On line prediction of roll grinding chatter based on EMD component and wavelet packet energy entropy

-

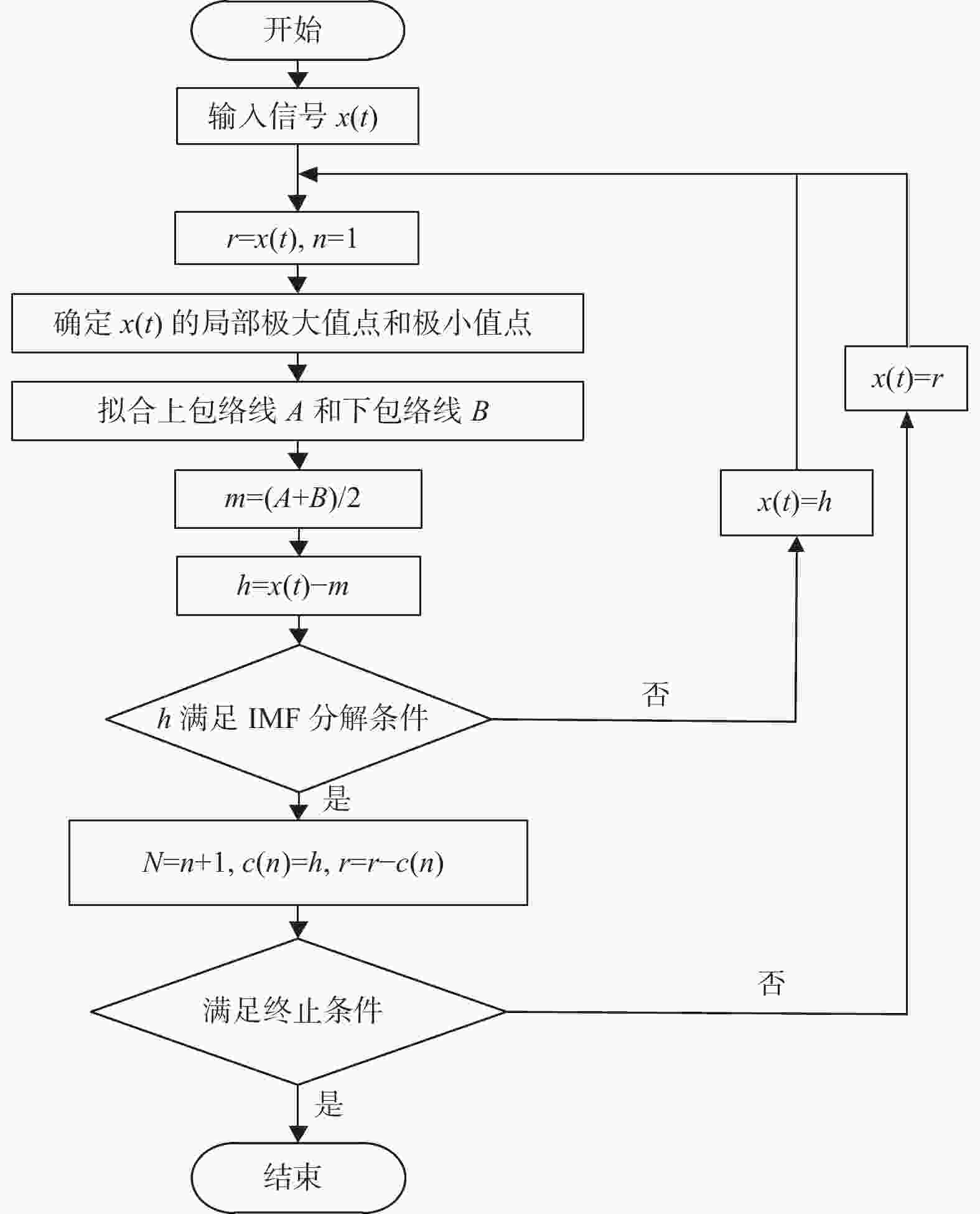

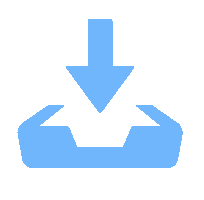

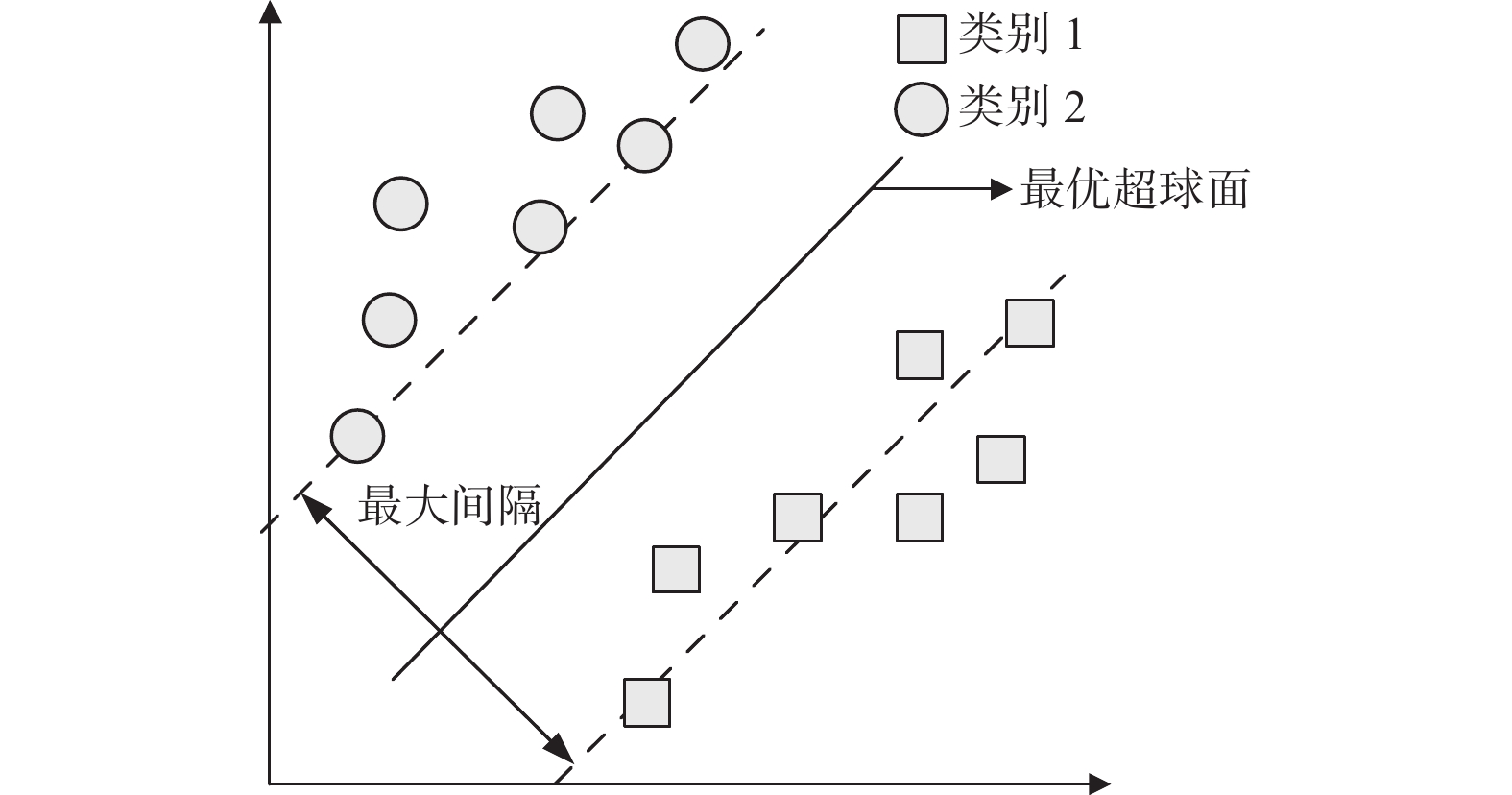

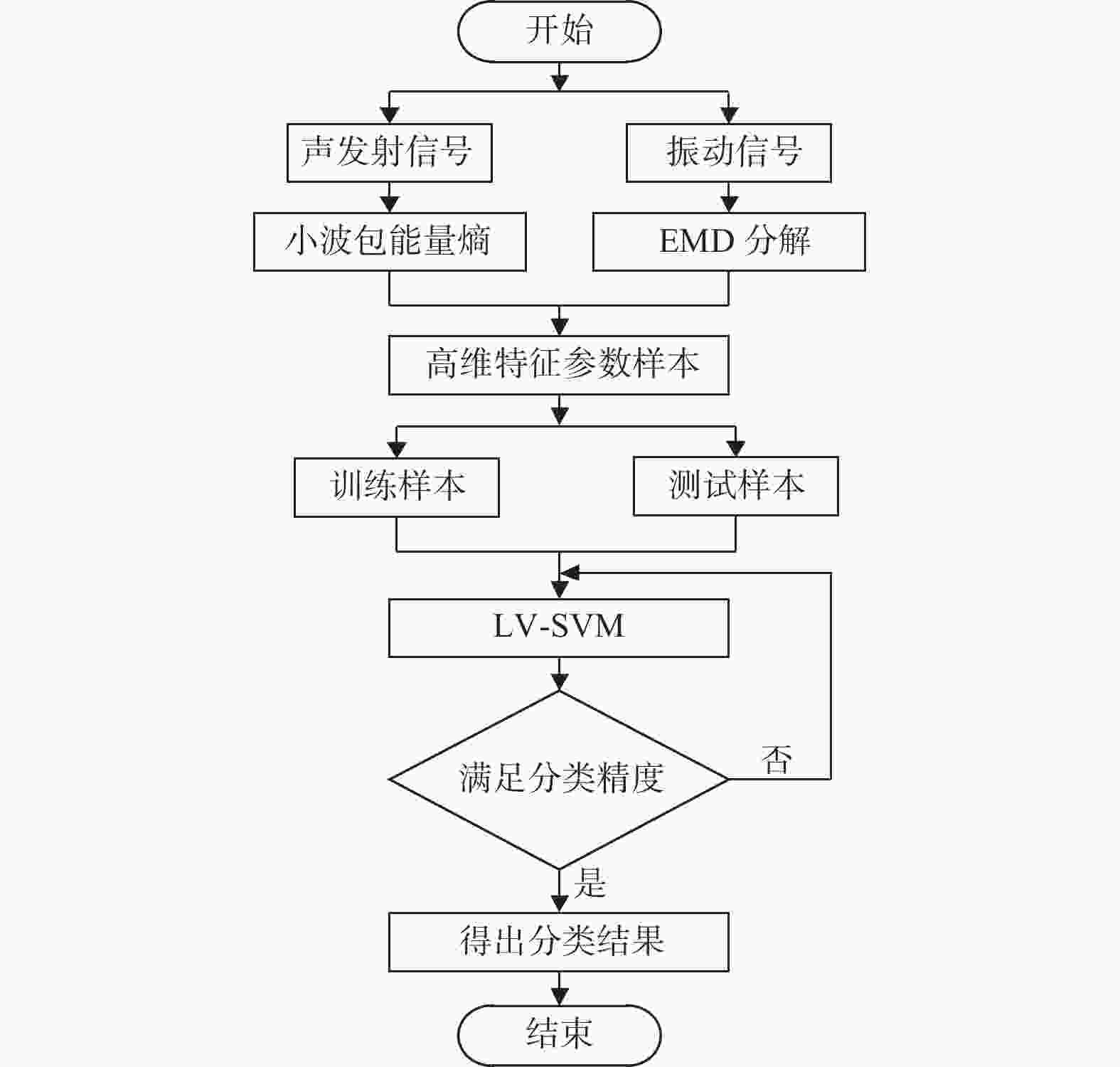

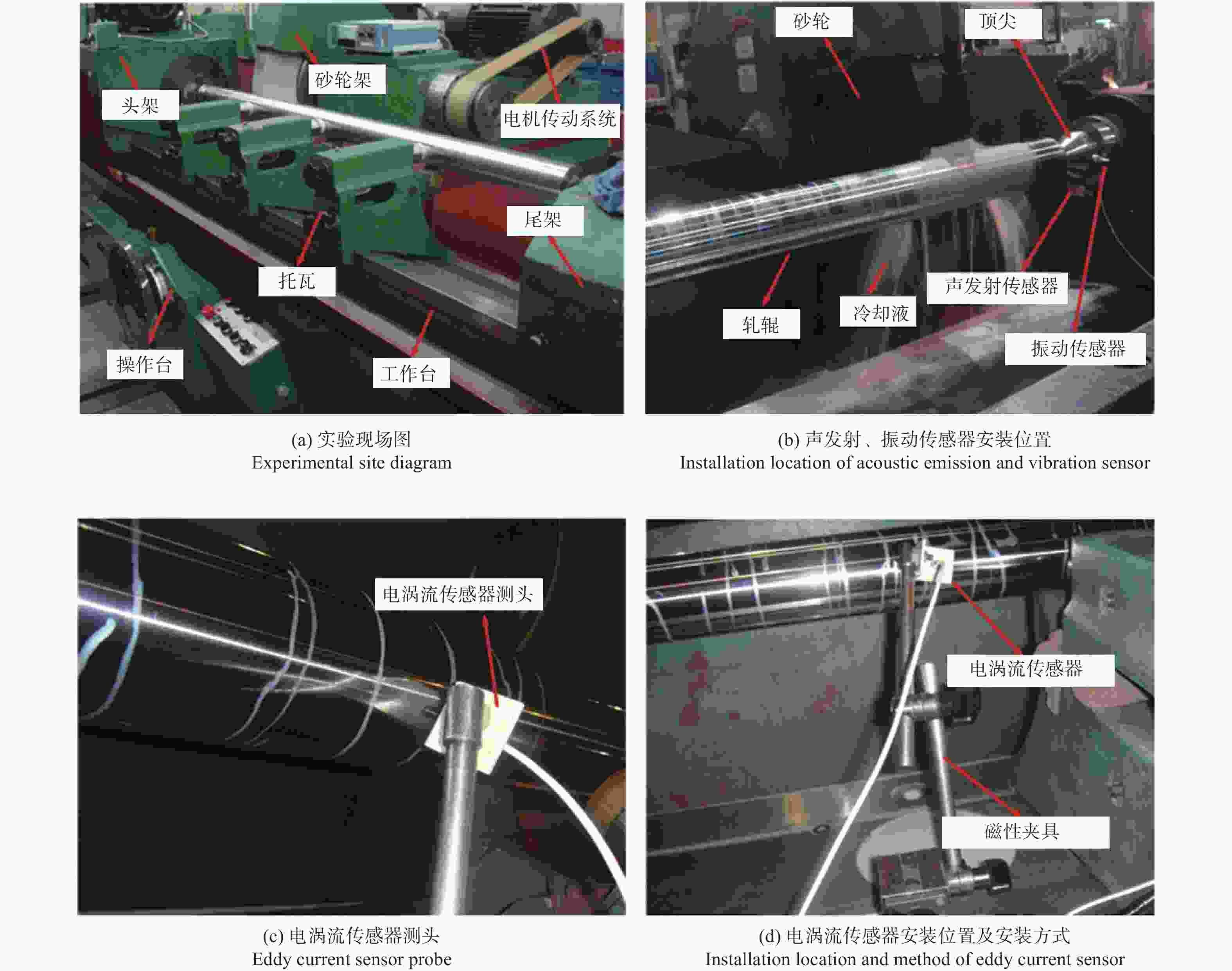

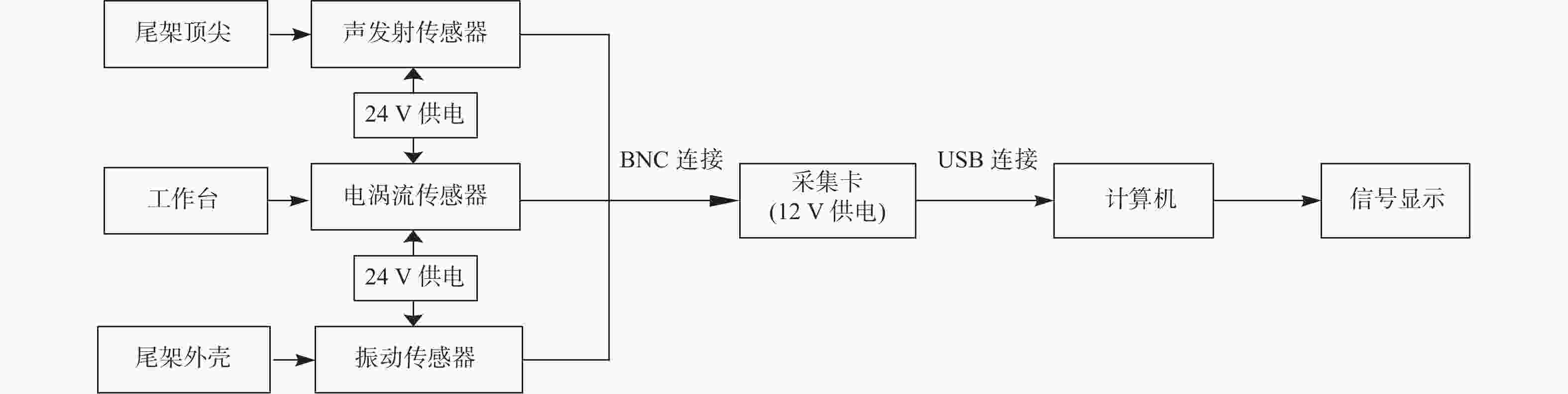

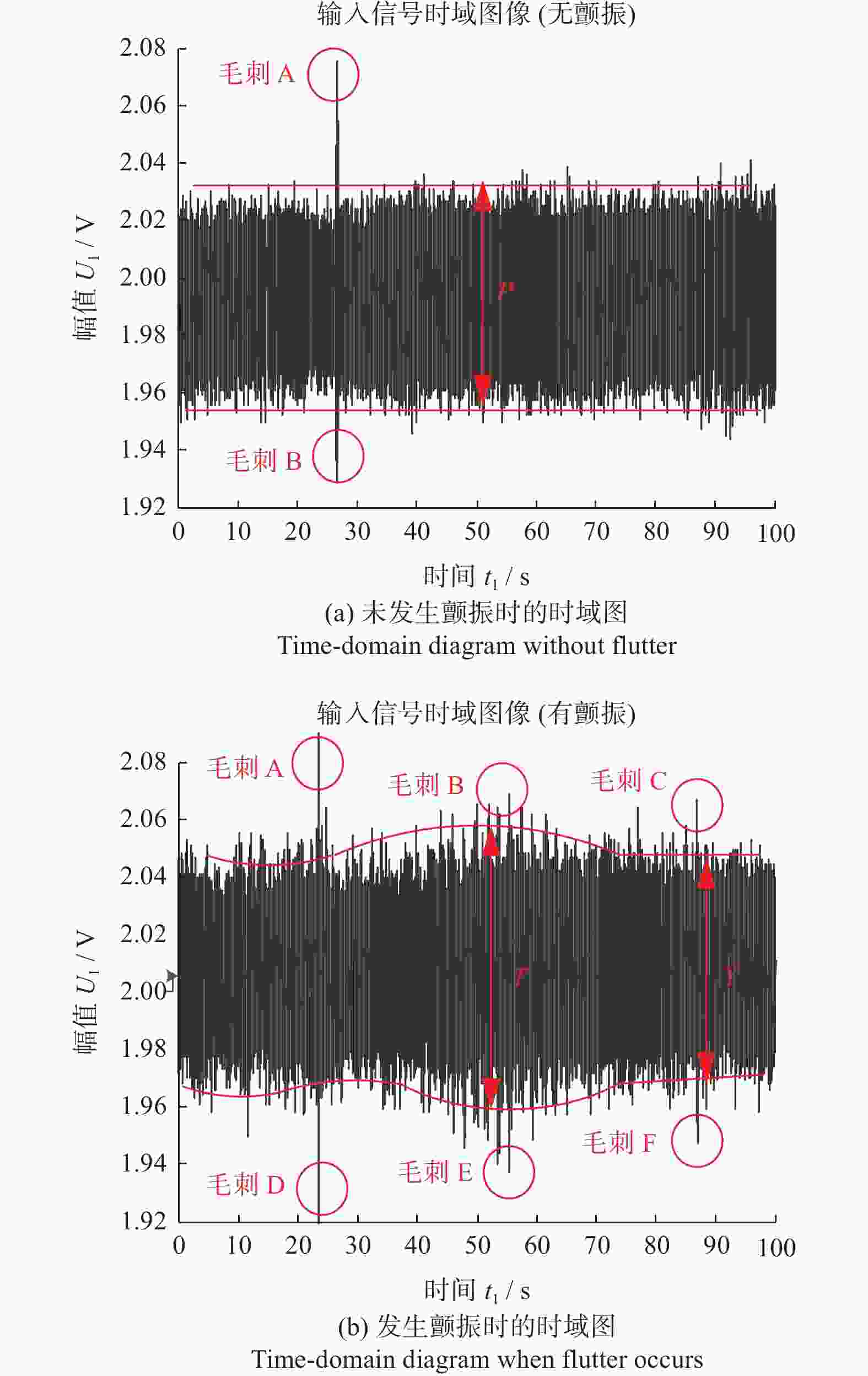

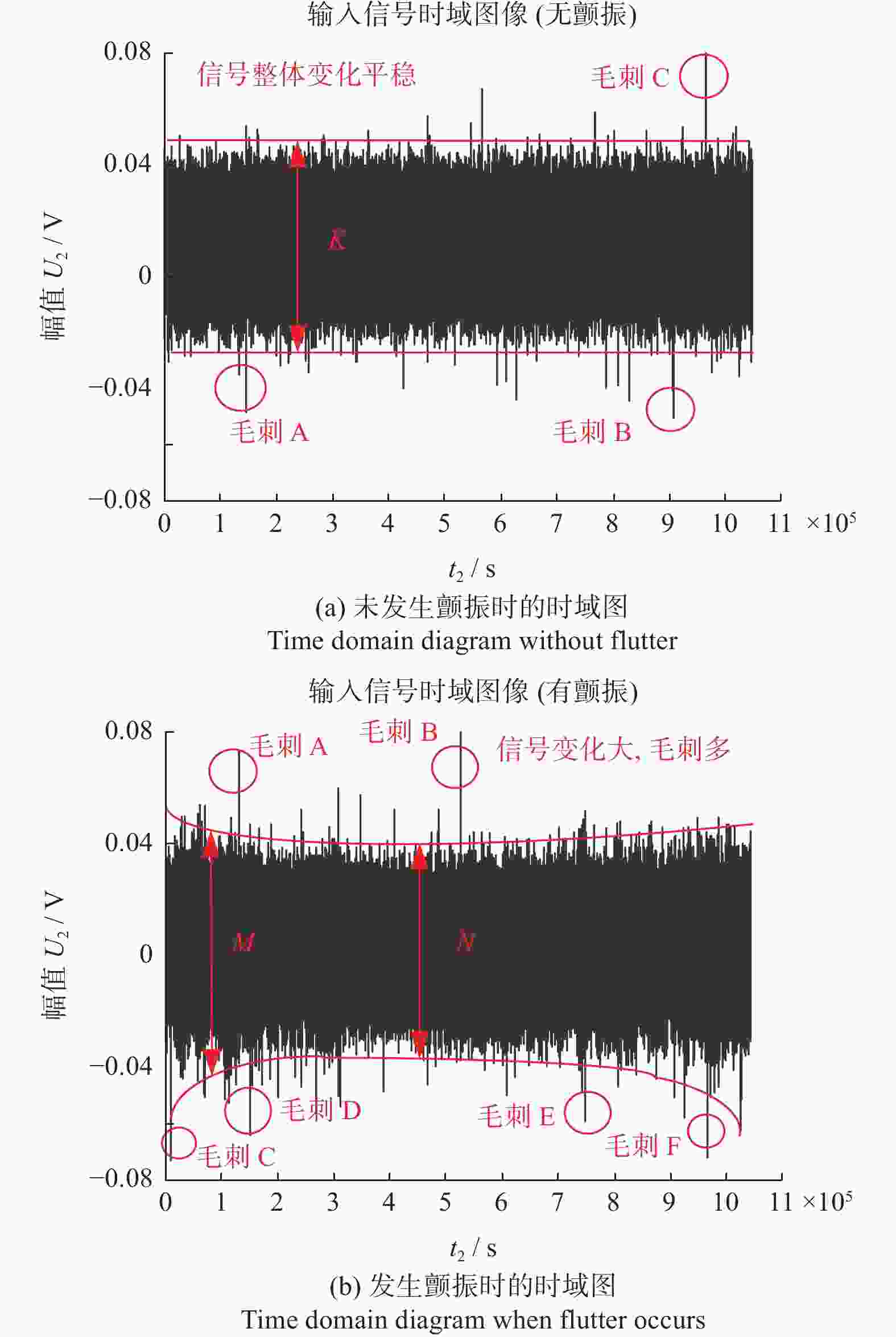

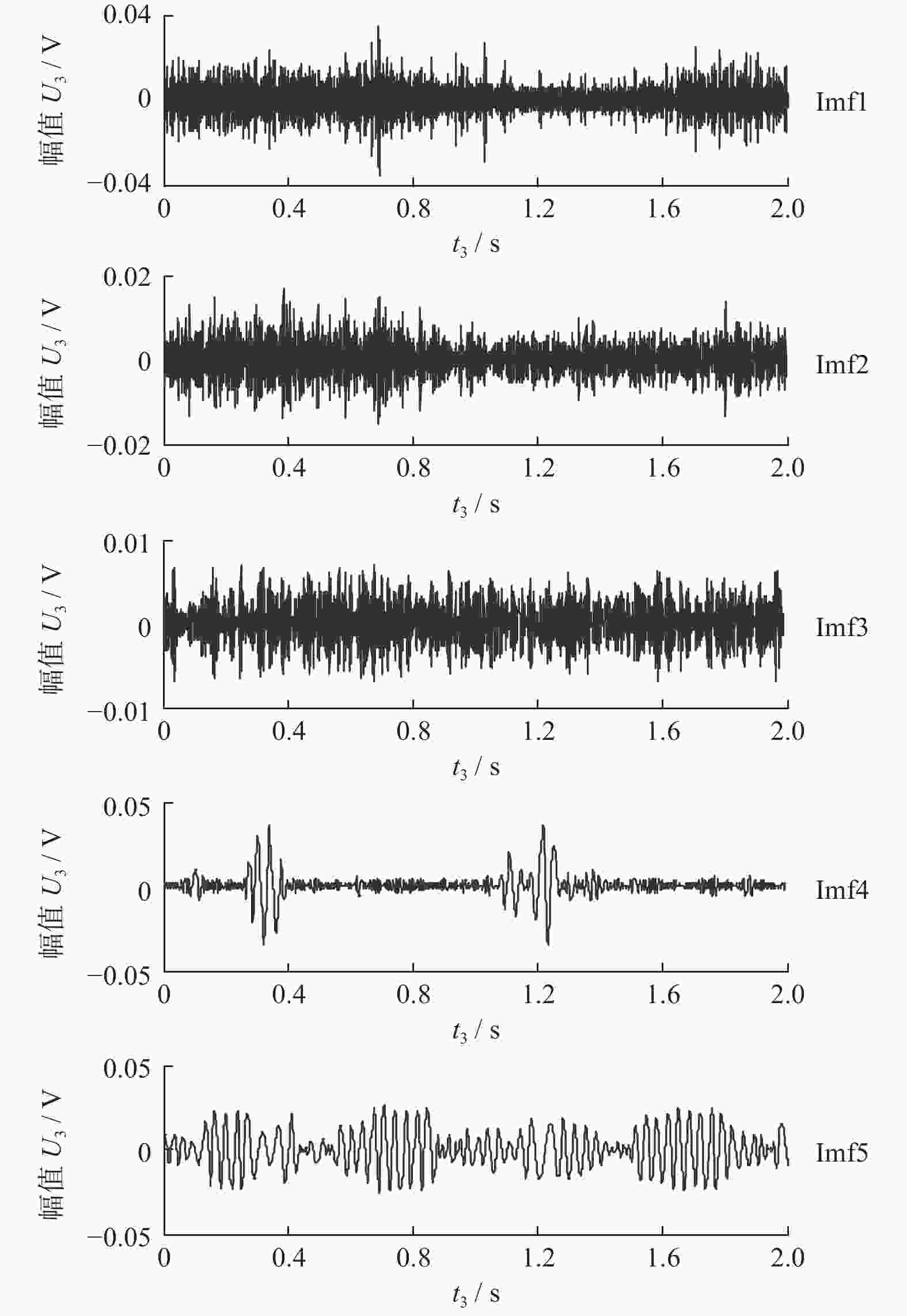

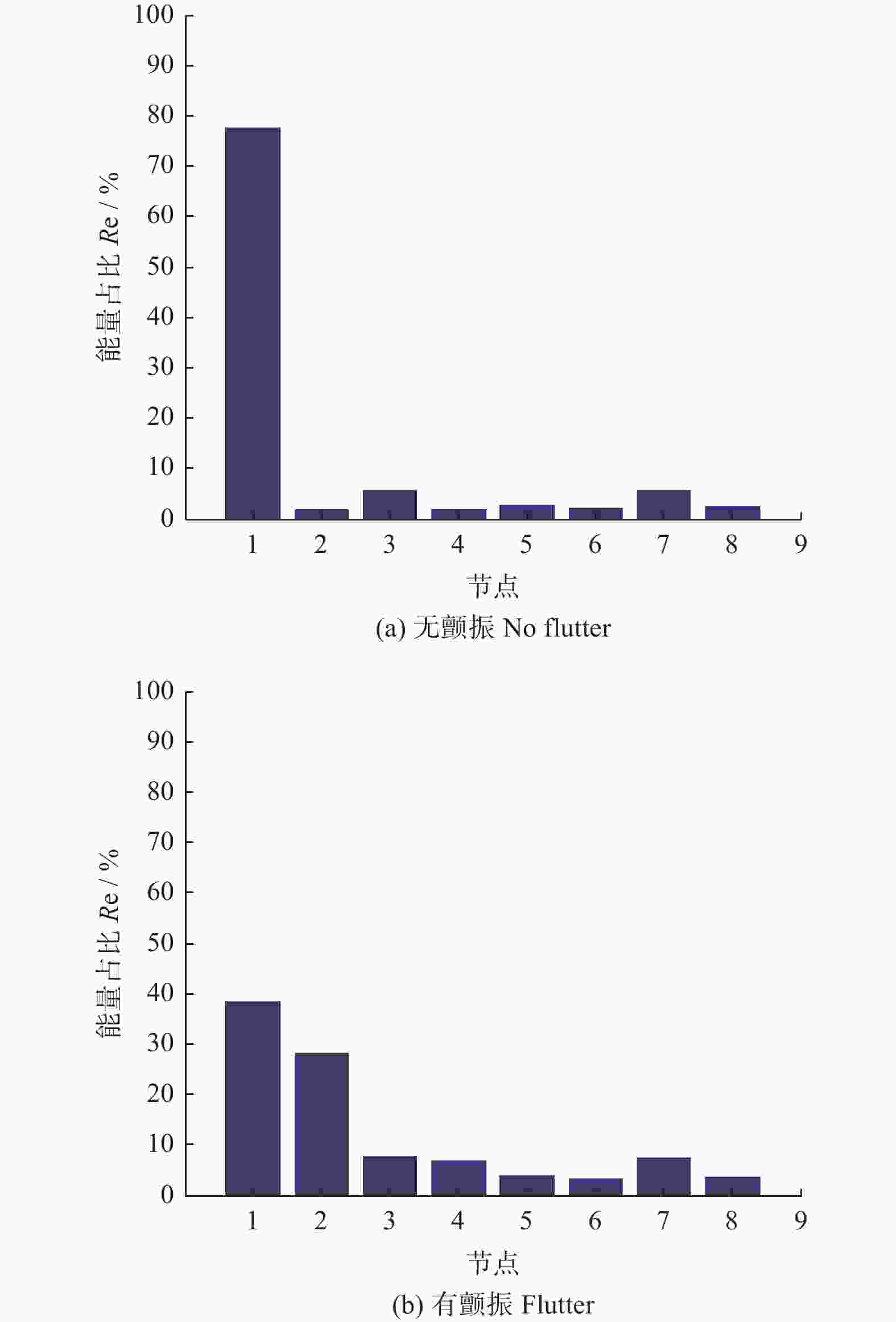

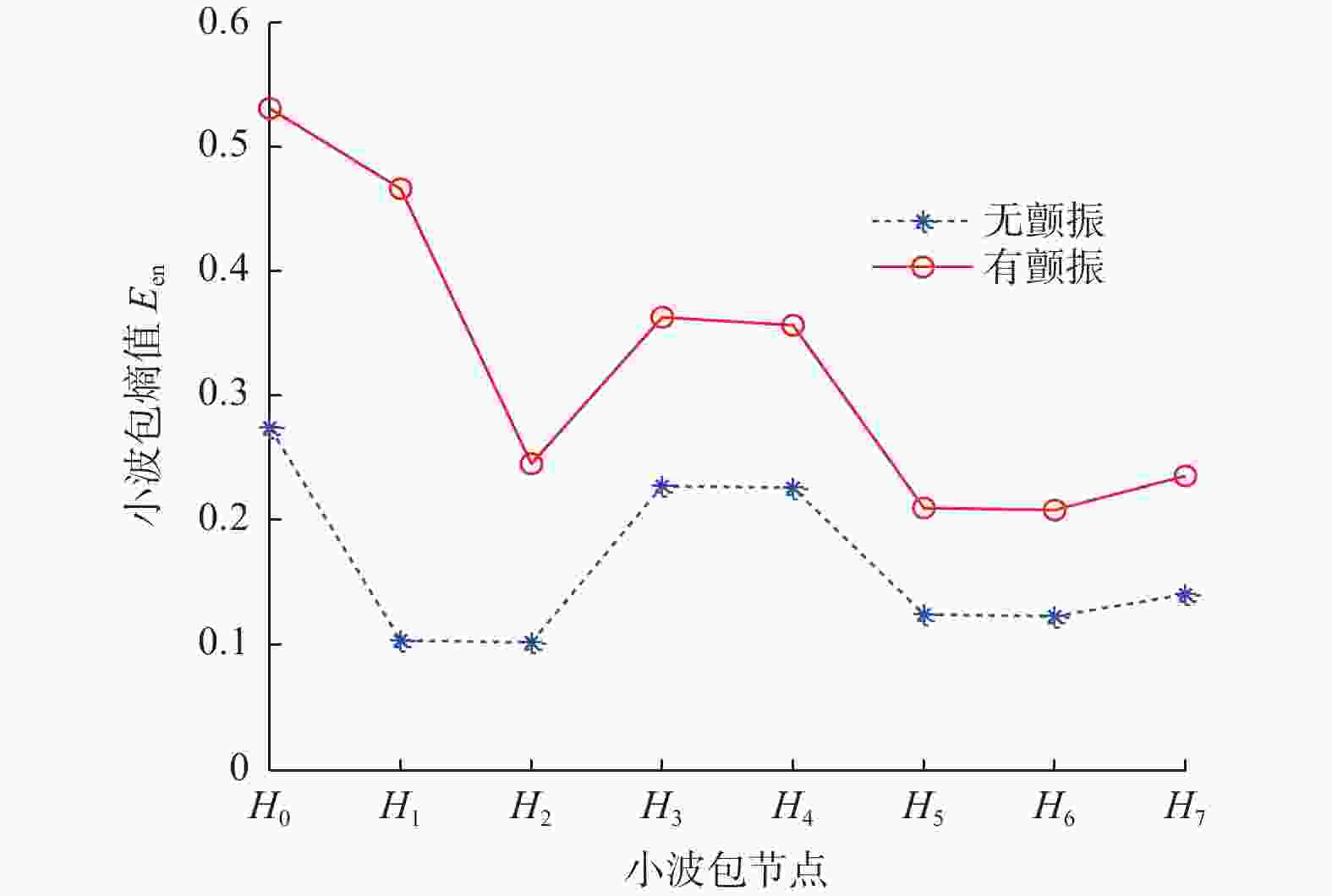

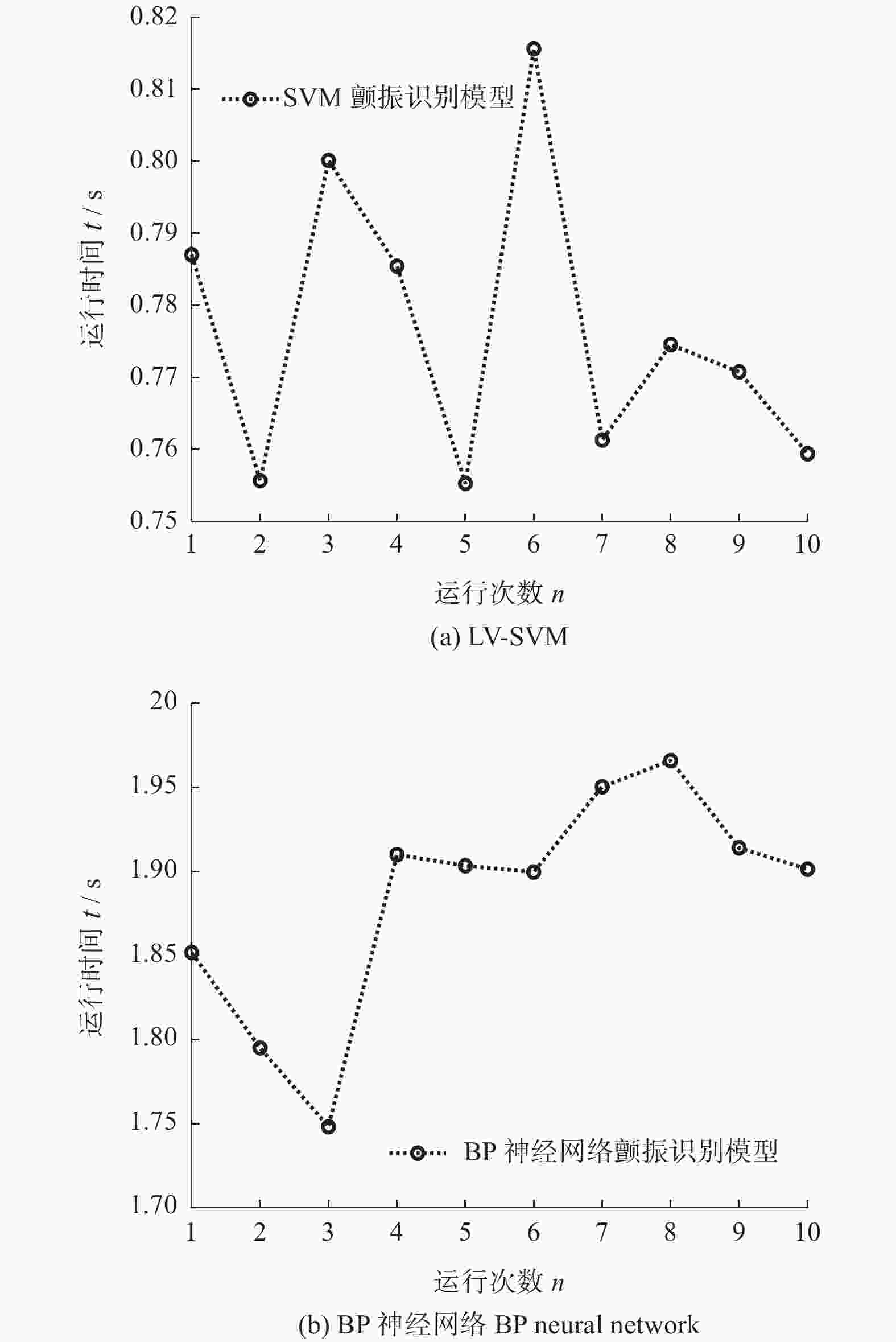

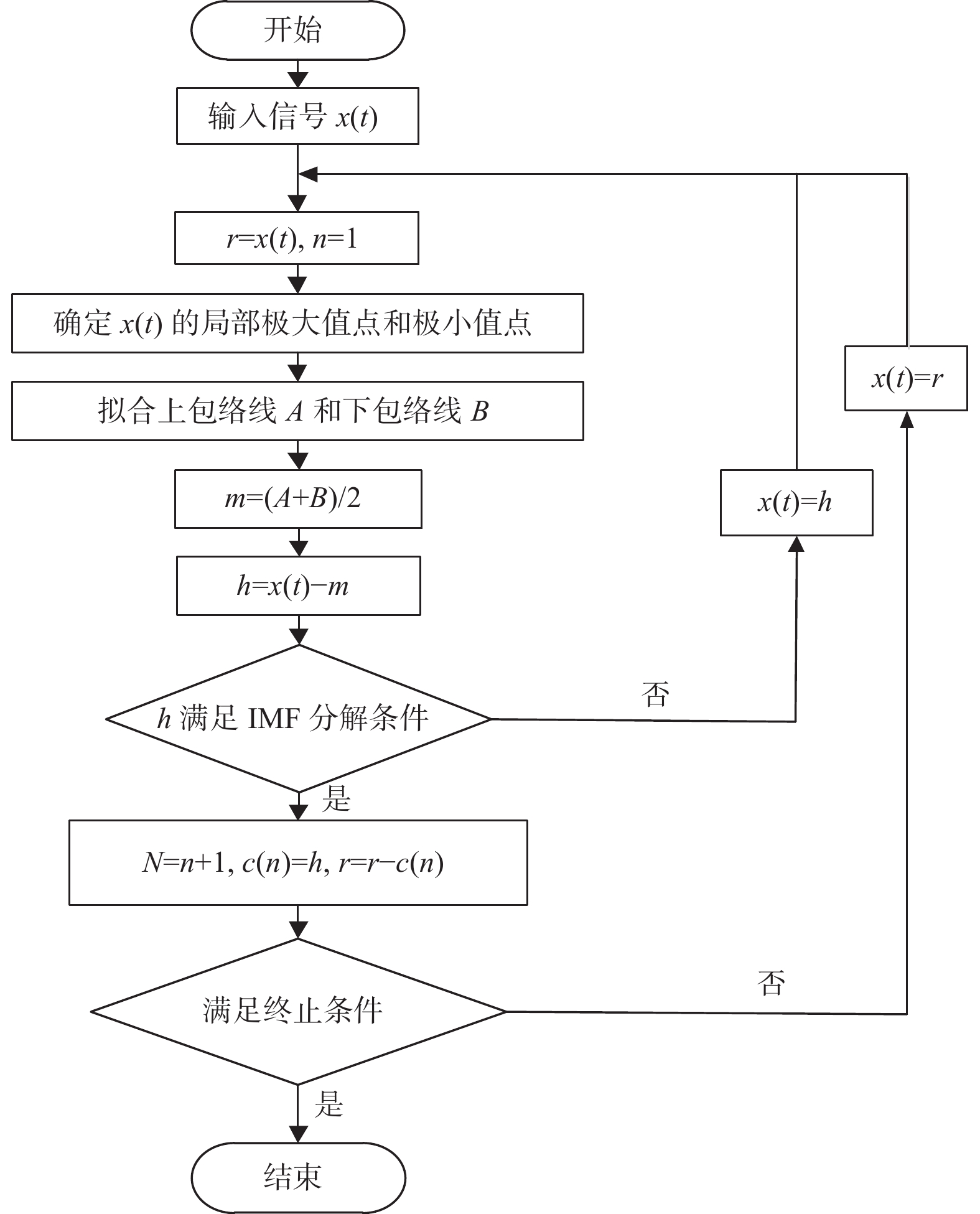

摘要: 针对轧辊磨削颤振时的时频域单一处理方法存在部分特征丢失的问题,提出了时频域相结合的方法对信号进行特征处理,并利用智能算法实现轧辊磨削颤振的在线预测。首先,利用经验模态分解( empirical mode decomposition,EMD)方法对振动传感器信号进行分解获得各固有模态函数(intrinsic mode function,IMF),剔除“虚假分量”后计算表征轧辊磨削颤振的时域特征。然后,利用小波包能量熵对声发射传感器信号求解频率段节点能量熵值,获得表征轧辊磨削颤振的频域特征。最后,将上述时频域特征降维后代入智能算法模型实现对轧辊磨削加工的在线预测。结果表明:LV-SVM模型的磨削颤振分类平均准确率达92.75%,模型平均响应时间为0.776 5 s;验证了时频域特性的EMD和小波包能量熵方法的LV-SVM在线预测轧辊磨削颤振的有效性。Abstract: To address the issue of partial feature loss in the single processing method within the time-frequency domain for roll grinding chatter, a combined time-frequency domain method is proposed to process signal feature. An intelligent algorithm is used to achieve online prediction of roll grinding chatter. Firstly, the empirical mode decomposition (EMD) method is utilized to decompose the vibration sensor signals, extrating the intrinsic mode function (IMF) while removing "spurious components" to calculate time domain characteristics associated with roll grinding chatter. Then, wavelet packet energy entropy is used to solve the frequency band node energy entropy values of acoustic emission sensor signals, obtaining frequency domain features characterizing the roll grinding chatter. Finally, the time-frequency domain features after dimension reduction is substituted into the intelligent algorithm model for online prediction of the roller grinding process. The results show that the the LV-SVM model achieves an average classification accuracy of 92.75%, with an average response time of 0.776 5 s. This verifies the validity of EMD and LV-SVM based on wavelet packet energy entropy in the time-frequency domain for online prediction of roller grinding chatter.

-

表 1 机床及砂轮基本参数

Table 1. Basic parameters of machine tool and grinding wheel

参数 规格或取值 机床型号 MM1300 × 3000 头架转速 n1 / (r·min−1) 18~140 主轴最高转速 n2 / (r·min−1) 8000 可加工最大工件长度 L1 / mm 1677 砂轮架移动分辨率 L2 / mm 0.001 砂轮架重复定位精度 L3 / mm 0.002 砂轮外径 × 内径 × 厚度 400 mm × 200 mm × 20 mm 砂轮线速度 vs / (m·s−1) 35 砂轮中氧化铝磨粒粒度代号 F120/140 砂轮修整方式 金刚石笔修整 修整比 R 0.7 每次修整量 L4 / μm 1.5 液压传动速度 v1 / (m·s−1) 0.1~4.0 快速进给量 ap / μm 50 表 2 输入特征IMFrms数据集δvar

Table 2. Input characteristic IMFrms dataset δvar

类型 序号 δvar Imf1 Imf2 Imf4 Imf5 总和 无颤振 1 0.011 3 0.005 1 0.006 3 0.010 5 0.033 2 2 0.008 1 0.004 2 0.006 8 0.011 2 0.030 3 … … … … … … 29 0.007 1 0.003 1 0.002 2 0.002 4 0.014 8 30 0.007 1 0.003 0 0.002 4 0.002 0 0.014 5 有颤振 1 0.009 1 0.005 6 0.002 5 0.002 0 0.019 2 2 0.009 5 0.005 1 0.002 3 0.002 0 0.018 9 … … … … … … 29 0.010 3 0.004 8 0.003 2 0.002 1 0.020 4 30 0.010 1 0.004 9 0.002 9 0.002 2 0.020 1 表 3 输入特征IMFrms数据集 δstd

Table 3. Input characteristic IMFrms dataset δstd

类型 序号 δstd Imf1 Imf2 Imf4 Imf5 总和 无颤振 1 0.011 4 0.005 1 0.006 3 0.010 5 0.033 3 2 0.008 1 0.004 2 0.006 8 0.011 2 0.030 3 … … … … … … 29 0.007 1 0.003 1 0.002 2 0.002 4 0.014 8 30 0.007 1 0.003 0 0.002 4 0.002 0 0.014 5 有颤振 1 0.009 1 0.005 6 0.002 5 0.002 0 0.019 2 2 0.009 5 0.005 1 0.002 3 0.002 0 0.018 9 … … … … … … 29 0.010 3 0.004 8 0.003 2 0.002 1 0.020 4 30 0.010 1 0.004 9 0.002 9 0.002 2 0.020 1 表 4 小波包能量熵计算值

Table 4. Wavelet packet energy entropy calculation value

类型 序号 单个节点处小波包熵值 EEN H0 H1 H2 H3 H4 H5 H6 H7 无颤振 1 0.273 8 0.103 5 0.102 1 0.227 7 0.225 4 0.124 4 0.122 4 0.140 3 2 0.279 7 0.112 9 0.106 5 0.228 8 0.227 4 0.125 6 0.123 6 0.141 8 … … … … … … … … … 29 0.285 9 0.132 7 0.108 6 0.229 6 0.226 3 0.126 0 0.125 2 0.142 6 30 0.286 5 0.147 4 0.110 8 0.226 3 0.222 9 0.124 8 0.123 2 0.139 2

有颤振1 0.530 7 0.480 4 0.244 1 0.347 7 0.341 4 0.200 4 0.196 4 0.223 8 2 0.529 4 0.479 7 0.251 5 0.358 8 0.352 2 0.208 5 0.204 9 0.232 6 … … … … … … … … … 29 0.530 4 0.466 3 0.245 9 0.362 2 0.355 6 0.210 0 0.207 6 0.235 8 30 0.526 1 0.412 0 0.245 6 0.399 1 0.397 1 0.241 2 0.236 4 0.269 3 -

[1] 韦莹, 唐水清. 浅谈轧辊磨削质量影响因素及主要缺陷控制 [J]. 金属世界,2021(5):38-43.WEI Ying, TANG Shuiqing. Analysis of influencing factors of roller grinding quality and main defect control [J]. Metal World,2021(5):38-43. [2] 郜志英, 臧勇, 曾令强. 轧机颤振建模及理论研究进展 [J]. 机械工程学报,2015(16):87-105,112.GAO Zhiying, ZANG Yong, ZENG Lingqiang. Review of modelling and theoretical studies on chatter in the rolling mills. [J]. Journal of Mechanical Engineering,2015(16):87-105,112. [3] IBRAHIM R A. Recent advances in nonlinear passive vibration isolators [J]. Journal of Sound and Vibration,2008,314(3/4/5):371-452. [4] GASPARETTO A. A system theory approach to mode coupling chatter in machining [J]. Journal of Dynamic Systems, Measurement and Control, Transactions of the ASME,1998,120(4):545-547. doi: 10.1115/1.2801501 [5] YUAN L, KESKINEN E A, JARVENPAA V M. Stability analysis of roll grinding system with double time delay effects [J]. Solid Mechanics and Its Applications,2006,130:375-387. [6] TLUSTY J, CRITCHLEY S, PATON D. Chatter in cold rolling [J]. Annals of the CIRP,1982,31(1):195-199. doi: 10.1016/S0007-8506(07)63296-X [7] 侯东晓, 郭大武, 陈小辉. 基于动态轧制力的四辊轧机垂直-扭转耦合非线性振动特性研究 [J]. 振动与冲击,2020,39(20):106-112.HOU Dongxiao, GUO Dawu, CHEN Xiaohui. A study on vertical-torsional coupled nonlinear vibration characteristics of 4-h rolling mill based on dynamic rolling force [J]. Journal of Vibration and Shock,2020,39(20):106-112. [8] AZEVEDO C R F, NETO J B. Failure analysis of forged and induction hardened steel cold work rolls [J]. Engineering Failure Analysis,2004,11(6):951-966. doi: 10.1016/j.engfailanal.2003.11.005 [9] SOMKIAT T, NARONGSAK P. Development of chatter detection in milling processes [J]. International Journal of Advanced Manufacturing Technology,2013,65(5):919-927. [10] 聂建华, 司伟. 一种基于振动信号处理的颤振预报方案研究 [J]. 工业仪表与自动化,2009(4):57-60.NIE Jianhua, SI Wei. The method for prediction of chatter based on the vibration signal processing [J]. Industrial Instrumentation & Automation,2009(4):57-60. [11] JI Y J, WANG X B, LIU Z B, et al. Early milling chatter identification by improved empirical mode decomposition and multi-indicator synthetic evaluation [J]. Journal of Sound and Vibration,2018,433:138-159. doi: 10.1016/j.jsv.2018.07.019 [12] CAO H R, ZHOU K, CHEN X F. Chatter identification in end milling process based on EEMD and nonlinear dimensionless indicators [J]. International Journal of Machine Tools & Manufacture,2015,92:52-59. [13] LU K B, LIAN Z S, GU F S, et al. Model-based chatter stability prediction and detection for the turning of a flexible workpiece [J]. Mechanical Systems and Signal Processing,2018,100:814-826. doi: 10.1016/j.ymssp.2017.08.022 [14] YAO Z, MEI D, CHEN Z. On-line chatter detection and identification based on wavelet and support vector machine [J]. Journal of Materials Processing Technology,2010,210(5):713-719. doi: 10.1016/j.jmatprotec.2009.11.007 [15] WANG Y, ZHANG M K, TANG X W, et al. A kMap optimized VMD-SVM model for milling chatter detection with an industrial robot [J]. Journal of Intelligent Manufacturing,2022,31:1483-1502. [16] 钱士才, 孙宇昕, 熊振华. 基于支持向量机的颤振在线智能检测 [J]. 机械工程学报, 2015, 51(20): 1-8.QIAN Shicai, SUN Yuxin, XIONG Zhenhua, Support vector machine based online intelligent chatter detection [J]. Journal of Mechanical Engineering. 2015, 51(20): 1-8. [17] 董新峰, 张为民, 姜源. 基于EMD复杂度与鉴别信息的磨削颤振预测 [J]. 振动、测试与诊断,2012(4):602-607.DONG Xinfeng, ZHANG Weiming, JIANG Yuan. Grinding chatter prediction based on EMD complexity and discriminant information [J]. Journal of Vibration, Measurement & Diagnosis,2012(4):602-607. [18] 任瑶, 李国富, 应小刚, 等. 基于小波包熵与SVM的导轨摩擦磨损状态识别 [J]. 计算机工程,2016,42(11):281-284.REN Yao, LI Guofu, YING Xiaogang, et al. Guideway friction and wear state recognition based on wavelet package entropy and SVM [J]. Computer Engineering,2016,42(11):281-284. [19] 聂鹏, 董慧, 李正强, 等. 基于改进EMD和LS-SVM的刀具磨损状态识别 [J]. 北京工业大学学报, 2013(12): 1784-1790.NIE Peng, DONG Hui, LI Zhengqiang, et al, State recognition of tool wear based on improved empirical mode decomposition and least squares support vector machine [J]. Journal of Beijing University of Technology, 2013(12): 1784-1790. [20] 于德介, 杨宇, 程军圣. 一种基于SVM和EMD的齿轮故障诊断方法 [J]. 机械工程学报,2005,41(1):140-144. doi: 10.3901/JME.2005.01.140YU Dejie, YANG Yu, CHENG Junsheng. A gear fault diagnosis method based on SVM and EMD [J]. Chinese Journal of mechanical Engineering,2005,41(1):140-144. doi: 10.3901/JME.2005.01.140 [21] 张磊, 郑侃, 孙连军, 等. 基于小波包敏感频带选择的复材铣边颤振监测研究 [J]. 机械工程学报,2021(6):1-9.ZHANG Lei, ZHENG Kan, SUN Lianjun, et al. Investigation on chatter monitoring of composite milling edge based on the selection of Sensitive [J]. Journal of Mechanical Engineering,2021(6):1-9. [22] 路俏俏, 黎敏, 王晓景, 等. 基于信息熵的轧辊裂纹声发射三维定位方法 [J]. 机械工程学报,2013,49(18):78-84. doi: 10.3901/JME.2013.18.078LU Qiaoqiao, LI Min, WANG Xiaojing, et al. 3D location of acoustic emission to roll cracks based on information entropy [J]. Journal of Mechanical Engineering,2013,49(18):78-84. doi: 10.3901/JME.2013.18.078 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS