Calibration of emissivity value of 18CrNiMo7-6 steel and study on cylindrical grinding temperature

-

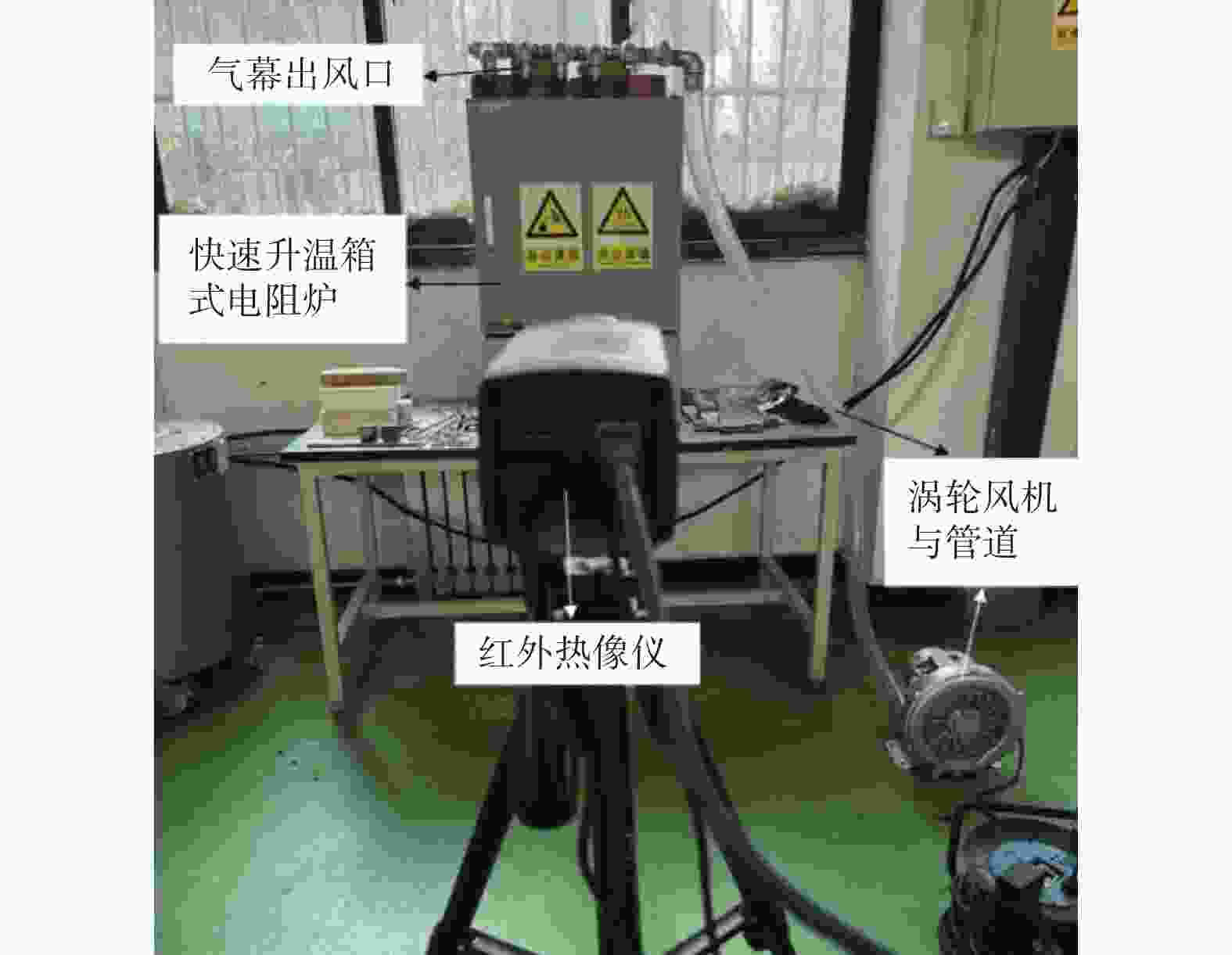

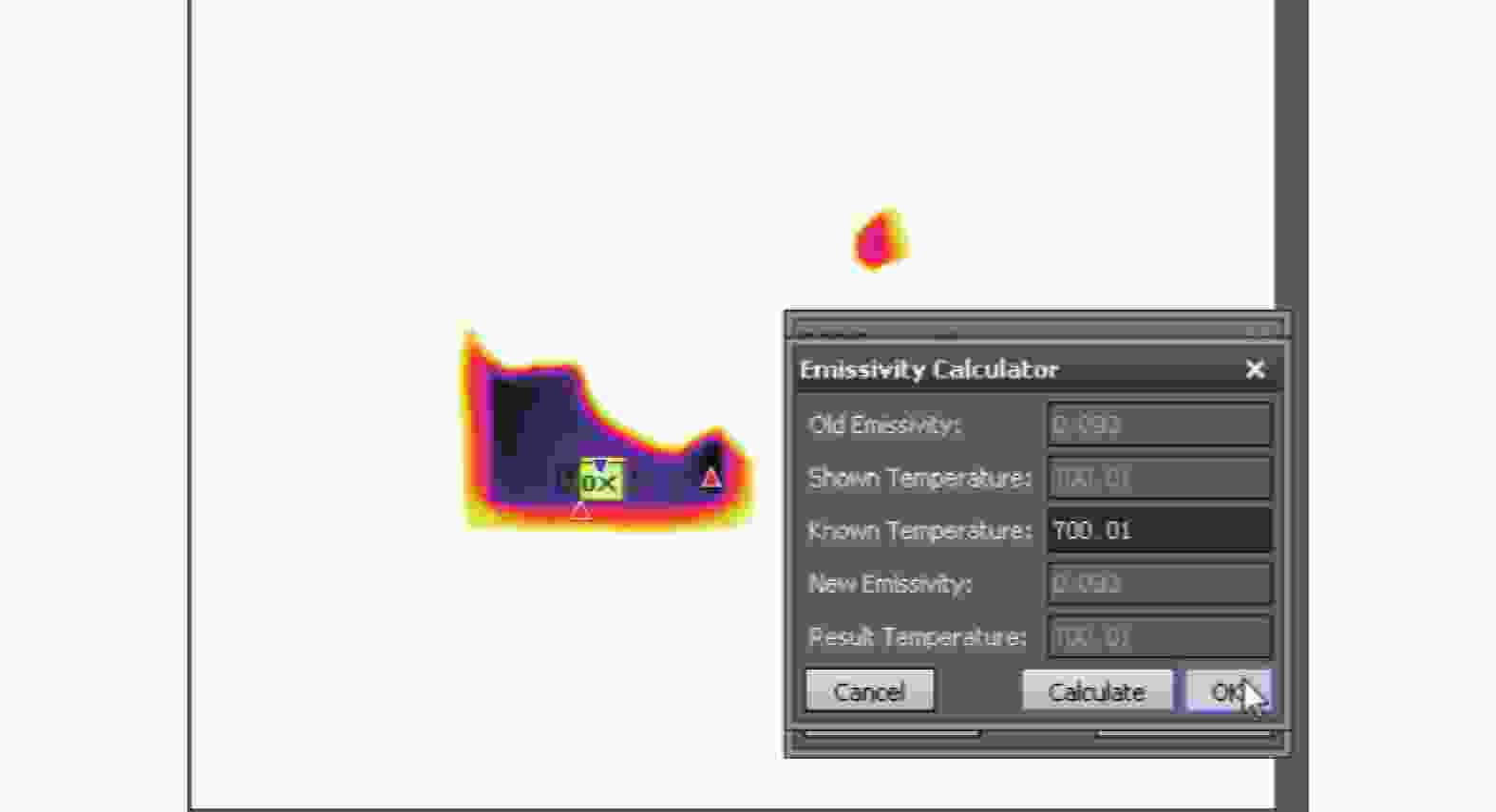

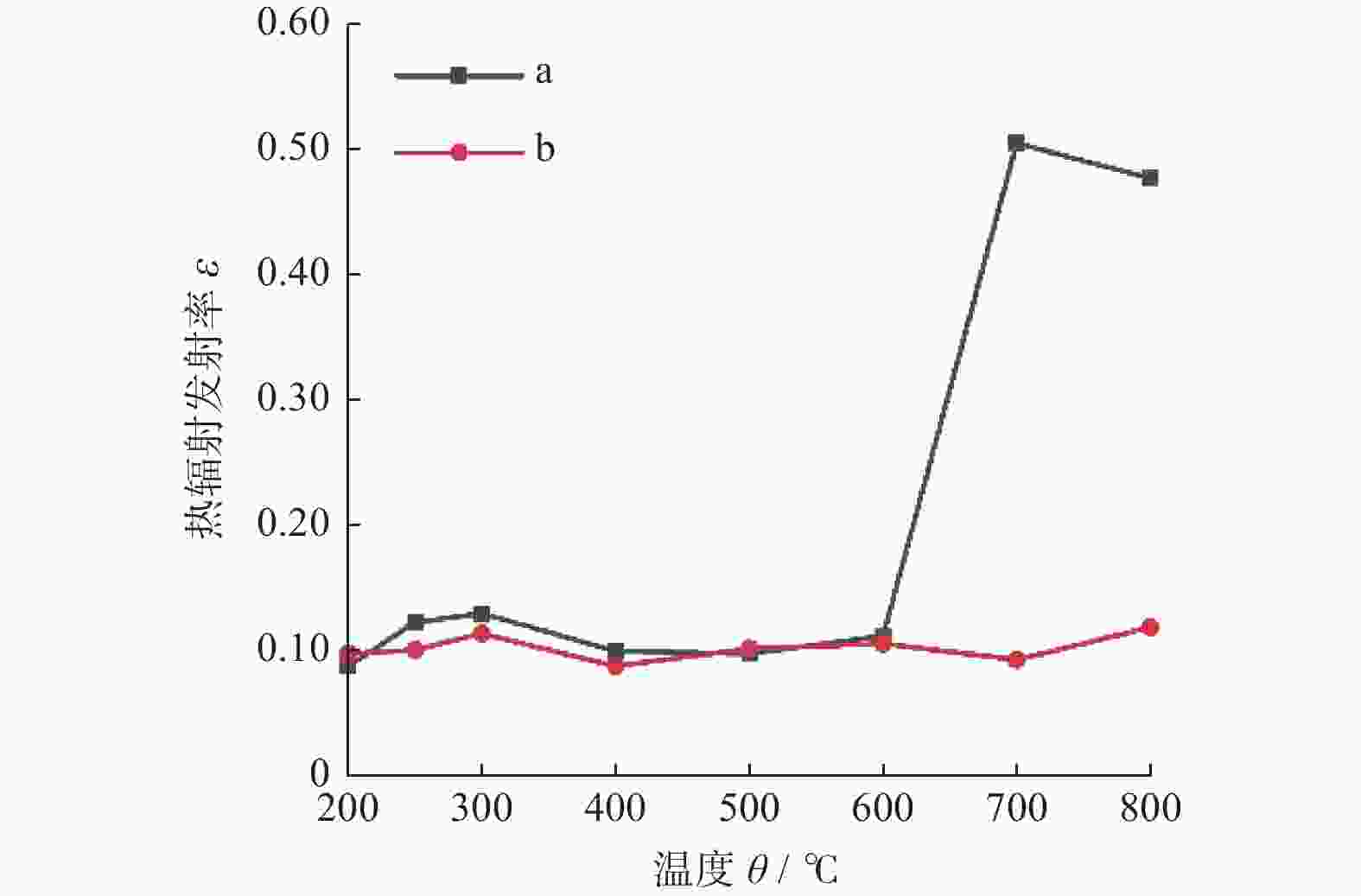

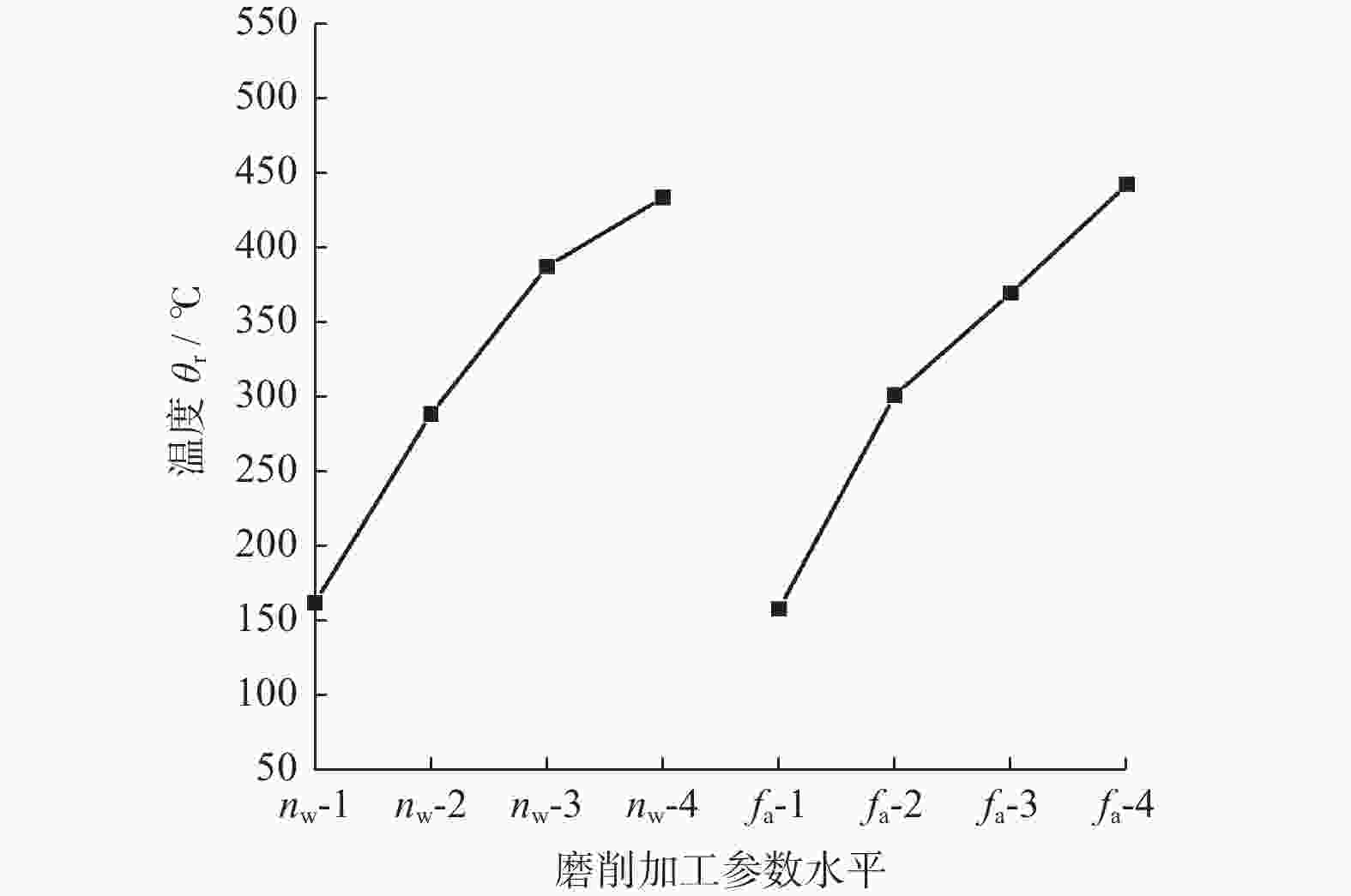

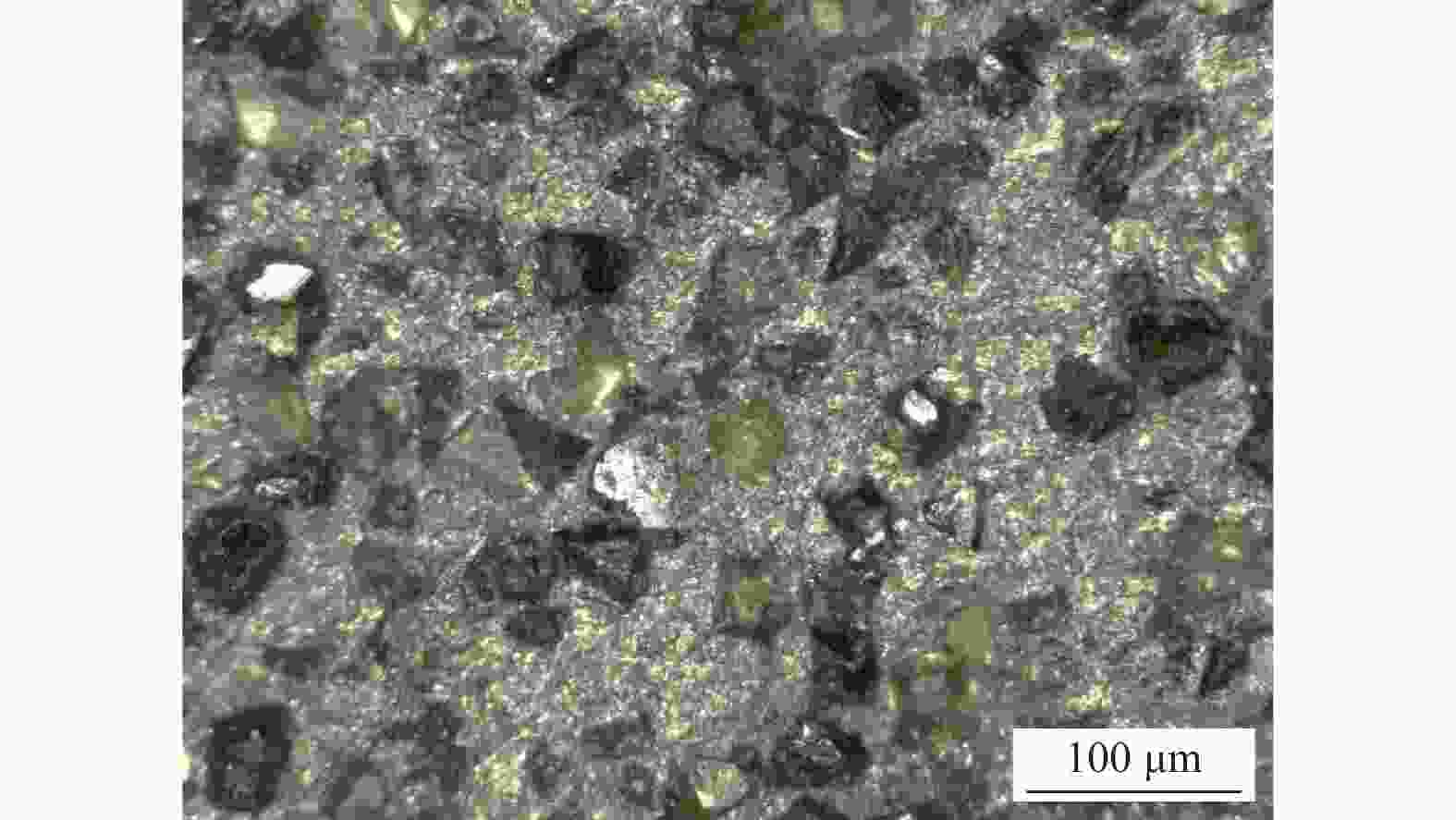

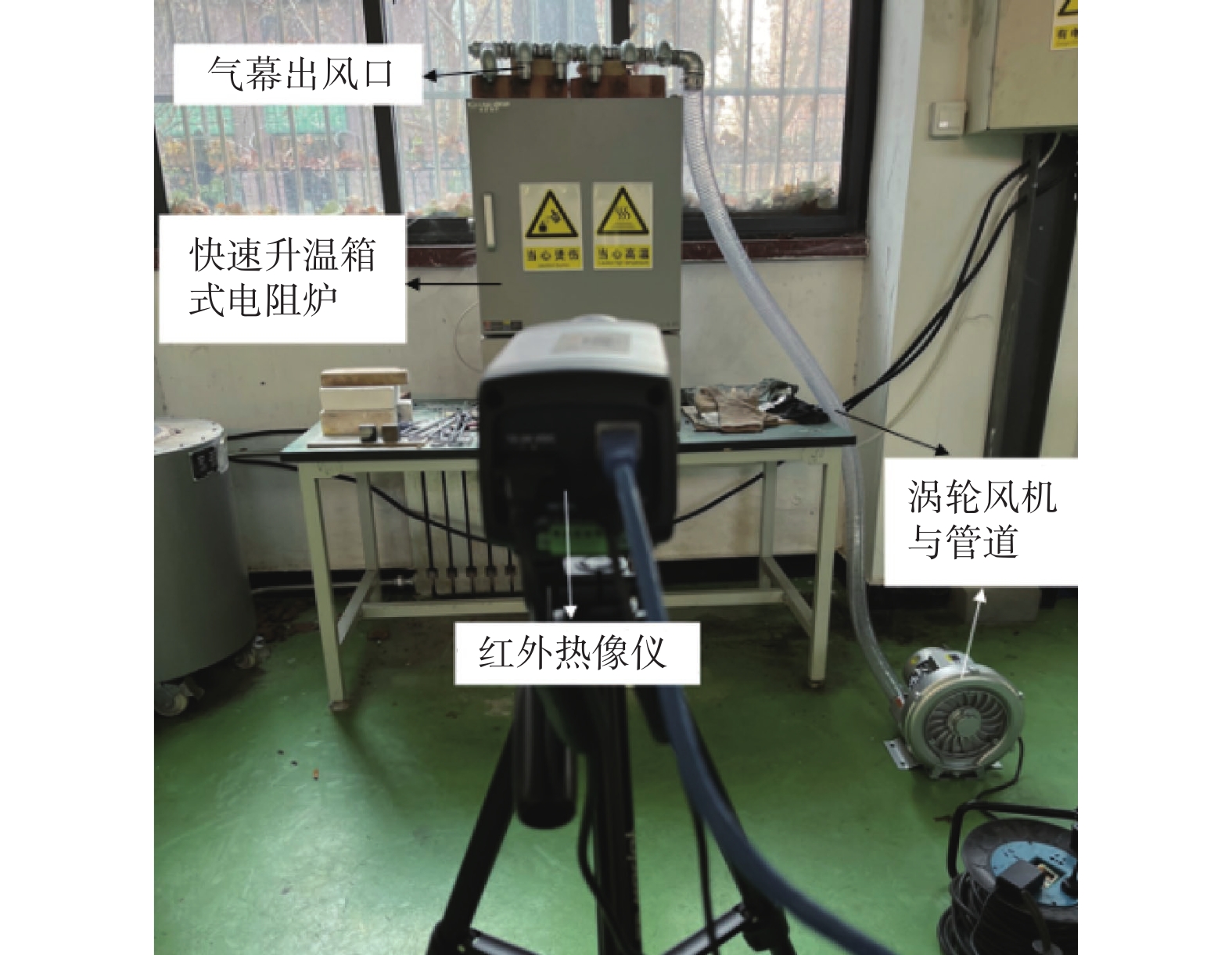

摘要: 为研究齿轮钢外圆横向磨削过程中工件温度受加工参数变化的影响,以18CrNiMo7-6齿轮钢作为工件材料,CBN砂轮作为磨具进行试验,使用红外热像仪对磨削过程温度进行检测。提出一种增设气幕装置的热辐射发射率值标定方案,通过气幕生成的高速气流减缓外界空气进入加热炉,防止标定过程中试样被氧化,保证高温条件下标定得到的发射率值的准确度;依据检测结果,分析工件转速${v_{\text{w}}}$、工件每转的磨削深度${f_{\text{a}}}$、砂轮磨粒粒度${d_{\text{g}}}$、砂轮直径${d_{\text{s}}}$和磨削宽度$b$对温度的影响。结果表明:${f_{\text{a}}}$对温度变化影响最显著。通过拟合得到磨削温度与试验参数间的经验公式,其误差为9.27%。将磨削温度的试验测量结果与运用移动热源理论、瑞利分布模型和干式磨削热分配比模型进行理论推导的结果作对比,偏差为8.51%。Abstract: To study the variation rule of workpiece temperature concerning machining parameters in the cylindrical transverse grinding process of gear steel, 18CrNiMo7-6 gear steel was selected as the workpiece material, and a CBN grinding wheel was used as the grinding tool. An infrared thermal imaging instrument was used to detect the temperature during the grinding process. A calibration scheme of thermal emissivity value, incorporating an additional air curtain device, was proposed. The high-speed airflow generated by the air curtain was used to slow down the entry of external air into the heating furnace, preventing the oxidation of samples during calibration, thus ensuring the accuracy of the emissivity value calibrated under high-temperature conditions. Based on the test results, the influence of workpiece speed ${v_{\text{w}}}$, workpiece grinding depth per revolution ${f_{\text{a}}}$, grinding wheel grain size ${d_{\text{g}}}$, grinding wheel diameter ${d_{\text{s}}}$ and grinding width $b$ on the temperature was analyzed. The workpiece grinding depth per revolution ${f_{\text{a}}}$ was identified as the most significant factor affecting the temperature change. The empirical formula between grinding temperature and aforementioned test parameters was obtained by fitting, with an error of 9.27%. The test measurement results of grinding temperature were compared with those derived from the theory of a moving heat source, Rayleigh distribution model and dry grinding heat distribution ratio model, resulting in a deviation of 8.51%.

-

表 1 砂轮参数

Table 1. Grinding wheel parameters

砂轮

编号磨料

种类砂轮

外径

${d_{\text{s}}}$/ mm砂轮

宽度

${b_{\text{s}}}$/ mm磨料

粒度

${d_{\text{g}}}$/ μm砂轮

浓度

c / %砂轮Ⅰ CBN 450 22 12~22 100 砂轮Ⅱ CBN 450 22 53~63 100 砂轮Ⅲ CBN 450 20 12~22 100 砂轮Ⅳ CBN 450 26 53~63 100 表 2 正交试验参数

Table 2. Orthogonal test parameters

试验编号 工件转速

${n_{\text{w}}}$ / (r·min−1)工件每转的磨削深度

${f_{\text{a} } }$ / (μm·r−1)砂轮编号 1 30 0.2 Ⅰ 2 30 0.5 Ⅱ 3 30 0.8 Ⅲ 4 30 1 Ⅳ 5 90 0.2 Ⅱ 6 90 0.5 Ⅰ 7 90 0.8 Ⅳ 8 90 1 Ⅲ 9 120 0.2 Ⅲ 10 120 0.5 Ⅳ 11 120 0.8 Ⅰ 12 120 1 Ⅱ 13 180 0.2 Ⅳ 14 180 0.5 Ⅲ 15 180 0.8 Ⅱ 16 180 1 Ⅰ 表 3 外圆磨削试验结果

Table 3. Cylindrical grinding test results

试验编号 温度 θr / ℃ 试验编号 温度 θr / ℃ 1 107.72 9 217.42 2 119.83 10 328.71 3 171.40 11 603.23 4 208.88 12 399.50 5 130.51 13 216.34 6 367.44 14 389.17 7 278.67 15 424.76 8 377.79 16 743.31 表 4 磨削弧区切入端最高温度结果

Table 4. Results of the maximum temperature at the cutting end of grinding arc

试验

编号测量结果

${T_{\text{r}}}$ / ℃经验公式

计算结果

${T_{{\text{re}}}}$ / ℃经验公

式误差

$\left| {\Delta {T_1}} \right|$ / %理论计

算结果

${T_{{\text{rl}}}}$ / ℃理论结

果偏差

$\left| {\Delta {T_2}} \right|$ / %1 107.72 96.12 10.77 99.84 7.32 2 119.83 115.52 3.60 102.21 14.70 3 171.40 202.68 18.25 162.97 4.92 4 208.88 192.14 8.01 197.39 5.50 5 130.51 127.04 2.66 116.50 10.73 6 367.44 322.29 12.29 305.41 16.88 7 278.67 322.12 15.59 318.21 14.19 8 377.79 445.79 18.00 399.50 5.75 9 217.42 198.68 8.62 230.87 6.19 10 328.71 287.12 12.65 337.10 2.55 11 603.23 508.88 15.64 564.84 6.36 12 399.50 401.17 0.42 434.61 8.79 13 216.34 209.20 3.30 184.03 14.93 14 389.17 441.36 13.41 411.51 5.74 15 424.76 445.61 4.91 466.69 9.87 16 743.31 741.56 0.24 756.52 1.78 表 5 砂轮磨粒与工件材料物理特性

Table 5. Physical characteristics of abrasive particle and workpiece material

材料特性 CBN磨粒 18CrNiMo7-6 杨氏模量 E / GPa 720 210 泊松比 0.15 0.30 密度 ρ / (kg·m−3) 3.450$ \times $106 7815 比热容 c / (J∙kg−1∙K−1) 710 420 导热系数 λ / (W∙m−1∙K−1) 79.54 35.64 -

[1] ANDERSON D, WARKENTIN A, BAUER R. Experimental validation of numerical thermal models for dry grinding [J]. Journal of Materials Processing Technology,2007,204(1):269-278. doi: j.jmatprotec.2007.11.080 [2] 黄新春, 张定华, 姚倡锋, 等. 超高强度钢AerMet100磨削烧伤研究 [J]. 机械工程学报,2015,51(9):184-190. doi: 10.3901/JME.2015.09.184HUANG Xinchun, ZHANG Dinghua, YAO Changfeng, et al. Research on the grinding burn of the ultrahigh strength steel AerMet100 [J]. Journal of Mechanical Engineering,2015,51(9):184-190. doi: 10.3901/JME.2015.09.184 [3] MAHDI M, ZHANG L. The finite element thermal analysis of grinding processes by ADINA [J]. Computers & Structures,1995,56(2-3):313-320. [4] LI B Z, ZHU D H, PANG J Z, et al. Quadratic curve heat flux distribution model in the grinding zone [J]. The International Journal of Advanced Manufacturing Technology,2011,54(9/12):931-940. doi: 10.1007/s00170-010-2990-y [5] PANG J Z, LI B Z, LIU Y, et al. Rayleigh heat flux distribution model investigation and workpiece temperature prediction in the cylindrical grinding [J]. The International Journal of Advanced Manufacturing Technology,2017,89(9/12):3231-3241. doi: 10.1007/s00170-016-9220-1 [6] 左振. 硬质合金磨削过程的温度分布及热量分配比例实验研究 [D]. 福州: 福建工程学院, 2022.ZUO Zhen. Experimental study on temperature distribution and heat distribution ratio in cemented carbide grinding process [D]. Fuzhou: Fujian University of Technology, 2022. [7] 钱宁, 徐九华, 傅玉灿, 等. 面向绿色高效磨削的振荡热管砂轮磨削温度与强化传热分析 [J]. 机械工程学报,2022,58(15):105-120. doi: 10.3901/JME.2022.15.105QIAN Ning, XU Jiuhua, FU Yucan, et al. Investigation on grinding temperature and heat transfer performance of oscillating grinding wheel for high-efficient green grinding [J]. Journal of Mechanical Engineering,2022,58(15):105-120. doi: 10.3901/JME.2022.15.105 [8] XU X P, YU Y Q, HUANG H. Mechanisms of abrasive wear in the grinding of titanium(TC4) and nickel(K417) alloys [J]. Wear,2003,255:1421-1426. doi: 10.1016/S0043-1648(03)00163-7 [9] 庞静珠. 高速精密外圆磨削热及其监控方法的研究与应用 [D]. 上海: 东华大学, 2015.PANG Jingzhu. Research and application on grinding heat and its monitoring methods in high-speed cylindrical precision grinding [D]. Shanghai: Donghua University, 2015. [10] 蔡李靖, 周凯来, 沈桂竹, 等. 红外热像仪高精度测温标定技术 [J]. 红外与激光工程,2021,50(10):202-209. doi: 10.3788/IRLA20210043CAI Lijing, ZHOU Kailai, SHEN Jiazhu, et al. High-precision temperature measurement and calibration technology of infrared thermal imager [J]. Infrared and Laser Engineering,2021,50(10):202-209. doi: 10.3788/IRLA20210043 [11] 白梦洁. 隧道中气幕防排烟系统关键参数及控烟效果研究 [D]. 徐州: 中国矿业大学, 2020.BAI Mengjie. Key parameters and smoke control effects of air curtain smoke exhaust system in tunnel [D]. Xuzhou: China University of Mining and Technology, 2020. [12] 张凤, 何康, 冯世杰, 等. 高超声速风洞M a=5中劈尖试件的红外测温 [J]. 中国测试,2019,45(7):37-41. doi: 10.11857/j.issn.1674-5124.2018020010ZHANG Feng, HE Kang, FENG Shijie, et al. Infrared temperature measurement of wedge shape specimen in the hypersonic wind tunnel at M a=5 [J]. China Measurement & test,2019,45(7):37-41. doi: 10.11857/j.issn.1674-5124.2018020010 [13] 王栋, 马少奇, 赵静雯, 等. 18CrNiMo7-6外圆磨削力对残余应力的影响 [J]. 组合机床与自动化加工技术,2021(11):27-30. doi: 10.13462/j.cnki.mmtamt.2021.11.007WANG Dong, MA Shaoqi, ZHAO Jingwen, et al. Effect of grinding force on residual stress in 18CrNiMo7-6 cylindrical grinding [J]. Modular Machine Tool & Automatic Manufacturing Technique,2021(11):27-30. doi: 10.13462/j.cnki.mmtamt.2021.11.007 [14] 唐进元, 周伟华, 黄于林. 轴向超声振动辅助磨削的磨削力建模 [J]. 机械工程学报,2016,52(15):184-191. doi: 10.3901/JME.2016.15.184TANG Jinyuan, ZHOU Weihua, HUANG Yulin. Modeling on grinding force assisted with axial ultrasonic vibration [J]. Journal of Mechanical Engineering,2016,52(15):184-191. doi: 10.3901/JME.2016.15.184 [15] PANG J Z, WU C J, SHEN Y M, et al. Heat flux distribution and temperature prediction model for dry and wet cylindrical plunge grinding [J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture,2019,233(10):2047-2060. doi: 10.1177/0954405418815365 [16] ROWE W B. Thermal analysis of high efficiency deep grinding [J]. International Journal of Machine Tools and Manufacture,2001,41(1):1-19. doi: 10.1016/S0890-6955(00)00074-2 [17] ROWE W B, BLACK S C E, MILLIS B, et al. Grinding temperatures and energy partitioning [J]. Proceedings of The Royal Society A,1997,453(1960):1083-1104. doi: 10.1098/rspa.1997.0061 [18] JIN T, STEPHENSON D J. Analysis of grinding chip temperature and energy partitioning in high -efficiency deep grinding [J]. Proceedings of the Institution of Mechanical Engineerings, Part B:Journal of Engineers Manufacture,2005,220(5):615-625. doi: 10.1243/09544054JEM389 [19] ROWE W B, MORGAN M N, QI H S, et al. The effect of deformation on the contact area in grinding [J]. CIRP Annals,1993,42(1):409-412. doi: 10.1016/S0007-8506(07)62473-1 [20] QI H S, MILLIS B, ROWE W B. An analysis of real contact length in abrasive machining processes using contact mechanics [J]. Wear,1994,176(1):137-141. doi: 10.1016/0043-1648(94)90207-0 [21] 张锦涛. 18CrNiMo7-6钢外圆磨削温度及表面完整性研究 [D]. 郑州: 郑州大学, 2021.ZHANG Jintao. Research on cylindrical grinding temperature and surface integrity of 18CrNiMo7-6 steel [D]. Zhengzhou: Zhengzhou University, 2021. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS