemical mechanical lapping of SiC single crystal substrate with fixed abrasives [D]. Xinxiang: Henan Institute of Science and Technology, 2019. [4] CHEN G, NI Z, XU L, et al. Performance of colloidal silica and ceria based slurries on CMP of Si-face 6H-SiC substrates [J]. Applied Surface Science,2015(359):664-668. [5] 刘宁, 朱永伟, 李学, 等. 硬脆材料平面研抛的材料去除机理研究进展 [J]. 材料导报,2022,36(7):86-97.LIU Ning, ZHU Yongwei, LI Xue, et al. Research progress of material removal mechanism in plane lapping and polishing of hard-brittle materials [J]. Materials Reports,2022,36(7):86-97. [6] 梁华卓, 付有志, 何俊峰, 等. 单晶SiC基片的磁流变化学复合抛光 [J]. 金刚石与磨料磨具工程,2022,42(1):129-135. doi: 10.13394/j.cnki.jgszz.2021.0108LIANG Huazhuo, FU Youzhi, HE Junfeng, et al. Magnetorheological chemical compound polishing of single crystal SiC substrate [J]. Diamond & Abrasives Engineering,2022,42(1):129-135. doi: 10.13394/j.cnki.jgszz.2021.0108 [7] ZHANG P, YANG J, LI L. Trajectory uniformity of the double-sided mechanical polishing of SiC single crystal substrate [J]. Materials Science in Semiconductor Processing,2020(107):104814. [8] 王磊, 吴润泽, 牛林, 等. 碳化硅晶体电化学机械抛光工艺研究 [J]. 金刚石与磨料磨具工程,2022,42(4):504-510.WANG Lei, WU Runze, NIU Lin, et al. Study on electrochemical mechanical polishing process of silicon carbide crystal [J]. Diamond & Abrasives Engineering,2022,42(4):504-510. [9] DENG H, ENDO K, YAMAMURA K. Damage-free finishing of CVD-SiC by a combination of dry plasma etching and plasma-assisted polishing [J]. International Journal of Machine Tools and Manufacture,2017(115):38-46. [10] ZHANG L, DENG H. Highly efficient and damage-free polishing of GaN (0001) by electrochemical etching-enhanced CMP process [J]. Applied Surface Science,2020(514):145957. [11] YUAN Z, HE Y, SUN X, et al. UV-TiO2 photocatalysis-assisted chemical mechanical polishing 4H-SiC wafer [J]. Materials and Manufacturing Processes,2017,33(11):1214-1222. [12] DENG J, LU J, ZENG S, et al. Preparation and processing properties of magnetically controlled abrasive solidification orientation—solid-phase Fenton reaction lapping-polishing plate for single-crystal 4H-SiC [J]. Surfaces and Interfaces,2022(29):29. [13] 徐慧敏, 王建彬, 李庆安, 等. 碳化硅晶片的化学机械抛光技术研究进展 [J]. 现代制造工程,2022(6):153-161.XU Huimin, WANG Jianbin, LI Qing'an, et al. Research progress of chemical mechanical polishing technology of silicon carbide wafer [J]. Modern Manufacturing Engineering,2022(6):153-161. [14] ZHANG Z, LIU J, HU W, et al. Chemical mechanical polishing for sapphire wafers using a developed slurry [J]. Journal of Manufacturing Processes,2021(62):762-771. [15] MURATOV V A. Tribochemical polishing [J]. Annual Review of Materials Science,2002,30(1):27-51. [16] SU J, XU R, WANG Y, et al. Study on lapping paste of 6H–SiC single-crystal substrate in tribochemical mechanical lapping [J]. Journal of The Institution of Engineers (India):Series E,2020,101:141-148. [17] ZHU Z, MURATOV V, FISCHER T E. Tribochemical polishing of silicon carbide in oxidant solution [J]. Wear,1999,225-229:848-856. doi: 10.1016/S0043-1648(98)00392-5 [18] LIN Y C, KAO C H. A study on surface polishing of SiC with a tribochemical reaction mechanism [J]. The International Journal of Advanced Manufacturing Technology,2004,25(1/2):33-40. [19] 苏建修, 张学铭, 万秀颖, 等. 固结磨料研磨SiC单晶基片(0001)C面研究 [J]. 纳米技术与精密工程,2014,12(6):417-423.SU Jianxiu, ZHANG Xueming, WAN Xiuying, et al. Study on fixed abrasive lapping SiC single crystal substrate (0001) C Surface [J]. Nanotechnology and Precision Engineering,2014,12(6):417-423. [20] PRESSER V, KRUMMHAUER O, NICKEL K G, et al. Tribological and hydrothermal behaviour of silicon carbide under water lubrication [J]. Wear,2009,266(7/8):771-781. [21] WANG H, NIU F, CHEN J, et al. High efficiency polishing of silicon carbide by applying reactive non-aqueous fluids to fixed abrasive pads [J]. Ceramics International,2022,48(5):7273-7282. doi: 10.1016/j.ceramint.2021.11.288 [22] 刘雨薇, 张卫正, 叶福浩. 单个微凸体接触过程中的闪点温度研究 [J]. 西安交通大学学报,2016,50(3):90-93,126.LIU Yuwei, ZHANG Weizheng, YE Fuhao. Research on the flash temperature in single asperity contact [J]. Journal of Xi'an Jiaotong University,2016,50(3):90-93,126. [23] QI W, CAO X, XIAO W, et al. Study on the mechanism of solid-phase oxidant action in tribochemical mechanical polishing of SiC single crystal substrate [J]. Micromachines (Basel), 2021, 12(12). -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS